Thermostatic vs. Digital Mixing Valves: Which One is Right for You?

A sponsored post from our friends at Caleffi:

There is not one tool that is perfect for every task. When it comes to thermostatic and digital mixing valves, both can maintain a Goldilocks setpoint (not too hot, not too cold). Thermostatic valves are a road-tested, simple way to get the job done. They use a wax element and sliding cartridges to regulate the temperature. They don’t require wires or reading glasses to install. On the other hand, digital mixing valves have bells and whistles that can provide a big upgrade to a domestic hot water system.

Over time, mixing valves will scale. The temperature and the hardness of the water are two of the factors that can speed up that process. There isn’t a specific way to predict the appropriate service intervals unless you have a service record at that site to work from. You have two valve technology choices to keep the ongoing scale buildup in check:

Thermostatic Mixing Valves: Simple and Reliable

If you need a straightforward way to regulate water temperature, thermostatic mixing valves (TMVs) are a tried-and-true solution. They use a wax element and sliding cartridges to control temperature, with no wires, and no complicated setup. This makes them a great fit for residential and small commercial applications.

They are available in many different kit combinations and assemblies for a small lay length if space is limited. If the setpoint doesn’t need to change and remote access isn’t required, they are a great fit.

Why Choose a Thermostatic Mixing Valve?

- Easy installation - no electrical wiring needed

- Simple setup - Adjust the knob and verify with the gauge

- Ideal for set-it-and-forget-it temperature control

What to Watch Out For?

- Scale buildup - Regular maintenance is required to keep the scale at bay

- No advanced features - Thermostatic valves don’t offer automated controls or self-cleaning functions.

Pro Tip: Keep service records to track maintenance intervals to help predict the right service schedule.

Learn more about Caleffi's TMVs options.

Digital Mixing Valves: Precision and Performance

For retrofit and new commercial projects, a big advantage of digital is the ability to see into the past with data logging. There are cases where the mixed water temperature bogs down, and you can access the data logger to do some plumbing detective work. We have helped plumbers identify cross connections and sporadic DHW recirc pump performance just by having a timestamp of when the temperature sensors show a drop. A thermostatic valve wouldn’t be able to tell much of a story.

Digital mixing doesn’t mean complicated. Out of the box, they plug in with a wall transformer. You answer a few quick questions on the screen and you are set up for a simple mixing operation. If you want to run a Legionella bacteria management program, that is an option, too. The vast majority of retrofit switches to digital mixing valves are in projects where the plumber is tired of rebuilding a big high/low thermostatic mixing station that is constantly scaling up.

What Makes Digital Mixing Stand Out?

- Automated self-cleaning - daily ball rotation helps prevent scale buildup

- User-friendly - no need for a laptop, everything is accessible at the valve

- Thermal disinfection scheduling - helps manage Legionella risks with calendar-based programs

- Building automation integration - compatible with MODBUS® and BACnet™ for seamless system control

Learn more about our digital mixing valve, LEGIOMIX®.

Choosing the Right Valve for your Project

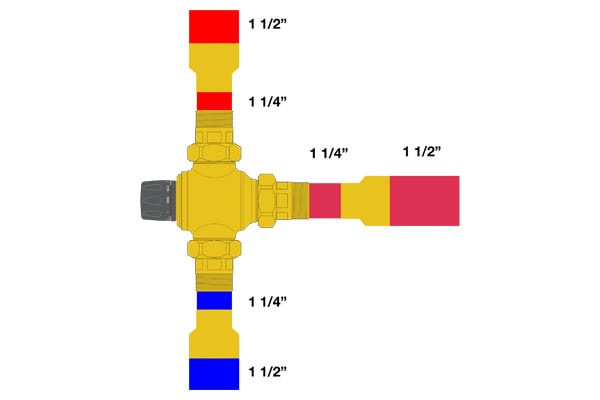

Pro Tip: Size the valve by the flow rate required, not the pipe size of the valve. Most times you can go a pipe size or two smaller with a properly sized digital because the flow path through the ball element is less restrictive than a bigger brother thermostatic. Here are a couple of examples of what that could look like:

Forum Moderator

Comments

-

What are cases when mixed water "bogs down" as mentioned in the digital mixing valve paragraph?

0 -

An example might be where the water heater cannot keep up with demand, so DHW drops below the mix valve setpoint. Hotels at high occupancy are a common example of DHW temperature fall off.

In one application a LegoMix at a correctional facility, an inmate sued the prison for a shower scalding issue.

The maintenance staff was able to use the 40 days of data to show that the temperature never exceeded 115° during the period he claimed to have been scalded.

As a result every other facility in that State installed LegioMix valves.

In buildings with BAS, that data can be stored on their system also.

If the data shows a temperature below the mix setpoint that would be an indication of DHW supply falling off.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Would you recommend digital mixing valves for residential applications in 1-4 family homes? Thanks.

0 -

I have a residential house with 2 people and have tried both thermostatic mixing valves and electronic ones. I found with the thermostatic mixing valve I often had trouble with very low flow rates (I believe they are rated for .5 gal per min and above) and that the temperature would get too high at a small sink. I tried a cheap digital mixing valve from China and it solved that problem but I had two issues. One is that the temperature was limited to 50 degrees C which wasn't quite warm enough to heat an old cast iron bath tub. The second problem is that this valve seems to starts the cold water and adds hot water to get the desired temp. That means there is a small slug of cold water every time you start the water flow. Zero issue for filling a tub but if you are rinsing dishes with lots of small bursts of water it gradually gets cold as each small slug of cold water fills the supply line. The thermostatic mixing valve wax takes much longer to respond so was not an issue that way. Better (more expensive) valves might not have this problem but it would not surprise me if they do. One other thing to be aware of is that the Chinese fittings use European threads and adaptors which I found very hard to source here in Canada. I ended up making an adaptor on my lathe which might not be an option for everybody.

Brian

0 -

The smallest Legiomix is 3/4" it needs 2.2 gpm minimum

The 520 AngleMix needs .5 gpm, but it is a wax cartridge type valve. I don't know of any thermostatic that works with less than .5 gpm.? There needs to be turbulent flow around that wax cartridge for it to move properly

If you have a dhw recirc, that is another way to meet the valves minimum. Although 2.2 gpm would be a large recirc system.

The 3/4 LegioMix with that high Cv is probably a very large multi bath home, small motel application.

The thermostatic is a dependable valve, but needs cleaning occasionally with hard water.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements