My proposed Install

Ed the Heater Man asked me to post this.

My question to him was is the circulator right after the Taco Air Scoop necessary.

Comments

-

-

That drawing shows a PS type of arrangement which needs that circ.

Note that the PS piping is not correct as shown as each should connect to the a set of closed space Ts. As you have it, you don't have proper separation and you can have flow reversal if the pumps are not set properly.

Since you already have a 4 way for boiler protection, not sure what the PS piping gets you. I would stick to a single pump with zone valves. I think that needs a differential bypass or a delta P circ.

0 -

i'm not sure if the return protection valve would work right without it being primary secondary.

either you should connect the manifolds to the loop with closely spaced tees or get rid of the supply-return connection and control the manifolds with a zone valve on each and only have one circulator at the boiler.

i think it would work right with a supply and a return main and a circulator for each manifold but no circulator at the boiler but i'm not positive of how the flow would work at the mixing valve.

essentially most of the water circulates in the supply and return or primary loop and the mixing valve only sends a little through the boiler.

0 -

A follow-up question.

The system as it is currently piped has been working well for 15+years. Yes it may have been done better but it does keep our home comfortable.

Please bear with me. If I leave the circulator ,in question, in place & ot wired would it create any problem?

0 -

It will work well if the loop pump flow rate is higher than the sum of the two zone pumps.

Depending on the pipe sizing and the cracking pressure of the zone checks, the loop pump might push a bit flow through zones that are off. Not a big issue.

If already piped and you have all the bits except the boiler, I don't see any real reason to change it.

0 -

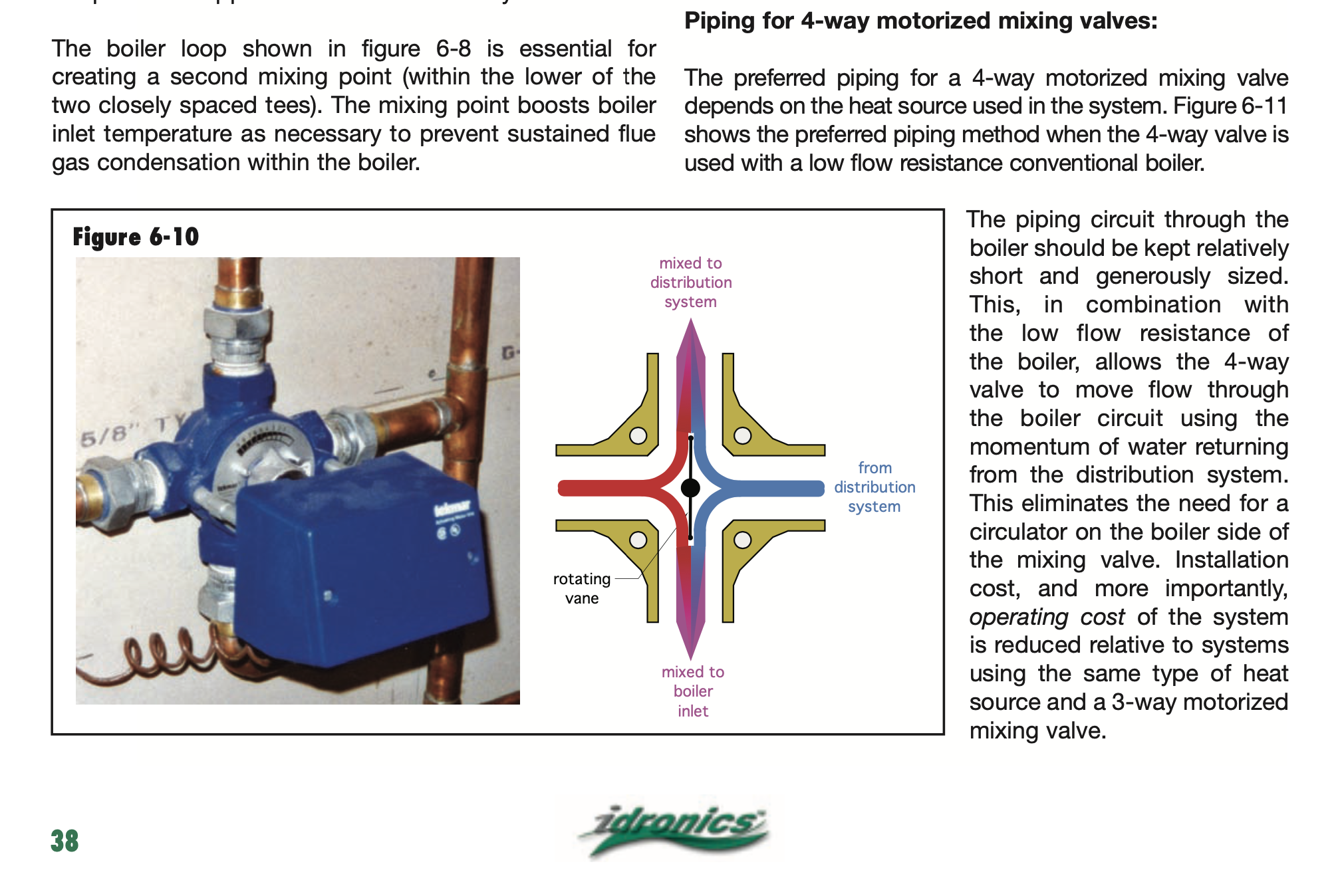

A 4 way motorized mixing valve works well, IF you have a low pressure drop boiler, CI for example. And the valve needs to have an actuator and controller. The control adjust the desired mix temperature and also protects the boiler. Additionally it can have an ODR function.

This was the go to mixing/ protection system when CI boilers were the main boiler used on low temperature radiant. It does not require a P/S piping. It works fine with one properly sized circulator.

If you had a high pressure drop boiler, you would need that separate boiler circ.

A 4 way valve is unique in that it has two mix points, the system and the boiler circuits.

Your system as described in past posts should work with a single pump. Although it has been a moving target as to what you are trying to accomplish :)

My vote was for a mod con, but since you went with CI you need to adjust piping, mixing, and protection accordingly.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

looking at the drawing, it looks like primary/ secondary system, and demands the secondary pump. I suggest reaching out to Taco tech support to validate your drawing before executing. 401-942-8000

Joe Mattiello

N. E. Regional Manger, Commercial Products

Taco Comfort Solutions0 -

Thanks!

0 -

-

0

-

Hot Rod,

Again thanks for your time in responding to this setup. Forgive me if I get repetitive!

Based on keeping my current piping setup and the new boiler, Weil-McClain CGa4, would you be willing to provide a simple diagram of how it should be setup?

Thanks !

0 -

I’m a single pump/ zone valve type.

Unless the zones need 6, 8 gpm or more I use a single variable speed delta P circulator. A single ECM saves power and modulates to the loads.

Do you know the gpm requirements for each manifold?

Here is my suggestion for either method.

Now if you have a high temperature zone , that would parallel the boiler loop before the mix valve

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Bob,

Thank you for your time! I assume that in the top diagram the"Z" is a zone valve. And in the bottom I just use the circulators at each zone.

0 -

I would read through this post and revisit your boiler choice.

TLDR; Your 80% nameplate efficient boiler is somewhere around 65% to 70% actual efficiency. Worse in case of natural gas as wet gas losses are higher.

Looking at the price delta between a cast iron VS modcon, the ROI is there, a well dialed in modcon will get you actual mid 90s efficiency.

Takes up less space, doesn't use house air for combustion and you don't have to worry about back drafting them.

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements