Help with hydronic piping to reduce hammer from circ pump

First off, thanks for the help on my previous post. I was able to swap out my boiler, upgrade my circ pumps and get the system dialed in and am pulling good run times with 15-20 ΔT. System is running more efficiently than the original install….

One last issue to tackle though. My zone valves 25ft away (1 1/2 pipe) from the boiler and system pump. Considering the volume of water moving through the pipe, the water slams into the closed ZV and rattles a bit. It only happens when a single zone has been calling and is satisfied. Zone valve closes and the circ pumps shuts off, but the water is still being pumped.

I'm running a deltaP circ pump, but considering the volume of water in the system between pump and ZV, I don't think it can scale down quick enough.

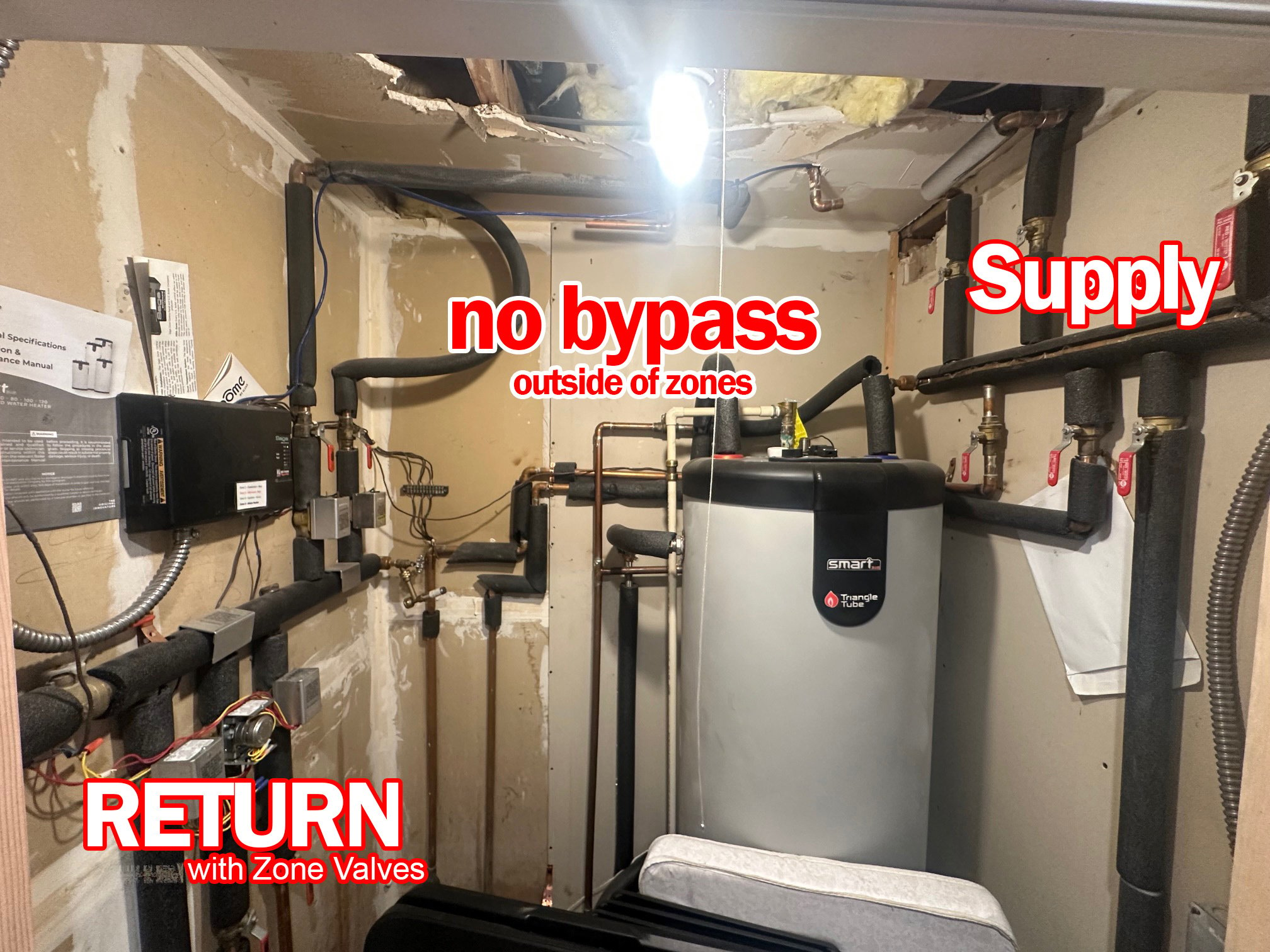

I currently have a small arrestor on the supply side near the zones, which helps a bit, but hammer is still evident. There is no bypass between the supply/return on my Zone Valve setup.

My question is… would a bypass valve between the supply & return help? Or would you get a bigger arrestor? Or, does have a tip on how to shut off system pump before zone valves? I'm running a sage ZV controller…

Comments

-

Are those Honeywell zone valves, the 8043?

Usually ZV hammer is caused by a fast closing valve against a high velocity flow, flow above 4 FPS, perhaps. It's more about the speed, not the volume of the fluid.

However if the ∆P circ is on the correct setting it should easily address the velocity? What circ do you have and what is the gpm or W. when the valve makes the noise?

One common hack for the HW is to remove one of the two springs from the brass sector gear. This slows the close speed by 2 seconds, and that fixes many of the hammer issues.

It does change the close off pressure of the valve by a couple PSI also. So make sure that zone isn't bleeding through when it is off and other zones are flowing.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Any 1 1/2" zone should have its own circulator with no zone valve.

There was an error rendering this rich post.

0 -

-

If you are using the end switches on the zone valves, through the relay board, the pump should stop before the ZV is closed completely.

Or is the pump powered constantly? The ∆P circs should be able to have continuous power, rev down to maybe 7W when all zones are off.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

They are 8043s. A mech friend told me to try the caleffi ZVs as they are motorized and slightly slower… but the problem still persists. I have removed a spring on the 8043s and it also helps, but hammer is still noticeable.

Grundfos ALPHA 15-58 for the system set to Constant Pressure. With 1 or 2 zones open its 3-4 GPM and 16-18ish wats. Min is set to 2.2 gpm to satisfy the boiler.

0 -

The 1 1/2 is the main trunk to the manifold. Each zone is 3/4"

0 -

I have two Sage controllers and end switches are wired, however the system pump is powered directly from the boiler. I'm not able to power the circ from the controllers because of the distance between. I might be able to wire a relay to power the circ pump from the controllers.

0 -

I recently helped a retired plumber near me with a ZV hammer issue. He tried several of spring return valves and they all hammered. Single speed 15-42 on a 4 zone fin tube home.25 year old Eries were replaced, he has been changing end switches over the years, they are no longer available.

Identical problem of 1 zone only operating, it caused the hammer, when it closed.

I went back with this valve and it solved the problem. Slow opening, slow closing. It takes maybe 45 seconds to close completely, but the end switch opens quickly to stop the circ.

I don’t have an answer as to why a delta P doesn’t solve it.

A pressure bypass valve may, but I don’t think a delta P circ and PAB would work together. in fixed speed function it would.

I feel confident the thermal ZV do the trick, for problem hammer issues.The Caleffi are very low current draw, so 6 or more on a 40vA transformer or relay box

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

This solution had briefly crossed my mind, as I have some similar valves on my in-floor manifold.

In trying to not spend $600 on a ZV replacement, I was looking at the bypass or a relay.0 -

What does distance have to do with wiring your circ to your zone valve relay?

0 -

In reality, the ∆P circs should not even need to be turned on/ off. That is the selling feature of the device. Plus the off season exercise function needs the pump to be powered 24/7.

It is unusual to have a system where one spring removed and the ∆P circ don't solve the issue.

But it is what it is.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I'd have to cut/patch drywall and paint. Trying to avoid that.

0 -

It runs offseason for DHW.

deltaP pumps are fine deadheading?

0 -

Are you sure the pump turns off immediately when the call for heat ends? Or is there a delay? If the pump is still on - even for a second during zone valve closure - it will hammer.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

There is a slight delay… not long at all, but enough for hammer.

Just not sure the right way to solve it is. Sounds like ∆P and bypass valve don't play nice together. Powering the circ pump from two separate controllers doesn't seem possible. A bigger arrestor might fix hammer, but probably isn't the correct solution?0 -

I don't know of any spring return ZV that breaks the end switch instantly. Either a cam has to move off the micro switch, or the magnet away from the reed switch in the Caleffi. But no more that a few seconds for that to happen, during maybe a 7 second to complete close off.

I know PABs work, but I'll see if they work with ∆P circs. As a zone valve closes, the PAB bypass opens, so the circ may think another zone is opening and speed up, not slow down??

I would think the expansion tank behaves like a water hammer trapped air space. The only difference is the water hammer arrester could be right at the ZV.

But it shouldn't take this much technology!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Try putting a Y splitter for hose bibs on your drain, and add a second arrester. Then you have double the "cushion."

I added one arrester to our banging washing machine supply, and that helped but didn't totally eliminate the bang. I put a second arrester on the other end of the supply hose, and that totally eliminated the bang. It's a cheap and easy upgrade.

Or to get more complicated, if you can power the pump directly from the controller with a relay, then you can run the ZV off a time delay relay that delays closing the ZV.

https://www.grainger.com/product/6A859?gucid=N:N:PS:Paid:GGL:CSM-2295:Y8ZQJW:20500801:APZ_1&gad_source=1&gclid=Cj0KCQjwhMq-BhCFARIsAGvo0KcFfDSqBd6jTp2qV8KaN8VnsLiaDmHGz597CBAIEKl8OzcjE_0qOdgaAtWaEALw_wcB&gclsrc=aw.ds

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements