No Primer or Cement .... for PVC pipe pressure fittings

Hello HeatingHelp.com community! : )

My current OEM project (early prototype stage) requires the fabrication of a large multi-port (10 to 20 ports x 2) manifold of 2" pressure rated PVC pipe and fittings (crosses, T's,elbows and couplers) in very close proximity to each other.

Unlike prime and cement connections for non-pressure DWV (drain/waste/vent) assembly, pressure (120psi) prime and cement connections are much more un-forgiving to its proper joining (prime/cement) of the fittings.

Even a tiny leak anywhere in the manifold , would render the entire manifold assembly unusable and un-repairable!

With conventional prime and cementing, you can't pressurize (test) the assembly before 6 to 8 hours of cure time!

My quest is to develop a primeless/cementless PVC to PVC joining method without any required curing time.

I do this now for joining PVC "pipe to pipe" for a special OEM application already (see pic below).

….. the joint is in-between the two arrows! (heat induced PVC polymer to PVC polymer chain bonding) ……. no primer or cements!

The joint is as strong or stronger than the pipe itself!

As I can't "spin weld" PVC "crosses, T's,elbos,etc" together, my thoughts are to "inductively" heat an "susceptor" to fuse bond the PVC together.

Basically,

You insert into the fitting's socket a micro-mesh (very thin) stainless steel screen covering the entire socket's inner wall (think: a roll of wire mesh screen 1" wide adjoined to a peelable carrier tape of self sticking PVC plastisol). The (one side sticky) wire mesh peels off in segments as to the inside diameter of the target PVC socket.

Pic below shows the susceptor micro-screen (dark gray) protruding in front of the 2" PVC pipe intwords a 4" x 2" reducing coupler (screen does not go all around in this example).

With pipe and fitting incerted together .……………… I now "inductively" fuse the PVC together! (3 seconds max.)

If your familiar with a "ProPress" tool (see pic below) …… It will look just like it!

The "jaws" that surround the pipe, instead of being solid metal, is actually a "split ring" stator coil that induces its magnetic field into the seseptor!

…… unlike a ProPress tool , this inductive heating unit would be super light weight!

In a conventional prime and cement process …. only around a quarter of the chemically bonded joint is actually a "PVC to PVC bond as the socket is "tapered" and the pipe is not.

The void "non-contacting" area in the taper is a cement bond only.

Inductively bonding like this creates a full socket "PVC to PVC" polymer linked bonding!

…..an possibly, the stainless steel mesh screen completely being embedded within the polymer bond ……… would serve to strengthen the bond aka: "rebar".

….. your thoughts on this?

Comments

-

I have put PVC joints together with Epoxy (can't remember what brand it was). We had to ty into an existing water system and start it up immediatly. Before using the epoxy on that job we epoxied some fittings at the shop and immediately tried to twist them off. The joints were stronger than the pipe as the pipe broke.

1 -

-

I don’t believe so but here’s the link to the manual. Fusing is down in section 4.2 / 4.3

https://www.jmeagle.com/sites/default/files/jme_MDPE_YELLOW_GAS_Installation_Guide_03-2011_web.pdf

0 -

I'm very familiar with that prosses!

See in the butt splice, the large bead that forms on the outside (and forms the same bead on the inside)? ……. that's because they have to "sink" (heat a longer section beyond the joint itself) a lot of heat into the two ends to properly create an "interfacial" molecular bond of the polymers ….. adding an undesirable distortion (internal ridge) inside the pipe. : (

Susceptor heating quickly heats up only the immediate surfaces to be bonded.

…… and there process can't be used for the elbows, T's, crosses in the assembled manifold.

1 -

Interesting! ….I'll look into your suggestion for sure Ed!

I will see what the manufactures of Epoxy and PVC have to say for use in this application.

In the fabrication of joining two "butt" ends of CORIAN (Dupont) countertop material (a polymer as well) together ….. we "crazy glue" two scrap blocks of corian close to the joints seam so we can attach metal clamps to pull the joints together.

It bonds extremely strong and works perfectly for the short time that it needs to be! …… but , in a short time thereafter, the bond releases by itself! : (

There must be something about when its in the final cure stage, it reverses its strong bonding attribute.

…. you can then just pick the glued blocks off with your fingers!! : (

0 -

I was just getting used to soldering that new fangled copper pipe stuff. What ever happened to good old cutting and threading steel pipe and iron fittings?

You kids are always trying to re-invent the wheel!

PLASTICS!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

you might look into Aquatherm PP pipe as it is a heat fusion material

I didn’t think PVC could be melted together?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

…….. I'm with you ED!

I miss the good old days when everything was connected with okem and lead! : )

but really,

When I started working with plumbing (i'm not a plumber) PVC was still a new thing. ……. I figured " I can do that!" : )

On this one job, the inspector came in and said since the rest of the house was already done in cast iron pipe, I had to replace it with the same!

I didn't even know what okem and poured lead was! : (

My god! ……. that's when plumbers really worked for a living! : )

LOL!! : )

1 -

"I didn’t think PVC could be melted together?" - Hot_Rod

You sure can!

McCoy manufacture makes the machines just like the one you pictured above ……… they also have the same machine to "melt" PVC pipe butt joints together as well.

……. No one has an "inductive" PVC Polymer to PVC Polymer molecular linked chain bond for "pipe to fittings" connections.

0 -

Hi, For what it's worth, I needed to do some 4" poly pipe butt joints to build a 600' length of line. Had to pull the pipe using a small pickup. When the tires started spinning on the ground, I moved up to a bigger truck and finished pulling the pipe. That line operated at 105 psi for years with no problems. This convinced me that fusion welding is pretty strong.

Yours, Larry

1 -

I used to install some Aquatherm. My old boss was sold on that stuff. We revamped a whole school with it.

I will say the stuff is tough as nails and if you make the joints right it will never leak.

On large size pipe the machinery involved is a n issue and getting it into place to fuse the joints is an issue. Smaller stuff is ok

Problem (and it's a problem) is:

Expansion and contraction is a big issue

Also, hangers. You get into the larger sizes and you need hangers every 3'. It is saggy and doesn't support itself well so it looks crappy

How many buildings have the structure where you can get enough hangers/

Doesn't sound like a big issue but it is.

1 -

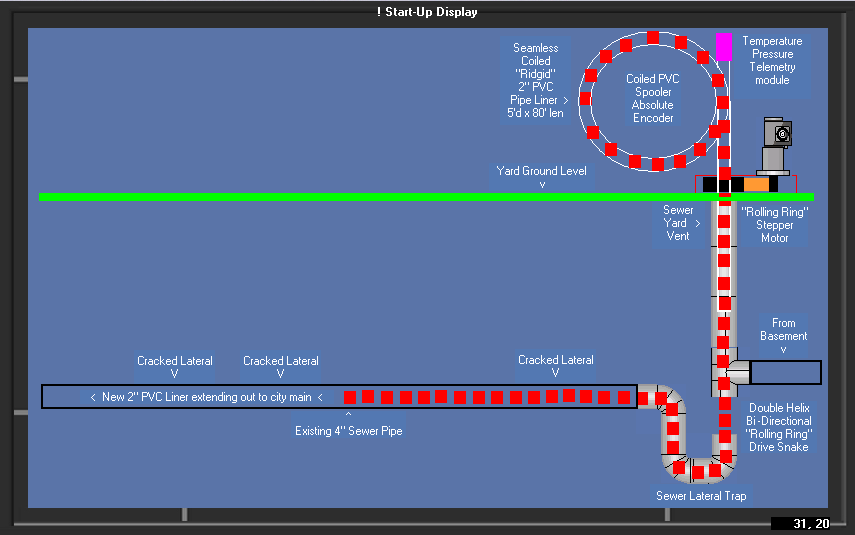

In the pic above, of my spin weld of the 2" PVC pipes together, I couldn't

just use a standard PVC coupler, because that 2" inch pipe in its entire length (60ft) was placed (pushed down from the lawn vent) inside an existing 4" underground (damaged) cast iron sanitary sewer lateral.

Once in place, I "ballooned" that 2" PVC up to a 4" diameter to effectively re-line the damaged lateral with new pipe …… No digging! : )

Hey! ….. kind of like an angioplasty and stent repair on a sewer lateral! LOL!!

A standard coupler at the joints would have severely "necked-down" the expansion of the repair liner at the joints.

0 -

Blaze master Orange CPVC uses a one step primer/glue...very thick & red. Not sure of the curing time. Mad Dog

1 -

Hi Mad Dog-2!

I'm not an expert, but I recently changed out an entire single story roadside motel (two separate buildings same lot) that had CPVC originally installed.

The stuff would just break in your hands! Seems like every month I'd get a call for a flooded out guest room there! : (

I would never use CPVC after seeing that!

….. I thought even FlowGuard Gold® CPVC is under a nasty recall as well?

1 -

…… another path to an inductive susceptor is a PVC based plastisol + graphene (1%) …. brush on paste.

The graphene produces the required bonding temperatures (thru magnetic induction) for a molecular polymer to polymer bond.

The PVC powder molecularly bonds (melts) all around socket gap voids

Graphene nano-tubes are 100 times stronger than steel!

….. and 3 times more thermally conductive than diamonds and even more so than copper!

0

Categories

- All Categories

- 86.8K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 56 Biomass

- 425 Carbon Monoxide Awareness

- 108 Chimneys & Flues

- 2K Domestic Hot Water

- 5.6K Gas Heating

- 105 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 69 Pipe Deterioration

- 962 Plumbing

- 6.3K Radiant Heating

- 385 Solar

- 15.3K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 47 Job Opportunities

- 18 Recall Announcements