Monoflow Tee vs Diverter Tee

Hi all, I'm hoping for an explanation on what the difference between these two tees. I'm a little unclear, as some of the diagrams I see look pretty similar. Thanks in advance for your help!

Tom

Comments

-

-

-

Perfect! Thank you gentlemen! That explains a lot. Appreciate it!

0 -

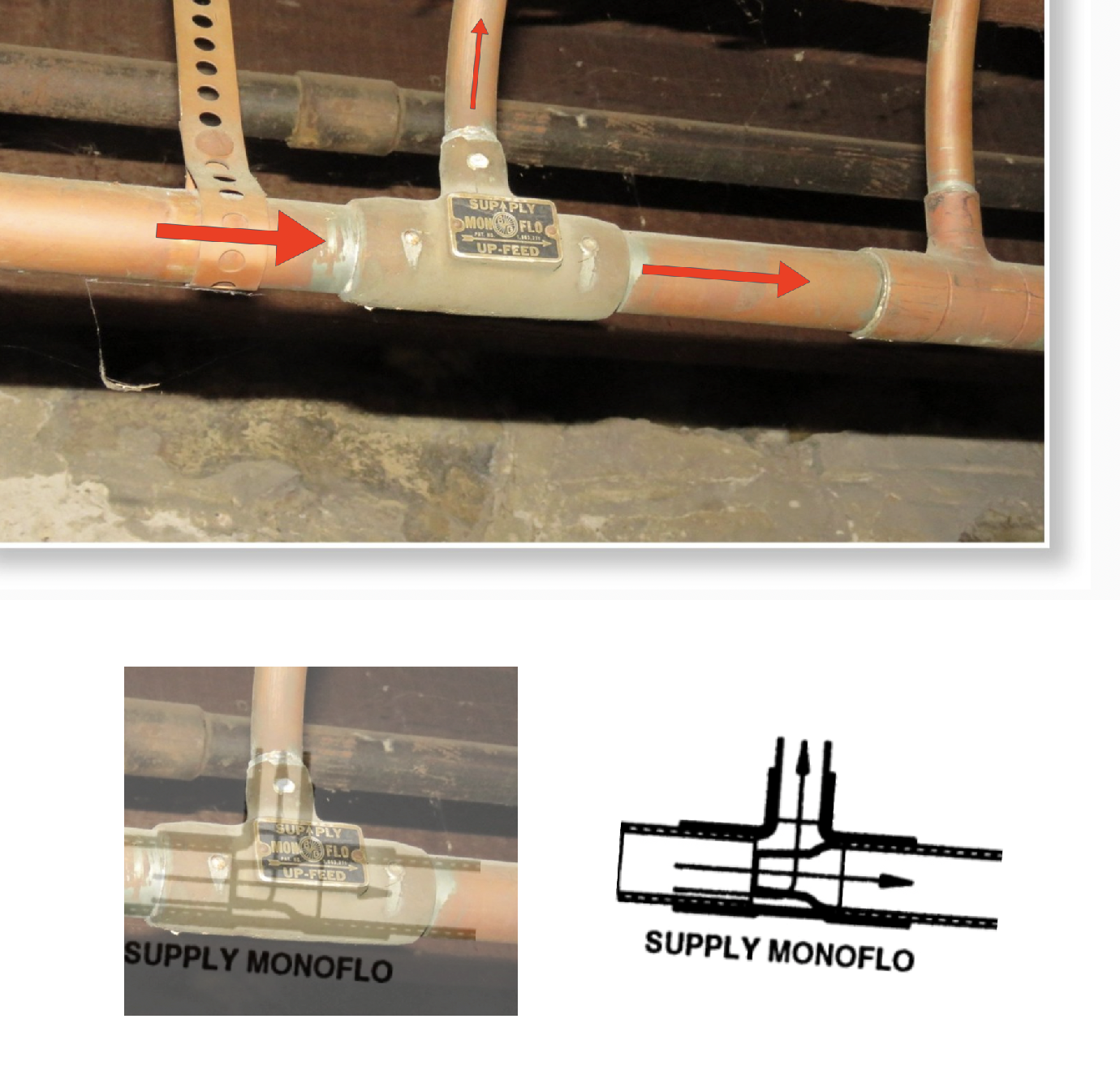

OK, two follow up questions. I read on the screenshot that the Monoflo can be installed at either the supply or return riser. Here is a pic of the boiler and one of the Monoflo tee. My questions are:

- This tee is labeled "Up-Feed" It looks like the screenshot posted didn't differentiate. Are they pretty much the same fitting if used on the supply or return side? (If so, any idea why this one is labeled "Up-Feed?)

- I am currently reading Dan's book on Primary /Secondary pumping and he mentioned the space between the supply and return pipes shouldn't be too close. Does placing the Monoflo tee at the supply side allow the supply and return to be closer?

I ask question 2, because the supply and return are pretty close and there is no secondary pump involved. (BTW, the boiler was out of service during the inspection and was slated for replacement)

Thank you!

0 -

Is there a circualtor or is that a gravity system? The boiler somehow looks older than the system it is connected to. At very least it is the original boiler including the conversion burner.

Monoflo tees have a partition in them (b&g calls it a venturi but how much venturi effect it produces is questionable at best). One port of the run is open to the full diameter of the tee, the other run port is partially partitioned off and divided between the run and the branch so it divides the flow between the main and the branch to the emitter. If the tee is at the supply of the emitter then the partition is at the outlet of the tee on the main. If the tee is at the return from the emitter then the partitioned side of the tee is at the inlet from the main.

The partitioned run of the tee always goes to the section of pipe between the supply and return to the emitter because that section is where the flow is divided between the main and the emitter.

If the divided side is placed toward the section of main between emitters instead of the section across an emitter it will restrict the flow in the entire main.

I think the full monoflo deign book is on b&g's website somewhere too.

0 -

Thanks for the response! That's interesting, as what I have here doesn't appear to meet either of the diagrams. So just to clarify, the Monoflo in my photo would have the narrow part facing towards the flow?

For reference, this house was built in 1910. I inspected it in 2018 and am unable to locate my photos from the inspection, which would certainly be helpful. That said, I believe it was a gravity system. Come to think of it, it does appear that the supply piping is newer than the boiler. I imagine it was probably galvanized at time of installation??

0 -

The tees should be oriented like this. You could have it on the supply or the return or both but the orientation always has to be like this:

Copper pipe and fittings in the form we know of now has been around since the 1930's. There were other diverter tee systems that predate monoflo that were designed for gravity. In theory monoflo should work with gravity circulation but it is uncommon if it was ever installed that way. I could see that boiler and conversion burner being late 40's or early 50's. The house may not have had central heat until then.

0 -

-

Your right about the holes in the tees. I haven't seen those in a long time. Guess they wanted to make sure the solder was "in there!!!

Never saw the holes in a Monoflo before but have seen it in regular fittings

0 -

are we sure there isn't a circulator somewhere?

@EBEBRATT-Ed @EdTheHeaterMan ever seen a monoflo gravity system?

i think i have seen copper fittings from the 50's with the hole in them

0 -

There may be a circulator that I've forgotten about. I may be wrong about the gravity. Memory is a bit shaky going back 7 years. As for the age of the unit, the house is an an area where central heating systems were installed when they were constructed back around 1910, so I believe it to be original to the house. We were still using coal in the late 40's in the city, though the conversion to gas was likely somewhere in the early '50's.

0 -

-

It is possible they were burning coal in that boiler when it was first installed but that has more the look of being from the era where dedicated oil and gas boilers weren't commonly available yet and it was a coal boiler installed with a conversion burner. That conversion burner is very old.

you could find the date of the patent number on the monoflo tee, it isn't older than that. My guess would be just before or just after wwii for the monoflo system and probably the boiler.

1 -

In the second photgraph (with the boiler) there appears to be a Honeywell pump relay hung on the wall below the switch. My guess is this relay is an RA832 style or a RA845 style. Based on the pipe sizing and the relay I would think it is a "pumped" system. I have seen some unusual systems, but I have never seen a true monoflow system with gravity flow.

2 -

i have not seen an actual Monoflo® system without a Circulator pump. I'm pretty sure that won't work efficiently without a pump. This particular Monoflo® predates the Red Circle® tees that @hot_rod pictured above. Here is what is going on inside that particular fitting.

My guess is that the original boiler was placed in that home in 1910 and was hand fired at that time. Sometime in the 1940s the home went tru a renovation to remove the cast iron radiators in all the rooms, and head banger pipes in the basement. The owners must have wanted to "modernize" to those new convectors that were all the rage. That is also when the boiler was converted to natural gas with "touch of a dial" operation (AKA Thermostat). The circulator pump is probably an old 3 piece B&G pump around the back of that United States Red Top boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

That all makes sense Ed!

0 -

there was a similar older system designed for gravity circulation but it would need bigger pipes and pitch.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements