Advice HB Smith Boiler firebox replacement

I need to decide whether to have the firebox relined or replace the unit. It has worked well until now. My oil supplier is steering me to replace the whole boiler saying that we will recoup the cost with the greater efficiency. Also the hot water coil has some corrosion at the connections so that may be on its way out as well.

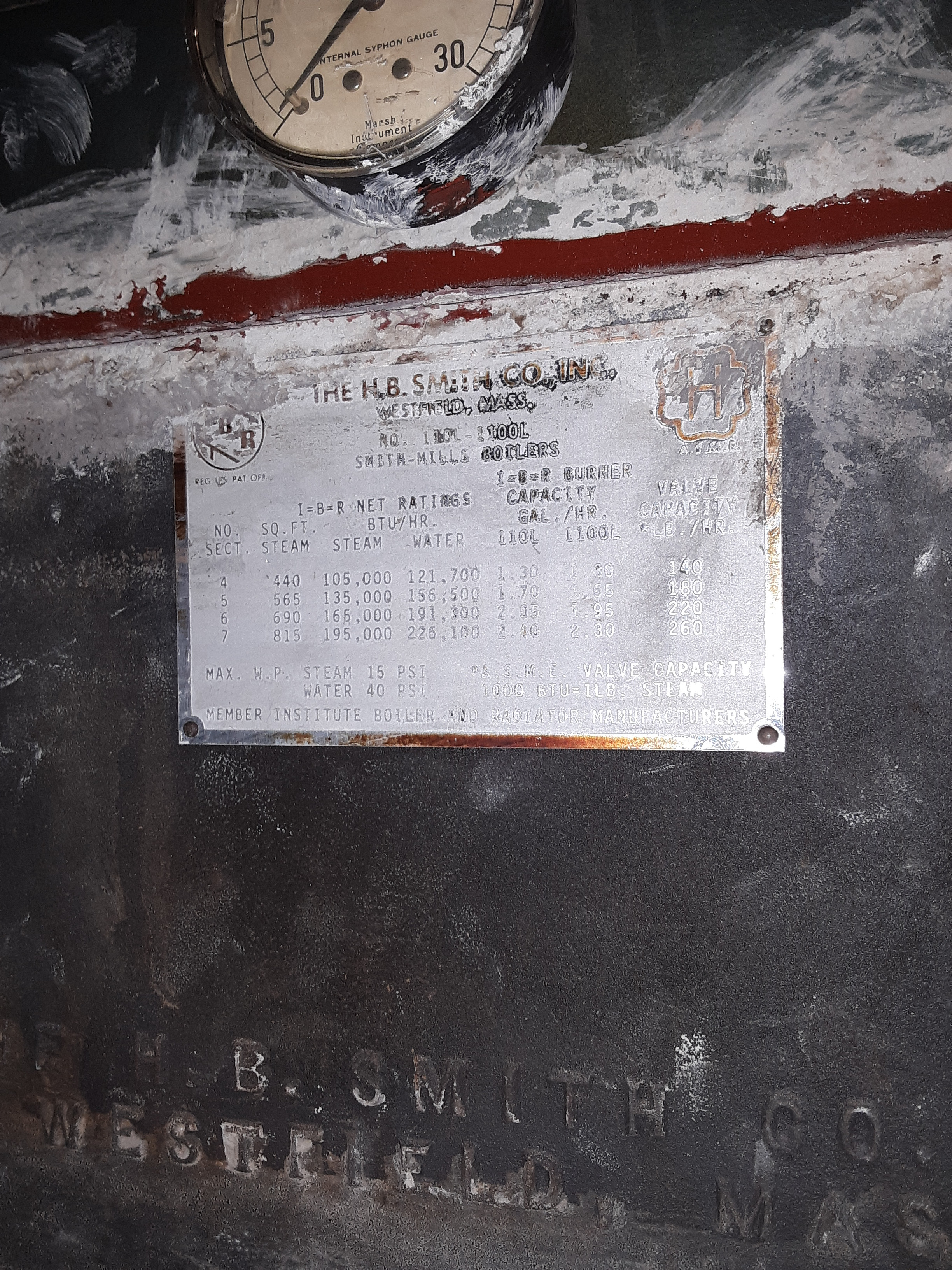

I looking for a sanity check about which direction I should take. Below are some images of the boiler.

Thanks for looking!

Max Ehrlich

Comments

-

-

Fix it.

The 1100 series Boilers are good boilers. I would not give up on it just for a combustion chamber replacement.

The problem is finding someone that will do it. Obviously, your oil company doesn't want to fix it they want to sell you a new boiler.

So i would search around for someone. Check "find a contractor on this site" and post your location someone may know someone or have a recommendation.

As far as the coil goes, I would take the connections apart and clean them up and reattach them. If need be that coil can be easily replaced but there is no need to do that unless the coil is leaking.

HB Smit was the only boiler MFG to use bolts and nuts to attach the coil to the boiler (instead od threaded tapped holes)

If possible post a few pictures of the combustion chamber.

Your service tech may be crying wolf. If you look at the boiler name plate you have either a 4,5.6 or 7 section boiler. So the model # would be a 1100L-#of sections (either 4,5,6,7)-S (for steam)

Now that I am thinking about it I am not sure the 1100 had a normal combustion chamber. I think it just has loose material on the floor of the chamber to insulate the floor and the sides of the mud leg.

Unfortunately I threw out the gobs of HB Smith books I had. (they got wet and moldy in a flood) but will look on line4 -

-

" My oil supplier is steering me to replace the whole boiler saying that we will recoup the cost with the greater efficiency."

LOL. When you see their price quote for a new boiler and do the math, you'll find that the maybe 5-10% efficiency improvement will result in a payback period of like 40 years. Find someone who will fix it.2 -

@maxnix

To update my previous post. That boiler is an HB Smith Model 1100-#of sections-S (for steam)

The dates to around 1970 give or take. The boiler was sold to be used on steam or hot water.

To find the number of sections all you need is a measuring tape. The boiler is 23 5/16 wide.

4 section is 19 3/4 long max firing rate on oil 1.30gph

5 section is 24 1/4 long " " 1.65 gph

6 section is 28 3/4 long " " 1.95 gph

7 section is33 1/4 long " " 2.30 gph

In any event the boiler has no combustion chamber as in a normal combustion chamber

It is what Smith called their "low set" design where the mud legs of the boiler sit on a steel channel base that is about 1" high. That is what the "L" in the model numbers mean.

With the advent of the forced draft high speed burners (Carlin 100crd, Beckett AF) around 1970 Smith took their 1100 boiler that did have a combustion chamber and a cast iron base and did away with the CI base and combustion chamber. This is because the newer high speed burners did not require a combustion chamber.

The only thing required is to insulate the floor of the firebox and up the side of mud legs (the lower part of the boiler sections about 3".

Now, if your oil company is telling you the "combustion chamber is crumbling" they don't know what they are doing.

I do not know the name of the product that Smith used on the combustion chamber floor it used to come in burlap bags and it was a loose material and was just dumped on the floor of the fire box. Probably not available anymore. It may have some insulation under that material I don't remember.

They used the same "Low set" design on the 2000L and 2500L boilers if anyone has tangled with those.

If it had to be replaced, I would use regular 2 1/2 X 4 1/2 x9" insulating fire brick

The other giveaway to what this boiler is is that the burner is mounted on an angled front plate with the burner tipped foreword slightly. This is to keep the flame from hitting the sections.3 -

Ed, thanks for the detailed response, I do recall one of the service techs who seemed to be familiar with that type of boiler a couple of years ago saying we need a new Blanket that goes underneath and he may have said vermiculite could be used to insulate the floor.

0 -

I spoke with the manager about chamber issue and he changed the story slightly, he says that the real concern is the door is now missing it's insulation and that he cant get a replacement. Is this something that can be fixed?

Thanks again for reading this!0 -

@manix

Door insulation is an easy fix. You don't replace a boiler over missing door insulation. Kaowoll sells blanket type insulation and board type insulation. Check out "Foundry Service and supply" or google Kaowool. Then find an oil burner supply house or industrial insulation supplier and you can probably find it online.

It seems to me your oil company is "lazy" and wants to sell you a new boiler.2 -

I really appreciate it, that will save us over $10k!

I spoke with a tech guy at Smith boiler this afternoon and he recommended the same thing, using this material from Ceramaterials

https://www.ceramaterials.com/product/ceramic-fiber-board-single-hd-board-packs/

He said it could be bolted to the door with stainless hardware does that mean drilling through the cast iron? I read that there is also an adhesive to attach the material.

Does the lower part where the blower attaches need insulation as well?

1 -

@maxnix

The lower door will have some type of insulation or refractory material. You may be able to check the condition of that by removing the cleanout door and using a mirror and a flashlight. Can't remember if there is a opening to get a mirror through.

As far as attaching to the upper door you can easily drill through that and use 1/4-20 ss bolts and nuts and fender washers to secure the new insulation. You can attach it with spray glue but I don't think that will hold up to the heat but may be useful to tack the insulation on until you get the screws in.

The chances are if the insulation is bad the door(s) would crack or show some discoloration. It is possible that the old insulation could contain some asbestos3 -

https://www.lynnmfg.com/wp-content/uploads/catalog/Lynn-HVAC-Catalog.pdf

Everything you all talked about is on page 3, 4, and 5 of this catalogue.

Most plumbing supply and HVAC supply companies know of this company and can order it, if it is not already in stock. They may even have a tech support guy that knows what you should do. I have talked to them many times in my 40+ years of working on oil burners

The phone number is in the very first post along with the tech support email address.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

R.E.Michel should have most of this in stock, at least at their main warehouse.EdTheHeaterMan said:https://www.lynnmfg.com/wp-content/uploads/catalog/Lynn-HVAC-Catalog.pdf

Everything you all talked about is on page 3, 4, and 5 of this catalogue.

Most plumbing supply and HVAC supply companies know of this company and can order it, if it is not already in stock. They may even have a tech support guy that knows what you should do. I have talked to them many times in my 40+ years of working on oil burners

The phone number is in the very first post along with the tech support email address. All Steamed Up, Inc.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

@Steamhead , When I see that type of equipment all I can say is "Give me a day with that boiler and it will look and work like new"

New door gaskets in leu of furnace cement around the door. Cleaning all that white gunk off the sheetmetal jacket and a can of black spray paint will make that thing look like new. A few pieces of stuff from that Lynn Catalogue and is will be sealed as tight as the day it was installed.

Wish I could still do that work! I would jump on that in a New York Minute.

That can all be done for a fair price and someone could make some nice scratch doing it. That's what is wrong with the kids these days. If it don't look nice, you need to replace it.

.

Then the replacement will be installed wrong and the customer will be worse off that if they left it alone.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

@EBEBRATT-Ed @EdTheHeaterMan @Steamhead

Thanks for the help keeping this old system alive! Looks like this weekend I will be digging into this further. What precautions should I take other than powering the unit down and wearing a mask when opening this up?

0 -

Get some nitrile gloves. Triple up on them.

The soot in there will take 3 weeks to grow out of your skin on your hands if you get it on your hands.

@RayWohlfarth has a story... i think it was Ray that told about the first oil burner that he cleaned , that was sooted up.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

It's been a while since I have done this type of repair. But I do remember using a Hightemp spray adhesive that was very helpful.

@maxnix When you contact tech support, ask about an adhesive they would recommend. It just might save you a lot of time and headaches.

A lot of great advice on this thread.

BRAVO!1 -

I took off the access door to have a look at the back side. Its a little sooty but there is no residue from insulation if there ever was any before. I bought two 1" sheets of ceramic board and a bottle of sodium silicate. I will clean off the inner surface of the door to help aid the adhesion. I'm debating if it's necessary to use fasteners as well

Edit: Maybe the fasteners are to hold the insulation in place while the silicate hardens? The data sheet says it can take 24 hrs to set.

0 -

I now have the same issue you have with my firebox lining in need of replacement after a cleaning and I happen to have the exact same boiler, HB SMITH NO. 110L-1100L. I have been told that some manufacturers have lining kits specific to boiler makes/models, does anyone know if this is true? I called HB Smith and was told that due to the age of the boiler they don't have any paperwork on this model.

I would appreciate any thoughts and insight.0 -

@RQU100

Just read the above posts. Those low set boilers do not have a combustion chamber. But Smit sold that boiler as an 1100L & 1100 and maybe some other modes using the same sections depending on your boilers age.

So post a few pictures so we can see what you have0 -

0 -

Pics 1and 2 are the inside of firebox, stuck my phone into burner hole to show inside of firebox0

-

0 -

That is a low set boiler. I can't tell from the pictures inside the fire box. Did someone vacuum up all the loose material used for the chamber floor? It was kind of like vermiculite. Is the metal channel on the floor that the boiler sits on exposed inside the fire box. It shouldn't be.

Looks to me like someone vacuumed out the chamber floor material and your down to the metal.0 -

yes, material was accidentally vacuumed up to metal last week so I haven't used boiler yet. Need options for replacement the insulating material.0

-

Your going to have to pull off the burner mounting plate so you can get in their.

You need to google and contact Lynn Products. They sell what you need

What I would use is "insulating Fire brick" It can be cut with a hacksaw. They come 2 1/2" thick x 4 1/2" wide x 9" long

I would start by putting brick on edge along both sides up against the boiler sections and along the front and back of the boiler. So you have 1 brick 2 1/2" wide x 9" long around the entire perimeter.

Then fill in the middle with the 4 1/2 x 9" bricks laying flat so the floor is 2 1/2 " thick. Lynn or HB Smith may have other advise.

You can't "buy" a typical combustion chamber for that boiler. They used to (Smith) supply bags of loose material (maybe it was vermiculite) and you just dumped it in their and levelled it out

1 -

-

@tim smith

Not sure that castable has any insulating value? Iam not sure. Thats why I recommended the fire brick which can easily be cut.

Smith use to use some stuff that they shipped with the boiler in burlap bags. It was something similar to vermiculite but was a dark color. Never knew what it was and they don't have it anymore. Maybe it was something left over from their foundry process.

They used it in the 1100L, 2000L, 2500L, 3500 boilers. Above that size the 4500 and 6500 they used brick over insulation if I remember correctly.

I am located about 10 miles from the old foundry in Westfield, MA so we had lots of Smith boilers here. I had and old catalog I made up with manuals etc for all their boilers but it got damaged in a flood and moldy so I had to toss it.0 -

taking it all in guys but what about insulating the burner hole?0

-

@RQU100

Call Lynn Products, go on their web site you can see what they sell. They can advise you.

@MikeAmann

The only problem I see with the kaowool blanket is when cleaning the chamber area it gets sucked into the vacuum. Hard to vac soot off it without damaging it. That where someone went wrong and caused this

issue.

If it was mine I would pull the burner plate it's only 4 bolts and use insulating fire brick. The Kaowool if fine to insulate the clean out door or burner plate0 -

Casteable works great. Would not hurt to put 1" kaowool blanket under castable and up couple inches to give a little expansion room for castable when heating up. Then do brick walls and back. Usually use pound in plastic refractory like super hybond 2800 degree formable refractory. This is the long term method. Other way is Lynn preformed firepot with 1"ceramic insulation blank on bottom. Different ways to skin a cat. Lynn mfg is a good resource for the preform firepot and its installation. If you have not done this before you really need to hire someone to do it.

Good luck0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements