How to keep an electronic record of when boiler fired

I manage the central steam boiler of a shared 15-unit coop building, where everyone has different demands for heat but we try to arrive at a heating policy that suits as many people as possible without wasting money. We control the boiler via an indoor thermostat which fires it to keep this room between 74-76 degrees. However, after the fact, there is no record of when the boiler was on or off, so there are some arguments like "the boiler didn't come on at all last night", and no way to answer such claims. So, I would like to install a wifi-connected device which can keep track of exactly when it was firing. Ideally, this would be connected to inputs that would tell me not just whether the thermostat was activated, but also whether the boiler was actually firing or not, so I could tell how many minutes are between cycles to maintain our designed steam pressure.

This is a Weil-McLain LGB-9 Series 2 steam boiler. I'd love it if a stock solution to track this existed, but if not, any device that can record voltage across two terminals and publish that to the web would suffice.

Thanks everyone in advance for the time and effort you put into answering questions.

Comments

-

A smart thermostat that just logs when the thermostat is activated is extremely off-the-shelf and easy. I built a custom solution with a microcontroller that logs when my boiler is running and firing (monitoring the status LEDs with light sensors), but it definitely wasn't 'off the shelf'.

It looks like this company might actually have a solution you can buy - maybe something like this: https://www.onsetcomp.com/products/data-loggers/ux90-001x2 -

Yes a data logger is what you need. Supco is one company that makes them. I have not used any in quite a while0

-

-

A low cost work around is a TempStick made by ideal sciences. It is a small 1.5 by3 inch black box that you can put on a surface that will get hot if/when the unit fires, it will report the temp change, to wifi every hour or more often, if needed over the last 24 hrs. Bought one 5 years ago and use it to monitor the pump house, first used it to monitor the house when we were away for the winter. Just bought a second one, It is -20C right now and the pump house is 9 C at 8:17

$140 not a bad deal battery operated you just have to remember to save the record every day.0 -

Your solution is amazing @fentonc -- I suspect you and I are similarly enthusiastic about understanding and maximizing the efficiency of our systems. When I saw the other post you linked -- the "firing" (y/n) graph is what I am looking for. I'd like to measure long the initial fire is to achieve steam pressure (ours is a steam system, running at 12oz of pressure), and how long each subsequent firing is to maintain that pressure until the thermostat is satisfied. Your solution of of a DIY microcontroller might be what I resort to doing if I can't find a ready-made solution.fentonc said:A smart thermostat that just logs when the thermostat is activated is extremely off-the-shelf and easy. I built a custom solution with a microcontroller that logs when my boiler is running and firing (monitoring the status LEDs with light sensors), but it definitely wasn't 'off the shelf'.

It looks like this company might actually have a solution you can buy - maybe something like this: https://www.onsetcomp.com/products/data-loggers/ux90-001x

The smart thermostat would be an easy solution if all I wanted to track is whether the thermostat is activated. If I want to track firing cycle length, I guess I really just need to find a wifi-connected data logger that can measure voltage across two terminals inside the boiler.

I'm kind of surprised that stock solutions do not exist for this. I asked Weil Mclain, and they confirmed that they do not sell or suggest any such tracking device. I'm just a self-educated noob, but it seems that keeping track of how long boiler cycles are over time might be an easy way to determine, for instance, if steam traps have failed open somewhere in the building. I suspect there is a litany of other problems that having such historic data would also help diagnose. If you have a 15-apartment, 60-radiator shared building like I do, I have to rely on people to tell me if something is wrong with their radiators, and often they don't even know there is a problem.

0 -

Ive thought of that too, that would exactly measure what I want. I guess its a matter of which I can find an easier solution for measuring and reporting: voltage or natural gas.Peakedtoosoon said:Install a smart gas meter.

0 -

I think I'm going to try out this Sense Energy Monitor: https://www.amazon.com/Sense-Energy-Monitor-Electricity-Usage/dp/B075K6PHJ9/ref=sr_1_8?crid=2XBIHMCG04GGY&keywords=wifi+voltage+sensor&qid=1670267187&s=hi&sprefix=wifi+voltage+sensor,tools,88&sr=1-8&th=1

I will report back if I get it installed!0 -

-

This one from aliexpress - steps down the 24v at the zone controls to 3.3v for the Pi to consume on the GPIO.fentonc said:@jad3675 What optocoupler did you use?

https://www.aliexpress.us/item/2251832820242690.html?spm=a2g0o.order_detail.order_detail_item.3.32d2f19cyxQW9l&gatewayAdapt=glo2usa4itemAdapt&_randl_shipto=US0 -

So it just gives you something like a 60 Hz 3.3v signal if 24VAC is present and then it's de-asserted if it's absent?0

-

@Fdarby82 Keep in mind that an induction clamp goes on a single 120v conductor, not a whole cable (with multiple wires. On my boiler, I would probably put it on one of the power leads going to the ignition transformer. Be cautious about leaving lids off of electrical stuff if the boiler area is accessible to the public (tenants).

30+ yrs in telecom outside plant.

Currently in building maintenance.1 -

Yep. You can read it with a simple gpio call in python - it triggers on the voltage rise on the GPIO pin. Board is powered from the Pi. Pretty simple to wire up on both the zone and the Pi side.fentonc said:So it just gives you something like a 60 Hz 3.3v signal if 24VAC is present and then it's de-asserted if it's absent?

GPIO.setmode(GPIO.BCM)

GPIO.setup(2,GPIO.IN)

GPIO.setup(3,GPIO.IN)

GPIO.setup(4, GPIO.IN, pull_up_down=GPIO.PUD_UP)

while True:

sleep(15);

if(GPIO.wait_for_edge(2, GPIO.RISING, timeout=50)):

logging.info("Basement Valve Open!")

statsd.gauge('Basement Zone Status', 1, tags=["Zones:Basement"])

sleep(3);

else:

logging.info("Basement valve is closed!")

statsd.gauge('Basement Zone Status', 0, tags=["Zones:Basement"])

2 -

Hey Dave, if your kind response is about my "Sense Energy Monitor" comment, that device is actually installed around the main input leads to the electrical box itself, and monitors all major electric devices served by the box... I think it uses AI to determine the precise electrical signals given off by each appliance, so I'm hoping it will be able to detect the boiler, too. What I don't know is whether the boiler siphons electrical power while its firing (as opposed to perhaps just when it switches between firing and not), and if it doesn't continuously use electricity when firing, then I suspect this device won't do what I'm seeking.Dave Carpentier said:@Fdarby82 Keep in mind that an induction clamp goes on a single 120v conductor, not a whole cable (with multiple wires. On my boiler, I would probably put it on one of the power leads going to the ignition transformer. Be cautious about leaving lids off of electrical stuff if the boiler area is accessible to the public (tenants).

Anyway, I bought it and I will report what I find (assuming I work up the courage to install it myself in the main electrical box of the building!)0 -

I guess it goes without saying that working inside a live electrical panel can be fatal.

Odd things can happen, like leaning on the (inside of) panel while looking at something else. Or fumble a tool or such and instinctively reach to grab it.

Just sayin.. use caution.

Ive never heard of AI determining which electrical load is running. I suspect you run a thing with nothing else running, and then document that in the app. If the app sees that same current flowing, it identifies that identified load. It will be interesting to see how it does in a real-world situation.

If, instead of clamping on the mains, you clamped on the hot wire thats going to the boiler, it would obviously read that line.. but how much else is on that line.. circulators etc ?

30+ yrs in telecom outside plant.

Currently in building maintenance.0 -

I am monitoring every run my boiler makes because I have a new system. I put a security camera, one that can do continuous record in 5 minute clips and record sound, in front of the boiler's LED panel. Once a day I download all the videos and find the on times and off times. It is laborious but I sort of like doing it. I put the data in a spread sheet.

I don't think it would work for most people because the thumbnail of every video has to be checked to see when the temperature is higher than the thumbnail of the previous video, and then play that video to get the date stamp time when the boiler turned on and then off from the burning gas sound. A bit laborious.I'm not a plumber or hvac man and my thoughts in comments are purely for conversation.0 -

Note that the Mexican-made "Sense Energy Monitor" is not UL Listed. In New York, its installation would be prohibited in a multiple dwelling both by code and by our insurers. Even in a single family home, it would be problematic. Apparently it requires a separate 220 circuit breaker installed for connection, though it appears that induction clams are also available.

The monitor senses different electric loads and uses its manufacturer's "intelligence" to identify the loads. Your type of heating system has small loads that are always on, like transformers and controls as well as small loads that turn on with a heating call like the solenoid gas valve and ignitor. It may be difficult to sort them out and identify them with the software. Perhaps you can apply this to only detect the boiler load you are seeking to analyze. Perhaps not.

A data logger on your gas valve would be a much better and more simple choice, though it's possible that this thing can be installed with that limited capacity. A 15-unit coop with steam heating should have some sophisticated energy management controls. If it doesn't, their installation and proper operation can realistically save you upwards of 30% in gas bills and increase comfort for everyone. Check out Heat-Timer and Tekmar. Targeting heat for each unit at 76 degrees is irresponsible to the unit owners who have to pay the bills and can expose the management (or board) to a serious members' lawsuit.

When was the last time that distribution system was balanced and maintained?

That aside, please let us know if this monitor accurately identifies your heating system loads and if it does what you are seeking.1 -

@Jersey2 - if your boiler has status LEDs, using a light sensor right in front of the LED works great an doesn't involve any electrical surgery.

@Dave Carpentier - The "AI" part is probably a little overhyped - that 4KW step that runs for an hour is pretty easy to identify as a dryer. The 700W or so that turns on for a few minutes every hour is probably the fridge. You could try to train a neural net to identify things, but it probably wouldn't do much better than some hand-tuned filtering rules. There's probably no reliable way to identify an intermittent <50W draw without having a dedicated monitor for it (there are lots of wifi-enabled kill-a-watt style plug monitors though).0 -

What type of burner are you using? if your using a power flame or fireeye burner they might be using a Honeywell 7800 series burner control relay which has what i think your looking for built into the unit. All you need is a keyboard display module to access the information. it can be connected to the building management system for analysts if needed.0

-

The burner is a stock one for the LGB-9 Series 2; other than that I'm not sure. We had this boiler installed about 11 years ago, before I moved in.pedmec said:What type of burner are you using? if your using a power flame or fireeye burner they might be using a Honeywell 7800 series burner control relay which has what i think your looking for built into the unit. All you need is a keyboard display module to access the information. it can be connected to the building management system for analysts if needed.

0 -

Thanks for this detailed response @Long Beach Ed . The monitor only uses the separate breaker to power itself (and piggybacking on an existing breaker is an alternate option); the induction clamps are what it uses to sense. I agree with you that it may not work to identify the specific load of the firing; I won't know until I get it installed.Long Beach Ed said:Note that the Mexican-made "Sense Energy Monitor" is not UL Listed. In New York, its installation would be prohibited in a multiple dwelling both by code and by our insurers. Even in a single family home, it would be problematic. Apparently it requires a separate 220 circuit breaker installed for connection, though it appears that induction clams are also available.

The monitor senses different electric loads and uses its manufacturer's "intelligence" to identify the loads. Your type of heating system has small loads that are always on, like transformers and controls as well as small loads that turn on with a heating call like the solenoid gas valve and ignitor. It may be difficult to sort them out and identify them with the software. Perhaps you can apply this to only detect the boiler load you are seeking to analyze. Perhaps not.

A data logger on your gas valve would be a much better and more simple choice, though it's possible that this thing can be installed with that limited capacity. A 15-unit coop with steam heating should have some sophisticated energy management controls. If it doesn't, their installation and proper operation can realistically save you upwards of 30% in gas bills and increase comfort for everyone. Check out Heat-Timer and Tekmar. Targeting heat for each unit at 76 degrees is irresponsible to the unit owners who have to pay the bills and can expose the management (or board) to a serious members' lawsuit.

When was the last time that distribution system was balanced and maintained?

That aside, please let us know if this monitor accurately identifies your heating system loads and if it does what you are seeking.

RE: Energy management controls: We are a very, very basic coop :-), built in 1920, in Champaign, IL. This isn't like the NYC coops where units pay $10,000 a month each in maintenance... these units sell for about $100k each . Before I moved in 2 years ago, no one even knew anything about the boiler, and it ran 24/7 fall through spring whenever the outdoor temp was below 55 degrees, resulting in all the units needing to keep their windows open because it was way too hot even with their radiators off. Now we have the indoor thermostat which modulates the boiler and at least keeps it off most of the time. The pressure used to be set at a ridiculous 7.0psi, resulting in insane and thunderous water hammer (visitors said I should sue the seller for not disclosing), when I've since discovered it is supposed to run at about 0.7psi, which makes it is both silent and heats all the rads at that pressure. That being said, I would love to do more to increase efficiency, and will check out the links you mentioned. I would love to install a thermostat which can also keep the boiler off at certain times of day, but our current thermostat only operates on temperature. I would also love to know if there is some way to downfire it during its cycle so that after it reaches pressure, it's just on "simmer" to maintain. The boiler is probably sized 1-3 sizes too big for our load. I think an LGB-6 would have sufficed.

. Before I moved in 2 years ago, no one even knew anything about the boiler, and it ran 24/7 fall through spring whenever the outdoor temp was below 55 degrees, resulting in all the units needing to keep their windows open because it was way too hot even with their radiators off. Now we have the indoor thermostat which modulates the boiler and at least keeps it off most of the time. The pressure used to be set at a ridiculous 7.0psi, resulting in insane and thunderous water hammer (visitors said I should sue the seller for not disclosing), when I've since discovered it is supposed to run at about 0.7psi, which makes it is both silent and heats all the rads at that pressure. That being said, I would love to do more to increase efficiency, and will check out the links you mentioned. I would love to install a thermostat which can also keep the boiler off at certain times of day, but our current thermostat only operates on temperature. I would also love to know if there is some way to downfire it during its cycle so that after it reaches pressure, it's just on "simmer" to maintain. The boiler is probably sized 1-3 sizes too big for our load. I think an LGB-6 would have sufficed.

RE: "Target heat at 76 is irresponsible"... We have two unit owners who demand it hotter than that, and so I have been cranking it up to 79 degrees last winter in the colder months to satisfy them; no one else takes enough interest to demand a more reasonable setting, even though many are too hot still. It's been an ongoing battle as I try to figure out why those two unit owners are so cold when I only have access to their units by permission.

RE: "Last time distribution system was balanced" -- I don't actually know what this means. I've had contractors do basic inspections of the piping (horizontal pipes are all properly sloped), but there is a long way to go. We don't even have a complete inventory of how many and what size radiators are in the building!

If you'd like to chat about my setup, I would welcome it from someone as knowledgable as you! I bet you'd find lots of things about our setup very interesting. (for instance, we have no steam traps on any of our radiators! Only F&T traps at the end of the lines before they go back to the condensate tank!)0 -

It's just a Weil Mclain atmospheric boiler so no can do on the Honeywell 7800. You should be using at a minimum a Heat timer boiler management control (or similar). This will automatically cycle the boiler off or on and vary the run time based on outdoor temperature. trying to control with a single thermostat for a system like this is really not practical. wont solve your balance problem.

Is your system a one pipe or two pipe system?0 -

It is so interesting to me that, based on this thread, it seems LOTS of people have the same question -- we want to know exactly when our boiler is firing! But how is it no stock solutions exist for this? It just seems that the boiler manufacturers should have an easy add-on for tracking and analytics.Jersey2 said:I am monitoring every run my boiler makes because I have a new system. I put a security camera, one that can do continuous record in 5 minute clips and record sound, in front of the boiler's LED panel. Once a day I download all the videos and find the on times and off times. It is laborious but I sort of like doing it. I put the data in a spread sheet.

I don't think it would work for most people because the thumbnail of every video has to be checked to see when the temperature is higher than the thumbnail of the previous video, and then play that video to get the date stamp time when the boiler turned on and then off from the burning gas sound. A bit laborious.1 -

It's a 2-pipe system. I should also point out that we have Danfoss Thermostatic controls on every radiator (https://www.supplyhouse.com/Danfoss-013G8252-RA-2000-Operator-Valve-Mounted-Dial-w-Remote-Sensor), so in theory (my theory at least) is that regardless of the main thermostat setting, as long as the boiler fires enough, everyone should be able to get their apartment to the temperature they want via these individual radiator controls. Most people in the building report that they are very satisfied with the heat now, and their ability to control it in their apartment. The problem is just one of efficiency... we don't want the boiler firing in excess if 13 out of 15 units are perfectly comfortable, and its not clear why the remaining 2 units are so cold (both have more radiator EDR per square foot in their apartments than any other unit). A central thermostat may not be ideal, but since we have just one boiler, with only one firing setting, and no separate zones, I'm not sure what other controls might increase efficiency other than lowering the thermostat and coupling it with a timer to keep it off at certain times of day.pedmec said:It's just a Weil Mclain atmospheric boiler so no can do on the Honeywell 7800. You should be using at a minimum a Heat timer boiler management control (or similar). This will automatically cycle the boiler off or on and vary the run time based on outdoor temperature. trying to control with a single thermostat for a system like this is really not practical. wont solve your balance problem.

Is your system a one pipe or two pipe system?0 -

BTW I am not familiar with "heat timer boiler management control" or how that could "automatically cycle the boiler off or on and vary the run time based on outdoor temperature". I'll have to research this further (or feel free to educate me?). My only experience with this was when we had an outdoor thermostat before, when the boiler ran literally constantly when the outdoor temp was under 55 degrees; there was no timing, it just ran constantly, resulting in all 15 units being much too hot and having to keep windows open while the boiler burned. The basement was nearly 100 degrees back then!pedmec said:It's just a Weil Mclain atmospheric boiler so no can do on the Honeywell 7800. You should be using at a minimum a Heat timer boiler management control (or similar). This will automatically cycle the boiler off or on and vary the run time based on outdoor temperature. trying to control with a single thermostat for a system like this is really not practical. wont solve your balance problem.

Is your system a one pipe or two pipe system?0 -

@pedmec @Long Beach Ed I started an alternate thread about heat-timer and tagged you on it, if you'd be willing to share your expertise.0

-

How do we find this "alternate thread".0

-

-

Its here @pedmec https://forum.heatinghelp.com/discussion/comment/1724321pedmec said:How do we find this "alternate thread".

0 -

@Fdarby82

"we want to know exactly when our boiler is firing! But how is it no stock solutions exist for this? It just seems that the boiler manufacturers should have an easy add-on for tracking and analytics."

Some do, for instance the new Viessmann E series boilers track all of that information internally off the shelf, you can access it quite simply from the user interface to see total burner hours. Once connected to the internet you can access that information remotely, and I think it even tells you burner hours for specific timeframes as I have seen screenshots showing gas usage during a specific timeframe. This won't help you out as Viessmann doesn't have steam residential boilers, but it is pretty cool

https://www.viessmann-us.com/en/services/viessmann-apps/vicare.html

For the most part manufacturers do not include this type of set up due to keeping costs lower, and traditionally (prior to the tech being consumer ready, and priced correctly) this type of information was all gathered from the buildings BMS contractor, allowing the manufacturer to just need to create a gateway point for BMS into their control, and the BMS company would program their own interface to access these values. I have seen some really cool setups that talented controls contractors put together using the full suite of information a boiler manufacturer has allowed access to.

1 -

This is the closest thing I've seen to something I'd love to have. I want to augment the data I get from my Ecobee and beestat readings with actual data from the boiler. For those unfamiliar, Ecobee thermostats and beestat, provide wonderful graphs with temperatures at the thermostat (and any remote sensors in the system), when the thermostat calls for heat, and outside temps. The problem is that this information doesn't tell me what the boiler is actually doing while the thermostat is calling for heat. I want to know if and when the pressuretrol, LWCO, and auto-feeder are active. The ecobee data showing only calls for heat can sometimes be misleading, such as when I kill the power at the boiler but the thermostat keeps calling for heat. This happened last weekend when I had the boiler offline for several hours to repair a pipe and the ecobee data says I had a several-hour burn on a mild day.

What I'd love to see is a simple graph showing time stamps for when the boiler fires and for how long, and when it is shutdown by either the the pressuretrol or the LWCO. Further, since the LWCO does safety checks, it would be helpful to know when the autofeeder actually adds water. In an ideal world I'd have sensors showing actual pressure, etc. etc., but that's unrealistic and unnecessary.

I just need a little system that can log when the appropriate circuits open and close and translate that data into a graph showing the activity of each device over time. With that information I can have a better understanding of how these components in the system are actually working over time, even when I'm not standing next to it and seeing this activity with my own eyes. I know enough to know it's possible, but I also know I don't realistically have the time to learn how to do it. I'm surprised someone with the knowledge hasn't offered to sell their services to this community with a kit, or a relatively clear set of instructions. I know it's a niche request, but I also know I'm not the only one who would delight in this capability.

0 -

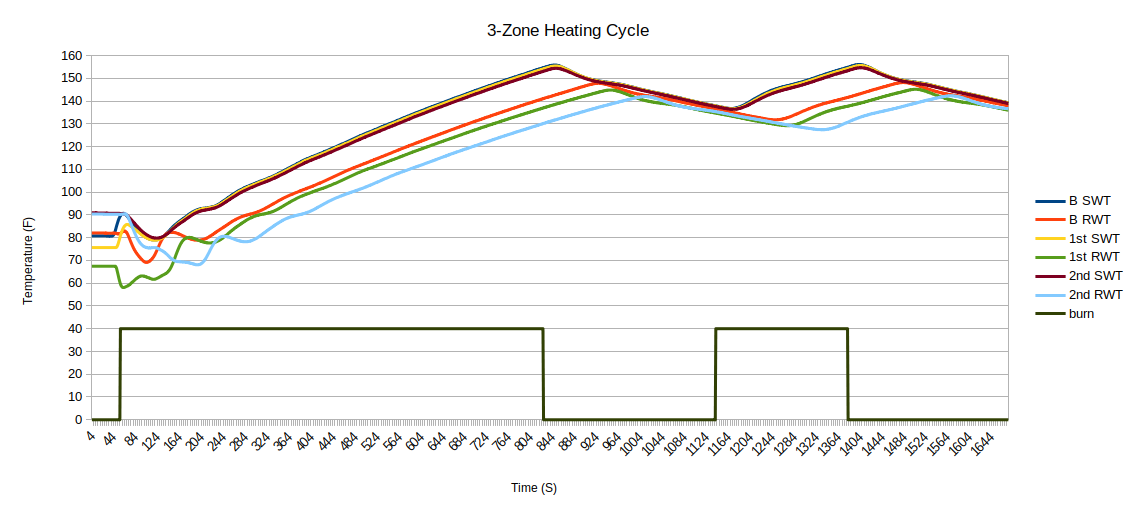

I made this graph with my "boilertron" setup. It uses a microcontroller with 6 temperature sensors, and then light sensors to monitor the 'burn' and 'circulate' indicator lights on my boiler. Lots of one-off, situation-specific design choices. It's a lot of work with pretty much zero potential profit to make an off-the-shelf version of this, but cobbling together your own isn't very difficult if you have any experience with microcontrollers and hobby electronics.

0 -

@meshelman I suspect there is an off the shelf (Hardware) Programmable Controllers - Smart Relay & PLC that would give you the data and the graphing features you desire. With opto-coulped interfaces (as mentioned above in the thread) to monitor the desired functions and graph the data. You may have to learn how to program the controller to do what you want.

for example, this series are fairly inexpensive, not sure about the data capture and graphing capabilities.

https://www.factorymation.com/SG2_PLR_Smart_Relay/Full-feature_PLR_SB

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements