Near boiler piping

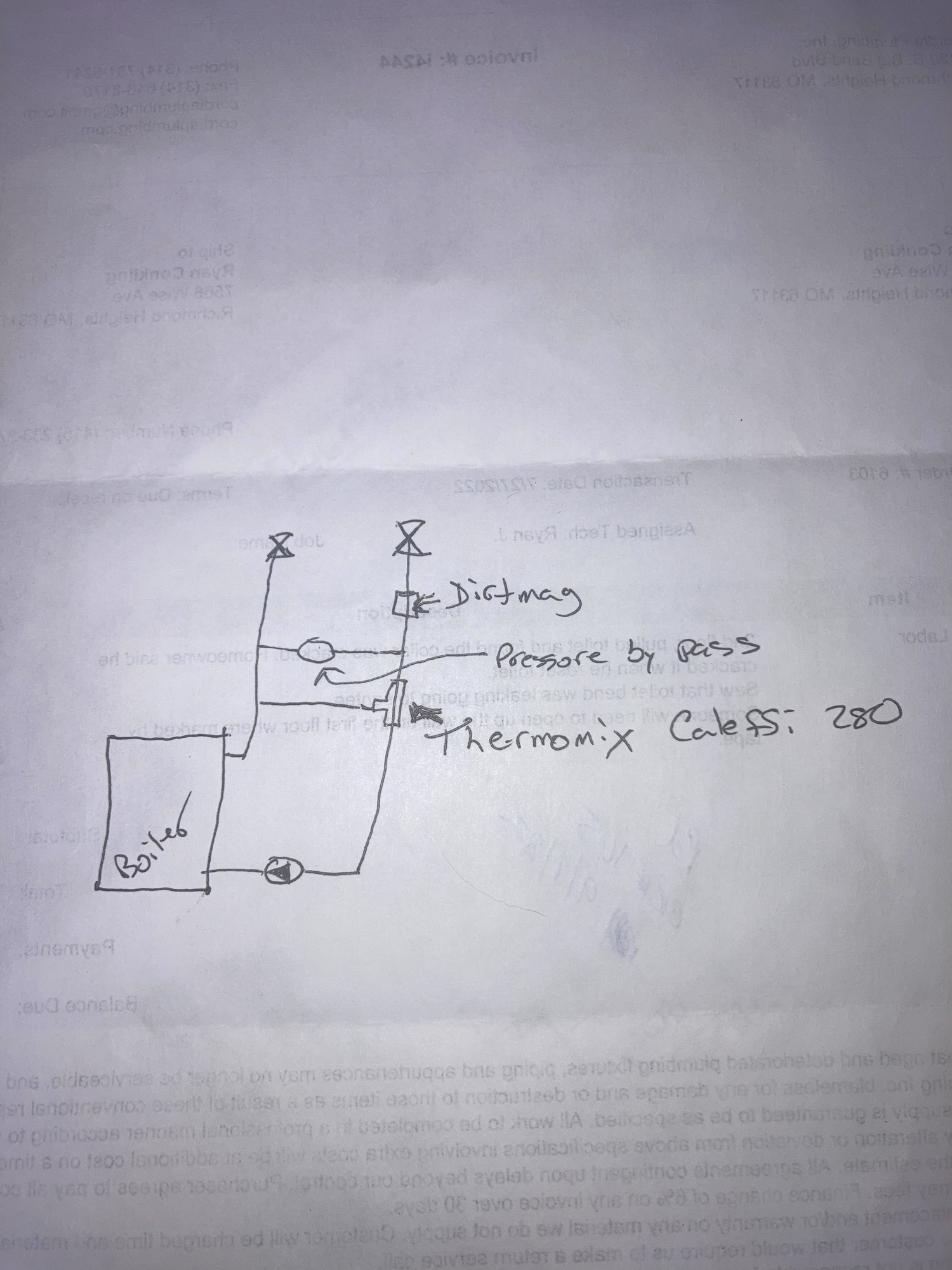

I want to get your thoughts on my near boiler piping plan.

I am trying to extend the life of my old Dunkirk CI boiler. Its direct piped in a converted gravity system feeding 8 radiators. DHW is provided by a separate DHWH.

I will be having TRVs installed on all the rads. So while the system is empty I want to update the piping to increase the longevity of the boiler as well as set it up for a simpler replacement when the time comes.

Im going to be adding a Caleffi 280 boiler protection valve to keep return temps up, a differential bypass valve, a dirtmag separator, along with several much needed ball valves.

Here is my plan:

Are the components in the proper locations?

Is an air separator necessary? The system bleeds easily from each rad.

Would copper and propress be acceptable here? Im concerned about the weight of the valves.

Here is the current system piping:

One might think its a waste of money to do this. But Im doing the install and in my mind all the parts can be transferred to the new boiler, except the thermo valve if a mod con is installed.

Thank you

Comments

-

yes you want an air purger. Use a microbubble type and you can put it right against the boiler. No straight pipe needed. A purge valve on the return, either a one piece Webstone PurgeBall, or ball valve and boiler drain above it. Expansion tank and fill on return near circ inlet,

Also a valve on either side of the pressure bypass, they don't shutoff 100% for purging.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks Bob,

I want to keep it as simple as I can. Im keeping the current overhead expansion tank and fill port in the current location. I grew up in a U.A. fitter family but I chose a different path. So my skill level is novice at best .

.

How big of a deal is it that the expansion tank is upstream of the pump?

I was planning on using the 1" Dirtmag Pro on the horizontal run to the pump.

Here are some more complete photos.

Appreciate the input.0 -

I'm not a fan of the differential pressure bypass valve due to the amount of failures over the years. I understand ts a required item with fixed speed circulators and non electric trv's. Had plenty of managed property with trv's that sounded like the gremlins had hammers when the DPB valve fails to do its job. I would use a delta p variable speed circulator that would react to the opening and closing of the trv's in conjunction with the DPB.

@hot_rod will help you with all the specifics. he can do all the math, lol.0 -

Ditch the over head expansion tank and move the pump to the supply and add a spriovent air eliminator install the thermic valve on your return w the by pass taken off the supply side of your pump . Dependent upon radiator load and pipe sizing maybe adding a a flow rate indicators on your return to balance the flow . A dirt mag is a excellent idea to include . If relocating the pump is in order do add webstone isolation flanges a smart move for sure . Adding trv is fine but remember these are on off and they do not modulate the flow. Instead of the differential by pass valve save some money both ways and look into ecm pumps like a grundfos alpha saving on the valve and installing and save electric being there draw is next to nothing and if using trv they will adjust flow according to what’s open . As for the dirt mag I ve been using adey units they come w isolation valves and the magnet is quite strong plus it gives you a place to add cleaner or a system corrosion inhibitors and when removed you can visually see the iron oxide .

Switching your pump to the supply pumping away from a bladder type expansion tank alone will be the biggest improvement you can do . Doing this will finally allow your pump to use it discharge pressure to circulate water instead of lowering the suction to accomplish this . This alone will improve your system efficiency by giving your far better distribution and in all the years I have been installing in this fashion and even re pipes ever jobs fuel usage was decreased and customers comfort levels increased to the point of no further complaints and issues .

Just some ideas .peace and good luck clammyR.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

How would I ensure constant flow through the boiler if I don’t have a Pressure bypass valve and all the TRVs close?clammy said:Ditch the over head expansion tank and move the pump to the supply and add a spriovent air eliminator install the thermic valve on your return w the by pass taken off the supply side of your pump . Dependent upon radiator load and pipe sizing maybe adding a a flow rate indicators on your return to balance the flow . A dirt mag is a excellent idea to include . If relocating the pump is in order do add webstone isolation flanges a smart move for sure . Adding trv is fine but remember these are on off and they do not modulate the flow. Instead of the differential by pass valve save some money both ways and look into ecm pumps like a grundfos alpha saving on the valve and installing and save electric being there draw is next to nothing and if using trv they will adjust flow according to what’s open . As for the dirt mag I ve been using adey units they come w isolation valves and the magnet is quite strong plus it gives you a place to add cleaner or a system corrosion inhibitors and when removed you can visually see the iron oxide . Switching your pump to the supply pumping away from a bladder type expansion tank alone will be the biggest improvement you can do . Doing this will finally allow your pump to use it discharge pressure to circulate water instead of lowering the suction to accomplish this . This alone will improve your system efficiency by giving your far better distribution and in all the years I have been installing in this fashion and even re pipes ever jobs fuel usage was decreased and customers comfort levels increased to the point of no further complaints and issues . Just some ideas .peace and good luck clammy

I’m t really trying to keep the changes/cost to a minimum. In general the system heats quite well. But evening out the rooms temps would be nice. Hence the TRVs.

What’s the benefit in ditching the overhead expansion tank? The current one is finally not waterlogged and working nicely.

0 -

These are systems. You either go 100 percent old school like you and I currently have, or you go all in on pumping away. Four years ago I replaced my leaking air over water overhead tank with an identical part. No other changes. My system works great. No TRVs, and no plans for TRVs. The old school systems are almost bulletproof. I might be able to circulate pea gravel through mine. My boiler is 75 years old.rconkling said:What’s the benefit in ditching the overhead expansion tank? The current one is finally not waterlogged and working nicely.

Pumping away with a Mr Bubble air bleeder, DirtMag, and bladder tank does have the major advantage of quickly making and maintaining an anaerobic environment. No oxygen = no rust. An air over water tank system will always have more oxygen.

In addition to having these expensive doodads, they have to be in the optimal location in the system. Mr Bubble works best at the highest temp and lowest pressure location. So after the boiler output, but before the circulator @hotrod do I have that right? There are also reasons for the preferred location of the bladder tank on a pumping away system. Off the top of my head I can't articulate them, but they have their logic.

I don't understand the logic of your project. Do you really need TRVs? What you are doing is a lot of work. It's almost November. Time to shut the hood and drive on. If you go ahead with this, why not go all the way and get the modcon now?. Either way I wish you luck and will be following your project.

0 -

I started out just wanting to add boiler protection to keep this old dog running, and it snowballed from there. I could dial it back and with out dirtmag, discal, and bpv. But I figured why not. Since most of the parts can be used on the future boiler.We would like to even out the temp variation upstairs and the two bathrooms get really toasty. Hoping it would also lower consumption.I would install the upgrades while the system is drained and the contractor is doing the TRVs. I also like to tinker, for better or worse, learning and improving systems.I’m in St Louis so we have quite a few 70-80* days ahead of us before winter really sets in.I priced out a new knight boiler and it’s a big chunk of change to replace something that still working just fine, in a home that I don’t intend to live in long term.0

-

pumping away works, and is correct for, either / any tank type,WMno57 said:You either go 100 percent old school like you and I currently have, or you go all in on pumping away.

it's the practice of the circ pulling from the tank, and adding all of its DP to the remainder of the heating(or whatever) loopknown to beat dead horses0 -

Another question about TRVs.

I've read here about the importance of having TRVs on all the rads. with the pressure bypass valve.

Else where I 've read that 1 rad, in the coldest room where the T-stat is located, should be left open to provide the constant flow through the boiler. This would eliminate the need for the failure prone pressure bypass valve and reduce the cost and complexity of the project.

Which is preferred and why?

Thank you0 -

Except it is condensing most of the heating season.

Last year the return temps rarely exceeded 130*.

Since I opened it up and brushed it out a few weeks ago, it appeared to get a little hotter.0 -

To work best, or properly the compression tanks should have the B&G Airtrol fitting. Or equivalent brand. Yes, air removal is best at the hottest point in the system. So the Airtrol connects into the top of the boiler and does a good job with air. The dip tube is important to place removed air up top in the tank or it goes back into solution as the water cools.

If you keep the compression tank and add an air purger, attach a tube to the discharge and run it into the top of the tank, as the Airtrol fitting does.

The diaphragm or bladder tank does not need to be on or at the air purger, or at the boiler supply, but it likes to be at the inlet side of the circ

Systems with circulators on the return should also have the tank connection there, air purger at boiler supply

Rumor has it circs we’re on return to make packaged boilers safer to ship?? Also the 3 piece circs appreciated the cooler fluid in the return, the are air cooled motors and early fin tube would run 200F or higher to cut down on the amount of fin tube, so they could run close to their max temperature rating .

I suppose the same could be said for expansion tanks on the return

If the system is zoned with all TRV you need a device to prevent dead heading the circ. A low flow switch, PAB, or delta P circ are some options

A PAB is just a disc with a spring. If sized and set properly, circ not oversized, they should be silent. The ECM delta P solves the TRV question and save electricity also, the best option

There were some rebate programs to switch to ECM, check here.

They may be back with the new energy conservation bill, at the federal level if not by your utility

wwwdsireusa.orgBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Because trv's work by wax expanding, pushing the valve needle against the valve seat as it gets hotter until it closes completely. But pic a circulator that does not know that the valves are closing. its constantly circulating water. And as more and more valves close the boiler water picks up more and more velocity in the open valves until the velocity doesn't allow the valve to close. the valve starts hammering away. Bang, bang, bang until another valve opens. And that's what your left with, a banging system. You blame the trv's but it really ain't their fault. there was no place for the velocity energy to disparate. I going to add that leaving one trv open is really not solution. you might need to more to bypass the system that one trv can supply. you also could have velocity noises going thru that open one that will drive you crazy at night when your trying to sleep. Maybe in a very small system but as the system starts to get bigger you need more system bypass.

And that's why i recommended the delta p circulator. It feels the pressure changing in the system and reduce or increases its flow accordingly.0 -

I learned about a waterlogged tank last year when my PRV kept leaking and the boiler gauge showed zero PSI. I'd add water to increase the PSI and it would only take seconds for the PSI to spike. It would fire once, the floor would be wet, and back to zero PSI.hot_rod said:To work best, or properly the compression tanks should have the B&G Airtrol fitting. Or equivalent brand. Yes, air removal is best at the hottest point in the system. So the Airtrol connects into the top of the boiler and does a good job with air. The dip tube is important to place removed air up top in the tank or it goes back into solution as the water cools.

If you keep the compression tank and add an air purger, attach a tube to the discharge and run it into the top of the tank, as the Airtrol fitting does.

The diaphragm or bladder tank does not need to be on or at the air purger, or at the boiler supply, but it likes to be at the inlet side of the circ

Systems with circulators on the return should also have the tank connection there, air purger at boiler supply

Rumor has it circs we’re on return to make packaged boilers safer to ship?? Also the 3 piece circs appreciated the cooler fluid in the return, the are air cooled motors and early fin tube would run 200F or higher to cut down on the amount of fin tube, so they could run close to their max temperature rating .

I suppose the same could be said for expansion tanks on the return

If the system is zoned with all TRV you need a device to prevent dead heading the circ. A low flow switch, PAB, or delta P circ are some options

A PAB is just a disc with a spring. If sized and set properly, circ not oversized, they should be silent. The ECM delta P solves the TRV question and save electricity also, the best option

There were some rebate programs to switch to ECM, check here.

They may be back with the new energy conservation bill, at the federal level if not by your utility

wwwdsireusa.org

Thought the PRV was bad so we swapped it out real quick, well its working lol, releasing the pressure.

So I had to add the SOV to the tank line and I added a B&G drain-O-tank air charger to get the water level correct.

Boom, works like a charm.

So a Delta-P ECM pump would negate the requirement for the 519600A I have on order?

0 -

Thank you. I am aware what you have described.pedmec said:Because trv's work by wax expanding, pushing the valve needle against the valve seat as it gets hotter until it closes completely. But pic a circulator that does not know that the valves are closing. its constantly circulating water. And as more and more valves close the boiler water picks up more and more velocity in the open valves until the velocity doesn't allow the valve to close. the valve starts hammering away. Bang, bang, bang until another valve opens. And that's what your left with, a banging system. You blame the trv's but it really ain't their fault. there was no place for the velocity energy to disparate. I going to add that leaving one trv open is really not solution. you might need to more to bypass the system that one trv can supply. you also could have velocity noises going thru that open one that will drive you crazy at night when your trying to sleep. Maybe in a very small system but as the system starts to get bigger you need more system bypass.

And that's why i recommended the delta p circulator. It feels the pressure changing in the system and reduce or increases its flow accordingly.

The one radiator that could be left without a TRV is 30 sections with 1.25"-1.5" supply and return piped to 2" main distribution pipes. Motivated by a TACO 007. This was just an option mentioned elsewhere that is in contrast to what I have read here so I was curious if it was a solution.

If the Delta-P pump is similar cost as the bypass valve, then thats a no-brainer.

0 -

Delta P circ or pressure bypass. They will not work togetherrconkling said:To work best, or properly the compression tanks should have the B&G Airtrol fitting. Or equivalent brand. Yes, air removal is best at the hottest point in the system. So the Airtrol connects into the top of the boiler and does a good job with air. The dip tube is important to place removed air up top in the tank or it goes back into solution as the water cools.

I learned about a waterlogged tank last year when my PRV kept leaking and the boiler gauge showed zero PSI. I'd add water to increase the PSI and it would only take seconds for the PSI to spike. It would fire once, the floor would be wet, and back to zero PSI. Thought the PRV was bad so we swapped it out real quick, well its working lol, releasing the pressure. So I had to add the SOV to the tank line and I added a B&G drain-O-tank air charger to get the water level correct. Boom, works like a charm. So a Delta-P ECM pump would negate the requirement for the 519600A I have on order?

If you keep the compression tank and add an air purger, attach a tube to the discharge and run it into the top of the tank, as the Airtrol fitting does.

The diaphragm or bladder tank does not need to be on or at the air purger, or at the boiler supply, but it likes to be at the inlet side of the circ

Systems with circulators on the return should also have the tank connection there, air purger at boiler supply

Rumor has it circs we’re on return to make packaged boilers safer to ship?? Also the 3 piece circs appreciated the cooler fluid in the return, the are air cooled motors and early fin tube would run 200F or higher to cut down on the amount of fin tube, so they could run close to their max temperature rating .

I suppose the same could be said for expansion tanks on the return

If the system is zoned with all TRV you need a device to prevent dead heading the circ. A low flow switch, PAB, or delta P circ are some options

A PAB is just a disc with a spring. If sized and set properly, circ not oversized, they should be silent. The ECM delta P solves the TRV question and save electricity also, the best option

There were some rebate programs to switch to ECM, check here.

They may be back with the new energy conservation bill, at the federal level if not by your utility

wwwdsireusa.orgBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If you use an indoor thermostat, the radiator(s) in the room with the thermostat should not have TRV(s). The usual strategy is to put the thermostat in the coldest room, and use the TRVs to reduce the heat in the other rooms.

If you put TRV‘s in the room with the wall thermostat, and someone turns them down, the thermostat may never be satisfied which will waste a great deal of fuel and cause wear on rverything on the water side of the system.

Outside of North America it’s common to use an outdoor thermostat to set the circulating water temperature, and there is no interior thermostat; in which case the above does not apply.—

Bburd0 -

Thank you.bburd said:If you use an indoor thermostat, the radiator(s) in the room with the thermostat should not have TRV(s). The usual strategy is to put the thermostat in the coldest room, and use the TRVs to reduce the heat in the other rooms.

If you put TRV‘s in the room with the wall thermostat, and someone turns them down, the thermostat may never be satisfied which will waste a great deal of fuel and cause wear on rverything on the water side of the system.

Outside of North America it’s common to use an outdoor thermostat to set the circulating water temperature, and there is no interior thermostat; in which case the above does not apply.Yes. This is what I read elsewhere.The thermostat is inside, in the dining room that has no radiator. 15’ from the 9 window sunroom with the 30 panel radiator.I’ll see what the contractor has to say this Thursday.Appreciate the info.0 -

Its with great emotional and financial sadness I must declare this project dead.

Adding a flue liner to my chimney turned out to be 3-4x more expensive than I planned. Due to the damaged clay liner that needs to be removed.

The money is better spend on an upgrade. Hooray and sad all at the same time.

Im staring a new thread so I can make sure the new boiler is piped most efficiently.0 -

Nope, direct vent PVC through the wall.

The real bummer is my neighbors, who I bought the house from, had the chimney rebuilt from the roof up but didn't repair the lower internals . So 95 years of use, a lot of those with coal, then likely oil, and finally a condensing cast iron boiler, its worn out and more money than its worth to fix it. If the boiler was relatively new it would be a no brainer. 0

. So 95 years of use, a lot of those with coal, then likely oil, and finally a condensing cast iron boiler, its worn out and more money than its worth to fix it. If the boiler was relatively new it would be a no brainer. 0 -

My chimney was like that. it had been rebuilt from somewhere around the roof line and had clay tile sticking out the top but the tile was only in the section that was rebuilt.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements