Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

What kind of trap is this

Options

Jimbabwe

Member Posts: 10

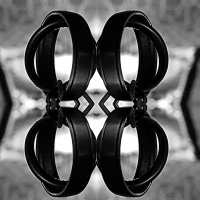

This is a trap I’m unfamiliar with, located in a boiler room in Chicago. One pipe steam system. Just looking for some info on what type of trap this is, approximate age maybe and what the internals are. Thanks gents.

This is a trap I’m unfamiliar with, located in a boiler room in Chicago. One pipe steam system. Just looking for some info on what type of trap this is, approximate age maybe and what the internals are. Thanks gents. 0

Comments

-

That's a rather large float-&-thermostatic trap. It's made by Sterling, a.k.a. Sterlco, an old name in the steam business, which believe it or not still exists:

https://www.sterlcosteam.com/

The float mechanism is in the bulbous main body of the trap. The smaller portion that looks like a radiator trap acts as the air vent.

How is the trap hooked up? Is that a below-floor condensate return reservoir and pump next to the trap?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

Yes, it drains into what I would describe as a condensate “pit” in the boiler room floor. Looks essentially the same as a sump pit to me but obviously a very different purpose.Thank you for the info, I thought it had to be some type of float style trap based on the body design. All of the other F&Ts are the standard Hoffman style. This one always catches my eye. I love to see interesting and different old components still doing their jobs lo these many years later.1

-

The Ol Canonball trap0

-

I believe Sterlco says it thusly: F&T traps operate in response to rising and falling condensate

levels and rising and falling temperatures near the thermostatic

vent, as follows:

• Condensate initially fills the trap body to a predetermined

level, which is sufficient to seal the valve seat opening.

• As the condensate level continues to rise, the float will rise

causing the valve to pull away from the seat.

• Condensate will then be discharged into the return line

through the trap outlet. The rise and fall of condensate level

causes a continuous discharge which is typical of F&T traps.

• Air entering the trap is discharged through the thermostatic

vent. The opening and closing of the vent is dependent upon

the temperature surrounding the thermostatic element.

• As the element cools with more air accumulating, it opens to

allow the air to vent to the atmosphere1 -

That is an old Sterling #FT-80-15 2" F&T. Originally made in Milwaukee, WI. The trap is no longer made, but the rebuild kit is available. It is part #693.00542.00.

I can't see the rest of the piping, but it looks like in may be a "master trap" which is a very bad idea. If it is, remove it.0 -

I agree totally if it is Infact a master trap, they have no business on single pipe steam. However, the first thought I had was the rush of condensate back to the tank is of course part condensate and partially water at flash point. Perhaps, the trap was installed to prevent super heated condensate flashing to steam as soon as it hits atmosphere. This could have been a way to keep steam blooms out of the condensate tank. Whoever, installed it was using their head they introduce atmosphere into below atmosphere condensate negating the " flash" that would occur otherwise. I am heartened to see someone long ago that actually thought, I am presented daily with ideas that just will not work. All they have to do is get Dan's books or Myrons book, or Frank Gerrity they would actually enjoy the trade more if they understood what they were doing, ignorance is bliss until you go back four times and look like a fool. Stay Well and Hug your kids, we ainted getting no younger Cheers Jack1

-

This is why this is the best forum around for our trade. The wide array of knowledge, experience and willingness to share and help is invaluable. I was delighted to see that this made the wall this morning and all of your feedback is greatly appreciated. And yes, looking at it again it certainly does resemble a cannonball. And Jack may be on the mark as this feeds directly into a floor pit and could be there to negate the flash. I love you guys. Keep doing the good work.0

-

I came across this in Parsippany, NJ. 2 pipe system in residence. Would someone please explain the operation of these components.

No condensate tank present.

Utica PEG-300. TIA

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements