Fill the closed radiant heating - do I need backflow preventer and pressure reducer (autofill)?

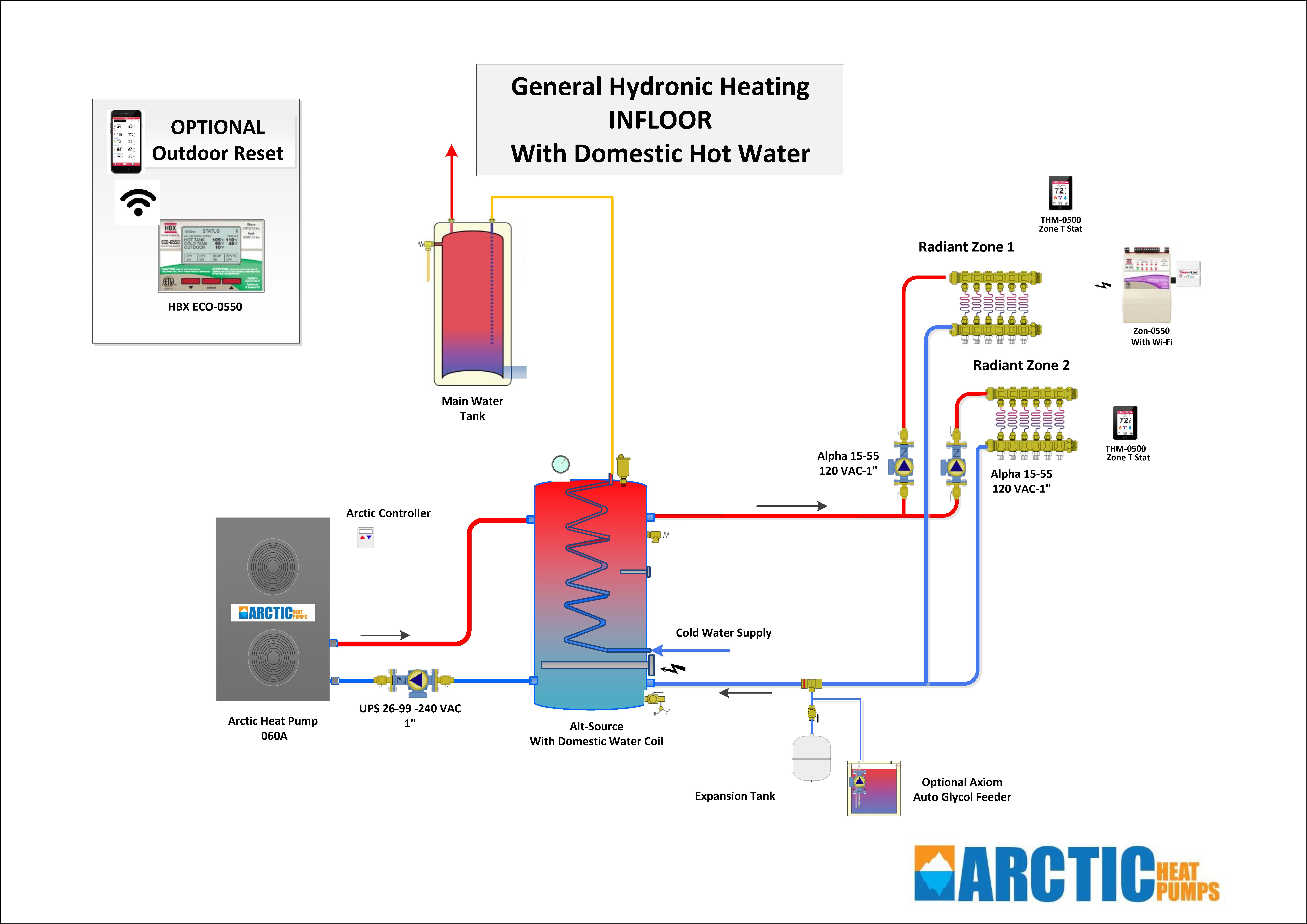

So I have a in-floor radiant heating in a 2 storey house, heat pump and buffer tank is in the basement, scheme is similar to this

1. When filling the system, do I need an Autofill device similar to this or can I just have fill and drain ball valves pair near the expansion tank and a garden hose filling from the city water supply?

2. Second question is on static pressure. Say I don't have a pressure reducer and am filling from the bottom with a garden hose attached to a city water supply through a fill-drain. I assume city supply is 30-40psi. Can I do it during filling/purging with the drain valve open on the other side so that the water is filling the system and draining on the other end?

3. Do I understand correctly that during filling once the water is in the system all the way up, once I close first drain then fill valve from city water supply, the pressure in the system will be set to just a hydrostatic pressure due to the house height (i.e. 20 feet * 0-.4433 ~ 9 psi), i.e. I can not "pump" water in and have a higher pressure even if filling with higher pressure simply because of water being non-compressible?

bonus question:

when I fill from the city line with no pressure reducer and drain valve open, i.e. water circulating through the system and draining on the other side, what the manometer in the system will show? city line pressure? Will it then momentarily drop to hydrostatic pressure once I close the fill and drain valve?

thank you!

Comments

-

Will the system have glycol or plain water? Yes you could fill with a garden hose, carefully so not to exceed the pressure relief setting at 30 psi. If you go with that method, be sure there is a discharge line on the relief valve that can go to a drain. Quite a bit of water will flow from the relief when you exceed the pressure setting.

Fill pressure is elevation 20' x .433= 10 psi, then add 5 psi to assure positive pressure at highest point, so a 15 psi static fill

The expansion tank needs to be set at 15 psi before you start pressurizing.

All hydronic systems continue to vent air for a few days on first start up, so you need something to maintain that 15 psi.

Could be an Axiom, or a fill valve, or an additional expansion tank and fill valve.

Looks like a reverse indirect as the buffer, so your system may hold 50 gallons or more, lots of potential air

A small transfer or sump pump in a plastic garbage can or 5 gallon bucket is a great way to fill and purge. It allows you to see when the purge flow is "clean". Purge until you gat a solid, clear stream. if cloudy, it still has entrained air.. You may need to repurge after it heats for a bit as air will come out of solution with heat added.

Better yet would be to run a cleaner for a few days get oils, flux, dirt, etc completely cleaned out.

How is your fill water? Should be below 10 GPG hardness, low TDS. The heat pump may have a water spec in the manual?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

For many reasons i would use the Axiom autofill unit.

1. Set it and forget it...Just adjust your system pressure and let the unit take care of it !

2. It will not flood your home

3. You can see how much fluid is being replaced and react if the usage is high.

4. Aux Alarm outputs.

5. You can control the system Fluid quality

From exsample: Glycol/deionized water mixture or Deionized water only.

Depending on the quality of the City water utilizing City water can have very bad results on

your heating system and may void your warranties

Adhere to the manufactures recommendations ,The new ANSI H

1001.1 or the VDI 2035.

As for Static system pressure: In order to keep the expansion tank rubber bladder from rubbing

on the inlet fitting i would mantain 18 PSI and the Nitrogen side of the expansion tank at

approx.16 PSI.0 -

Thank you for your feedback.

It is a 100% water system, no glycol.

So bottom line is (correct me if I am wrong)

- I do not need an Autofill device

- I can fill with a hose using a fill/drain valves pair

- to build up working pressure _after_ purging air for a while I simply open the fill valve, close drain valve while looking at the pressure gauge. Once I see 15psi, I close drain and then fill valve. Viola, done

- I probably will have to repeat the last step a few times in the next few weeks

Is that about right? I wonder why people would install $300+ Autofil device then? It seems like I am missing smth very obvious, pardon my ignorance0 -

You want a top quality low water cutoff device, properly installed. Should a leak develop this prevents the boiler from firing and melting down, or the heat pump from going into lockoutapolyakov said:Thank you for your feedback.

It is a 100% water system, no glycol.

So bottom line is (correct me if I am wrong)

- I do not need an Autofill device

- I can fill with a hose using a fill/drain valves pair

- to build up working pressure _after_ purging air for a while I simply open the fill valve, close drain valve while looking at the pressure gauge. Once I see 15psi, I close drain and then fill valve. Viola, done

- I probably will have to repeat the last step a few times in the next few weeks

Is that about right? I wonder why people would install $300+ Autofil device then? It seems like I am missing smth very obvious, pardon my ignorance

Looks like you have a large volume system if that is a reverse indirect, so you have some capacity to cover a tiny seep or drip, should it occur.

A 100% air and water tight system is not always possible, so occasionally you may need to add a small amount of additional water.

Much of the new equipment is coming with low pressure switches also. So if pressure drops, the system will lock out, boilers for sure, good chance heat pumps do also to protect themselves, look into it. That would result in you system shutting down maybe when you are not around?

If you go naked I would use a #60 or 90 expansion tank and allow a few gallons into it for a bit of reserve.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks, Bob, this makes sense to me. Actually you touched on an important question. My system, like I said is a pure water and it is about 250 gal total volume include the buffer tank and radiant loops. Working temp will be around 35 deg celcius (radiant floor heat hence low temp) I estimated this expansion tank https://www.pexuniverse.com/amtrol-extrol-60-expansion-tank seems about the same as you suggest?

how can I double check my claculations, is there a simple way to say with X galons of water and this temp you should use this volume expansion tank?

0 -

Great Idea! However the word "maintain' could be misinterpreted.Derheatmeister said:As for Static system pressure: In order to keep the expansion tank rubber bladder from rubbing on the inlet fitting i would mantain 18 PSI and the Nitrogen side of the expansion tank at approx.16 PSI.

My attempt below to clear this up:

First set the gas side of the expansion tank to 16 PSI.

Then, initial fill the wet side of the system to 18 PSI.

When done (assuming the isolation valve between the expansion tank and the system is now open) the pressure on both sides will be equal (probably 18 psi), and the rubber bladder will be away from the inlet.

I'm no expert here, but I think a greater initial differential might be better, like 12 - gas, 15 - wet. I have an air over water tank,so no personal experience, and no bladder either.

0 -

https://www.westank.com/calculator/apolyakov said:Thanks, Bob, this makes sense to me. Actually you touched on an important question. My system, like I said is a pure water and it is about 250 gal total volume include the buffer tank and radiant loops. Working temp will be around 35 deg celcius (radiant floor heat hence low temp) I estimated this expansion tank https://www.pexuniverse.com/amtrol-extrol-60-expansion-tank seems about the same as you suggest?

how can I double check my claculations, is there a simple way to say with X galons of water and this temp you should use this volume expansion tank?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I am confused. In the calculator, initial pressure based on my building height (typical 2 storey house) sets to 18.7 psi which I assume is psig (i.e. gauge pressure). This doesn't make sense to me as I expected this number to be around 8 psig (20 feet * ~0.4) and my work pressure to be 12psig as I tought this is more or less standard and the xpansion tank itself is set to 12psig

thanks for education, Rob

0 -

The heigh difference between the expansion tank and highest pipe or emitter

X .433

so 20’? Call it 9 psi, add 5 psi for positive pressure at that high point. 14 psi fill no pressure, tank at 12 psi

Pressure will increase as water heats, do the fill cold, read the pressure at highest temperature to see the change

o harm in additional pressure, but you have less room from relief setting. Higher fill pressure will require a larger tank.

Plug whatever numbers you have into the sizer see how that acceptance number changes

It can get more complicated with 2 or multi temperature systems where not all the fluid sees the wide temperature swing, keep it simple use the sizer program😉

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

so I fill at 14psi. I assume if tank is at 12 I will need to adjust it to 14. Or do I need to adjust it to operating pressure instead, not fill pressure?

what is dictating my operating pressure at 95F temperature? In other words, in calculator I can put higher number for operating pressure and get lower tank, but what in practice determines this number? I can think of applying physics here and calculating water volume at 95F, then assuming some water will get into expansion tank I can probably calculate pressure isnide this tank using Boyle-Naryott's law like P*V = R *T etc. I have a feeling though practitioners don't do it

For example, say I want my operating pressure to be 18 psi (i.e. fill static pressure + 4 psi), does it mean I adjust my 7.6 galon tank from 12 to 18 and change my relief valve to 20 psi and be done?

0 -

First you need to know the temperature of the water you fill with. Commonly we use 50F. You could measure your actual water after it runs for a few minutes. Well water stays fairly consistent, public water varies depending on where it is stored. Phoenix water runs over 80F due to the heat in the streets! Your entire system may be 68 or 70F when you start or fill use 70 if you want.

Then you need the volume of fluid in the system as the pressure increase as you heat is related to how much that volume will expand

With the online programs you can play with all the numbers and see how the tank size changes based on temperature rise

Also at play is the pressure in the system. Keep the static fill pressure as low as you can and assure that 5 psi at the uppermost point. That too will help keep the tank size smaller as you have more pressure range available from 12- 30 as you would 18- 30 psi

30 psi is where the relief valve will start to discharge, I use 28 not knowing how accurately they build relief valves

Bottom line, the lower the operating temperature the less expansion space required.

The lower the fill pressure the smaller the required tank size

keep in mind common tanks go 15, 30, 60, 90 size, error up if you fall on the line, no harm in having an oversized tank and price doesn’t change a whole lot.

Some suggest checking and adjusting the tank to whatever fill pressure you decide on, that works. 14 fill pressure 14 in the tank

myself and others suggest the tank is set 2 psi lower then what you plan on filling. That allows a small amount of water into the tank for some buffer when air vents out, and before the fill valve kicks on

Or if you are not using any fill system , that expansion tank fluid gives you what is known as a safety seal.

A common practice in solar thermal, since they do not have fill systems, under-charge the tank.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements