Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Any tips for installing hePex for hot water baseboard? Regarding thermal expansion.

Options

cckriss

Member Posts: 38

I will be using 1/2” hePex. I’ve already ran 1 home run and it went pretty well. This is the longest loop at 90 feet with 12 feet of element. There are alot of bends as this is going to an addition. I used no 90 degree fittings. I used either the bend supports or it’s own natural sweep bend.

I know to leave the 90s unsupported to allow movement. Any other tips?

For the straight sections, should I stagger the clips to allow it to “snake”? I dont have the room for an expansion loop.

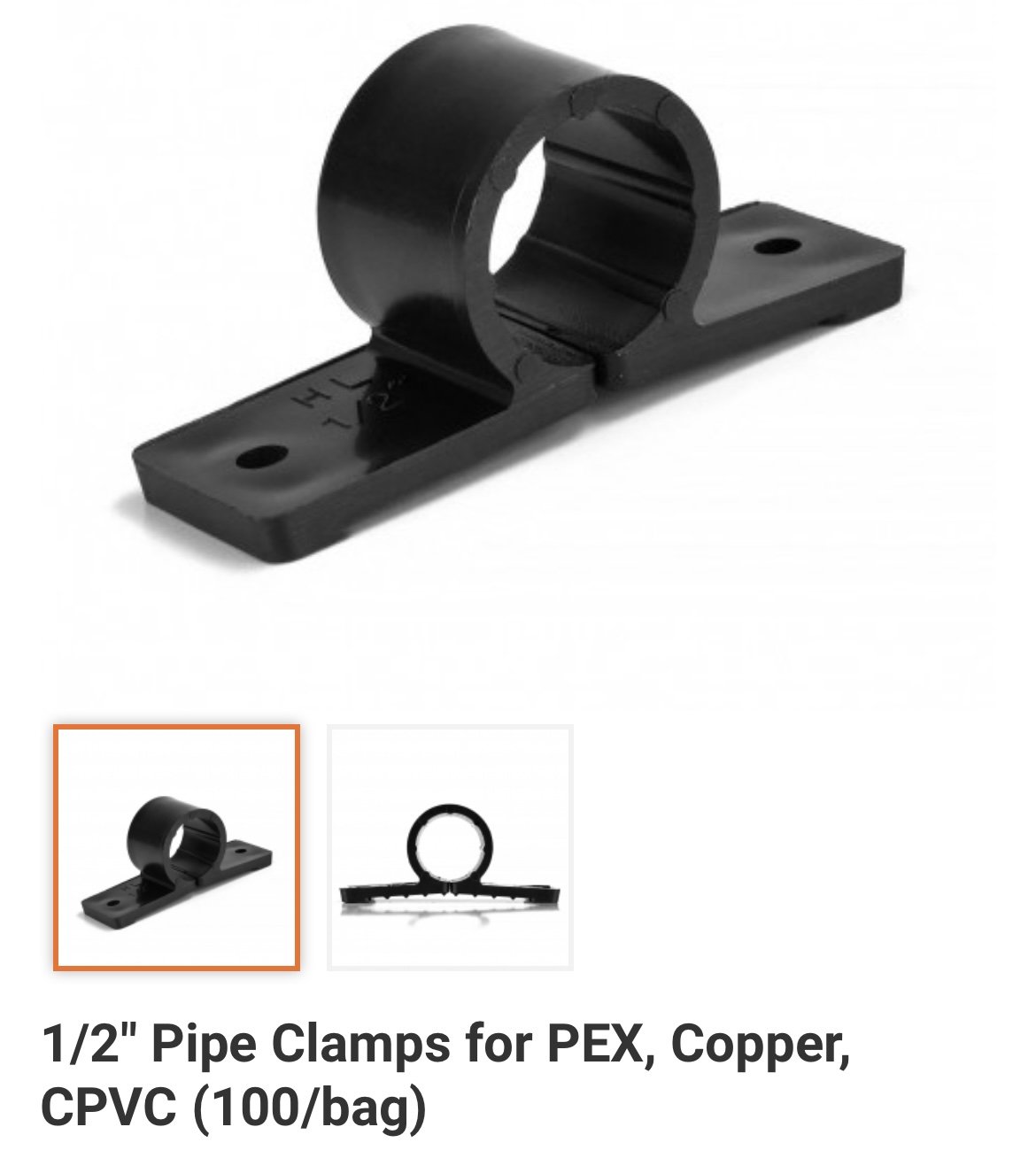

I am using these clips. I paid extra attention so the pipe touches no wood framing,

I know to leave the 90s unsupported to allow movement. Any other tips?

For the straight sections, should I stagger the clips to allow it to “snake”? I dont have the room for an expansion loop.

I am using these clips. I paid extra attention so the pipe touches no wood framing,

0

Comments

-

You have a good plan, allow movement room. Don't lay pex over pex if you can help. Yes to those clips.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Make sure the ends of the element are free to move too.0

-

What does pex over pex mean? Does that mean above each other if I were to secure them to the side of a joist?hot_rod said:You have a good plan, allow movement room. Don't lay pex over pex if you can help. Yes to those clips.

Going underneath joists, should I stagger the clips? To make them snake-like?0 -

I drilled 1-1/8” holes for the pex risers going into the copper baseboard. I’m more concerned about the heating element lifting up off of the brackets from the pex expansion.cckriss said:mattmia2 said:Make sure the ends of the element are free to move too.

The pex itself should be able to flex enough for the baseboard to expand, just make sure the hole is lined with something that lets the tubing slip. I would use a 90 fitting under the floor instead of bending the pex at the risers for for the baseboard so that the expansion on the lateral piece of pex is isolated in the horizontal plane instead of being able to push up the curve in to the riser.0 -

Do you recommend using brass 90s as opposed to the black plastic ones? Because of the high temp of a hydronic heat systemmattmia2 said:The pex itself should be able to flex enough for the baseboard to expand, just make sure the hole is lined with something that lets the tubing slip. I would use a 90 fitting under the floor instead of bending the pex at the risers for for the baseboard so that the expansion on the lateral piece of pex is isolated in the horizontal plane instead of being able to push up the curve in to the riser.0 -

I'd use the EP fittings. Once you start buying more than a few brass fittings you might as well have used copper.0

-

I second the EP fittings. The pex itself will limit your max temp in the same way EP fittings will, both are rated beyond what is needed for residential hot water heating. The one thing to note, make a list of material and check availability. EP fittings are currently still being rationed by allocation to distributors and some of us are just sitting here waiting around for truckloads of the stuff

Brass fittings tend to be readily available, and will make sense if you are transitioning to and from copper. 0

Brass fittings tend to be readily available, and will make sense if you are transitioning to and from copper. 0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements