Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Boiler sight glass stained black

Options

LastFreeMason

Member Posts: 5

in Oil Heating

This is our first winter with oil heat and I’ve come across an issue that has stumped me.

The sight glass on the boiler has gone from crystal clear with cloudy, but transparent, water to stained black, as if it was burned, and I’m unable to see the water now.

the boiler picked up a lot of rust when we first started running it. The sight glass showed flakes and the water would turn red-brown but not opaque. A tech suggested we drain it until clear. I got about 4 gallons out and it looked better, but not clear. Refilled it. I did this again after another week when the cloudy water and flakes came back again.

I reached out to the tech again and he suggested it needed to be skimmed. He came and skimmed it, said there was some oil but not a lot. He added some vinegar.

After about a week I noticed the water getting more cloudy and the sight glass staining. I thought it would stop or it was a result of the vinegar. Now, about 2 weeks later (maybe 3?) the sight glass appears painted black and I can’t tell the state of the water in the boiler.

Do I just need to clean the sight glass periodically? What is the cause of the issue?

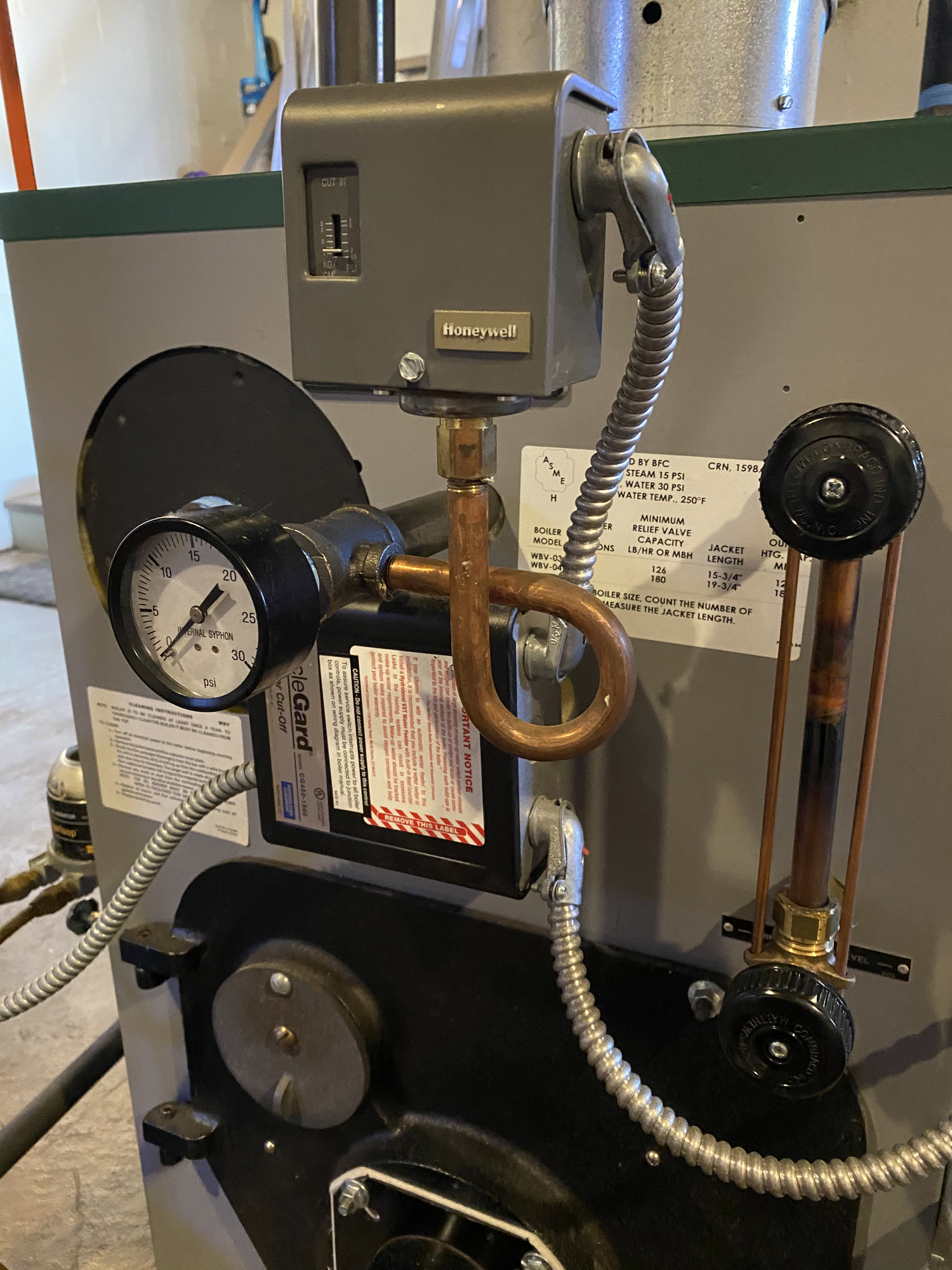

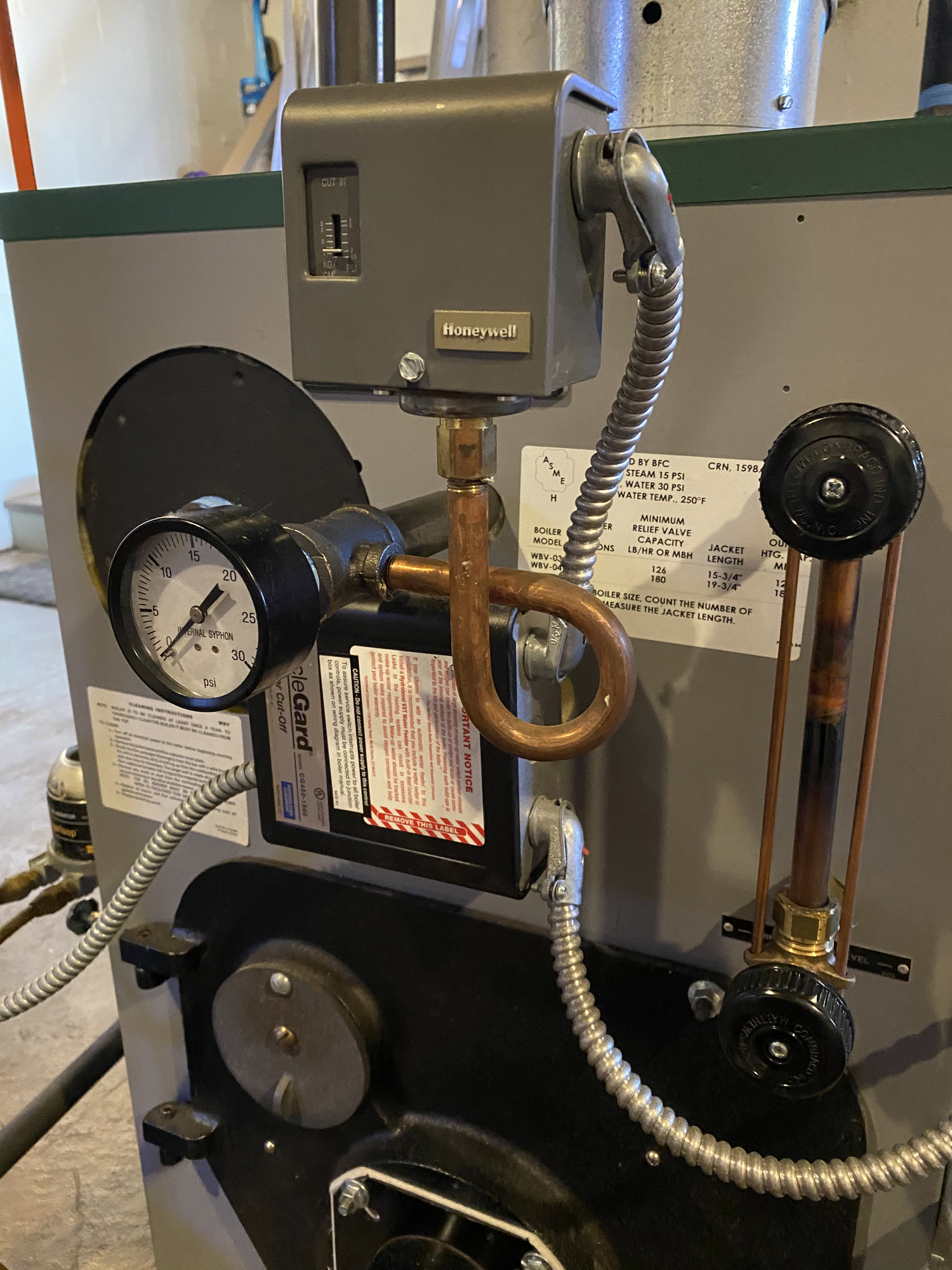

Pictures attached of sight glass and setup

The sight glass on the boiler has gone from crystal clear with cloudy, but transparent, water to stained black, as if it was burned, and I’m unable to see the water now.

the boiler picked up a lot of rust when we first started running it. The sight glass showed flakes and the water would turn red-brown but not opaque. A tech suggested we drain it until clear. I got about 4 gallons out and it looked better, but not clear. Refilled it. I did this again after another week when the cloudy water and flakes came back again.

I reached out to the tech again and he suggested it needed to be skimmed. He came and skimmed it, said there was some oil but not a lot. He added some vinegar.

After about a week I noticed the water getting more cloudy and the sight glass staining. I thought it would stop or it was a result of the vinegar. Now, about 2 weeks later (maybe 3?) the sight glass appears painted black and I can’t tell the state of the water in the boiler.

Do I just need to clean the sight glass periodically? What is the cause of the issue?

Pictures attached of sight glass and setup

0

Comments

-

You can shut the two valves on the gauge glass and remove the glass (carefully) and clean it with a brush. It would be good to have some spare washers and a spare glass or two as they can break fairly easily.

If you have a good hardware store (not likely any more) or a heating supply house they can help you out with the parts or ask your tech. Take the two packing nuts off and slide the nuts and packings up towards the middle of the glass. The glass will then be loose you lift the top as high as it will go and tip the bottom out.

When you replace it tighten the packings hand tight and if they drip just tighten them a little bit.

The vinegar may have loosened up some stuff.

Have your tech skim it again or show you how to do that1 -

Thanks for the help on this. I took the sight glass out, cleaned it with a brush until it was clear again, skimmed the boiler through the sight glass points (no skim tap tubing installed), and reinstalled the glass.

After about 2 weeks, the glass was black again.

Repeat…another 2 weeks and black again.

On thing to note is that the sight glass turns black from the top down, as if some sort of oily substance is sliding down from the top sight glass port.

Is there something else I need to do or should I focus on getting tubing on the true skim tap and go from there?0 -

@LastFreeMason

Yes you did the right thing but not long enough. Skimming through the gauge glass isn't the best way because it is small, The installer should have left you a skim tapping.

Best way is to find the water capacity of your boiler from the install manual.

Take a bucket and put TSP in the bucket at the rate of 1 lb /50 gallons of boiler water

Mix some water with the TSP and pour it into the boiler through the safety valve tapping.

Put the safety valve back on

Start the burner until the steam supply pipeis good and hot but not steaming.

shut the burner off and skim.

The flow while you skim should be a trickle, no bigger than a pencil. Add water to the boiler to adjust the skim flow. If you can use a larger skim tapping it would be better

Do this for an hour until the water coming out looks clear.

Drain the entire boiler and when cool enough refill and drain again refill and drain onece more. Then refill and put into operation

When they MFG boilers a lot of oil gets in them during the process and gets absorbed into the cast iron

This is completely normal for a new boiler, the installer should have done this for you.

0 -

I won’t be able to give this a shot until January, but when I do, I’ll share how it goes.

Thanks for the assistance.

Is there anything I should know regarding adding the skim tapping on that front face next to the siphon gauge? I’m planning to use black steel or galvanized steel with some Teflon tape and either a ball valve or a cap on the end to close it off when I’m done.0 -

@LastFreeMason

Should be easy. Just take the plug out in the middle of that round plate and put a nipple in there. A ball valve is a little better but$$ but a cap is fine as once this is done you shouldn't have to skim again for a few years if at all. Keep if full size of that tapping

In fact on this site go to "system help center" go to "steam" go to "boilers" scroll down and there is a video on how to skim a boiler.1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements