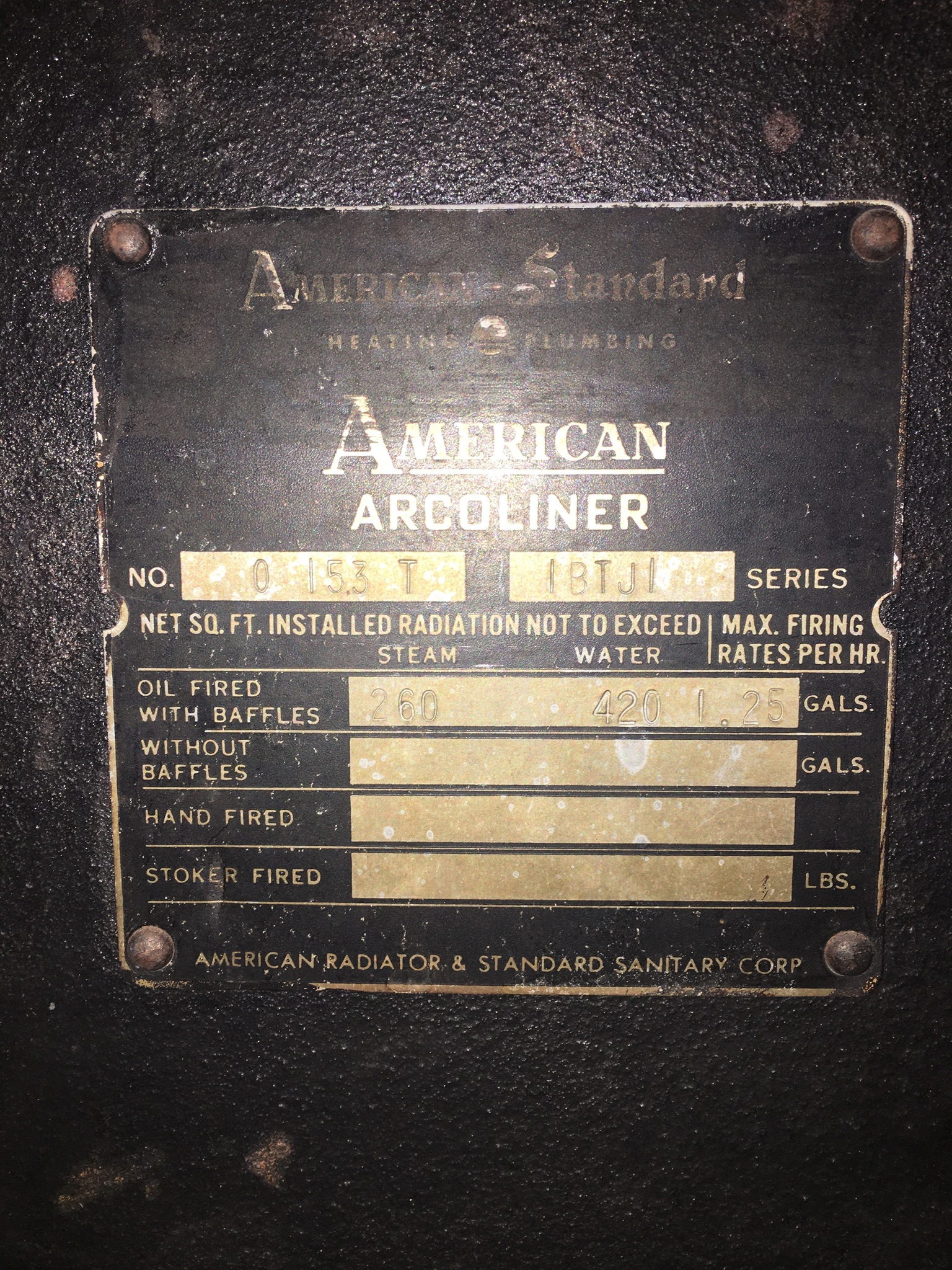

Museum piece 1949 Arcoliner

He’a adamant that he doesn’t want to replace the boiler but I’m thinking new controls, main vents, a new gauge on a proper pigtail and a fireomatic switch would do a world of good for this beast.

Comments

-

Cool! Now let's see the inside.

There's a cad cell primary so the stack primary is probably disconnected. It went from a 90 second safety to 45 seconds. Do I hear 15? 5 with a Riello? Is there a clean out door to access the chimney base?

You'll notice the doors aren't sealed at all. Only the weight of the cast iron on a catch. Makes it difficult to get accurate measurements of combustion.

It will probably outlast us all, but that doesn't make it right.2 -

-

-

That looks almost exactly like the 1947 American Standard Severn boiler I had in my house in Pennsylvania. There are a few minor differences in the trim. It had the same Beckett replacement burner, the combustion efficiency was over 80%, and it was still going strong when I sold the place in 1998.—

Bburd1 -

-

-

Thanks guys. I’m going to pass this all on. I’ll take some pictures inside tomorrow.

The stack relay has been abandoned with the new primary. Should the old relay be removed or just leave it in?

The 30PSI gauge definitely needs to be replaced. I’m assuming it should have a brass pigtail?

The pressurestat also has no pigtail. I’m thinking one there, plus a brass tee with a 3 pound gauge for better measuring.

Nick0 -

I learned to clean oil heaters on those things in the 1970s If the boiler was sold as an oil-fired, the Arco Piggyback burner just hung on a hook above the air tube opening. The weight of the burner on the hook was enough to form a seal to the air tube opening. A good puff back would lift the burner off the air tube opening and bounce back down and re-seal. The seal was an asbestos rope to form a gasket.HVACNUT said:Cool! Now let's see the inside.

There's a cad cell primary so the stack primary is probably disconnected. It went from a 90 second safety to 45 seconds. Do I hear 15? 5 with a Riello? Is there a clean out door to access the chimney base?

You'll notice the doors aren't sealed at all. Only the weight of the cast iron on a catch. Makes it difficult to get accurate measurements of combustion.

It will probably outlast us all, but that doesn't make it right.

I also had a way to seal the doors that preserved the exterior look of the boiler. I would use DRY (just add water) Asbestos furnace cement (there is a non-asbestos product available today) and roll it in my hands to make a long 1/2" diameter bead of cement the consistency of plumbers putty or glazing compound. Then I would press it on to the door at the point where the door makes contact with the opening of the boiler. This would form a seal and the squeeze-out was hidden by the door design. Using 1/2" diameter or less, there was very little shrinkage of the cement and the seal would be there until the next maintenance. I did notice the CO2 reading was a few percent higher when properly sealed.

Every 10 years or so. I might remove the jacket and check the furnace cement seal between the boiler sections. replace some of the old asbestos corrugated insulation with pink fiberglass and put the jacket back together. That entire jacket just slides apart piece by piece.

If you still have the original asbestos insulation, I recommend you don't touch it. We know so much more today than when I was a kid

Mr.Ed

PS. I purchased the dry (just add water) non-asbestos furnace cement by the name of Stick-Tite from R E Michel. Sid Harvey may also have it. It is tough to find. The name is false advertising though, If you mix it real wet and pile it on heavy, it will shrink and leave a gap and cracks in the seal you are trying to make. I try to mix it as dry as I can and use it sparingly.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Yes. A pigtail is required, and brass resists clogging better than steel. Apparently the "internal siphon" gauges don't last long. A 30 psi gauge is required, but a 3 psi gauge is more useful. If you install both, you can put them on the same pigtail, which not only saves money, but you can tell if the pigtail is plugged if both gauges stop working at the same time.NTL1991 said:The 30PSI gauge definitely needs to be replaced. I’m assuming it should have a brass pigtail?

If you need to replace the Pressuretrol pigtail, make sure the loop is perpendicular to the mercury switch.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

I've never used this product, so I may be totally wrong, but from working with other cements, grouts and mortars, it sounds like your cement might be drying before it sets, which could indicate a dry environment or a product that's gone bad. If it's the environment, it might help to cover it with plastic while it sets.EdTheHeaterMan said:PS. I purchased the dry (just add water) non-asbestos furnace cement by the name of Stick-Tite from R E Michel. Sid Harvey may also have it. It is tough to find. The name is false advertising though, If you mix it real wet and pile it on heavy, it will shrink and leave a gap and cracks in the seal you are trying to make. I try to mix it as dry as I can and use it sparingly.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

Yes, a very dry environment. The fire door of a boiler (as pictured by OP) and the vent pipe connection to the base of a masonry chimney. After the tune-up is completed and you fire up the boiler, the heat from the flame and hot combustion gasses will dry out that cement real fast. I don't think plastic on those hot surfaces will hold up very long.Hap_Hazzard said:I've never used this product, so I may be totally wrong, but from working with other cements, grouts and mortars, it sounds like your cement might be drying before it sets, which could indicate a dry environment or a product that's gone bad. If it's the environment, it might help to cover it with plastic while it sets.

The nice thing about the Stick-Tite is that it performs similarly to the old dry asbestos cement. You can peel it off the base of the chimney and soak it in water. It will become pliable again and you can reuse it. I have done that on occasion when running low. The trick is to use it as mortar or caulk, not like a glob of plaster to fill in a large gap.

Respectfully submitted,

Mr.Ed

PS

I'm retired now, so I don't cement many boiler doors or chimney bases anymore. But it was a great observation. Thanks Hap.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Can't see from the pics. Is that a clean out door above the flue?NTL1991 said:Thanks guys. I’m going to pass this all on. I’ll take some pictures inside tomorrow.

The stack relay has been abandoned with the new primary. Should the old relay be removed or just leave it in?

Some of the older homes had the barometric damper in the chimney itself, instead of the flue pipe. If theres no draft regulator, then the idle stack loss on that thing must be insane.

0 -

Oh, I guarantee it won't.EdTheHeaterMan said:I don't think plastic on those hot surfaces will hold up very long.

I meant to cover it with plastic while it's setting, then take it off after, so the water gets used for crystallization instead of evaporating. You know how you have to keep concrete wet if you pour it on a hot, dry day? That's what I was thinking, FWIW.

I meant to cover it with plastic while it's setting, then take it off after, so the water gets used for crystallization instead of evaporating. You know how you have to keep concrete wet if you pour it on a hot, dry day? That's what I was thinking, FWIW.

I'm retired now too, but not from heating. I never did that, so I appreciate your patience when I try to share my, um, wisdom.EdTheHeaterMan said:I'm retired now, so I don't cement many boiler doors or chimney bases anymore. But it was a great observation. Thanks Hap.

Just another DIYer | King of Prussia, PA

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

That stuff will take 24 hours to cure, I'm outta' there in 1 hour and you just can't tell a homeowner that they need to leave the heater off for 24 hours to let the chimney cement set. Some unreasonable customers actually want the heat back on before you leave the job... especially if it is cold outside! Go figure!Hap_Hazzard said:Oh, I guarantee it won't.

I meant to cover it with plastic while it's setting, then take it off after, so the water gets used for crystallization instead of evaporating. You know how you have to keep concrete wet if you pour it on a hot, dry day? That's what I was thinking, FWIW.

I meant to cover it with plastic while it's setting, then take it off after, so the water gets used for crystallization instead of evaporating. You know how you have to keep concrete wet if you pour it on a hot, dry day? That's what I was thinking, FWIW.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

Some more pics for you guys.

Really tiny system. 676 sq foot Cape.

Yes, Barometric damper is installed directly in the chimney. It appears the previous owner had a stainless liner installed in the old flue...

Surprisingly quiet system aside from the burner. No pipe noise at all.

0

0 -

back in the '50's (i'm 2yrs. dan's junior) here in pittsburgh we used to have sat. nite wrestling @ 6pm

on local nbc affliliate , channel 11, WIIC at the time.

anyway..... you always heard this promo from any room in the house. "who can...american"!

i always thought american heating was a local outfit, until i grew up and started involvement with their

fixtures, fittings, hvac equip. with the trades.

but it's still, to this day "who.....can american!0 -

Did You Know? One of Alfred Fuller’s favorite aphorisms was “the word ‘American’ terminates in ‘I can,'”

The Fuller Brush CompanyEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

He sounds like a joy to work for....EdTheHeaterMan said:Did You Know? One of Alfred Fuller’s favorite aphorisms was “the word ‘American’ terminates in ‘I can,'”

The Fuller Brush Company0 -

I remember these Behemoths with the Arcoflame burner. My first years were dealing with these, Torrid Heat, Timken, GE down fired, Williams 50/10, Stewart Warner low pressure and on and on. There was one of these, FHW, in my house until 2010, The previous owner changed it to a Weil-McLain G03.

They were easy to clean. Fire 'em up to 200 degrees, grab a garden hose, open the doors and spray a fine mist into the flues. You better hope the Mrs. didn't have laundry hanging outside. Everything around the house was peppered with soot. That's what the old timers, or now, Dead Men, taught me. I'll be there some day, hopefully not for a while. A long while!

The things we remember...0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements