Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

failing thermostatic mixing valve?

Options

eappleton

Member Posts: 111

Hi all,

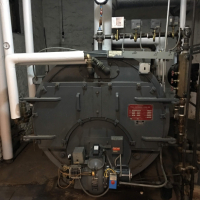

We have a hot water supply problem that has cropped up. It seems like the mixing valve at our boiler has failed. I'm wondering whether we should service the existing one or install a new valve. Or if there is another approach we should consider.

I live in a 25-unit coop and am an amateur. In normal circumstances, our hot water hasn't been perfect, but it's relatively reliable. Some residents talk about running their water for a while to get hot water. Mostly, we don't get complaints. We got a bunch of new complaints in the last few weeks. I watched the water temperature coming out of the boiler at a few times in the last few days. It gets up to 120 degrees when the boiler is running but then drops down to 100 degrees after the boiler has been off for an hour or so, then climbs again when the boiler starts up.

This is the mixing valve.

It's a Watts LFN170-M3, correct?

https://www.supplyhouse.com/Watts-0559126-1-1-4-LFN170-M3-Commercial-Master-Tempering-Valve-Lead-Free

I'm not sure of the size. Is it 1 1/4? I see that on one of the connections.

The valve was installed about 5 years ago. I have been told that the valve can probably be repaired or cleaned. I found this repair kit.

Repair kit for LFN170M3: https://www.supplyhouse.com/Watts-0125153-1-1-4-2-Repair-Kit-for-LFN170M3

I have also been told that Holby is a preferred brand in mixing valves. We would need something like this? Pricey...

https://www.supplyhouse.com/Holby-HOLBY1250LT-1-1-4-Bronze-Thermostatic-Tempering-Valve-Low-Temp

Here's the piping around the mixing valve, by the way.

So, the basic question is should we repair our current mixing valve or install a new one? Can we convince run-of-the-mill boiler technicians to repair mixing valves? My guess is that they just want to install new ones.

Thanks all.

Eric

We have a hot water supply problem that has cropped up. It seems like the mixing valve at our boiler has failed. I'm wondering whether we should service the existing one or install a new valve. Or if there is another approach we should consider.

I live in a 25-unit coop and am an amateur. In normal circumstances, our hot water hasn't been perfect, but it's relatively reliable. Some residents talk about running their water for a while to get hot water. Mostly, we don't get complaints. We got a bunch of new complaints in the last few weeks. I watched the water temperature coming out of the boiler at a few times in the last few days. It gets up to 120 degrees when the boiler is running but then drops down to 100 degrees after the boiler has been off for an hour or so, then climbs again when the boiler starts up.

This is the mixing valve.

It's a Watts LFN170-M3, correct?

https://www.supplyhouse.com/Watts-0559126-1-1-4-LFN170-M3-Commercial-Master-Tempering-Valve-Lead-Free

I'm not sure of the size. Is it 1 1/4? I see that on one of the connections.

The valve was installed about 5 years ago. I have been told that the valve can probably be repaired or cleaned. I found this repair kit.

Repair kit for LFN170M3: https://www.supplyhouse.com/Watts-0125153-1-1-4-2-Repair-Kit-for-LFN170M3

I have also been told that Holby is a preferred brand in mixing valves. We would need something like this? Pricey...

https://www.supplyhouse.com/Holby-HOLBY1250LT-1-1-4-Bronze-Thermostatic-Tempering-Valve-Low-Temp

Here's the piping around the mixing valve, by the way.

So, the basic question is should we repair our current mixing valve or install a new one? Can we convince run-of-the-mill boiler technicians to repair mixing valves? My guess is that they just want to install new ones.

Thanks all.

Eric

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)

0

Comments

-

Get a real boiler tech. Maybe they can solve your domestic hot water problems too.

There was an error rendering this rich post.

0 -

Sounds like the boiler water temperature is too low, especially if it's 100 deg.

You have 2 pipes coming into the mixing valve. cold city water probably 40-50 degrees hot water from the water heater should be 140 degrees. Mixed water goes to the faucets at about 1200 -

Thanks @EBEBRATT-Ed. So we should adjust the mixing valve so the temp is 140 leaving the mixing valve? It loses 20 degrees getting to the taps?

But the fluctuation between 120 and 100 shouldn't be happening either way, right? Doesn't that indicate that the mixing valve is bad?Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

@eappleton

Your cold water line temp going into the mixing valve is probably 40-50 degrees. It is what it is.

The water going to your hot water faucets from the mixing valve usually the middle pipe is usually called the "mixed water" when you have a mixing valve. So the mixed water going to the faucets should be about 120.

The hot water from the water heater that goes in the mixing valve obviously has to be higher that the mixed temp going to the faucets. It should be about 140.

The 140 from the water heater mixes with some of the cold water in the mixing valve to reach the 120 set point.

Obviously the cold water temp varies with the outdoor temp (somewhat). and the temp from the water heater will change slightly and the mixed temp will vary a little depending on the draw of mixed water0 -

Thank you for the explanation. I should have provided more information. Our hot water is produced by our boiler (one-pipe steam system). We don't have a separate hot water heater.

The hot water from the boiler varies depending on whether it is producing steam or not. I guess it's about 200 at the top end. I don't know how low the temp gets between cycles but I can check.

The hot water from the boiler varies depending on whether it is producing steam or not. I guess it's about 200 at the top end. I don't know how low the temp gets between cycles but I can check.

When I talk about the hot water fluctuating, I mean the mix coming out of the mixing valve.

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

I took some infared photographs of the piping and the boiler just after turning off from a steam cycle and after being off for an hour. The mixed water was 120 degrees just after the steam cycle, with incoming boiler water at 184 degrees. After sitting for an hour, the boiler water dropped to 146 degrees F and the mixed water dropped to 100 degrees.

My guess is that the valve is stuck, releasing enough cold to modulate a boiler water temp of 184 degrees, but once the boiler water temp drops to 146, the same amount of cold is dropping the mixed water temp.

Just after a steam cycle ended:

Temperature at the boiler:

Temp at the cold water pipe leading into the valve:

Temp at the hot water pipe leading into the valve:

Temperature of the mixed water leaving the valve:

After the boiler had been off for an hour:

Temperature at the boiler:

Temp at the cold water pipe leading into the valve:

Temp at the hot water pipe leading into the valve:

Temperature of the mixed water leaving the valve:

Is it possible that the valve is not bad? If it is, can it be serviced or should we buy a new one? Thanks in advance for the help.

EricSingle-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

-

@EBEBRATT-Ed Thanks for confirming and that is a great suggestion.

I spoke with the technician and he wants to try adding a circulation pump first (we have never had a circulation pump in the past). This seems crazy to me. Granted, he hasn't been here yet to confirm what I'm seeing with the mixing valve but this just seems like a hammer in search of a nail. If a technician doesn't see a pump, they want to add one?

My guess is that these systems produced consistent hot water in the past without pumps. Am I wrong?

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

So the DHW is generated by a coil in the boiler? Has them coil ever been serviced? If so, could it be limed up and not allowing sufficient flow?

If you add or reconnect a DHW recirculation there is a specific way the thermostatic needs to be piped.

A better option is to upgrade to an electronic mixing valve for dealing with recirc and adding an anti legionella function maybe.

Code dictates no higher than 120F to the building. I'd be sure you watch that supply water temperature, for liability issues if nothing else.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks @hot_rod. I spoke again with technician this morning who explained his suggestion:

- Replace the Watts valve with a Holby, since the Holby is better quality and can be serviced more easily. He said it wasn't worth servicing the Watts. He has replaced them twice in the same year on some jobs.

- Add a circulation pump. He said that the lack of a circulation pump puts strain on the mixing valve.

I think we are leaning towards the solution above, though the cost is a lot more than simply replacing the Watts valve.

I understand that there is a thermal loop necessary for the Holby valve. I would be interested in more information about the piping necessary if we get a circulation pump. I think saw some of this in your recent webinar on mixing valves, but I didn't really understand it

Yes, I think the coil supplies DHW. I don't know if the coil has been serviced. I guess this isn't part of the regular yearly boiler cleaning. I can ask the technician if this is something they do, since they will doing a cleaning soon.

EricSingle-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

So there is a recirc return line coming into the boiler room?

Is it gravity operated? If so there might be a sticking check valve on it.0 -

@JUGHNE Yeah, there are many hot water returns, if that's what you mean. There are 6 apartments on each floor and a couple apartments have kitchens and bathrooms without a shared wall, so there are approximately 8 hot water returns.

They are all gravity operated. Our technician showed us where one was turned off. It has a ball valve so was visibly off. Unfortunately, the other hot water returns are ancient gate valves. Many of them spin loose so we don't know if they are open or closed.

It seems that part of the fix here should be an inventory of the hot water returns. But there is no way to know if the valve is working, other than lack of proper circulation? We won't hear the water move as the valve is opened, correct?

Our super suggested that the valves on the hot water returns could be repacked? Or maybe we should we bite the bullet and replace the valves to make sure.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

-

@Larry Weingarten That makes sense to me. We have insulation covering the pipes but maybe a reading of the valve itself would work. I guess we would wait until we sort out the mixing valve first, then take a reading of all the heat return valves. That’s brilliant!Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0

-

Wondering about sizing a new Holby valve. There are 25 apartments in the building, but two of them have been empty for years and many people have a second home outside the city. Currently, four apartments are empty. According to the attached chart, buildings with up to 24 families should use 1 1/4" valve. Up to 40 families should use 1 1/2" valve. I've been told that oversizing is a problem. Since we should have more low-flow devices going forward and some adjustments are empty, is 1 1/4" the right choice? (I'm preparing myself for the technician's desire to install 1 1/2".)Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0

-

“24 families” is awfully close to 25 apartments; and depending on the size of those apartments, they may have only one or two occupants rather than entire families.Sounds like 1 1/4” to me.—

Bburd0 -

@bburd and @Youngplumber: I am thinking 1 1/4" is best. I'm not sure what an average "family" is, but the apartments in this building tend to be small. Mostly 1-bedroom apartments. There are a lot of single people and couples. Only three apartments with more than 2 people. People tend to move out once they have kids.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0

-

it's tough to get an accurate DHW load number. The 1950's Hunters Curve that is currently used can over estimate by 80%. I believe UPC has a newer more realistic calculator.

Mixing, really any control valve, should be sized by Cv, in DHW thermostatics generally you look at a 15- 20 psi drop at max. flow as acceptable.

If you over size a thermostatic the issue will be regulation when only a small load is flowing. Most larger valves need a 5 gpm or more minimum flow to be temperature stable.

A building with that type of load uses a hi-lo mixing assemble. Maybe a 1-1/4 for high loads paralleled with a 3/4 for low loads.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod For the hi-low mixing assembly you're describing, are these mechanical or electronic valves? And is there other equipment needed to switch between the two valves?Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0

-

Part of the reason I ask is because our technician will probably recommend 1 1/2" Holby mechanical. If we did a high/low mixing assembly, it works be about $ for the 1 1/4" Holby and $500 for the 3/4" Holby. It's comparable to 1 1/2" for $.

Though the piping and other work might be a lot more...Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Our technician is recommended the following solution for our hot water issues:

- a Holby 1 1/2” mechanical mixing valve (from this conversation and the Holby chart, I think we need 1 1/4”). He says it’s much easier to service than the Watts valve we have now.

- a circulation pump (the system was designed to use gravity). He is recommending the Taco 010 stainless steel domestic circulator. I think this is the model:

https://www.supplyhouse.com/Taco-0010-SF3-0010-Stainless-Steel-Circulator-1-8-HP. The technician says that the pump will take stress off the valve and will make sure that hot water is available at the taps.

Any thoughts on this solution? Do you think both are necessary? Would you recommend his pump? (I noticed that it doesn’t seem to have a timer. It runs continuously?)

@hot_rod suggested a hi/low mixing valve assembly might be appropriate. I’ve also heard electronic mixing valves recommended...

Thanks,

EricSingle-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Pretty much all mixing valves have a minimum flow requirement to provide stable temperature regulation. Many larger valves need 5, 7 or more gpm to work properly. I do not see a number for that in the Holby data, they do indicate the recirculation must be running 24/7, so I suspect that is how they assure adequate min. flow.

Keep in mind recirculation comes at a cost, and in an older building that may not have well insulated HW and recirc, that could be a substantial amount of energy consumption maintaining the loop.

The valve size is really about max gpm and the pressure drop that is acceptable, generally 7- 10 psi is acceptable, looks like the Holby graph has a line at 10 psi.

So the question always becomes what is the max flow rate required. Not many building owners can answer that, so either assumptions need to be made or flow test and data log for a week or so.

Looks like that 1-1/4 Holby is comfortable at 35 gpm.

The Caleffi Legiomix is an electronic ball valve style, mixer, very high Cv and we rate the gpm at a 7.5 psi drop. So a 1" would cover that 35 gpm load at a low pressure drop, 3 gpm min for stable operation.

Once a day the ball rotates to "rub off" any limescale. It's the hard water lime scale that causes frequent maintenance on mix valves. The Legiomix are usually less $$ compared to a high lo station.

Do the showers have single handle temperature balance valves? That is usually where people would notice the temperature fluctuations if valve minimums are not met. Temperature balance tub/ shower valves mostly eliminate any complaints.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The showers are different, depending on renovations. My guess is that about half of the showers have single handle temperature balance valves and the others have separate hot and cold valves.

I noticed that you mentioned that the hot water coming out of the mixing valve should be 120 per code. That's what ours is set at (thought the valve doesn't seem to be working). I noticed that the New York City housing rules say that hot water should be provided at a constant minimum temperature of 120 degrees. Seems like it should be a bit hotter coming out of the boiler? Or does it not lose significant temperature on the way up?@hot_rod: Keep in mind recirculation comes at a cost, and in an older building that may not have well insulated HW and recirc, that could be a substantial amount of energy consumption maintaining the loop.

This concerns me. The pipes are only insulated in the basement. It seems like we'll be releasing a huge amount of heat into the building by circulating hot water 24 hrs/day, year-round. Not only will this run the boiler more often, it will heat up the building in the summer, no? Maybe not significantly, but...

I believe the Holby requires a circulation pump. Does the Caleffi Legiomix? I read the user guide and other documents and didn't see it mentioned. Since it handles very low and very high flow rate demand, maybe the recirculation pump isn't necessary?

I'm now considering either:

1) a Holby 1 1/4” mechanical mixing valve and a Taco 010 stainless steel domestic circulator

OR

2) a 1" Caleffi Legiomix only

One issue with the Legiomix is that I'm not sure how we would use the thermal disinfection system, since we don't have anti-scalding devices at the faucets.

Eric

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Pretty much all mixing valves require some flow to keep a stable temperature. The sensing "device" be it a metallic spring, thermal motor or thermistor need flow moving across them to be able to respond.

If you do not have, or want a recirc line, which is how the mix valve always meets its minimum flow, then a hi-low is best.

Use a small valve for low flow down to say 1/2 gpm, the larger valve for the higher flow. The Caleffi AngleMix is a great lo flow mixer with scald protection if the cold fails.

You can easily assemble a hi lo at the site.

Ao here is how the Caleffi hi-lo works. Flow goes thru the small valve, as the pressure reducing valve see a pressure drop, it opens and allow flow thru the larger valve, the smaller valve stays in play also. So basically the small valve handles all flow until it sees maybe a 10 psi drop, then the large valve kicks in. At that point flow is adequate for the larger valve to remain stable, maybe around a 7 gpm flow.

Correct that you cannot use the high temperature legionella feature unless every faucet in the building has a point of use protection. Many of the Legiomix we sell are just used a mixers, not the legionella function. Areas with hard water are no problem for the ball valve type mix valves.

It takes a bit of fiddling to get a hi-lo with prv set up properly, here is the routine, and an example of how they flow.

https://www.caleffi.com/sites/default/files/file/na10477_02.pdfBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi all,

Just wanted to share the resolution of our hot water issues. We ended up installing a Holby 1 1/2” valve. It was all a little hectic on the day of the repair and the technician couldn’t get the 1 1/4.” He was also installed a circulation pump. The hot water was immediately much, much better. One line is still slow to heat. We found a hot water return with a spinning handle and pipe above that was cool to the touch so the culprit is clear. We’re scheduling that repair.

Thanks for all your help,

EricSingle-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Glad you got it resolved0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements