Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Viessmann operaton/ program question

Options

TAG

Member Posts: 797

Is there a particular/ recommended slope setting for radiant heat in the boiler program? My installers were on the phone with Viessmann when they fired it up -- they just wanted to get it going as the house was hovering around 40 degrees. That was about 3 weeks ago --- Builders Sub just finished the spray foam yesterday. The lower slab and all the Warmboard has been running -- living room (about 900sf) retrofitted plates is not yet operational.

The house warmed up over the first day and the builder has been lowering the room set temp on the boilers display everyday .... it was warm when I arrived today ... so dropped it down two degrees to 60.

I'm wondering -- is there a sensor for that temp on the display? ........or is it a projected temp based on the slope? I don't see how having a temp sensor on a warm boiler would do any good.

I'm using one temp water for the whole house -- so I'm going to have to play with the flow or the thermostats once the house is finished. My hope is by running the ODR on what the Warmboard needs I will only have to play with the slab and maybe the plate system. Either using flow or the thermostats/ floor sensors in the slab

Buderus gives basic starting points depending on application --- I don't see that for Viessmann.

The single alpha II pump seems to be working well for the system side and should have no problem when the plate system gets connected .... this week sometime. Although the only sound coming from the whole system seems to be the check valve on that pump. Have another alpha for the boiler loop to the LLH. The mechanical room is tight and two of the four manifolds are remote. No water hookup yet -- so the DHW is not operational. Just a simple 3 speed pump there.

The house warmed up over the first day and the builder has been lowering the room set temp on the boilers display everyday .... it was warm when I arrived today ... so dropped it down two degrees to 60.

I'm wondering -- is there a sensor for that temp on the display? ........or is it a projected temp based on the slope? I don't see how having a temp sensor on a warm boiler would do any good.

I'm using one temp water for the whole house -- so I'm going to have to play with the flow or the thermostats once the house is finished. My hope is by running the ODR on what the Warmboard needs I will only have to play with the slab and maybe the plate system. Either using flow or the thermostats/ floor sensors in the slab

Buderus gives basic starting points depending on application --- I don't see that for Viessmann.

The single alpha II pump seems to be working well for the system side and should have no problem when the plate system gets connected .... this week sometime. Although the only sound coming from the whole system seems to be the check valve on that pump. Have another alpha for the boiler loop to the LLH. The mechanical room is tight and two of the four manifolds are remote. No water hookup yet -- so the DHW is not operational. Just a simple 3 speed pump there.

0

Comments

-

It seems like you are doing fine. One supply temperature for the whole house should be fine, running on ODR. You don't even need a thermostat on the wall. Make sure though that you dial in the right curve for your radiation scheme. There is guidance in the I. and O. manual for setting the right curve.0

-

That's my question --- the curve. I see how it can be changed ... I will have to go over the manuals again .... it's a little confusing.

With Christmas next week .... I'm not sure when the drywall will be installed. I don't need the house as warm as it is .....

I'm also trying to see where the "off" point is set .... It got really warm yesterday (outside) ...almost 60 and I would have liked it to turn off.0 -

Spend some time with the manuals. The correct settings will keep the house at a constant setpoint. Using the same curve for both Warmboard and a slab could be problematic unless the slab manifold ports are adjusted way lower. Otherwise, the slab will be overheating.0

-

True about needing different water temps for Warmboard and slab. Study the manual. Take your time. Tweak things. Be patient. Don't make rapid, large adjustments or shut things off.

Putting up lots of new drywall and all the taping will create LOTS of moisture. It won't dry well if there is substandard heat. New construction has a lot of extra moisture.

The "off" point you are referring to is WWSD--warm weather shut down. You get to choose that number if you go "deep" into the menu. Study.0 -

My load calculations put the water temps closer vs what I would have thought for the three delivery methods. I was originally going the mixing valve route for the slab ... but, mechanical room is so tight and 1/2 of the slab heats a bathroom and dressing room that will not be a problem if it's a little warm. Do have thermostat wires to every room should I need to add them. Have slab sensors in place for both parts of the slab and the plate system.

I'm really impressed with the Warmboard. Have used it previously for an addition .. and a couple odd rehabs where we put in some new floors. This is the first project were a large part of a project is using it. The house is about 5k sf -- the slab is around 900sf and so is the retrofitted plate.

I have to figure out the slope --- it's sending out too much heat.0 -

Lower the slope...moderately. Wait and see.0

-

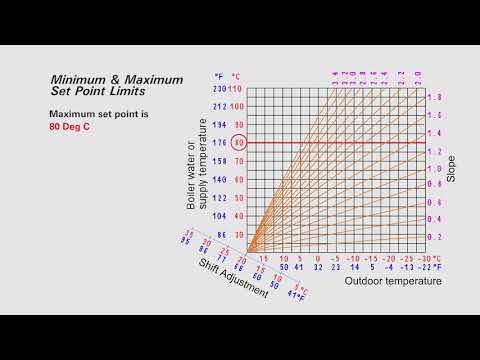

The settings for the heating curve are described on P39 of the service manual. I usually start at a curve of "1" for panel floors and a ".7" for slabs. Since you're setting one temp for the circuit, you'll have to start at "1". Wait 24 hrs before making another adjustment.0

-

I'll be interested to see how the one heating curve with no mixing valves works with a Warmboard/slab/plates system with the boiler on outdoor reset. I would expect to see the slab lag behind the plates and the plates lag behind the Warmboard.

We use construction thermostats to limit the temperature in the rooms while the house is being built. They come in assorted temperature settings. It keeps the general contractor out of the boiler room.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Thanks Paul ---- I played with it today a little but other than turn the set point down lower ... I left it alone. I'm not sure how much the installers changed when they fired it up. I was with them --- the guy from Viessmann was very helpful. We were most concerned about making sure we had the conversion to propane correct and that it was working. I think if I can set it to the lower ,7 ... that will be good for the current conditions. Don't want it too hot. This is an older model 200 as the project was very delayed being completed. The installers did a nice job -- they have only worked on a couple Viessmann boilers .... Never installed one .... They followed the manuals and checked everything with Viessmann prior to starting.

Alan: With most of the house Warmboard ... that's going to be the target temp for the ODR. I agree that the slab will most likely be on the hot side. The problem I have is the slab is two rooms -- one internal to the building and the other open with windows and a staircase. So even if I did a second curve w/ mixing the two slab areas are different. I had them wire for Honeywell room/floor sensor thermostats in each of the rooms. The slab has 8 loops (4 each room) -- Hope I can figure a way to modulate the zones to match the heat need.

For the retrofit area they installed the heavy extruded plates and fully covered the subfloor .... I think that's the best chance of getting close to the Warmboard output and response. My heat need in that room is a little less ... So, it may just work. I did a room/floor sensor in that area as well to control a zone vale for the whole manifold.

The boiler is currently running off the outside sensor and the LLH sensor. Nothing else is connected -- have all the zones fully open. I'm just seeing how it works ... but, it too hot.0 -

You can always punch in a lower desired interior, target temp. on the boiler (the "set" temp. displayed). Remember, the boiler is sensing the outdoor temp. and its return water temperature, and doing its best to give you the air temp. you set on the boiler. It's helpful to the boiler if you set the ODR curve that "best matches" the type(s) of radiation you have.0

-

Psb75. That's what we have been doing ...lowering it each day. .... obviously with little insulation in the house it was not going to work all that well .... thankfully it's been very warm. Now with the spray foam finished -- its tighter than a clam. We expect it to drop to 15 by mid week.

0 -

The VIessmann boiler is a very nice machine. It "knows" or in this case right now, is "learning" the rate at which BTU's are "leaving" your house. It will make and deliver the appropriate amount if you "tune' it correctly.

0 -

I played with it a bit more .... It seems that with radiant you want a flat slope with most of the adjustment in the "level" . Does this seem correct ?

It's also hard to understand what is really going on when you change the room set point temp.

I'm going through some propane ... that's for sure0 -

-

I played with it a bit more .... It seems that with radiant you want a flat slope with most of the adjustment in the "level" . Does this seem correct ?The larger your radiant surface, the flatter the slope.It's also hard to understand what is really going on when you change the room set point temp.That becomes your warm weather shutdown temperature.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Allen -- it seems when I change the room set temp the boiler lowers it's water temp?

0 -

Without indoor feedback (vitotrol), it’s a pure guessing game.You will need to guess at a trifecta of numbers: slope, shift and indoor setpoint. Also, if your moon set point is lower than your Sun set point, your guessing game becomes more difficult. Also, in slab and WarmBoard- as stated—two different temps. That’s Guessing Galore.The two floors can’t possibly utilize the same slope; in-slab is always flatter. You could just “on off” the slab and try to nail the warmboard slope shift setpoint numbers. Most Viessmann purists would gag over that notion.So there’s a cheap way to chip away at this or an expensive way to deal (motorized mixing valve).0

-

When you change the room temperature, the heating curve is also changed, here's how: (starts at 1:45)

https://www.youtube.com/watch?v=chelwjUyMWw 0

https://www.youtube.com/watch?v=chelwjUyMWw 0 -

GW: I do have the V 300 control and it will eventually be installed -- when the house is finished.

The slab being warmer is expected and welcome -- This project is a small stone church that I'm making into a house. New slab ends in a open area with 28' ceilings and windows. The other end will be a bathroom and dressing area -- so a little more heat is fine. I do have the slab set up with two zones (4 loops of pex each) floor sensors etc. -- hope I can modulate the loops to minimize too many problems. Thought of mixing valve and second curve -- but the two areas are not equal anyway and the windows may have some solar gain.

The loads and Warmboard water temps are not that much different ... my goal is to get the Warmboard matched to the boiler. that's the bulk of the house 3k sf

Sunlight33: Thanks -- I have watched a couple Viessmann videos .. but, not that one. I have a 200 ... but, I get the theory. I have a couple of older Buderus systems -- with dials ... they seem easier 0

0 -

Yes the Buderus 2107 and BFU is total cake 🎂. I remember back when the GB142 came out- I made the bad assumption that the GB was at least as capable as the 2107—that was not fun to learn. I kinda “oversold” a job and had to throw some funky relays and a thermistor at it to get it to do what we would say it would do0

-

GW -- that's what my mind is working off of ... Buderus. Btoth the 2107 and the older Ecomatic --- I still own a house with a two curve one from 94.

Seems the Viessmann 200 is overly complex0 -

It looks like with current conditions ... .9 slope with a shift of 5 is doing the trick.

I turned down the slabs flow to 1L PM .... All the rest is wide open.

Parts of the stone building still leak as we are waiting for the new window sash ... but it's still very comfortable. Much better than with the old forced air. With the new sash this will be too warm.

The house also has a small loft way up high that was always cold -- toasty now with the Warmboard.

I'm so happy it's all working ....

Obviously -- when we finally move in there will be further adjustments. The 300 control will be installed as well1

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 62 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements