Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Update: Found a 3 Horned Bull - Steam system saved!

Options

motoguy128

Member Posts: 393

This house is 4 blocks away from mine. Boiler is hammering and over feeding. We checked the LWCO and feeder. Works fine. 3 mains piped bull headed, equalizer is a mess. We cleaned the pigtail and turned the pressure Down from 3 psi to the min of 1psi. Fed with a 1/2” gas connector. Be surprised it it can reach full firing rate. Flu liner has a big hole in it so we didn’t fire it.

Sorry for the crappy pics. Not much room or light. Flu liner has a Big hole in it so we didn’t even fire it.

The two outer mains are parallel flow 2” and tie together to a single dry return. Then there is a 3rd counterflow main that’s just a home run to two radiators only, with it’s own dry return. Unusual. The counterflow seems pitched a little shallow, but gets away with it because it probably has only 100 EDR on it. Just a single Hoffman 4A low capacity main vent. Counterflow main strangely has a large Relief Valve on it. It spews water apparently as well.

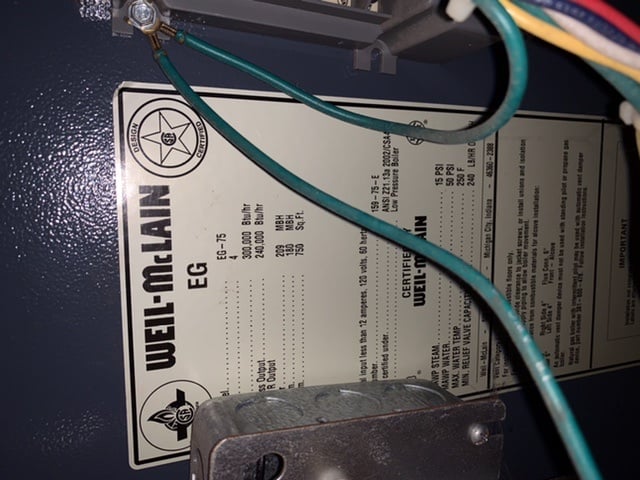

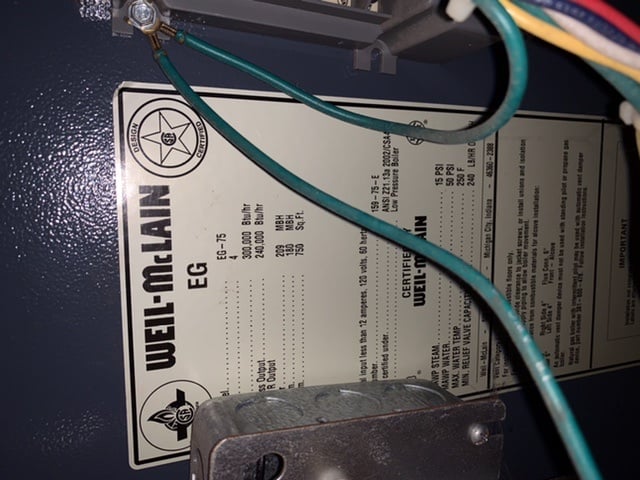

Boiler, a WM EG-75, it appears about 10-12 years old so it’s been a train wreck I suspect ever since.

Not sure if we will even quote fixing it. Would need probably 3-4 days to fix it and I’d have to do most of the work so service calls would back up. I might quote installing a pair of Big Mouth Vents and a Gorton 1 on the end of the counterflow main. Probably one of only 10 or fewer steam system left in our town. I’d be tempted to fix it just to save it, even if we don’t really make any money on it.

Sorry for the crappy pics. Not much room or light. Flu liner has a Big hole in it so we didn’t even fire it.

The two outer mains are parallel flow 2” and tie together to a single dry return. Then there is a 3rd counterflow main that’s just a home run to two radiators only, with it’s own dry return. Unusual. The counterflow seems pitched a little shallow, but gets away with it because it probably has only 100 EDR on it. Just a single Hoffman 4A low capacity main vent. Counterflow main strangely has a large Relief Valve on it. It spews water apparently as well.

Boiler, a WM EG-75, it appears about 10-12 years old so it’s been a train wreck I suspect ever since.

Not sure if we will even quote fixing it. Would need probably 3-4 days to fix it and I’d have to do most of the work so service calls would back up. I might quote installing a pair of Big Mouth Vents and a Gorton 1 on the end of the counterflow main. Probably one of only 10 or fewer steam system left in our town. I’d be tempted to fix it just to save it, even if we don’t really make any money on it.

0

Comments

-

If you fixed it you would be the only one that could service it...0

-

Update. I decided to give it a shot to save the system. That and it’s worth spending a few hundred or even a couple thousand rather than the cost of installing two ducted furnace systems as the alternate.

The plan is to : 1) removed the obsolete relief valve on the header thats blowing out water 2) Replace the little Hoffman #4 vent at the end of the main (vents about 100’ of 2” mains) with a single Big Mouth with a strainer 3) Remove the skim tapping plug and skim the boiler.

My biggest fear is the returns are plugged. Not likely since they are 2” and return to both sides of the boiler.

If this stops the overfilling and reduces hammering. Then I’ll look at repiping the header. Manual says a single 3” is OK, 24” above water line. That’s the easiest modification To minimally meet mfg specs to keep water out of the main.

Ultimately it worked ok I was told prior to another local company attempting to repitch the header and fix/replace broken pipe supports. This companies goal is to find work, more than it is to actually fix things.

Also the boiler is 7years old, so it worked more or less ok I’d assume after it was installed.

Question - Assuming this company actually corrected some dipped sections of the main, how would that make the hammering worse?

Maybe there was some other change or repair made I don’t know about. I’m wondering if the radiators have the vents flipped over in several rooms to “save heat”. Haven’t inspected that yet. Also haven’t estimated EDR for the radiators, but the home is 4451sqft, 1898 stick frame Victorian. The boiler size seems in the ballpark assuming typical radiator size and count for the room size and number of windows.

I’ve made it clear that I can’t guarantee it will fix the situation, only that I‘m correcting obvious deficiencies that might improve the problems.

Any thoughts?0 -

Maybe when they removed the sag from the main they removed the pitch from the pipes to some radiators or the radiators themselves or a return or didn't pitch it the right way.0

-

Did you mention that the dry returns are tied together above the water line? You may want to split them up individually and tie together below the water line.

It's good of you to give this project a shot, I'm sure the owners will appreciate your efforts.

Dennis0 -

The 2 parallel flow mains tie together at the opposite end of the basement from the boiler about 30’ away. Not practical to separate it.It took a while looking at it to figure out what the heck was going on.Why the separate counterflow I’m not sure. I can only guess that it feeds some sort of an addition. I was told it only feeds 2 radiators.0

-

Update: another steam system saved.

We got the skim port bushing out but the copper equalizer is in the way. Put on a 1-1/2 x 1/2” bushing and can add a brass hose fitting adapter of needed. Ended up we didn’t need to skim it.The old PRV came out easy. It was rated for 1900lbs at 15psi!! This is a EG-75 that has its own relief on the boiler. Put a plug in its place.The small main vent came out easy. Installed a big mouth with a wye strainer on the existing 1/2” pipe off a tee on the dry return.Drilled and tapped a -

1/4” hole on an elbow on the counterflow that serves the kitchen radiator. Put a left over straight vari-vent on it I had lying around. Not ideal but works now.Added a 8oz gauge. I had a suspicion it’s a vapor system given the two 2”’mains. Should have plenty of cross section.Added 8 way boiler treatment and fired it up. Ran at 1-1/2” oz water steady.Added strapping to replace bailing wire and loosened a 2” union that was leaking, re-taped one end and sealed that up. Realized that section was full of water. Stripped off insulation and spent an hours lifting the one main and getting the pitch back.Need to go back to add more supports to get it where it needs to be. It’s a 3rd home for the owner so he also wants a NEST installed. So need to pull 4 wire and install that.Probably needs a 3/4” pipe with two big mouths and about 10 new air vents. But we are in the right track.Apparently the header isn’t causing any specific issues at this point.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements