Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

What is this rock like lining material in my old oil burner boiler? lava rock cement? ceramic?

Options

LS123

Member Posts: 476

Hello heating help friends!

I was wondering if some of you who have experience having the privileged of working old steam boilers that were converted to oil from coal.

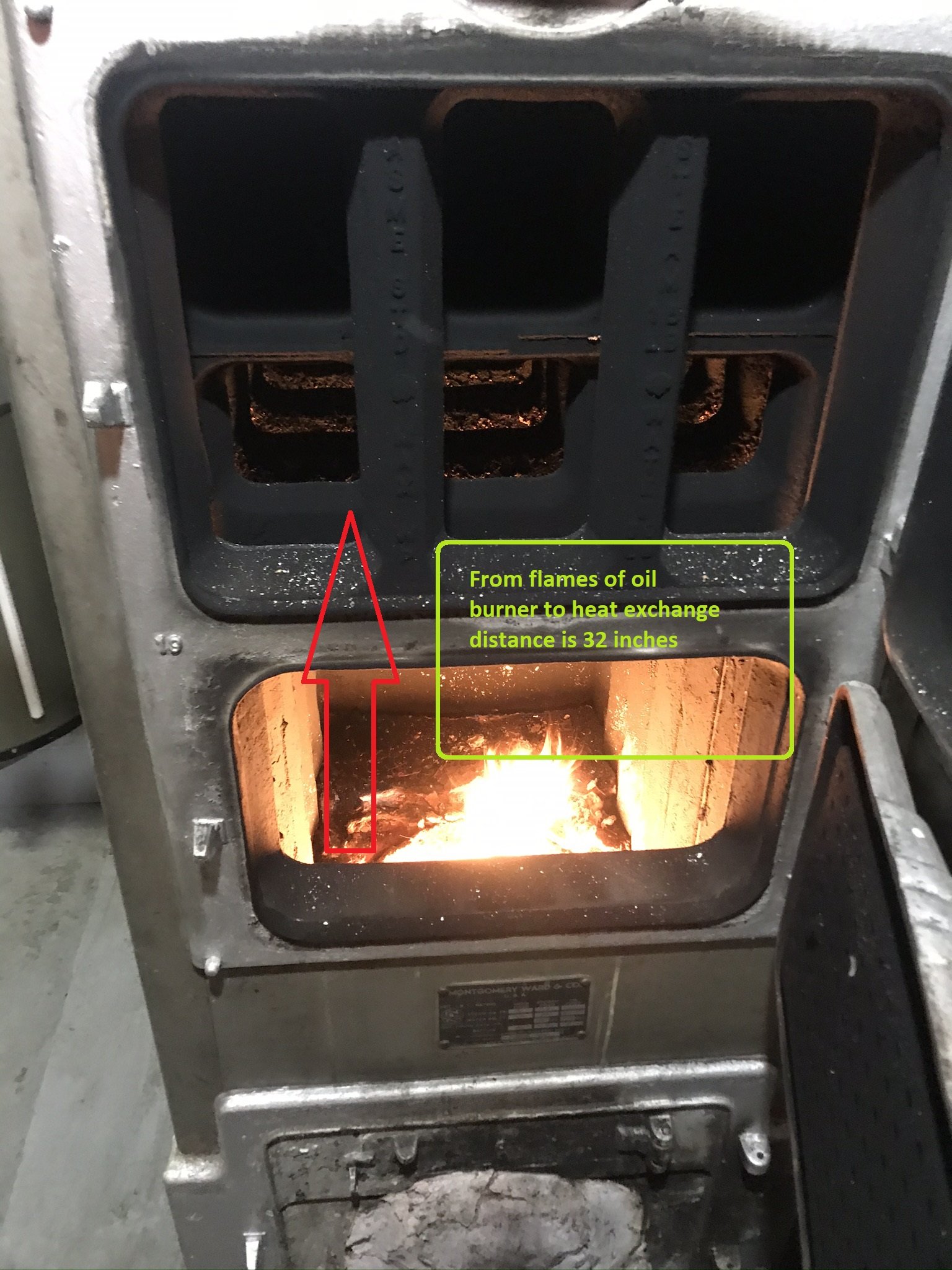

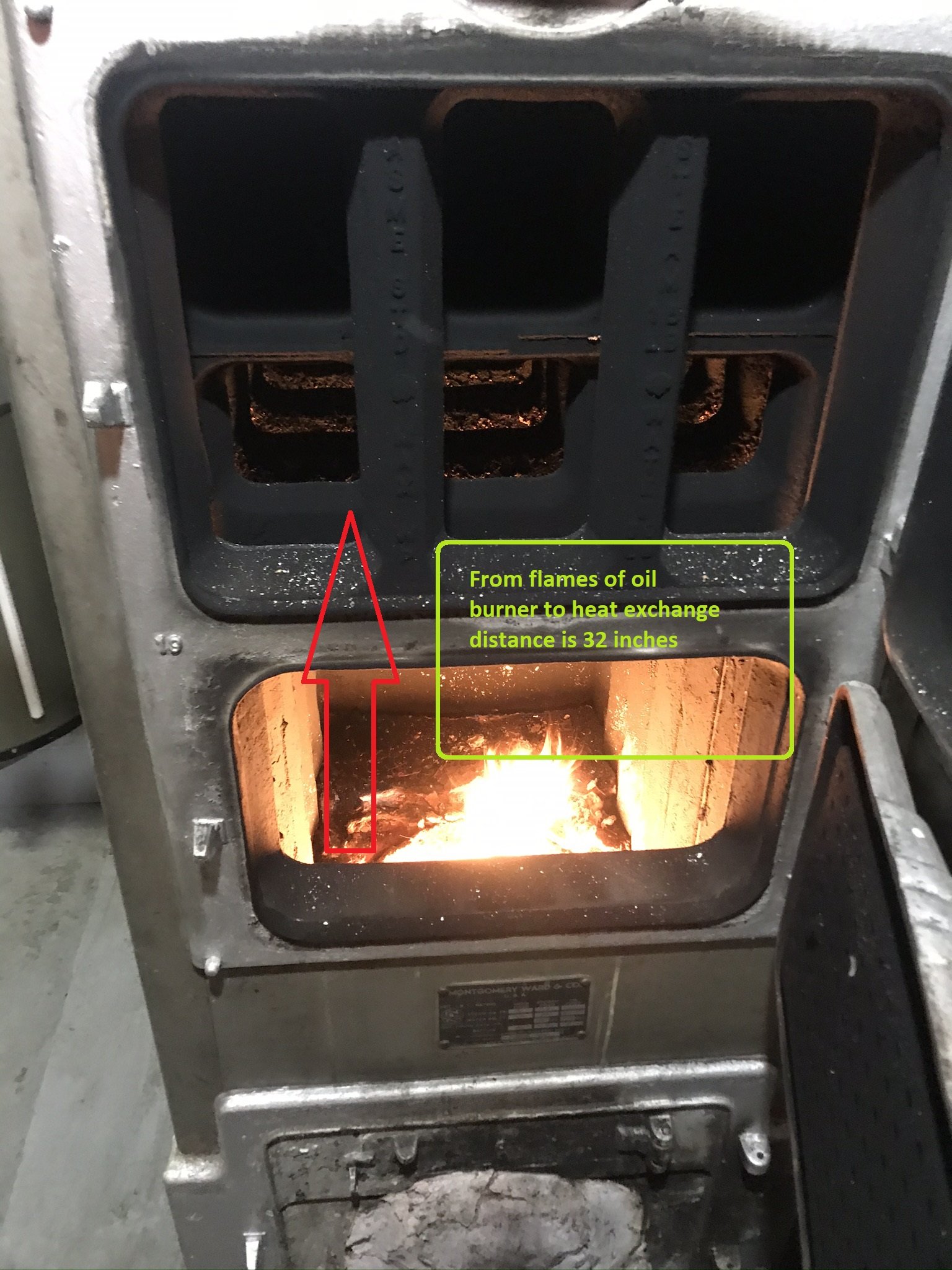

As you can see there is a rock like material insulating, protecting the boiler hitting oil fire directly on the metal box.

As you can see there some rock like substance has come out over last 70 years of its life.

(Q-1) Anyone know what is that rock like material made out of?

Pic2

Pic 3

I was wondering if some of you who have experience having the privileged of working old steam boilers that were converted to oil from coal.

As you can see there is a rock like material insulating, protecting the boiler hitting oil fire directly on the metal box.

As you can see there some rock like substance has come out over last 70 years of its life.

(Q-1) Anyone know what is that rock like material made out of?

Pic2

Pic 3

0

Comments

-

The original firebrick almost certainly has asbestos in it. As long as you don't break or crumble the brick it is not an issue.

The oil burner was likely installed in the 1960's to 1970's. The rock like material that is not brick is a high heat firebox "refractory" cement that again almost certainly has asbestos in it. Like the brick - it is not an issue as long as you don't crumble or crush it.

I'd keep the oil burner location where it is. It could be replaced by a newer oil burner or a gas burner.

The refractory cements and firebricks now available in the USA no longer has asbestos.

You can likely patch up the old cement and any broken firebrick with new refractory cement (done all the time in larger industrial boilers and furnaces, once you remove the loose and crumbling materials).

Personally, if that boiler was in my basement and I needed to replace the burner. I'd chip it out, remove any loose materials, while keeping things wet; wearing a N95 mask or cartridge respirator, and wearing old cloths that when you are done you toss away (undies, socks, shoes included). Everything gets double trash bagged and it can be disposed of in a normal dump. You then meander "all natural" to the shower and clean up.

Then I'd let an appropriate contractor install a new burner and patch things up with modern refractory cement.

Have a great day,

Perry1 -

@PerryHolzman ! thank you SO much for the info below. I just wanted to learn before I consult and pay for a contractor. Initially I was planing to replace it with a new steam boiler (Mega Steam or something of high end. Given the economy, I have lost a lots funds, and thinking I should run one more year with the old steam burner... Thanks again!!0

-

-

-

I'm pretty sure that's a Carlin flame-retention burner, maybe a 99FRD or 100CRD. The sooting in the upper flueways tells me the burner is out of tune. This is an easy fix for a knowledgeable tech.Big Ed_4 said:The fire tells me , your burner needs a good going over in the mean time ...

Megga Steam nice choice , Recommend with a Riello ..

Also, the flueways should be baffled so the hot gases will wipe the cast-iron better. This was popular during World War 2 when oil was rationed. The older books like Frank Graham's Audel Oil Burner Guide go into much detail on baffling.

All this will help you save up for your eventual MegaSteam replacement. These run well with Beckett burners too, not sure if Carlin is an option.

And don't forget the energy-efficiency upgrades available for the rest of the system, like main vents.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

@Steamhead ! its nice to hear from you! Thank you, yes the burner has probably not been tuneup for last couple of winters. I feel like take the oil burner out and start putting coal in it like it used have used back 70 years ago... no no I will not use coal

. perhaps a new burner, system upgrade might get me few more years. 0

. perhaps a new burner, system upgrade might get me few more years. 0 -

-

If you want a few more years , Upgrade the burner , You also need a new chamber .It needs to be a better shaped chamber. I would recomend a larger pear shape . Boston Machine are they still manufracting chambers ???

I also agree " set and adjust baffles " as mentioned by SHThere was an error rendering this rich post.

2 -

-

-

@Big Ed_4 thank you. Apparently I have an used burner from 2008. I will look in to about getting the chamber done. I just want to ride the economic impacts from the virus and then spend money with something like mega steam etc. I have to figure out how to how to adjust the baffle etc...1

-

you really need an oil burner tech with combustion analysis equipment. preferably an old timer that has worked on these before. They can probably clean and adjust it and patch up a few things if you just want to get a couple more years out of it.

Is there a low water cutoff somewhere in the control chain?

1 -

What model is the present burner?LS123 said:I found a unused burner in the garage in a box with all the documents in it. attached are few. perhaps this may be an older model. but it say it can fire as less as 0.5 GMH.

All Steamed Up, Inc.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

hello @Steamhead , the sticker say 18 was from 2008. it do not looked like ever been used. Maker Carlin, Model 41000. probable anything is better than what I have on the burner right now

0 -

@Steamhead

On another place it says on the burner below

------------

Carlin

Burner Mortor - Model J980220 -

-

Carlin 100 CRD. A good burner.

It will use a 60° or 70° nozzle, depending. The dimensions of the combustion chamber will decide.

I will say it's an upgrade because obviously its newer, and the primary is a 15 second safety vs 45 seconds on the existing R8184G.

I would ditch that primary in favor on one with pre purge. It will also need an oil delay valve.

I can't remember if the existing burner flange is bolted to the boiler plate or just cemented in place. If not I recommend a pedestal for the burner. The contractor can get one.

Also an amulet to protect the air tube.2 -

Looking at the first 2 pictures they appear to be from different boilers. The top picture of the chamber and flame shows a round chamber and the second picture shows the flame in a rectangular chamber. Are these pictures from 2 different units? If you are looking for good advice and knowledge listen to what the other guys have written, they are pretty much spot-on. That boiler was sold as a unit capable of firing #1 or#2 fuel oil, natural gas or soft coal, but not hard coal. The chamber material may contain asbestos. Moving the burner to the upper door is possible but there would be nothing gained and moving it would present it's own problems. The only way to increase the efficiency of the boiler's heat transfer would be to install turbulators or baffles as @steamhead mentioned. These would probably have to be hand made since due to the boilers age are no longer available. A good cleaning and burner set up is necessary. As far as when to replace this boiler, I would keep it until you see "water on the floor" from a section leak.0

-

Good morning mr. @HVACNUT !

No the burner not bolted to the boiler. Burner is bolted to the cement floor, then the whole where the nozzle goes covered by layers and layers of some heat tolerant cement. I would think looking at the burner, it seems like it had a long life time mingling with the boiler... its time to change things a bit

I do not know if the burner or the boiler meet the specification you mentioned. Once I get a Heating consultant I will ask that person to ensure that the the person make all the best changes to the whole system.

Thanks @HVACNUT

0 -

Hello and good morning Mr. @retiredguy !

In regards to pics --> The pictures 1-3 are from the same boiler, perhaps the angle I took the pictures may look different ( I had to be careful sticking my phone in to the fire box, because I just got a new Iphone. The phone I had been using fell in the water, I hope the phone would dry out soon)

In regards to fuel, I only have the option to use heating fuel (i am using fuel #2.) We don't have gas lines on the streets, and I do not want a huge gas tank on my property.

Not familiar with tabulators, would that be something help retain more heat before going out of flue?

Part of me want to keep the boiler, the other part of me is not sure about it. I know the boiler is well built, its been running for 70 years, so that is a very good boiler. I am sure it will run another 50 years as long as I maintain it. Thanks for the feedback @retiredguy0 -

We would use split fire brick to baffle that boiler and set them using a draft gauge , stack thermometer ,smoke tester and combustion analyzer . The flame of the fire should be further back for that boiler and sized for the gallonage needed .

There was an error rendering this rich post.

0 -

@LS123 , you already have a Carlin CRD-type burner on that boiler. I found an illustration from when they were using the "Miser" name shown on the front:

https://offerup.com/item/detail/411119671/

Assuming the existing burner is in good shape, there's no need to swap the whole burner out. The off-center fire could be caused by a bad nozzle- very easy to change with the right tools.

I'll say it again- you need a good oil burner tech.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements