Why doesn’t my oil tank fill all the way

Comments

-

-

-

-

The tank is never empty after you put oil in it for the first time. If the tank is not level, and the draw is from the bottom, there may be as much as 15 gallons left the bottom draw may never use.

Next the fill alarm or Vent alarm is designed the keep the oil at least 4 inches from the top, this is to allow for expansion. Cold oil delivered to a indoor tank will expand and overflow as the oil temperature warms up to the basement temperature.

outside above ground tanks can also have the problem. oil delivered on a 22° Tuesday will expand on a 42° Thursday. if there is no air space at the top, you may have an overflow.

finally if the oil feed comes from the top of the tank, the dip tube may not go down far enough to empty the tank. Your out of oil may still have 30 gallons left if the dip tube does not reach within 2" from the bottom.

From an out of oil situation (need to prime the burner) to a full tank you should be able to get 235 gallons on an upright tank and 215 gallons from a horizontal tank.

Pictures will help!Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

> @EdTheHeaterMan said:

> The tank is never empty after you put oil in it for the first time. If the tank is not level, and the draw is from the bottom, there may be as much as 15 gallons left the bottom draw may never use.

>

How do you figure? Maybe the old old tanks that had a side bung, but off the bottom, when the tank runs dry, it runs dry. Maybe a thin puddle of oil and sludge along the length. No where near 15 gallons left.1 -

-

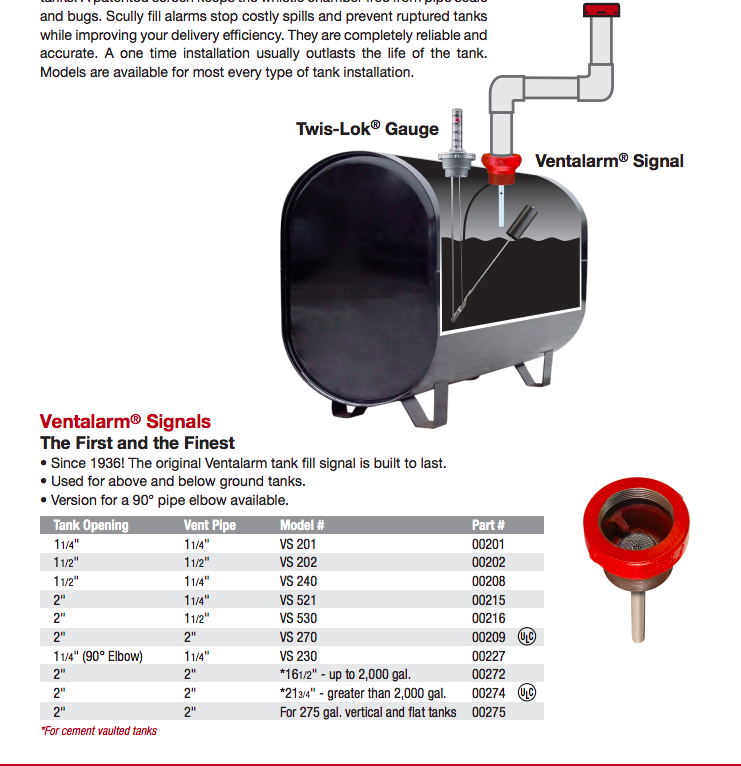

Could simply be the wrong whistle. They also make them for larger tanks (to allow more room for expansion) and the inside whistle tube is a lot longer. I put one in a smaller generator tank as the supply piping was 2" and 75' away. So what drained back into the tank after the whistle stopped wouldn't over flow.

I don't recommend cutting down a standard whistle tube, as you assume all liability if an overflow occurred.

I get 245-256 in an empty standard 275g vertical tank.

Tell the driver to fill at low speed, especially if the supply piping to the tank is creating (extra) foaming. Blasting it in at 90-100 gpm causes foaming that can hit the whistle when you're at 3/4 full.There was an error rendering this rich post.

2 -

@HVACNUT SAID: How do you figure? Maybe the old old tanks that had a side bung, but off the bottom, when the tank runs dry, it runs dry. Maybe a thin puddle of oil and sludge along the length. No where near 15 gallons left.

BUT DID NOT READ AN IMPORTANT WORD

> The tank is never empty after you put oil in it for the first time. IF the tank is not level, and the draw is from the bottom, there may be as much as 15 gallons left the bottom draw may never use.

The illustration shows a tank that is not level and has the exact problem described by @dillbilly

So a pic of the tank would help. Is it level? Is it a top feed? Is it vertical or horizontal. we are only speculating without more info!

@HVACNUT is correct IF the feed valve is at the low end. But that does not explain the problem or answer the question.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Example:

In my area, there was one oil dealer that resolved sludge in the tank problems by raising the dip tube on the top feed off the bottom 2" more... after several repairs of this type over the years, I have found that some dip tubes were 9" off the bottom of the tank. When asked why you would not just sell a new tank?

"I did not want to loose the oil account to gas heat. In some cases the cost of the new tank would start the discussion of putting in a power burner for about the same price and loosing the oil account. So I just fixed the tank as low cost as I could!"

Poor excuse in my opinion

Just put additive in the oil to reduce the sludge problem and sell the benefits of full service. Automatic Delivery, Service Contracts, Budget plans, Quality Fuel.

But not all oil companies have the same philosophy.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thanks for everyone’s comments. They helped a lot. It is a bottom feed oil tank. 25 years old. It’s level as the house was built by our reputable builder in a walk out basement.

The oil man who came last week said when he lifted the gage it was heavy. But he said that will not effect getting more oil into the tank. Is that true? We were going to have the vent pipe cut and have him put in a new whistle stop, but he said that won’t help either. He said we are stuck with 180 gals. I’m not happy as our house is 3500 sf.

The vent and fill pipe are probably 8-10 feet from the outside wall where the oil man fills it. We’ve had the tank “jump started” when it was totally out 5 times. We only got 185 gallons still.

The man who came suggested a slow fill like you suggested. Also during one of our oil deliveries the delivery guy sprayed the side of our house for some reason. Maybe this is all related.

Here are a few pix. Thanks for all your help!

I really appreciate it!!

https://share.icloud.com/photos/0VmzPSGzGQeF2zQuk2g4zL6TQ0 -

-

-

-

> @Alan Welch said:

> Never had a foaming problem with any tank with 1 1/4 " fills, only problem is when pumping too fast, would look for another reason.

You could be right about that but an 1 1/4" fill is not code anywhere that I know of.2 -

> @EdTheHeaterMan said:

> @HVACNUT SAID: How do you figure? Maybe the old old tanks that had a side bung, but off the bottom, when the tank runs dry, it runs dry. Maybe a thin puddle of oil and sludge along the length. No where near 15 gallons left.

>

> BUT DID NOT READ AN IMPORTANT WORD

>

> > The tank is never empty after you put oil in it for the first time. IF the tank is not level, and the draw is from the bottom, there may be as much as 15 gallons left the bottom draw may never use.

>

> (Image)

>

>

> The illustration shows a tank that is not level and has the exact problem described by @dillbilly

>

> So a pic of the tank would help. Is it level? Is it a top feed? Is it vertical or horizontal. we are only speculating without more info!

>

> @HVACNUT is correct IF the feed valve is at the low end. But that does not explain the problem or answer the question.

NFPA 31 requires a 1.25" pitch toward outlet on a 275. That pic is showing a back pitch1 -

@Robert O'Brien is right, but the back pitch happens over time. and it explains the issue. Pictures helped... you can now see the side opening, not a bottom opening so there is some left at the bottom. (about 4 to 6 gallons) But the pitch is not an issue here. the tank is level. The only thing left is to measure!!!

Standard 275 tank is 44" tall, 27" wide and 60" long. You may have a 42" tank that is 26" wide but a little longer than 60" Next measurement is immediately after the delivery, let the foam settle, then place a stick in the tank! How many inches of oil are there in the tank? Use the chart to determine how much room is left and determine the length of the whistle in the vent alarm. If the wrong whistle was used, then it may need to be cut

https://www.nationalfueloil.com/visitorAction_tankChart

Roth tanks will cut your whistle based on the tank size Fill pipe size and length to male allowance for how much fuel is in the fill pipe.

I believe that @dillbilly wants the extra capacity (if available) to reduce the chances of running out of oil. If the fuel dealer is using the proper K factor and a degree day calculation for automatic delivery, then he needs to target a 150 gallon delivery, not a 190 gallon delivery that would be normal for a 275 Tank.

The 190 gal target for auto-delivery will be too close for comfort in this case!Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

This was why my 330 inside tank could never take more than 250 gallons from first fill, on. It never filled more than 12 inches from the top. For years I put up with that and finally asked an oil service tech when he was out to do the annual cleaning of my boiler about it. He checked it and told me me the one used was for a 1000 gallon tank. He cut it, and it now fills to about 5" from the top of the tank after the short fill pipes have completely drained.STEVEusaPA said:Could simply be the wrong whistle. They also make them for larger tanks (to allow more room for expansion) and the inside whistle tube is a lot longer...

1 -

Wouldn't hurt to replace the fill and vent piping with the larger 2 inch piping required by code.

@dileerl your tank in the picture is piped incorrectly. The fill and vent pipe diameter is to small.

I can't tell from the pic but it also seems that you may have a few to many turns in your pipes. ( ninety degree angles ). This combined with the smaller pipe diameter is probably contributing to your issue.

If you can move the vent and fill to a area that exits the building with the fewest bends and the correct code required pipe size, this could help eliminate some of your problem.

Also consider adding another tank . Have it piped correctly with the fill and vent at a minimal distance from the tank.

1 -

The only thing wrong with the piping is no swing joints. It's actually to (new) code. The vent is bigger than the supply.

Have the driver fill on low speed until the whistle stops.

Then, have him crack open his nozzle to maybe a 1/4 or the slowest speed and still hear a whistle. When the whistle stops again, if your tank isn't filled, the whistle is too long. Having the fill drop in the bung next to the whistle isn't helping.

If you have to replace the whistle, support the vent pipe going out the building. With a pipe cutter, not a sawzall, cut the vertical pipe above the whistle, unscrew below the 90°. Replace with correct whistle and a union.There was an error rendering this rich post.

2 -

Thanks for your comments and help. I suppose by starting with a new gauge and whistle stop will help!! Can anyone recommend someone in Southern New Hampshire to do this work? I’ve had 3 HVAC people to my house now. They have no idea what’s wrong. All different answers. The last one being a 275 gallon tank only holds 180 gals. Very frustrating!0

-

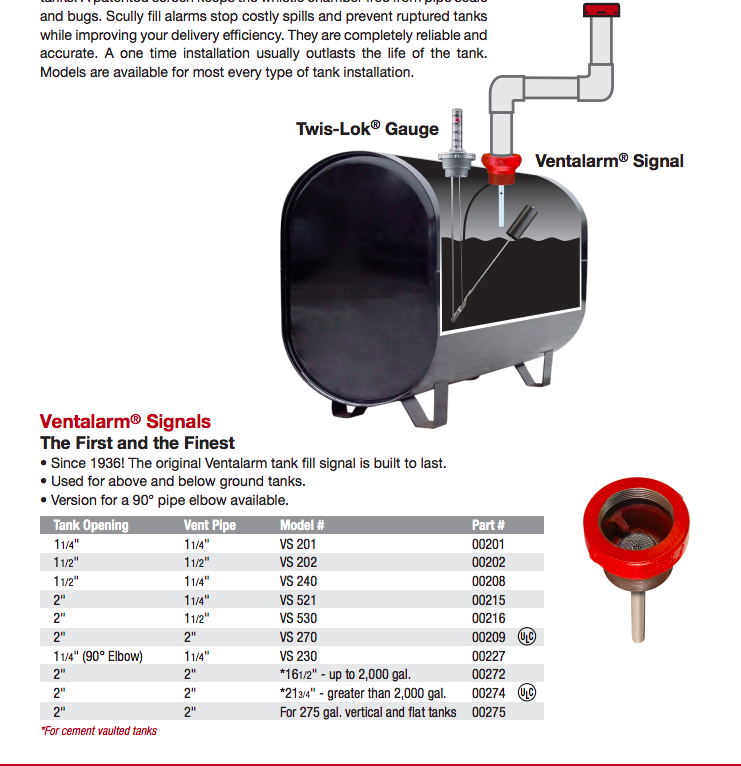

It appears in your picture that you may have a large tank vent alarm. The part number for the proper vent alarm for your tank is 00275 You currently have part number 00209. This is for tanks up to 2000 gallons. The installer can use that vent alarm if he follows the instructions to cut the whistle to the proper length for a 275 gallon tank. The original installed did not do that. If you want the proper vent alarm ask your professional for order part number 00275 and part number 01122 from Scully. The second part number is a compression union so the pro can cut the pipe and put it back together without threading the cut section of pipe.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I mentioned might be wrong whistle 2 weeks ago (we need a ' 'thumbs up' emoji).

I wouldn't use the compression unions. I'd have to look up in my code book to see if they are allowed.

If it's diy, you can take the proper measurements, get a union, a nipple, and either measure and get another nipple, or have HD, cut/thread the proper length.

Looks like if you picked up a 2' length, proper whistle, and a union, you can probably find a stock nipple that will be the right size.There was an error rendering this rich post.

2 -

It definitely won’t be a diy!! But I appreciate your help. I will pass it along to whoever I hire to replace the whistle stop. Right now in my local area (NH) no one seems to know what’s wrong. So frustrating. An oil man at my house did mention cutting the whistle stop. I was reluctant. But now it seems like the solution. I appreciate your help Steve.0

-

Thanks Ed. Nice diagram. When I find the right hvac guy I will pass this along. Now it makes complete sense. The whistle stop is for a much bigger tank. That would make sense why one time it didn’t work and the oil fill up man sprayed the whole side of the house. Another service man did mention a new Scully gauge.

Thanks for your help!! We’ve been dealing with this problem for 20 years. If you were local I would hire you! I will let you know the result after Xmas. 👍0 -

EdTheHeaterMan said:

It appears in your picture that you may have a large tank vent alarm. The part number for the proper vent alarm for your tank is 00275 You currently have part number 00209. This is for tanks up to 2000 gallons. The installer can use that vent alarm if he follows the instructions to cut the whistle to the proper length for a 275 gallon tank. The original installed did not do that. If you want the proper vent alarm ask your professional for order part number 00275 and part number 01122 from Scully. The second part number is a compression union so the pro can cut the pipe and put it back together without threading the cut section of pipe.

Since 1936!!1 -

Thanks Ignatz! I think you another person nailed it. The whistle stop is the wrong size. I will have to find a person like you in my area who knows about this issue. It makes sense now why the oil delivery guy sprayed the whole side of my house. Whistle stop didn’t work properly. Thank you so much!! 👍0

-

> @dileerl said:

>

>

> Here are a few pix. Thanks for all your help!

> I really appreciate it!!

> https://share.icloud.com/photos/0VmzPSGzGQeF2zQuk2g4zL6TQ

>

>

>

Your pictures are not showing for me. Does the site require an iCloud account to view?

Also, I'm curious if the repairs have made a difference?0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements