Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Replacing R8991A oil primary (obsolete) with modern primary and have pre/post purge.

Options

STEVEusaPA

Member Posts: 6,505

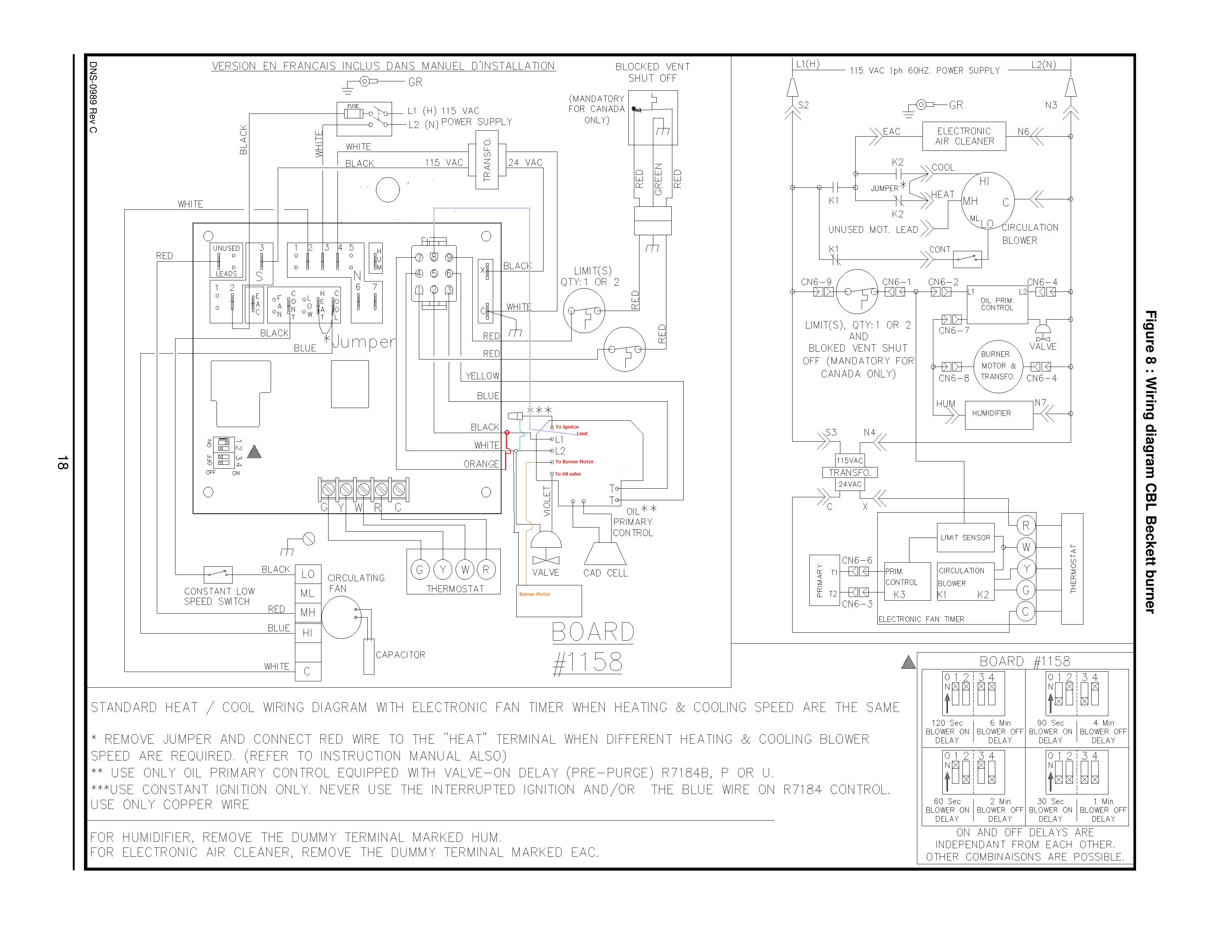

Hey Forum, I came across this the other day. Old oil primary bad (Honeywell R8991A primary & ignitor), and replaced it with new primary and new ignitor. Simple, following the first diagram.

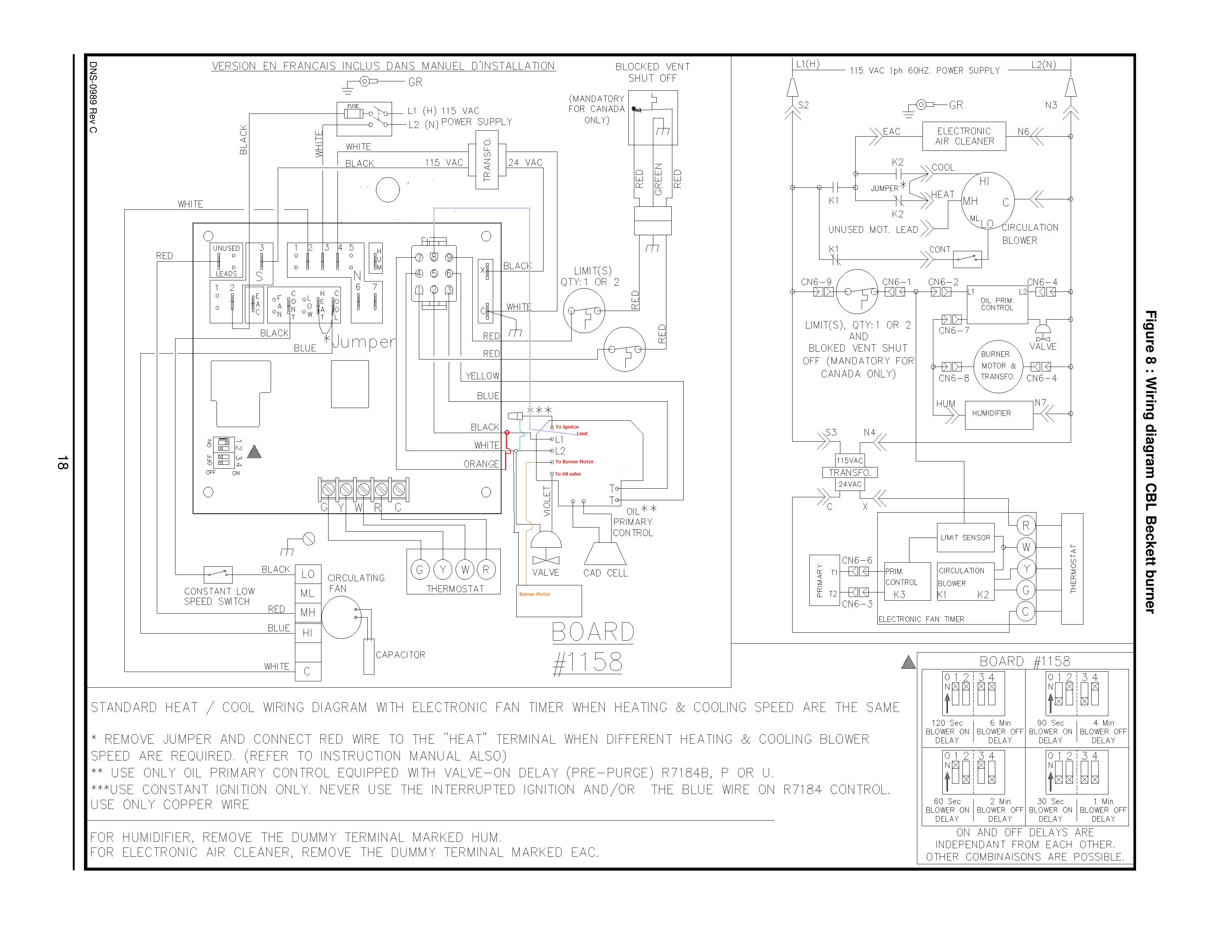

What I was wondering is if I can re-wire like my second diagram and get both pre & post purge.

Existing sequence of operation:

When a call for heat from t-stat:

1. T-T on board closes T-T on primary control (thru yellow and blue-3 & 6 on molex connector).

2. Primary constantly powered thru Black wire to L1, T-T closing powers Orange wire.

3. Orange wire goes thru molex on 4 & 7. If limit is closed sends power to 8 on the molex (violet wire) to power burner motor and transformer. And if limit is opened, no power to burner motor/transformer.

What I think I can do to give pre/post purge:

(The entire existing wiring harness goes from molex connector to the box on the burner)

1. Take orange wire from molex #7 and jump it at L1 at the primary, giving it constant power (like an older style fan/limit).

2. Take the violet wire from molex #8 and put it on the Limit terminal on the primary control. My thinking is on a call for heat, if the limit is open, nothing comes back on violet to the primary, and the burner motor/ignitor/oil valve stay de-energized. If limit is closed, burner runs off primary in the traditional sense.

3. Wire burner motor, ignitor, and oil valve from the primary as normally done.

As my brother always says (as one word with a southern draw)...ThinkIt'llWork?

I'm ok with it wired conventionally and it works fine. Just wondering if it can/should be done this way and take advantage of pre/post purge.

Thanks

Steve

What I was wondering is if I can re-wire like my second diagram and get both pre & post purge.

Existing sequence of operation:

When a call for heat from t-stat:

1. T-T on board closes T-T on primary control (thru yellow and blue-3 & 6 on molex connector).

2. Primary constantly powered thru Black wire to L1, T-T closing powers Orange wire.

3. Orange wire goes thru molex on 4 & 7. If limit is closed sends power to 8 on the molex (violet wire) to power burner motor and transformer. And if limit is opened, no power to burner motor/transformer.

What I think I can do to give pre/post purge:

(The entire existing wiring harness goes from molex connector to the box on the burner)

1. Take orange wire from molex #7 and jump it at L1 at the primary, giving it constant power (like an older style fan/limit).

2. Take the violet wire from molex #8 and put it on the Limit terminal on the primary control. My thinking is on a call for heat, if the limit is open, nothing comes back on violet to the primary, and the burner motor/ignitor/oil valve stay de-energized. If limit is closed, burner runs off primary in the traditional sense.

3. Wire burner motor, ignitor, and oil valve from the primary as normally done.

As my brother always says (as one word with a southern draw)...ThinkIt'llWork?

I'm ok with it wired conventionally and it works fine. Just wondering if it can/should be done this way and take advantage of pre/post purge.

Thanks

Steve

There was an error rendering this rich post.

0

Comments

-

From the ladder diagram it looks like the old primary was powered thru the limit controls into L1. What I'd do is leave the limit wiring as is and hook up the existing L1 wire that runs thru the limits, to the Limit terminal on the new primary. Then run a new 120V feed to the L1 terminal on the new one. This way, the various limit controls will start and stop the burner as they always have, and the hot feed to L1 will operate the pre/post purge timers.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Or... Just get a primary control with Pre and post purge features?0

-

Thanks Frank, I see it now.

There was an error rendering this rich post.

0 -

@Jellis This isn't a standard primary control wiring. The original control isn't wired like a typical new primary. The new control requires a constant hot for post purge and diagnostics, and a wire on the limit to tell it to shut the burner off when any limit opens.Jellis said:Or... Just get a primary control with Pre and post purge features?

There was an error rendering this rich post.

0 -

What is the make and model of your new primary control?0

-

I did something similar to my peerless WBV-03, ran a constant hot to the primary control. It could be my imagination but the boiler seems to stay really clean with a a brief post purge and pre purge.0

-

That's why we recommend those purges!SuperTech said:I did something similar to my peerless WBV-03, ran a constant hot to the primary control. It could be my imagination but the boiler seems to stay really clean with a a brief post purge and pre purge.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

It’s not your imagination. It does make a difference.SuperTech said:

... It could be my imagination but the boiler seems to stay really clean with a a brief post purge and pre purge.

There was an error rendering this rich post.

0 -

Prepurge & postpurge gives a cleaner start and stop. In the old days we had delayed oil valves with the delay built into the valve. They worked....most of the time0

-

Speaking of post purge.... some guys say post purge is a bad thing because it wastes BTUs by sending them up the chimney.

On an atmospheric vented boiler is a significant amount of heat wasted by a 15-30 second post purge? I love keeping the boiler clean but hate the idea of wasting heat. I can't imagine that a 30 second post purge would cool off the boiler that much more than natural draft. Has this been studied? Why not have a post purge on all oil fired equipment?0 -

I would think that the little heat blown out of the boiler on a 15-second post-purge is less than what would be wasted if the boiler gets dirty inside. Don't have any figures to back it up though........All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

I think the main benefit for post purge is cooling down the heat exchanger to prevent the excess heat that causes a little nozzle drip after the burner shuts down. That to me helps prevent a dirtier light off, keeping everything cleaner.

However, in a power venter situation, you post purging 4+ minutes, so you are getting off cycle efficiency losses out of the building.There was an error rendering this rich post.

0 -

> @STEVEusaPA said:

> I think the main benefit for post purge is cooling down the heat exchanger to prevent the excess heat that causes a little nozzle drip after the burner shuts down. That to me helps prevent a dirtier light off, keeping everything cleaner.

> However, in a power venter situation, you post purging 4+ minutes, so you are getting off cycle efficiency losses out of the building.

Thats why I added post purge to my peerless WBV-03. What I'd really like to do is find a way to add some post purge to EK boilers. 3 out of 4 system 2000 boilers I see all show evidence of nozzle drip after shut down. It doesn't cause any major issues but my OCD about making everything perfect makes me want to change them.0 -

I would think the thermal purge from the Energy Manager after a call would help cool down the heat exchanger, no?

It would be a good question for the EK people here on the wall regarding the dripping you see.There was an error rendering this rich post.

0 -

-

> @STEVEusaPA said:

> I would think the thermal purge from the Energy Manager after a call would help cool down the heat exchanger, no?

> It would be a good question for the EK people here on the wall regarding the dripping you see.

That was actually what caused me to make my first post on this site. The thermal purge helps cool the exchanger but the combustion chamber will really hold a lot of heat if the draft isn't adequate. A lot of homes I see don't get enough draft for the EK boilers until the chimney heats up. I noticed I never saw it happening on power vent models. I was told to ensure proper draft and make sure to check the cutoff on the oil pumps on those boilers. It's never been a problem, I almost never see any issues with the EK boilers that I service. I really like all the EK boilers.0 -

Thanks to all for your comments, and @STEVEusaPA , it’s great to hear that we helped play a role with your start on heatinghelp with all your helpful contributions through the years!

It looks like everyone has a good handle on this, here are a few thoughts off the top of my head:

With a property designed and operating system, the burner head and nozzle will always stay at an appropriate temperature from the fan with the burner running. Issues can arise from poor draft when the burner turns off.

One of the worst case scenarios is a negative pressure building/home that draws the heat back over the nozzle and head after the burner shuts off. Connecting outside air helps the burner “breathe” to eliminate after drip. We recommend this on all systems (especially as you never know when the home may have an impactful change like a strong range fan or weatherization); it’s required for all our systems that do not have natural draft.

Good draft continues to draw some air after shutdown, also keeping the head cool - this influences the nozzle temperature much more than boiler temperature on our systems as the boiler cools fairly quickly with thermal purge. With inadequate draft, the opposite is also true, and several things can be done to improve draft - see burner diagnostics on this link for more: https://energykinetics.com/heating-professional-resources/

If there are signs of poor draft like substantial after drip or head coking, fixing the draft problem and adding outside air are the correct solutions. This should resolve the cause, although I know some have used a short burner post purge (maybe 15 seconds). Draft must always be strong enough to allow the blocked vent puff switch to operate as a safety. Pre-purge only needs to be long enough to get the pump up to full operating pressure so anything over 1 second is fine.

Post purging the burner does steal some energy, so we avoid it where possible. This must not be confused with with boiler post purge (thermal purge) which puts more heat to use and can save 20% to 40% of annual fuel use. Having a boiler finish hot (no thermal purge) also means that the boiler heat drives off cycle draft and energy loss, so thermal purge saves energy in several ways.

Of interest, the burner fan moves 4 times as much air as the power vent fan running alone; dilution air vent systems like the 90+ Resolute move even less air through the burner during “post purge”, further improving efficiency. Our dilution air vent systems also have a characteristically clean light off.

RogerPresident

Energy Kinetics, Inc.0 -

@Roger , you don't say so in your post, but are we correct to assume you are with EK?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Yes, @Steamhead - I’m president. Sorry I neglected that in my signature!President

Energy Kinetics, Inc.0 -

You can set up your profile so that info comes up each time you post, as I have. It's a big help for when you get so busy you forget things like that.

So when are you coming out with a steam boiler? Burnham's MegaSteam reaches 86% AFUE, and they has a sad when we talk about firing it with a powered gas burner. Think you can beat them?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Thanks, @Steamhead - I appreciate your comment and suggestion. Sorry, no steam boilers in our near-term focus, though.President

Energy Kinetics, Inc.0 -

Thanks @Roger for your input on this. Now that I think about it I'm pretty sure that I don't see this happen on the boilers that have outdoor combustion air piped in as well. Another good reason to recommend this the owners of EK boilers. I wish other manufacturers showed as much commitment to quality and service as you folks at EK do. Happy new year!2

-

Thank you for such a fantastic compliment, @SuperTech - I appreciate your support. Happy New Year to you and yours!President

Energy Kinetics, Inc.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements