Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

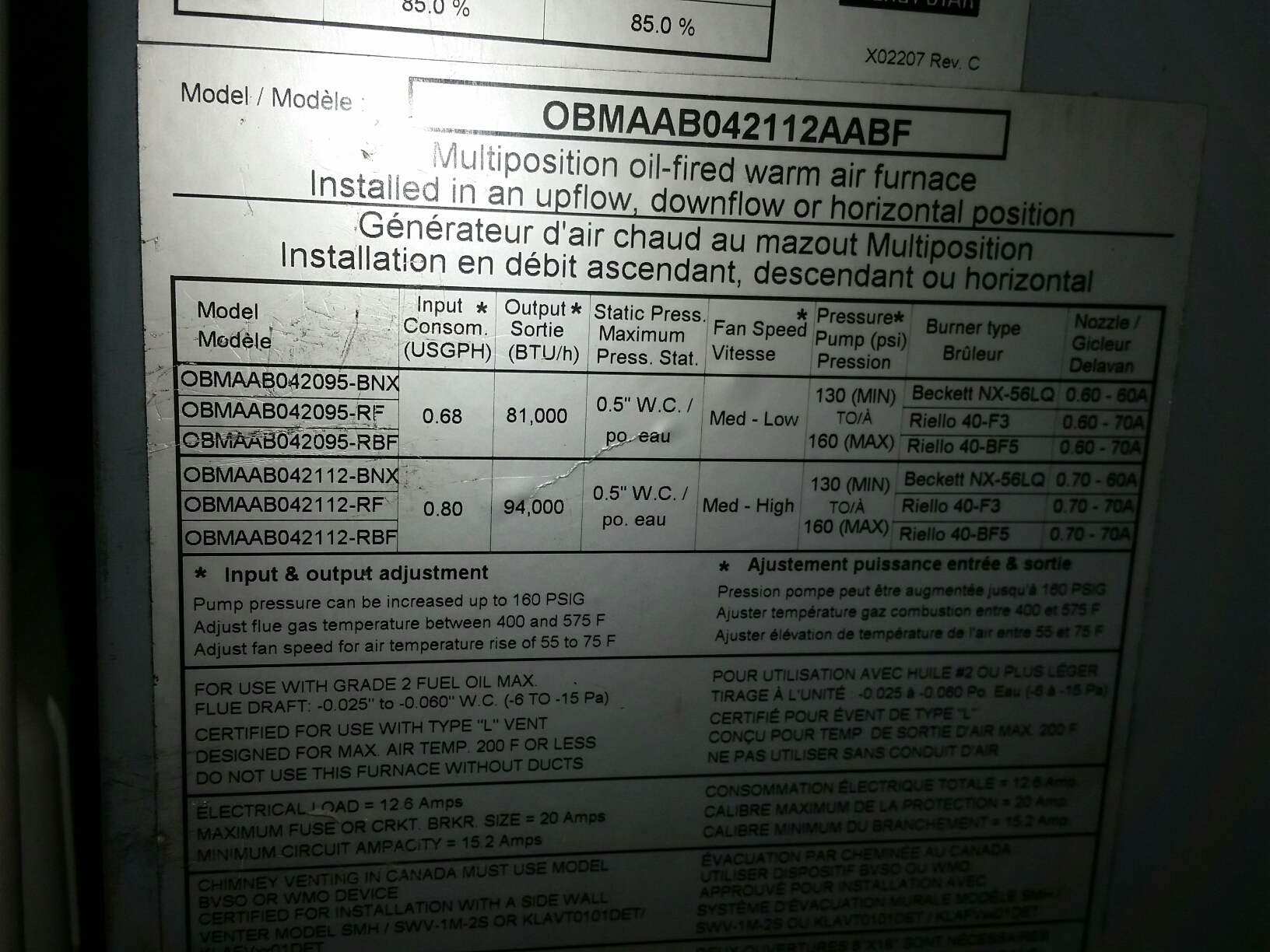

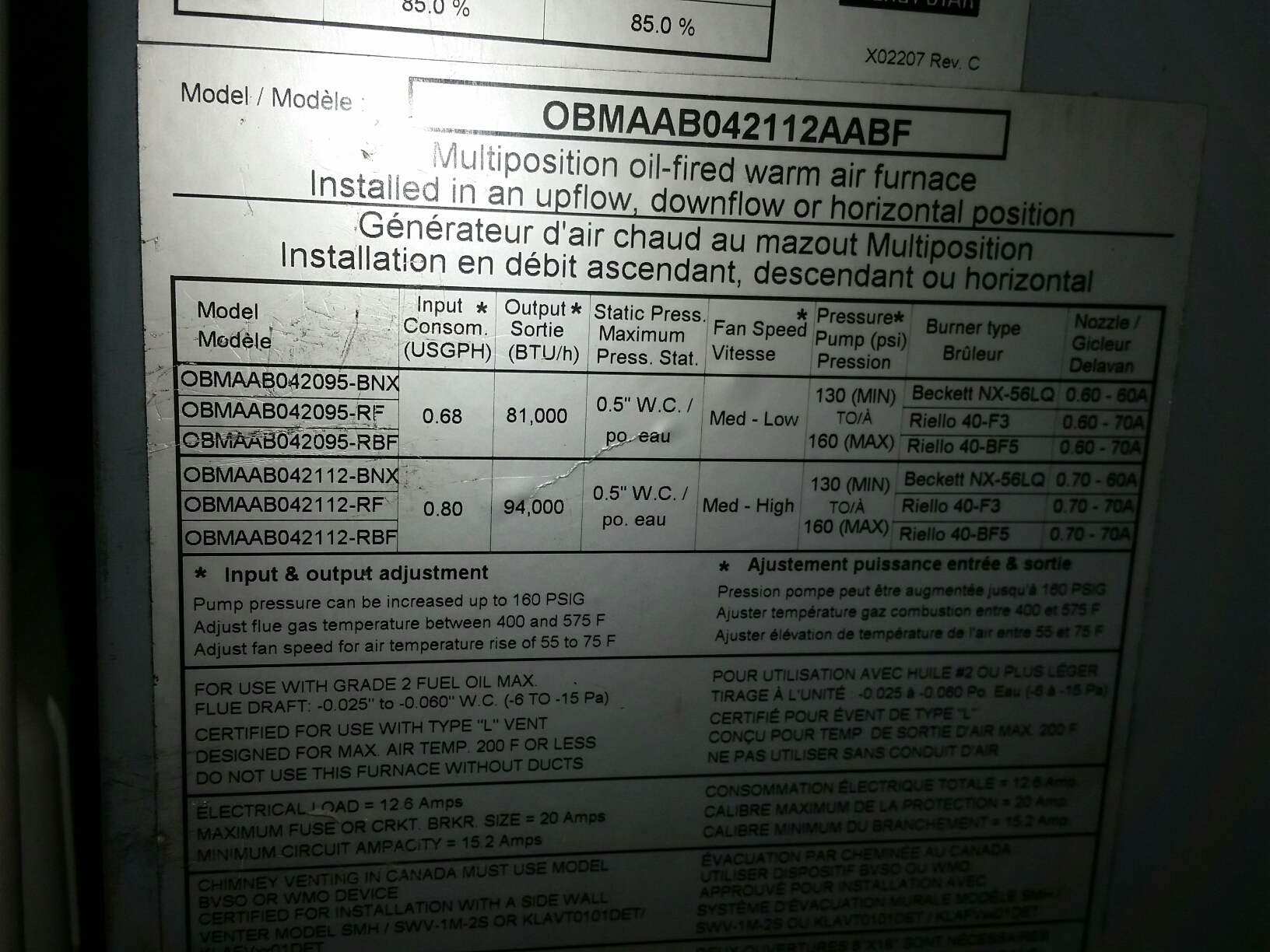

Is the right burner on my Carrier oil furnace?

Options

Brian26

Member Posts: 26

From what it looks like on the model number sticker it should have a Reillo 40-BF5? It currently has a Beckett NX-56LQ on it with a .60 60a nozzle at 145 psi that's on the mfg setting sticker on the bruner. It runs fine but was curious if it was specially made for the Reillo burner as the last 2 or 3 digits on the model seem to indicate the burner type? Mine end in BF for the BF5 burner? Shouldn't mine end in BNX with the beckett burner? I attached pictures of the model number tag and burner on it now.

0

Comments

-

It's fine. It's giving you set up instructions of 3 configurations for each of the 2 different btu outputs.

There was an error rendering this rich post.

0 -

Anyone know why the listed max pressure is 160 psi on the furnace label? I bumped the pressure to 175 to get the max firing rate of .80 off my .60 nozzle. It lights off like a rocket now but seem to run with better efficiency. I am doing a smoke test and using a combustion analyzer to make these adjustments.

Also, is it better to set the oxygen on the low side. The carrier manual says the target is 3.5-5 and 12-13 co2. I get much lower stack temps, higher duct temp rises and better efficiency at the 3-3.5 o2 level. I could go even lower on the 02 and still not get a trace of smoke. Could i drop it down to say 2-2.5 o2?0 -

I guess they are giving you a way to tweak your combustion.

I'd bring that pressure back down to 145 (look at the label on the back of the burner), and a .60 60A nozzle.

What were your numbers before you made changes?

For setting the burner, proper draft first. Then true zero smoke. Then I usually add enough air to drop the CO2 1%, and that's where it should be. I don't really worry about the final CO2 or O2 numbers, unless they are out of whack. Then I'll start investigating.

What's your net stack temp? Too low and your condensing, and condensing will do more damage and become more costly than a few efficiency percentage points.There was an error rendering this rich post.

0 -

I would be very, very careful with that furnace. You have the correct NX burner, but be careful about setting that air too low. I've seen quite a few techs set them up like that only to have the furnace soot up afterwards. And draft is super important.

Honestly I would shoot for 5-6% O2 and no more than 12% CO2. CO should be close to zero PPM.0 -

As far as I can see the "B" is for Beckett and a NX is what you have. The "R" is for Reillo and is what you don't have0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements