Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Creating a functioning dump zone for a hand-fired boiler

Options

Hi all. I'm new here, but have worked in the boiler manufacturing industry for 8 years in the past. There are two attached drawings which add to my comments if someone would be kind enough to look at them.

I am stumped. About 10 years ago I installed a hand-fired (HF) wood/coal boiler in my garage. Hot water went down to the basement, through an indirect domestic hot water heater, then to an oil boiler which had the 3 baseboard heating zones attached. In the Summer, I made domestic hot water in a loop which went from the HF boiler to the indirect and then back to the HF boiler. In the Winter, I changed a few hand valves and the circulation continued to the oil boiler (OB) and back to the HF boiler. If there was a call for heat, the zones would open and the hot water would flow through the zones and back to the HF boiler. All this was accomplished with a single Taco 007 circulator at the HF boiler, upstairs and it worked flawlessly for 10 years. My dump zone was the basement loop.

Last year, I put too much coal into the boiler on a warm Winter night and it overfired. The zones couldn't dissapate the heat and everything turned to steam. I lost alot of water and my system took on alot of air. It was almost Spring, so I was able to get the short loop through the indirect heater running, but I couldn't circulate through the heating zones without using the second circulator on the return line of the zones.

A few weeks ago, I thoroughly purged all the lines, but I can't get the heating loops to circulate unless I run both circulators. It might take a long time to get all the air out. It works great with both circulators running.

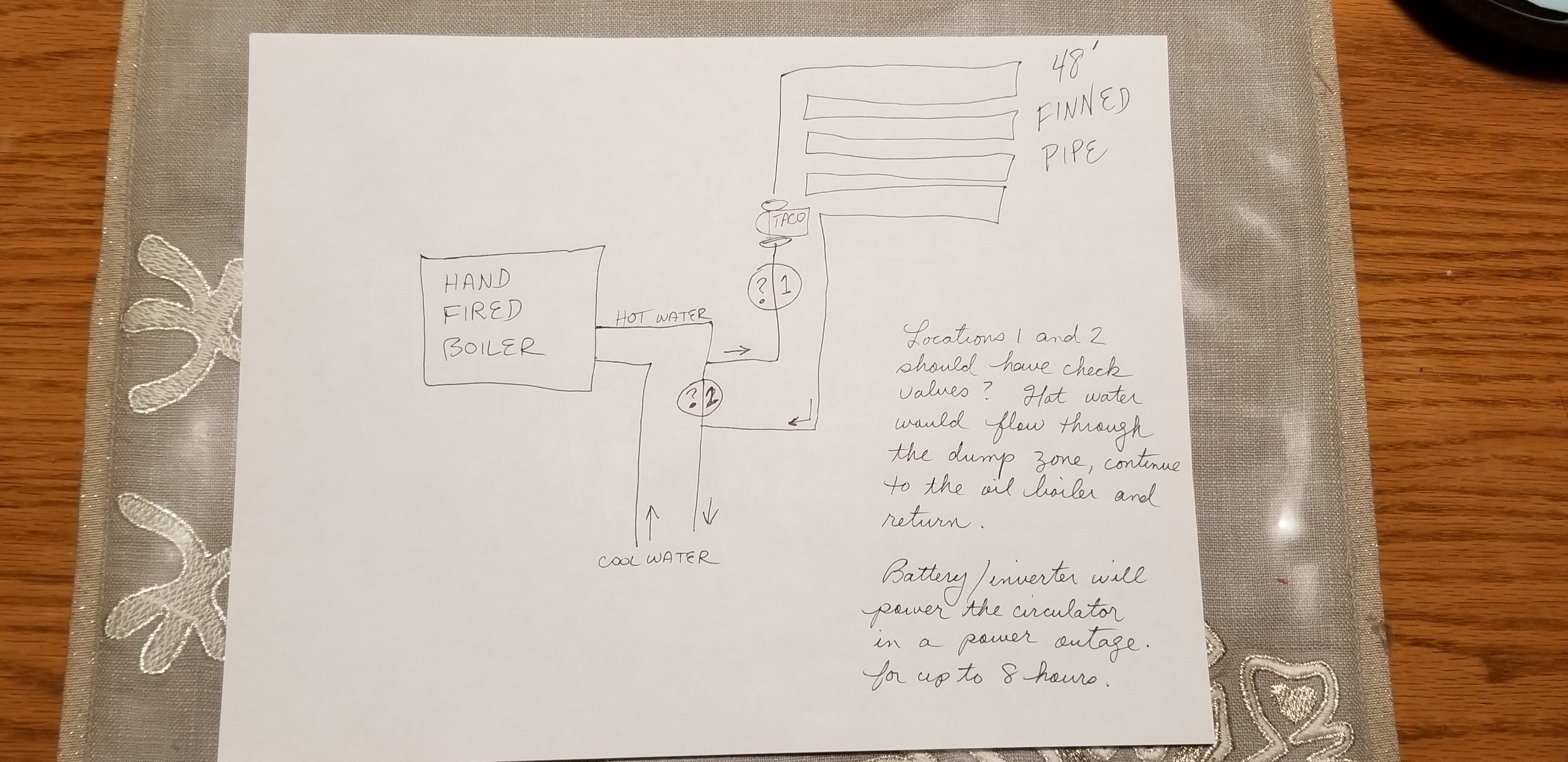

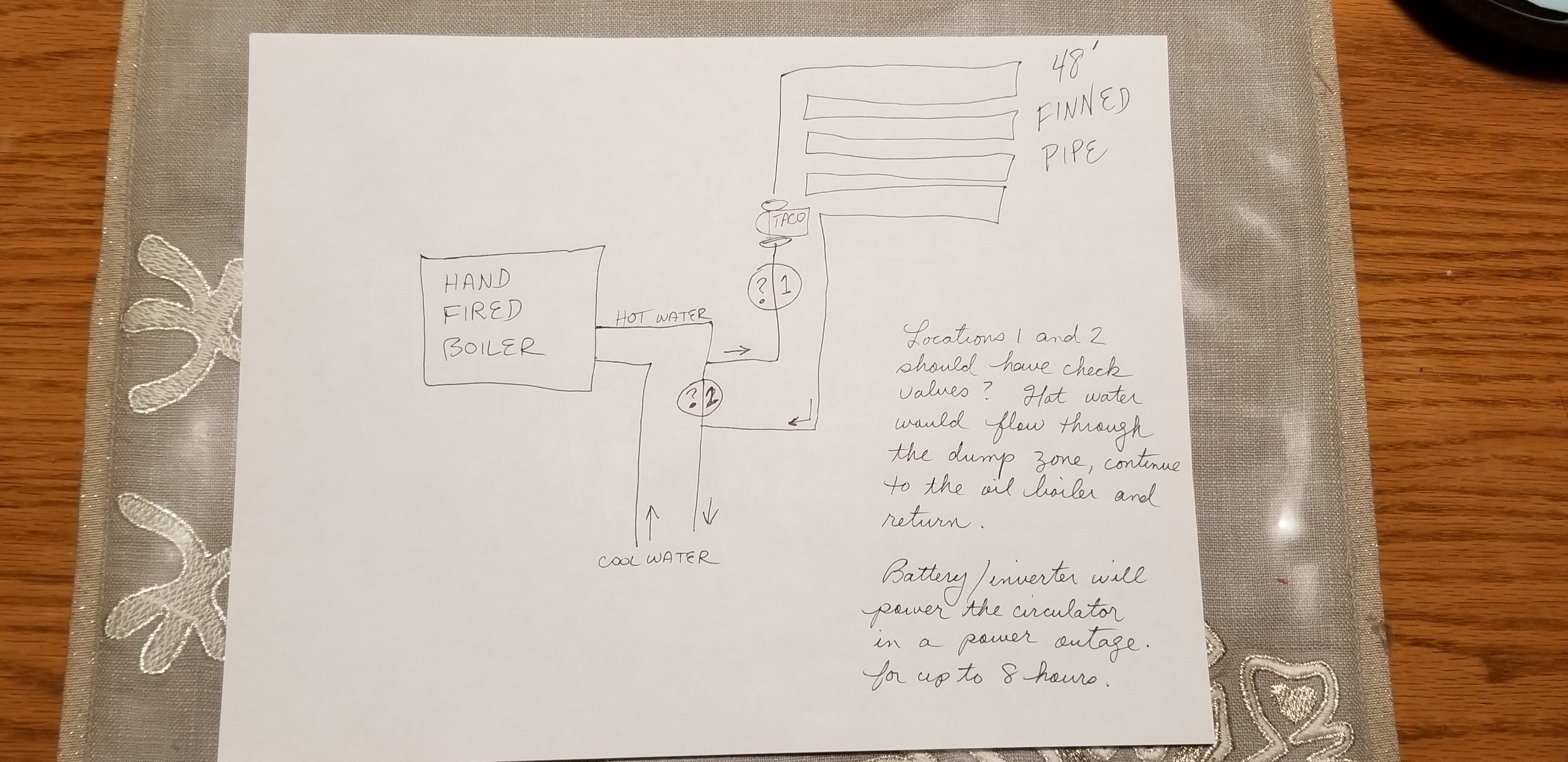

The smaller drawing shows a loop in the garage which will branch off the supply line and run through 48' of finned tube and then continue downstairs as before. I have a battery and inverter for this loop, which is necessary if there is a power outage. With the boiler filled with coal, it can circulate for 6 hours and stay at 160 degrees. If I lose electric after leaving the house, it can easily go to 300 degrees since it doesn't gravity flow.

Does my small loop make sense? The circled areas are where I think two check valves should go. Opinions please.

Thank you.

I am stumped. About 10 years ago I installed a hand-fired (HF) wood/coal boiler in my garage. Hot water went down to the basement, through an indirect domestic hot water heater, then to an oil boiler which had the 3 baseboard heating zones attached. In the Summer, I made domestic hot water in a loop which went from the HF boiler to the indirect and then back to the HF boiler. In the Winter, I changed a few hand valves and the circulation continued to the oil boiler (OB) and back to the HF boiler. If there was a call for heat, the zones would open and the hot water would flow through the zones and back to the HF boiler. All this was accomplished with a single Taco 007 circulator at the HF boiler, upstairs and it worked flawlessly for 10 years. My dump zone was the basement loop.

Last year, I put too much coal into the boiler on a warm Winter night and it overfired. The zones couldn't dissapate the heat and everything turned to steam. I lost alot of water and my system took on alot of air. It was almost Spring, so I was able to get the short loop through the indirect heater running, but I couldn't circulate through the heating zones without using the second circulator on the return line of the zones.

A few weeks ago, I thoroughly purged all the lines, but I can't get the heating loops to circulate unless I run both circulators. It might take a long time to get all the air out. It works great with both circulators running.

The smaller drawing shows a loop in the garage which will branch off the supply line and run through 48' of finned tube and then continue downstairs as before. I have a battery and inverter for this loop, which is necessary if there is a power outage. With the boiler filled with coal, it can circulate for 6 hours and stay at 160 degrees. If I lose electric after leaving the house, it can easily go to 300 degrees since it doesn't gravity flow.

Does my small loop make sense? The circled areas are where I think two check valves should go. Opinions please.

Thank you.

0

Comments

-

My first and foremost thought is that you are pumping toward your expansion tank which could be why you are having a hard time getting flow and air removal.

I've had very good luck with microbubble air separators, such as Spirovent or Caleffi, they are worth the money. Also, take a look at the impeller on the 007 woe your HF boiler. It may be damaged from cavitation and overheat.

Will your fin tube be arranged to gravity flow as an emergency dump?Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

What brand of hand fired wood and coal boiler to you have?

If its a harman you can buy a firebox reducer or do what I did with mine-

I bought a piece of channel iron as wide as the shaker grates and half as long as the firebox then I filled it with full firebrick right up to the flue breech and It worked perfectly-I wish I had done it 33+plus years ago.

You get a better smaller fire and finer ash with few if any clinkers.

You should plan on checking the circulator and if it needs an impeller install a new one- my taco pumps died completely before I changed them out in the middle of the winter 5 years ago.

As solid fuel man said your plumbing needs some work and I would change the dump zone coming off the coal boiler to a water to forced air garage heater in your garage perhaps with a shutter/plenum to the outside to dump the heat faster.

you need boiler drains at the end of your heating loops to purge the cold water of any air and then the microbubbler can handle the rest.

I have a B+G 15 gallon steel compression tank and an B+G airtrol valve and an B+G Internal Air Separator and no air scoop for my system and I no longer have to bleed my baseboard loop or crawl around on my knees to mess with it.

My oil and coal boiler were tied together in parallel with one circulator as a temperature balance unit and the other scting as a circulator for the 225 foot single loop.

In your case a series hook up would be simpler for you to plumb the circulator to pump away from the expansion tank. and have the second circulator tied in directly to the Zurn water to air garage heater with a plenum and shutter to the outside.

You need to add boiler drains to the ends of your heating loops to get the air out too.

I would change the location of the compression tank or get rid of all together and install a steel compression tank, Airtrol Valve and an Internal Air Separator in the garage above the coal boiler and add the boiler drains at the end of the heating loops if it was me as you will have little or no trouble with air bubbles or suffer with air locks.

If your bleeding and all your getting is water it ain't an air problem its a balance problem to quote Dan.

I would check that circulator first before I did anything else as teh impeller may be shot.

If you can make the coal boiler firebox smaller with a firebox reducer or firebrick with a piece of channel iron on the shaker grate frame that will only help you and you will not have spent a lot of money this winter.

Even having welding shop make up a firebox reducer for you will help you a lot of if you do not have a Harman boiler.

0 -

Thanks for the two replies. Let me look over what you said and get back to you.0

-

You have the boilers in series from what I can see? So when the oil fired boiler is running, a bit of that heat is going up the HF boiler flue?

If the dump zone is piped above the HF boiler and sized large enough it should be able to thermo-siphon excessive heat, depending on how much you over fire.

I'm not sure if you want to re-pipe if it has worked all these years. If the HF boiler is warm when the oil fired is running, you are wasting a bit of oil.

Does the HF flue get warm when the oil fired is running? I don't see the manual valves you mentioned?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The OB and HF are at opposite ends of the house and each has its own chimney. I agree about repiping since it's been working well for a long time. A plumber suggested this scheme to keep things simple.

On the drawing, I am pulling off the supply side to finned tubing hung in the ceiling, 55 feet, and returning to a return line at point (1). Because there are check valves in the basement, the cooled water is forced into the boiler at point (1) and (2).

The HF can perform 4 different heating functions, all controlled by hand valves. I wrote a manual for the "next guy" because only I know how it runs.

My newest question is, should the check valve and circulator be at locations 3 and 4 or on the cool side of the tubing. Do you suggest loation 3 as the check valve?

0 -

The dump zones on many of the wood and pellet fired boilers i see in Europe have swing checks, they call then gravity gates, that open for no power over heat protection.

We build a 3 way boiler protection valve/ pump that has a gravity gate inside that allows thermosiphon to an over heat heat dump circuit.

I would think a swing check on the hot piping

Some piping examples and theory here.https://www.caleffi.com/sites/default/files/coll_attach_file/idronics_10.pdfBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements