Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Plumbing buffer tank setup - HTP vs. John Siegnthaler

Options

Torsten

Member Posts: 3

In the process of installing an HTP 20 gallons SuperStor Ultra Stainless Steel buffer tank to a radiant system that is powered by a Navien NCB 180E.

In the SSU-20B's product documentation (LP-219.pdf), page 6, Figure 3, it appears that the recommended piping concept has the primary loop's supply connected at the bottom, and the secondary loop's supply connected at the top connection of the buffer tank.

That is contrary to previous setups I have seen, such as the one shown and described by John Siegenthaler, P.E. here: 'Alternate methods to pipe a buffer tank'

In his setup, the supply for both, primary and secondary loop, are connected at the top of a buffer tank, while the returns are connected at the bottom. That will result in hot water staying and moving through at the top, and colder water sliding through at the bottom of the tank. Those effects, according to Mr. Siegenthaler, are desirable because they maintain temperature stratification in the tank.

Is anyone able to share some advice on the differences of those setups and which setup to follow?

I can provide more details on the radiant setup if helpful.

In the SSU-20B's product documentation (LP-219.pdf), page 6, Figure 3, it appears that the recommended piping concept has the primary loop's supply connected at the bottom, and the secondary loop's supply connected at the top connection of the buffer tank.

That is contrary to previous setups I have seen, such as the one shown and described by John Siegenthaler, P.E. here: 'Alternate methods to pipe a buffer tank'

In his setup, the supply for both, primary and secondary loop, are connected at the top of a buffer tank, while the returns are connected at the bottom. That will result in hot water staying and moving through at the top, and colder water sliding through at the bottom of the tank. Those effects, according to Mr. Siegenthaler, are desirable because they maintain temperature stratification in the tank.

Is anyone able to share some advice on the differences of those setups and which setup to follow?

I can provide more details on the radiant setup if helpful.

0

Comments

-

https://www.caleffi.com/sites/default/files/coll_attach_file/idronics_15_na.pdf

Check this out it shows how to pipe Hydronic separation

Looks like to me boiler into top of tank system out top of the tank system return bottom of the tank boiler return bottom of the tank

The same way that hydro seaporators get piped.

The tank is just adding water volume to systems with micro small zones and to help keep the boiler from short cycling and to get your P/S piping.0 -

I would call HTP on Tuesday ask if that piping drawing is correct.

They may want that piped that way because fittings on this tank are not across from the other one. These fittings are on a 45 from each other.

Could cause a problem if not piped in the right way.0 -

"Hillbilly Reckoning"........You're using the buffer tank to add volume to the system. Piping it in at the top and out at the top, basically short-circuits the tank, and only uses the top of it.

I can also see the merits of the other way of installing it, but it would seem that would be more applicable with a very large buffer. And, perhaps as mentioned, one that has connections across the tank.0 -

Yet another option that has advantage being promoted in the GEO industry outworks for hot also.

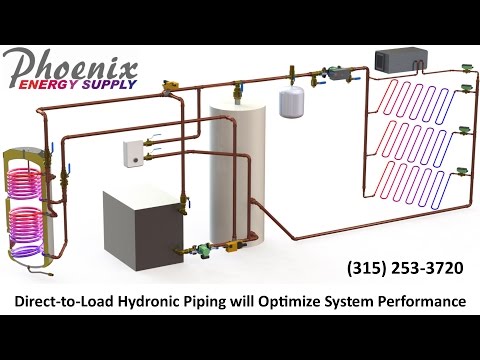

It's called the 3 pipe or direct-to-load" method. Promoted by engineer John Manning who specializes in GEO design. Proper buffering is critical with fixed speed heat pumps in zoned or small load systems, and the desire to drive efficiency with return temperatures.

I have installed 4 or 5 two pipe buffers now, several at my own place so i can watch them perform.

You need some resistance in the heat side piping. The small circ integral checks .35- .50 psi may not be enough check protection. A delta P or zone valve may be better.

If you have micro loads running a very tight ∆T, high flow rate, that low ∆ can cause some boiler short cycling as it reaches limit quickly. Low ∆ is more common in chilled water designs where this concept originated.

IF you assure a 15- 20∆ in your design 2 pipe works fine.

So with this 3 pipe the return must pass through the lower tank assuring some buffer always involved.

So it kinda depends on your system and goals, 2, 3, and 4 all have some pros and cons.

Here is John Manning presenting the direct to load 3 pipe concept in this video. He is GEO biased

https://www.youtube.com/watch?v=bFNIw_IrzYU&t=18s

https://www.youtube.com/watch?v=bFNIw_IrzYU&t=18s

of directBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements