Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Near Boiler Piping

Options

Jetman

Member Posts: 4

Well winter is going to be setting in and it's time to make a decision.

I would appreciate a critique of some of the near boiler piping schematics I am considering. There is so much information out there and after studying manufacturing data from sources like Caleffi, Taco and PM magazine need to decide.

Situation is a new construction in a second home in NH. House is being kept at 45F when un-occupied and boasted up to 65 when occupied. Fan coil heaters are being used to quickly heat the air, then panel rad’s take over for more comfort. Radiant floor heat also will be boasted albeit the time lag is long.

Fan coils are high temp loop, panel rad’s on high temp or considering thermostatic valve to lower 140F design temp, and radiant uponor quick track design temp at 115F. I have an oil fired boiler. There is no natural gas and even with the efficiency gain of a Mod-Con boiler, considering the price difference and BTU heating value, Propane is 2X the cost of oil. Decided to stick with oil.

Below are 4 sketches. Cost is a consideration, but I am willing to pay for features that are cost effective.

The panel rad’s are already piped as shown with thermostats in each room. What I need to figure out is the best way to tie in the, panel rad's, DHW, Fan Coil units and Radiant heat (All are already piped to the boiler room).

Another way to say this is, what is the best near boiler piping scheme? Note the figures did not load in order. Figs 1,4,3,2. (Go figure).

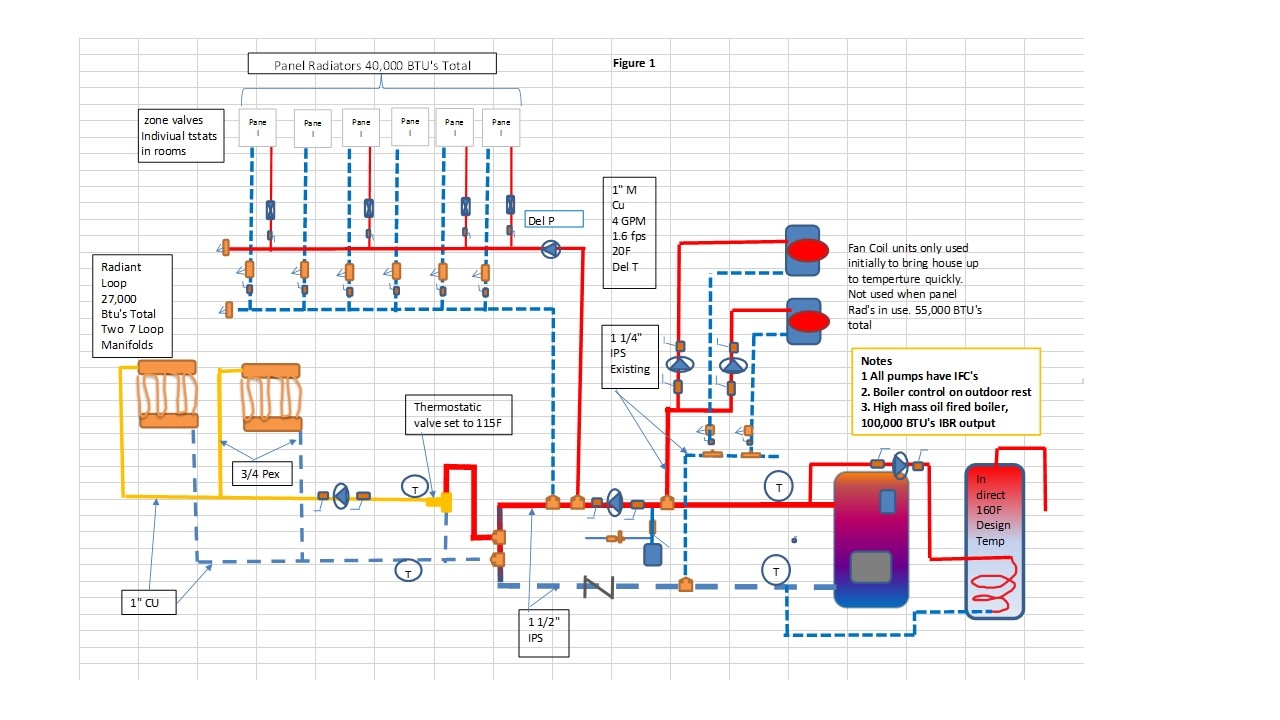

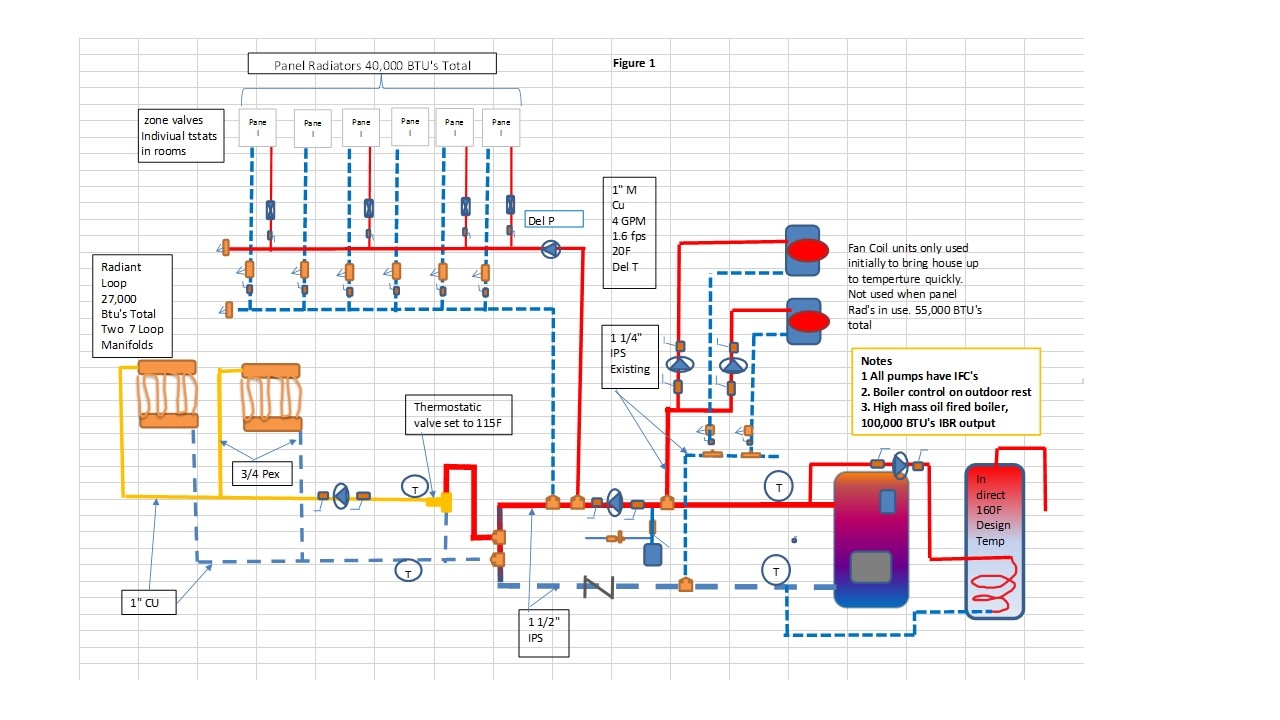

Figure 1 is a primary loop with secondary take off’s for the Panel rads and radiant floor heat (RFH). The DHW and fan coil units ( FCU’s) are piped conventionally.

Figure 2 is similar, except a boiler loop is added with a Boiler protection valve.

Figure 3 is a primary loop with RFH, Panel Rad’s and FCU’s on the secondary loop

Figure 4 incorporates a Low Loss Header. More expensive…is it worth it?

Fundamentally what are the factors that determine if you put the boiler on it's own loop and tie it into the primary loop, vs the primary loop going through a high mass boiler? Differences between Figure 1 and 2.

Appreciate comments. Winter is coming, it’s time to stop study

ing and start cutting chips. Thanks in advance.

I would appreciate a critique of some of the near boiler piping schematics I am considering. There is so much information out there and after studying manufacturing data from sources like Caleffi, Taco and PM magazine need to decide.

Situation is a new construction in a second home in NH. House is being kept at 45F when un-occupied and boasted up to 65 when occupied. Fan coil heaters are being used to quickly heat the air, then panel rad’s take over for more comfort. Radiant floor heat also will be boasted albeit the time lag is long.

Fan coils are high temp loop, panel rad’s on high temp or considering thermostatic valve to lower 140F design temp, and radiant uponor quick track design temp at 115F. I have an oil fired boiler. There is no natural gas and even with the efficiency gain of a Mod-Con boiler, considering the price difference and BTU heating value, Propane is 2X the cost of oil. Decided to stick with oil.

Below are 4 sketches. Cost is a consideration, but I am willing to pay for features that are cost effective.

The panel rad’s are already piped as shown with thermostats in each room. What I need to figure out is the best way to tie in the, panel rad's, DHW, Fan Coil units and Radiant heat (All are already piped to the boiler room).

Another way to say this is, what is the best near boiler piping scheme? Note the figures did not load in order. Figs 1,4,3,2. (Go figure).

Figure 1 is a primary loop with secondary take off’s for the Panel rads and radiant floor heat (RFH). The DHW and fan coil units ( FCU’s) are piped conventionally.

Figure 2 is similar, except a boiler loop is added with a Boiler protection valve.

Figure 3 is a primary loop with RFH, Panel Rad’s and FCU’s on the secondary loop

Figure 4 incorporates a Low Loss Header. More expensive…is it worth it?

Fundamentally what are the factors that determine if you put the boiler on it's own loop and tie it into the primary loop, vs the primary loop going through a high mass boiler? Differences between Figure 1 and 2.

Appreciate comments. Winter is coming, it’s time to stop study

ing and start cutting chips. Thanks in advance.

0

Comments

-

I always suggest the LLH, You might be surprised that the price is comparable IF you include dirt, air, magnetic, and hydraulic as separate components. Then add labor and fittings to connect it all.

The LLH should take up a lot less room to pipe and is not as intimidating to look at as a P/S loop.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements