Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Old AC refrigerant line work for new unit?

Options

D107

Member Posts: 1,945

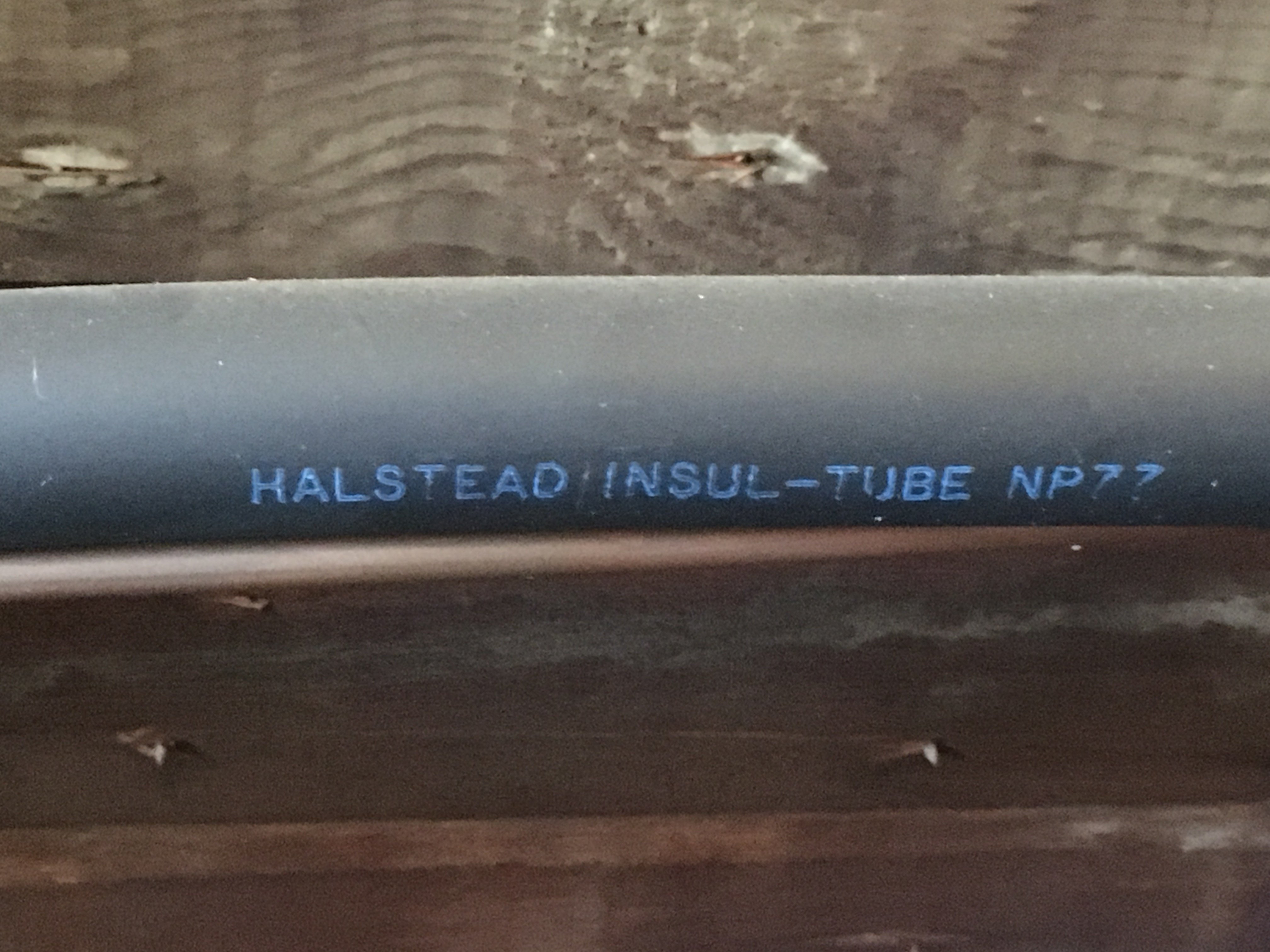

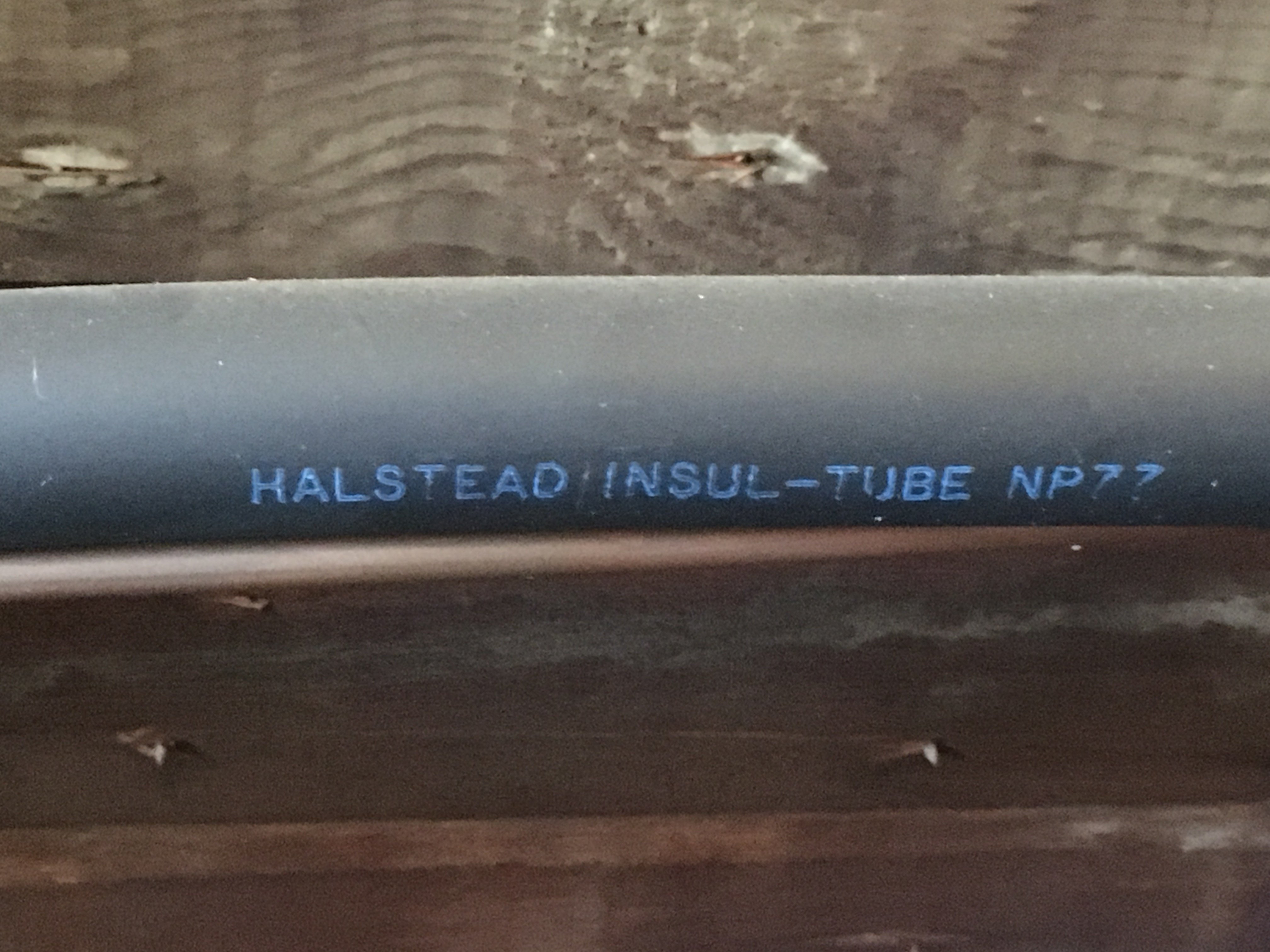

In my uninsulated, unvented attic I have an early 80s 3 ton Bryant unit--see photos. We are looking to have the rafters and gable wall insulated R 30 and R21 respectively with spray foam. The refrigerant line that runs from the attic air handler to the compressor outside runs through the bottom of the roof and down the side of the house. When we get a new AC unit, I'm anticipating, due to the insulation and a proper AC calc, needing only a two ton unit for the 1100 square feet of our house that is air conditioned. (If we somehow could extend our AC ducting to include the basement and side porch, square feet would be 1800 sq ft. Our walls are already insulated with about R-20 dense pack cellulose and rigid board insulation.) Anyway my question is would that Halstead Insul Tube NP77 refrigerant line be able to be used again for the newer, smaller AC unit--thereby saving us the trouble of messing with our new, sealed spray foam insulation to put through a new line? (I also wonder if, given a reasonably well insulated house in the NY area, if we could do away with the central AC and survive on two minisplits, one for each floor, maybe one for the basement?

0

Comments

-

Assuming the tubing size is still within acceptable range for the new unit and a pressure test is done it shouldn't be a problem. I would get the tubing set down away from that roof .

hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

1 -

Thanks, after the insulation I don't believe proximity to the roof will be an issue--it certainly is now! Imagine how much energy is wasted in that attic heat. Are those lines bendable after thirty years?0

-

Rising above the evaporator connections is not doing any favors for the rest of the system for sure. That copper is not as flexible as it once was due to work hardening but it can be bent. Be careful not to kink that where it comes up out of that wall though. But yeah there is no reason for it to be along the roof , there are multiple products on the market to support that tube better than it is now.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

1 -

Most new 2 -2.5 ton ACs will use 3/8 & 3/4" Outside diameter ACR tubing. Some 80's units used 5/16" OD for liquid, yours looks 3/8". Your AC is probably R-22 and new would be R-410A, the line set must be flushed before reusing.

Those lines will very carefully bend in large sweeps as you already have. The large line is very susceptible to kinking.

Where the lines leave the attic they look to be very close to the roof sheathing. Roofing nails can penetrate at least 1" for sure.

I had a unit lose all charge because of this.....attic from hell.....2/12 pitch, could pull extra line out from attic after tearing off soffit material. Major repair.

I would recommend a nail guard on the bottom side of the roof rather than trying to bend the lines down much. The line set at that point is probably already egg shaped and a little more invites a kink. Some steel that an air gun will not penetrate would do it. IIWM

So after foaming the attic in that manner, how does the humidity escape from the house? I know you said the attic was unvented but it still would breath a little, will the foam seal it too tight??

I just wonder as I live in a different climate, we don't do this here.1 -

Always a pro and a con with ducted vs ductless. Actually there are many.. what's your heating? If you're on oil or LP you may want to lean to the ductless. Oil is cheap now but who knows when it will take off again

Why run ac in the basement, you're not too warm down there are you?1 -

Nails , yes. The intense environment at the roof is not an issue , no problem it's actually great for the system. It's like the Angry Orchard commercials where they yell at the apples .hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

1 -

Thanks for the responses. To answer Jughne, the research I've done shows that in making the attic a conditioned space, closed cell foam, at R30 is thick enough to act as an air and vapor barrier, and won't get cold enough for rising house humidity to condense on. We will also have sheetrock over that as a thermal barrier. Stack effect will be stopped, so less humidity will be sucked into house in summer. I may have to install a fresh air intake for boiler though. Thanks for the nail guard idea--never thought of that. Will have to inspect it closely. To answer GW basement gets hot and even more humid. I run a dehumidifier--which of course makes it more hot and runs up electrical costs. Perhaps if I put in a boiler that can be vented through the wall, We can run an AC duct down to the basement through the 7" chimney. If we could run both a duct and return register line that would be optimal, but 7 inches probably too small.0

-

Most recommend the suction line be brought up slightly higher than the top of the evaporator to help stop migration while the compressor is off, no?hvacfreak2 said:Rising above the evaporator connections is not doing any favors for the rest of the system for sure. That copper is not as flexible as it once was due to work hardening but it can be bent. Be careful not to kink that where it comes up out of that wall though. But yeah there is no reason for it to be along the roof , there are multiple products on the market to support that tube better than it is now.

I realize, that doesn't mean 4+ feet like in the pictures, but I wanted to ask as I'll be running my lineset soon.

@JUGHNE My attic isn't vented either in NW NJ and I don't have any moisture issues up there. I keep meaning to do something with it, but it keeps getting put off. Also, it's one of those things where, it doesn't have a problem, so I'm very cautious about making changes.

I'd like to install a fan that turns on around 95-100F, but I need some kind of fairly tight makeup air damper that closes when the fan shuts off.

@David107 I'd be more concerned about the ductwork size than the lineset. Do you have plenty of returns for the new system etc?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

-1 -

@ChrisJ, well currently there is only one return on the 2nd floor, not the best I know. Previous owners installed this decades ago...Not sure if possible in this old house to put a second return register but current one could be enlarged. With the insulation I think I would have an HRV or ERV installed for some fresh air makeup.

0 -

The other question that relates to this--maybe I should start another thread--is will the 200ºF temp of the foam for 10-15 minutes right after installation cause any problem for the rubber tubing, the two copper tubes, or the refrigerant inside? Should refrigerant be drained beforehand? All the installers say don't worry about it, but there are questions about the heat also effecting the Romex, etc. and also the foam's tight insulating qualities effecting the ability of the heat in the electrical wires to dissipate properly--they're usually just in air. I may have to move this AC refrigerant line laterally through the parapet wall where it would have to pass through four inches of the foam.0

-

Most recommend the suction line be brought up slightly higher than the top of the evaporator to help stop migration while the compressor is off, no?

I realize, that doesn't mean 4+ feet like in the pictures, but I wanted to ask as I'll be running my lineset soon.

Nothing wrong with piping above the evap , but like you said no need to cut a hole in the roof for the inverted trap. Better off with a hard shut off txv ( most BDP / Carrier ) or a solenoid if off cycle migration is a concern.

hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements