Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Heat transfer plate noise?

Options

Gooch

Member Posts: 62

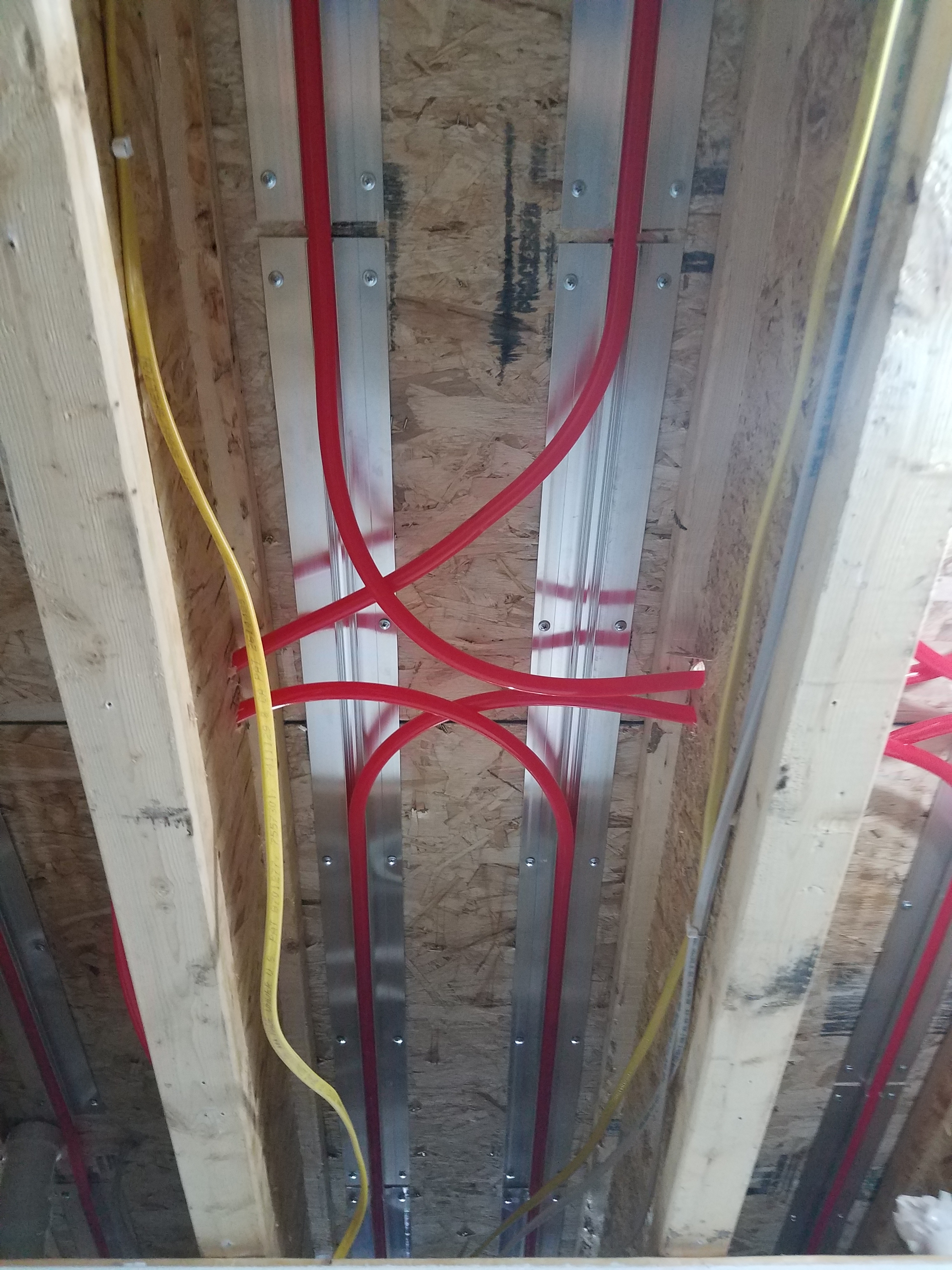

Just finished up installing transfer plates and pex to the underside of my subfloor for my main floor and I expected some noise and realize pex expands and don't expect to be able to eliminate it 100%. I have no squeeking, only thing I ever notice is some 'popping' or 'Clicking'. Is the sound I'm hearing the pex 'growing' in the track of the plates? I've got a few areas where the pex comes out of the track mid run(picture). Is this a noise issue? The only time I really notice it so far is on warmer days when there is no call of heat during the day and then in the evening on the first call for heat when the boiler sends water that it gets noisy for about a minute. I'm using ODR and by adjusting the lower end of the curve have quieted the floor down quite a bit already but if there is anything simple i can do before covering it up i'll tac

kle that aswell.

I understand PEX-AL-PEX would have been a better option but was concerned about kinking issues with trying to do a retro install.

Uponor joist track was used with pex universe PEX-B EVOH tubing.

kle that aswell.

I understand PEX-AL-PEX would have been a better option but was concerned about kinking issues with trying to do a retro install.

Uponor joist track was used with pex universe PEX-B EVOH tubing.

0

Comments

-

Pex rubbing against Pex as it heats up will make noise but its a better choice for plate jobs IMO.

I'd also double check to make sure all the plates screws are snug.

What supply water temp are you running at?Steve Minnich0 -

How tight was the tube fit? It should require a mallet or impact driver to install the tube. If so, it should not creak.

Some tube brands with a shiny EVOH barrier on the outside may allow some slipping, that may be the cause.

ODR or constant circulation limits that expansion and contraction.

Best to get it addressed before you cover up, it will haunt you Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Top of the reset is 110* F. Most days running around 100.

Did need to use a rubber mallet to install the tubing.

The surface of the tubing was shiny.

I agree I want to minimize the sound before covering it up.0 -

You might try the FAQ at www.radiantengineering.com

If you have tight control on the temperature swing, and the tube was a snug fit, that leaves the coating.

I know some of the tube manufacturers apply a PE coating over the shiny EVOH barrier to protect the O2 barrier. That takes the squeak out of transfer plate applications also.

Hate to see you have to re-tube, but....Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Is there some kind of compound (silicone or grease) I could put in the track and reinstall the tubing that wouldn't hurt heat transfer?0

-

What was the reason Uponor Hepex wasn't spec'd?0

-

Wouldn't it be better for the PEX to exit the plates at an actual plate end instead of just coming out of the groove mid plate?0

-

-

In the early days with the crappy, loose fit transfer plates you had to squeeze silicone adhesive in with the tube, same with some of the early Warmboard. A messy, messy job especially overhead.Gooch said:Is there some kind of compound (silicone or grease) I could put in the track and reinstall the tubing that wouldn't hurt heat transfer?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If I used silicone would that solve the issue in your opinion or would I be better off to retube it? If I did I'll make the effort to do it in pex-alpes and be done. But I want to avoid this mistake and what would you recommend for tube as my assumption that.pex is pex was wrong.0

-

-

I've never been able to get a thumbs up from a manufacturer regarding glues or adhesives on their tube. It's tricky to do, as too much silicone keeps the tube from clicking in tightly.Gooch said:If I used silicone would that solve the issue in your opinion or would I be better off to retube it? If I did I'll make the effort to do it in pex-alpes and be done. But I want to avoid this mistake and what would you recommend for tube as my assumption that.pex is pex was wrong.

If you don't have a lot of $$ in it, I would retube.

Uponor is a flexible, easy to install tube, and if it is their plates maybe that is best. If I were to guess those are Radiant Engineering plates? They advise against shiny barrier tube in their product, on their website.

You are correct PAP can be a bear to pull through a lot of holes without kinking. It helps to have a few extra hands to work PAP in overhead plates.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

-

I just don't want to have this issue if I retube it. He pex isn't cheap and if it still does it I might go crazy0

-

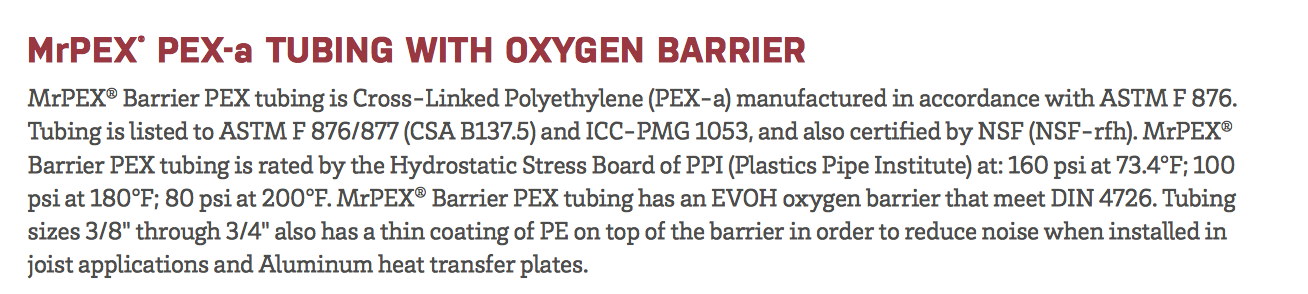

Mr Pex is another choice, Rehau also for Pex AGooch said:I just don't want to have this issue if I retube it. He pex isn't cheap and if it still does it I might go crazy

You want a tube with the PE overlay on the EVOH.

I have not used PERT, lower cost, maybe someone else has an opinion on that tube in plates?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

> @STEVEusaPA said:

> Are you sure you're not hearing the pex rubbing on the holes thru the joists?

It could be, and before I retube it I want to address this. Any recommendations? My thought was to take some 5/8 i.d. rubber hose and slit it and install through the holes.0 -

You might try some cut up pieces of plastic milk jug, it's nice and slippery.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

-

> @Stephen Minnich said:

> Pipe insulation is what I'd use. Again, I'd also make sure Pex is not rubbing against Pex anywhere. Ask me how I know this.

The cheap foam stuff? Or the more expensive neoprene stuff?0 -

I use the rubber type foam that we use on refrigerant lines.Steve Minnich0

-

Any issues experienced with the isolator talon straps?0

-

Yes but only with PAP and much higher water temps.Steve Minnich0

-

The pex against pex is more of a squeak sound. if you rub a few pieces together in your hand you will be able to identify that sound. It seems like you are hearing more of a metallic or pop sound?

Either the plates are moving against the floor, or the tube in the plate, is my guess. it looks like you have then screw tightly to the floor?

The real thin flashing thickness plates will make an oil can sound as the metal distorts.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The sound is more similar to that of a creak or pop ofor an old wood floor. Not metallic0

-

-

Any hole in the joist or TJIs should be generously sized. Most TJIs allow up to a 1-1/2 hole to be drilled anywhere in the web, it looks like you have some type of engineered joist, check their drilling chart.

The pre punched knockouts in those TJIs are 1-1/2"

Usually there is a distance required between multiple holes like you have.

With a large hole you have plenty of room to put 1/2 wall thickness insulation donuts in the hole.

Tube against wood is usually a squeak, or creaking sound not a pop. A pop seems like an expansion noise somewhere.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

http://www.siouxchief.com/products/support/supply-hangers/plastic-cts/cts-isolators/suspensulator

Would this work for the joists holes? Seems intended for it but dunno if it's meant for heating applications0 -

You can do a lot of holes with pipe insulation. Chop, chop.0

-

Overkill. The foam sleeves allow more movement compared to those.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok. Foam it is. Thanks0

-

Did the foam work? Did you find a solution?0

-

When we find that this will happen we cut the plates so we can travel right out of an end .hot rod_7 said:Sometime you need to jump out mid stream like that, for a weird layout.

I also notice that the holes the HePex is traveling through should have been larger . the pex has hit the backside and has no room to move anywhere but in the plates . expansion loops would have been niceYou didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

I had the same thing happen about 10 years ago (job was finished ,sheet rocked and painted). Plates have nothing to do with it. We had installed Zurn pex (never used that again) and it made the same popping sounds you are talking about. We switched it out to Uponor Hepex and not a single pop.

We ended up settling out of court and Zurn covered most of repair costs and what not.

0 -

Is that Everhot tubing? If so, the EVOH layer is on the outside and is pretty tacky. I did the same thing once upon a time and it did get quieter over time, but after a couple months I felt bad and replace the tubing with PERT. Quiet as a mouse0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements