Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Constant circulation with a coal boiler and CI radiators

Options

jrv8984

Member Posts: 45

Does anyone have any experience with Constant circulation and a coal boiler? Will it even work?

Treat this as a new install, in a 200+ year old stone Farm house.

AHS 260 Coal boiler is in the Garage roughly 300' or less round trip (1.25" pex-al-pex is already in the ground with a total of about 16" of closed cell foam surrounding it)

Cast iron radiators (currently only one is plumbed, so I can easily undo it and plumb them anyway I'd like)

70 gallon Vaughn Top Performer indirect hot water heater in the basement.

Is a low loss header (LLH) required? Or can I make this work without it?

is a particular brand of TRV better than others?

If I use an LLH should the indirect be plumbed into the supply before reaching the LLH, same goes for the dump zone?

Any best way to plumb the house, home run off of a radiant manifold? other ideas?

I believe I'll need a pressure activated bypass for the heating loop?

Anybody have any diagrams of their systems?

Thanks

Treat this as a new install, in a 200+ year old stone Farm house.

AHS 260 Coal boiler is in the Garage roughly 300' or less round trip (1.25" pex-al-pex is already in the ground with a total of about 16" of closed cell foam surrounding it)

Cast iron radiators (currently only one is plumbed, so I can easily undo it and plumb them anyway I'd like)

70 gallon Vaughn Top Performer indirect hot water heater in the basement.

Is a low loss header (LLH) required? Or can I make this work without it?

is a particular brand of TRV better than others?

If I use an LLH should the indirect be plumbed into the supply before reaching the LLH, same goes for the dump zone?

Any best way to plumb the house, home run off of a radiant manifold? other ideas?

I believe I'll need a pressure activated bypass for the heating loop?

Anybody have any diagrams of their systems?

Thanks

0

Comments

-

I'd recommend a primary secondary loop. You want to keep water moving 24/7 in the underground and through the boiler. After that with closely spaced T's you can do a deltaP circulator and zone valves to all your radiator zones. You can pipe them reverse return, direct return or home run. The Cadillac of systems (cast wise too) would be to use TRVs in each room.

There are other ways to pipe it depending on distances as well.

I would absolutly install a heat dump in the garage, either gravity circulated or at least with its own circulator in case of power or main circulator failure. Coal can run away if circumstances are right. Just as wood can.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

I need to stay away from ECM pumps in the house, unless there is one that is strictly DC for health reasons (don't ask). I could use one in the garage if needed though.

I was planning on using my basement as the dump zone until I can build a storage room in the garage, but now that I think about it, if the dump zone is in the garage I don't think TRV's in the basement would ever close, which wouldn't necessarily be a bad thing.

Can I do this with just a circulator at the boiler, or is a circulator on the secondary loop necessary?0 -

Like most things in the heating world you can get snazzy or keep it simple.

LLH, seems excessive. seems like a waste of money

If you don't want an ECM just leave one rad with no TRV.

As you stated you'll need to dump the heat if your home is fully warmed0 -

I was thinking that a LLH was a waste of money, but I'm not sure the best way to plumb it, have a bunch of ideas floating in my head, that I'll try to sketch out.

As it is my home will never be fully warmed for years, extensive restoration of the old farm house takes time (i.e. Currently Repointing the stone walls with lime mortar)

Ideally this would be a one circulator system, I realize that may not be the case though.

As to my question of how to plum the radiators, in my situation a home run scheme is pretty much my only option due to the design of the home. I will be tearing one addition down and rebuilding it, and possibly adding a second addition for the in-laws. When these things take place, I may be able to have up to 3 radiators on reverse return.

So in this situation would a radiant manifold be best, or should I make my own manifold from copper tees? If that's the case should I have all of my supply tees together and all my return tees together like a radiant manifold, or should it be supply and return, then supply and return, etc, etc?

When using TRV's is flow balancing to the radiators necessary, or can I skip that added expense?

Thanks

0 -

You can do it all with one circulator in the garage. Pump away from the expansion tank (circulator on supply) to your 1 1/4" pex to the house. In the house T in all your supplies then go to a differential bypass then T in all your returns, then back to garage. All your house zones will need regulating with either thermostats and zone valves or TRVs on radiators or some of each.

This is how I piped my wood gasification system to ensure adequate flow through the boiler but without any extra circulators. I still would, however, use a separate circulator like a 007 on a dump zone at the boiler in the garage.

Also, pipe the boiler in copper or black iron pipe then transition to your pex at least 10' from the boiler. One overheat situation and that plastic will not look like pipe anymore.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

I'm unaware of coal boiler operation, what's the max water temp? Don't torture your pex.0

-

Water is run at standard boiler Temps. 180f but with any solid fuelled boiler the fire cannot be turned off instantaneously. The possibility of boiling water, is high at some time during the life of any solid fuelled boiler.

I always pipe as much as possible in metal, leave pex for underground and distribution if one desires. But all hard pipe around boiler and dump zone should also be 100% metal pipe IMHO. Best practices.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

A small buffer tank is another option. It acts as the hydraulic separator, air & dirt removal, buffers the boiler, and allows you to pull the loads off via an outdoor reset control.

A two pipe buffer would also allow simple addition of a backup fossil filed boiler.

If you use a reverse indirect like a ThermoMax you get DHW as a side benefit.

Properly adjusted ODR will give you the constant circulation you are after.

You could zone a homerun system with TRV at each radiator for individual radiator control.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Here is an excellent read on piping and controlling biomass and buffer tank systems. It goes into detail on two pipe buffer tank piping and advantages.

http://www.nyserda.ny.gov/-/media/Files/EERP/Renewables/Biomass/biomass-hydronics-training.pdfBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don't know anything about coal boilers, but it would seem he has a perfect setup to dump heat with an uninsulated buried loop.0

-

I think the whole "heat dump" concept is a bit alarmist. Most modern fossil fueled boilers have a means to shut down or reduce the air needed to keep them from overheating. this works as the boiler hits setpoint or in the event of a prolonged power outage.

Unless you have air leaks, like around door gaskets the potential for a raging, runaway boiler is very rare.

A simple N.O. zone valve and a strip of fin tube is simple enough thermosiphon loop and requires no electricity, if the fear keeps you up at night.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

That's all I was talking about! Simple gravity dump above the boiler somewhere, even in the garage if not subject to freezing. Just no pex in that heat dump.

@hot rod I have to differ in opinion about for potential for run away. In the event of power outage, circulator failure etc. The potential for air to still be fed to the fire is too great IMHO. I've seen it more times than I have fingers on both hands. But admittedly most of those were with wood boilers. There are many Axman-Andersons in basements around here that have percolated.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

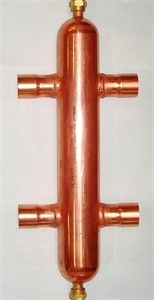

just some ideas floating around in my head, i'll try to comment on them later. Also found this LLH

newhorizonstore.com/Products/234-low-loss-headers.aspx

0 -

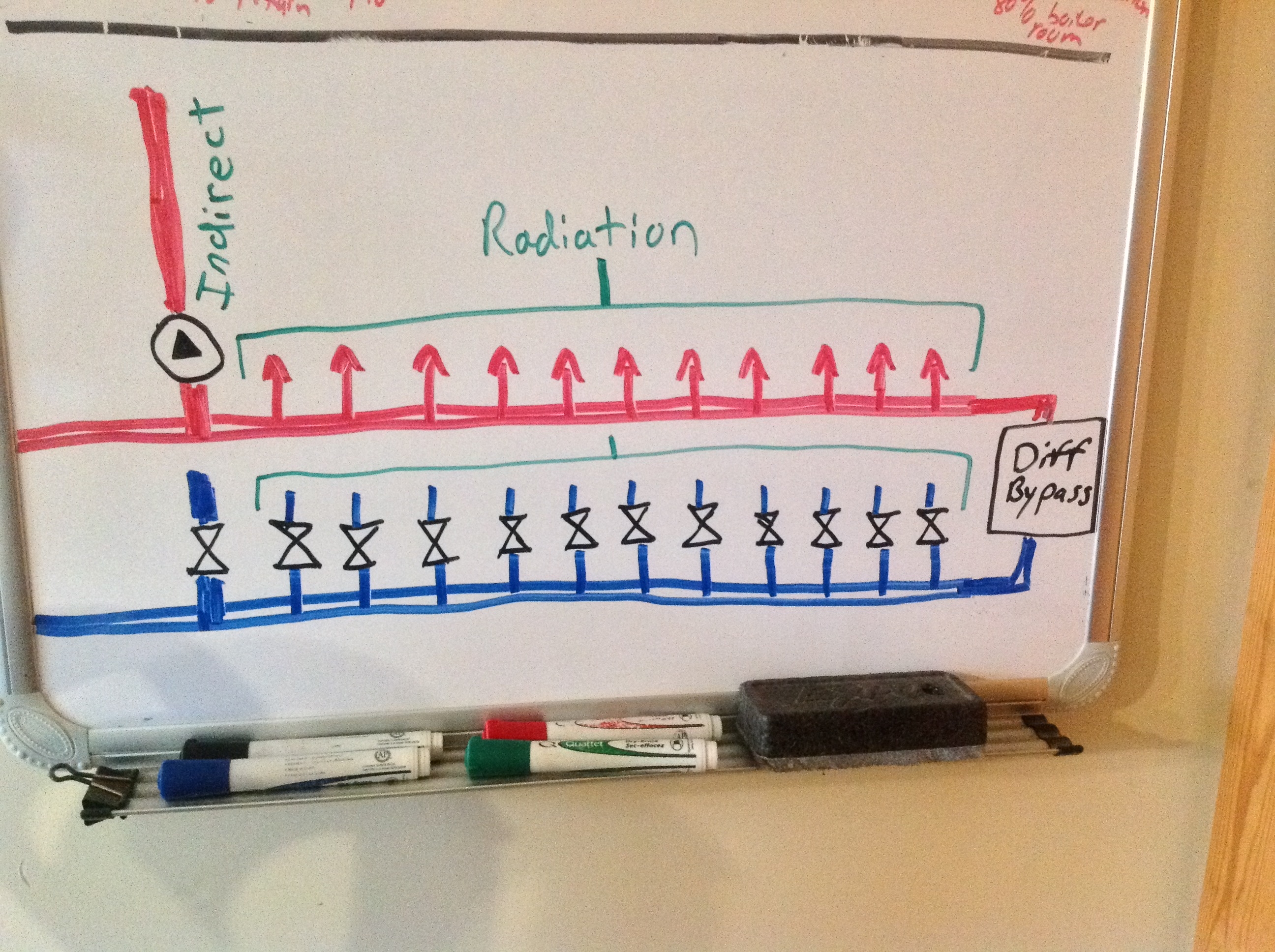

First drawing won't work.....Open the end of the loop and bring your return from the manifold down to the return to the boiler.

Second drawing won't work....Requires circ to the supply manifold.

Third drawing won't work.....Circuits off closely spaced tees require circs.0 -

This is a basic way to do it. With all circulators in garage.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

-

You can also have more circulators in the garage for attracting zone out there. The heat dump I show really should have a normally open zone valve and powered off boiler control, and a normally closed aquastat contacts, if boiler overheats breaking power to zone valve and dumping heat. Also In the event of power outage valve naturally opens.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

-

Is the diff bypass valve even needed in that design? If the TRV's are closed the water would just continue through the primary loop, won't it?

So if my supply is 1.25" and I'm using 3/4" to plumb the radiators how closely should my tee's be spaced, or should they be butted right up against eachother. Or I guess I could just use one of these

0 -

Without the differential bypass you will have no flow in the secondaries. So yes it is quintessential.

What I drew is a simple manifold system with the fewest components. It allows lots of flow through the boiler at all times, yet has the fewest circulators.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

Simple is good, but will it flow through the radiators well, or I guess that is part of what the bypass valve is for, to direct the flow up radiant loops, until the TRV's restrict flow enough that the pump gets close to dead heading, and then it opens.

So I was just thinking to use ball valves as a way to adjust the flow to the radiators since they're different sizes with unequal lengths of pipe, they're inexpensive and it's not like I have gauges to measure the flow, unless somebody has a better idea?0 -

So as far as the bypass valve, any recommendations?

As far as the dump zone, that is an area I want to maintain let's say 50 degrees, that's why I have the circulator, the zone valve makes sense in case of power failure. Guess I could plug that circulator into a ups somehow.

Suppose I could just have one pump for the time being with a zone valve and thermostat in the dump zone room.0 -

-

If the dump is intended to protect in a power outage also you might consider this piping. Or use a battery backup and UPS on a pumped dump loop. The thermal trap help prevent ghost flow also.

Large diameter fin tube and a bit of slope to it will assure gravity flow.

Include a boiler return temperature protection mechanism.

The ThermoBloc in the left drawing has a gravity gate built in to allow gravity over-heat protection, as long as some heat emitters are above the boiler piping it will thermosiphon.

Also know that the pressure bypass can be installed right after the pump instead at the end of the headers. No need to flow through the entire manifold length, it could save some heat loss energy for you.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Edited my last 3 posts0

-

Does the location of the bypass affect the flow to the radiators?0

-

Is a flow check necessary at the boiler if the circulator is going to be there pushing away from it?

Is it better to put a dirt separator between the expansion tank and circulator, or right before the return to the boiler?0 -

As long as you have the check in the circulator, or one downstream from it.

I prefer the dirt sep at the return to the boiler. Catch dirt before it gets into the boiler, pumps valves, etc.

If you plan on using ECM circs, use a magnetic dirt sep device.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Been looking at the pump curve charts, but looking for recommendations based on experience. Is a taco 011 sufficient for a 250 - 300' round trip to the boiler in addition to my longest radiation loop possibly being 150' round trip? Or is that overkill? Single radiator shouldn't need more than 2 gpm. The primary loop pex should be able to push 17gpm at a 20^T. Wasn't sure how to figure out the pump size for constant circulation.0

-

Bueller0

-

three things for pump sizing

How many GPM

The pressure drop of the entire curcit

Type of fluid.

GPM is basically how many BTU/hr you need to move

Pressure drop is all then pipe, fittings, valves, heat emitters in the loop

The size of then pex determines the pressure drop also. The main thing on that system is the size of that long underground loop, the diameter of the pex.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Inside diameter of my underground pipe is 1.26"+. That should be able to accommodate 160-170k btu (16-17gpm). Which is what I would like to be able to push into the house. If my primary loop piping maxes out at 300' that should be around 12.25' of head if my calculations are correct.

All of the house radiation loops will be supplied by 3/4" inside dia pex. Longest possible run when the house is finished should be 160' or less. So figure on radiator capable of 15-20k btu.

My figuring came up with needing around 14' of head @ 17 gpm.

This was all calculated at a 20^T.

I didn't know how it should be calculated for constant circulation since the radiation temp won't be yo-yo'ing.0 -

if design condition calls for 17 gpm, and the head works out to 14' It looks like the 0014 is a better choice. The 0011 is a higher head pump in my mind.

I'm a fan of ECM circulators these days, I think within the next few years PSC pumps will be obsoleted.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok, so a taco 0014, any recommendations for an delta-p ecm circ that will meet those requirements that isn't crazy expensive0

-

Is a Viridian 3452 my only option for an ecm pump0

-

The answer lies in the data

You could parallel a couple less expensive ECMs

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Is there anything between the Viridian 1816 and 3452 for ecm circulators?0

-

Should the ecm circs be wired to the tekmar 260 or just plug them in since I want constant circulation?

0 -

do i need a differential pressure bypass valve or some type of boiler protection valve if I am using ecm circs on constant circulation?0

-

If you use a delta P function on the pump it can be powered all the time. Most go into a sleep mode when not needed.

No need for a pressure bypass if you use delta P function.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The reason I suggested the fixed speed circulator and differential bypass was for flow through the boiler. I'm not familiar with the 260 it may not be sensitive to flow, as some solid-fuelled boilers can be. Check to be sure, as my word is certainly not gospel.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 19 Recall Announcements