Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Need advice, 20 degree difference between first floor and second floor one pipe stream furnace.

Options

BCEAGLES

Member Posts: 27

Hey Everyone,

New to the site,

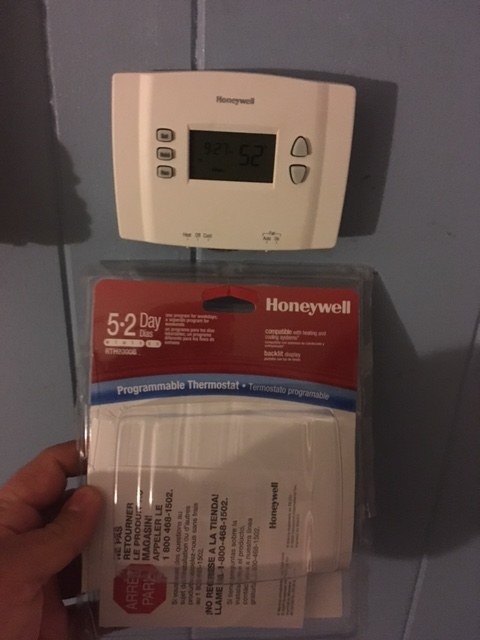

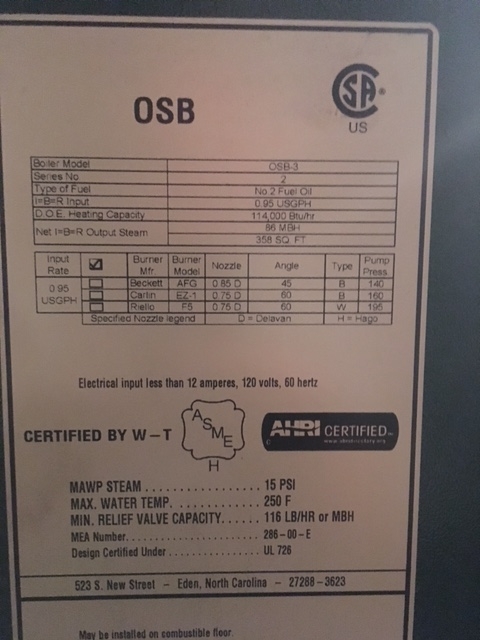

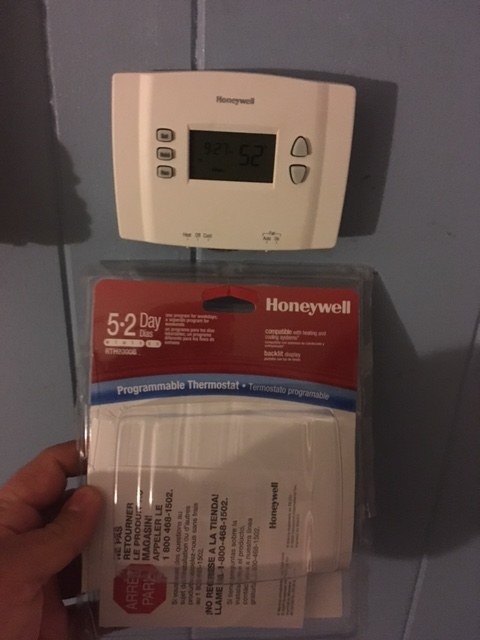

I have an issue with my steam system, a little background info, I just had a new oil fired furnace installed in the summer of 2015, its a one pipe system. its a two family house. I have 4 radiators on the first floor and 6 on the second floor. I took over this house after my grandfather passed away this year. I took care of him and he lived on the first floor and I live on the second floor. The first winter the furnace seemed to work fine, I have an adjustable thermostat put in and had it set to 68 in the mornings and 65 during the day. the second floor has always been a little warmer but nothing that felt unreasonable. The thermostat is located on the first floor. I started my furnace the first week of November and its been about 10 degrees different from the first floor to the second floor with the thermostat set at 55 degrees. Then about two and a half weeks ago it went to 15-20 degrees warmer on the second floor than the first floor. So now I have the thermostat set to 52 degrees and the second floor is 66-68. FYI no one is living on the first floor.

I have installed vent-rite adjustable vents on all the radiators. I recently took them all off and cleaned them with warm vinegar and I blew in all of them and they seem to be working. I have all of them set on venting the most air. I also replaced the batteries in the thermostat. I also put a table top thermostat in the same room as the wall mounted one just to make sure it was good and both were within 1 degree of each other. However I also just purchased a LUX touchscreen thermostat to replace the other one just in case.

from what I can see i do not have any main vents on the main and I take it there never was any. I have had the furnace skimmed several times and I have them coming again this Thursday to do it again. I have talked to my oil company and they seem to think the problem is as easy as just adjusting all the radiator valves in the second floor down to match the heat in the first floor.

I guess im scratching my head because this has never been an issue and even last winter with the new furnace it wasnt an issue. the first floor was always 65-68 degrees but the second floor was never 85-90. so why all of a sudden an imbalance? it also seems to be going through a lot of fuel for a temperature set at 52 degrees. full tank starting in November and just had to order another 150 gallons.

any suggestions on what I can do? or where to look?

New to the site,

I have an issue with my steam system, a little background info, I just had a new oil fired furnace installed in the summer of 2015, its a one pipe system. its a two family house. I have 4 radiators on the first floor and 6 on the second floor. I took over this house after my grandfather passed away this year. I took care of him and he lived on the first floor and I live on the second floor. The first winter the furnace seemed to work fine, I have an adjustable thermostat put in and had it set to 68 in the mornings and 65 during the day. the second floor has always been a little warmer but nothing that felt unreasonable. The thermostat is located on the first floor. I started my furnace the first week of November and its been about 10 degrees different from the first floor to the second floor with the thermostat set at 55 degrees. Then about two and a half weeks ago it went to 15-20 degrees warmer on the second floor than the first floor. So now I have the thermostat set to 52 degrees and the second floor is 66-68. FYI no one is living on the first floor.

I have installed vent-rite adjustable vents on all the radiators. I recently took them all off and cleaned them with warm vinegar and I blew in all of them and they seem to be working. I have all of them set on venting the most air. I also replaced the batteries in the thermostat. I also put a table top thermostat in the same room as the wall mounted one just to make sure it was good and both were within 1 degree of each other. However I also just purchased a LUX touchscreen thermostat to replace the other one just in case.

from what I can see i do not have any main vents on the main and I take it there never was any. I have had the furnace skimmed several times and I have them coming again this Thursday to do it again. I have talked to my oil company and they seem to think the problem is as easy as just adjusting all the radiator valves in the second floor down to match the heat in the first floor.

I guess im scratching my head because this has never been an issue and even last winter with the new furnace it wasnt an issue. the first floor was always 65-68 degrees but the second floor was never 85-90. so why all of a sudden an imbalance? it also seems to be going through a lot of fuel for a temperature set at 52 degrees. full tank starting in November and just had to order another 150 gallons.

any suggestions on what I can do? or where to look?

0

Comments

-

What pressure is the boiler running at when making steam? Does the water in the sight glass bounce around a lot when making steam?

You need to have main vents installed in the basement, how long are the steam mains and about what diameter is the pipe? Don't let them use wimpy vents, you want to vent the mains FAST.

You might be able to balance the floors by adjusting the venting rates of the two floors, slow the vent rate of the warm floor or increase the rate of the cool floor. Do this AFTER getting main vents installed.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Could be lots of things, but steam is rarely linear. Try setting the first floor back to 68º and observe what happens to the second floor as an experiment.

Where are you located? Perhaps someone here can pay a visit and look at the venting.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Hey Bob,

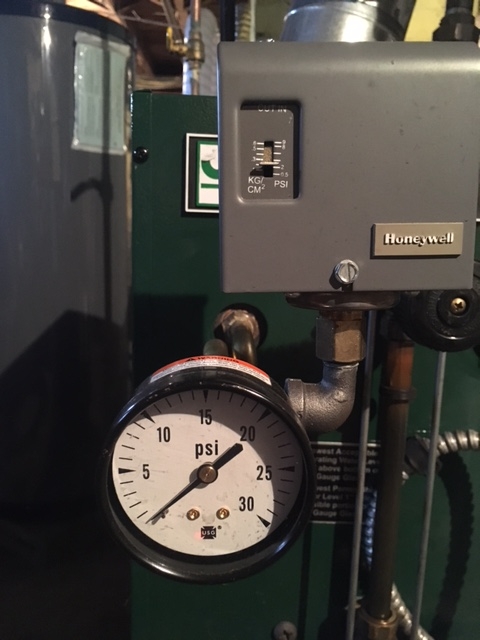

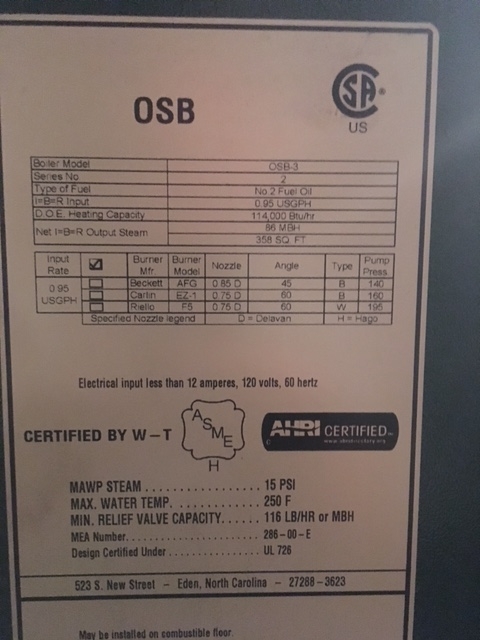

as for the pressure, the gauge is a 30psi and I have never seen it move. I have included a picture and the picture was taken when the furnace was on for about 20 mins. The water in the glass does move around, im not sure what a lot is? I have included some pictures of the pipes and a very crude diagram of the layout, its drawn as if you were looking down on top of the system.

the pipe length is approximately 22ft going to the rear of the house, 10ft 8 inches going to the left side and 11ft 6 inches going to the right. these numbers do not inlcude the smaller pipe that travel to the radiators.

the oil company said something about putting 35's on the main vent when I was talking with them, doesnt seem right. How much does adding main vents typically cost?

RI_Steamworks

I live in mass, when I had the first floor set at 58 the second floor would get to 80. so far the only way to keep second floor at 65-68 is to keep the first at 52 degrees

0 -

-

It looks like the boiler piping and the mains are 2" pipe. Is the steam main just one big loop or does it go back and then branch left and right? If the main T's to the left and right which way do those branches slope?

Does the main start high at the boiler and slowly slope down as it travels along (parallel flow) or does it start lower and slowly rise as it travels away from the boiler (counter flow) ?

The pigtail beneath the pressure gauge and the pressuretrol can get plugged, if that happens they can no longer see whats going on inside the boiler. Has that pigtail been checked or cleaned since the boiler was installed? The skim port for that boiler is the plug to the right of the top of the gauge glass, is that where they are skimming from? It often takes several skim sessions to get all the oils out of the water and each one takes a few hours. If they installed a skim port you could do that yourself.

the pigtail should be checked to make sure it's not plugged. The pressuretrol should be turned down as low as it will go and the white wheel inside the pressuretrol should be set to one, that will let the boiler run between 1 and 1.5 PSI.

If the system is just one loop a #35 main vent is probably too small, you would need at least a Gorton #1 (equals about 3 VentRite 35's) and you might want a Barnes and Jones Bigmouth or Gorton #2.

If the main does split and go left and right you would need a vent at the ends of the split. Sketch us a simple diagram showing the pipe layout of the main.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Hey bob,

thanks for the replies, my post and pictures seem to be gone?? I will try to re post them when I get home. I will also look again to seem the slope of the pipes.

The boiler has been skimmed about 6 times now, sometime they come and are here for 15-20 mins and a few times the guy is here 30-45 mins. its always a different guy. I watched one guy and the guy puts a pipe into the port that is next to the glass to drain the dirty water from. they drain it until it looks clean and then replace or clean the glass.

on a side note they dump the hot water in my sump and they killed my sump pump which they will replace.0 -

-

RI_SteamWorks

I am from Mass, when I put the 1st floor to 58 the second floor jumps to 80 degrees over time.0 -

BobC

After looking at the pipes they all seem to slant back toward the furnace. The first pipe that has a 90 degree angle goes toward the back of the house and it slants back towards the furnace, the second pipe that goes all the way across the house slants from right to left (higher on right and lower on left side) and there is a much smaller pipe that slants back to the furnace ( higher on left and lower on right towards furnace)0 -

How bigger are 6 rads on 2nd floor from 4 on 1st? And is pipe to 2nd floor (rad riser) larger than pipe to 1st floor rads (it should be)? Do all rads get hot when furnace is firing or are they cooler on 1st floor? I'm guessing 1st floor rads are not getting as hot, correct? If so, balancing has to be fixed. But if also as hot, did you check if they get hot at the same time as 2nd fl? Are all windows closed on the 1st floor? Are all 1st floor rad valves working? (I know, but you never know - couple of them windows cracked open, couple rad valves closed or happen to have a broken valve stem?)

Also, your pressuretrol seems set extra high. Roll that down as low as it'll get and set the inside wheel to 1. Those units can be notoriously inaccurate. Also, that pressure gauge is way too big to show correct pressure so you can see what is exactly going on. Get at least another 3 psi gauge if not also a vaporstat.

Remember, steam will go the path of least resistance, and high pressures slow down steam and eat more fuel. All else equal, steam will go to larger pipes first (2nd floor rads), then to wherever air gets out of the way quickest. All those places on your branches you have caps, you can install vents. Big mouths or Hoffman 75, Gorton 2. Get the air out of the way.

As to fuel, some of it may have to do with pressure. If you are making 3 or 4 or 5 psi when you only need 10oz, this will waste a lot of fuel. Esp. if you don't have main vents. Your old furnace may have had less volume of steam per hour which would have allowed that steam to get where it's going slower and on lower pressure. Your new boiler may have been operating with oils in it, restricting steam production and in essence slowing it down some. Then you flushed it, or partially skimmed and now it's creating more steam. This too may be an issue with new cleaned furnace creating more steam quicker and it going to where it can before pressure builds, so now it takes longer for steam to reach the rad (more steam made quicker), air is too slow to get out of the way = higher pressure with less steam in the system = takes more time = more fuel spent while cycling on too high of pressure while also waiting to satisfy the thermostat on an unbalanced system.

Also, have someone check your barometric damper and combustion (either the guys who installed it or 2nd opinion). I'm not sure if it's letting in too much or too little air into burners and this may also cause excess fuel consumption, in addition to perhaps CO issues (but probably it's overdrafting).

If you say guys skimmed boiler for 45 min, that's not skimming. That's flushing. Unless they skimmed for hours when the unit was installed. As explained above, better water quality in the boiler may have brought balancing to the foreground.

How's your water after a few days? How's water level sight glass? Is water calm? Dirty?How often do you add fresh water? This may also be related to not that great checkout procedure durin install and service calls: not skimmed properly, too high op pressure (can't really help if venting not adequate), barometric damper not set using proper procedures...

So, it can be a few parallel issues. Try venting the mains better, then slow down rad vents on 2nd floor and open them up on 1st floor. Without a main vents, your rad heating sequence will depend on rad venting, size of pipe to rad, distance of both rad to main, and rad riser at main to boiler. Shortest distance/largest pipe and ratio of 2 to boiler = first rad to heat.

Final thought: replace tstat. I've seen strange things happening bc of bad tstat. Get a 20 buck 2 or 3 wire mechanical one and see what it does.

Hope this makes sense.0 -

Oh, and as bobc said, check that main pipes pitch is good. It probably is if all worked fine with old boiler. You didn't mention banging pipes or water coming out of rads.0

-

MilanD,

Thanks for your input, I dont have any banging pipes or from what I can see water coming out of the rads. the rads on the first floor are smaller than the second floor. the second floor rads get hotter and faster than the first floor. if you look at my drawing I list the pipes that go to the first floor rads and the second floor rads. they are a mix on each main, so the pipe size is the same for both. appears to be a 2" pipe for main and a smaller pipe leading to the rads.

I just had the boiler skimmed again, and had the psi gauge checked and the pig tail checked. bother are working and clean. I had them adjust the pressuretrol down, it seems to be set just below the 2 and above the .5. the inside wheel is set to 1.

0 -

- Make sure the System Pressure is .5 PSI Cut-in and "1" Differential

- Make sure the Pigtail under the Pressuretrol is not clogged so the Pressuretrol can see the pressure.

- Make sure you have good, balanced venting on both mains. If you have good venting on the main that feeds most of the rads on the 2nd floor and marginal or no venting on the main that feeds most of the rads on the first floor, the 2nd floor will get steam first and consequently for a longer period, making those rads hotter and with more residual heat after the boiler shuts down.

- After getting the mains properly vented/balanced, Make sure the radiator vents are balanced. Vent Rads slowly. Slower on the 2nd floor, in your case.

- Make sure your thermostat, if programmable, is set properly. CPH set to "1 CPH" and that the thermostat is in a location that is fairly representative of the ambient temp on that floor. Also make sure their isn't a large hole behind the tstat, where the wiring comes through the wall, allowing a draft behind the tstat.

- Don't overlook any of the above as irrelevant or insignificant.0 -

@BCEAGLES

I saw the drawing and that's why I was wondering if it's just a matter of steam getting upstairs at a far greater ease than downstairs, being all risers are all on the same 2 mains. To me all this sounds like air blockage... and perhaps smaller rads downstairs now somehow not giving out enough BTUs to keep the place warm.

Pipe to 2nd floor is longer, so logic would say, all else equal (venting at the rad and pipe diameter), downstairs would get warmer sooner. However, the pipes are probably wider to 2nd floor (maybe 1 1/4 vs 1 or, harder to spot, 1 1/2 to 1 1/4 difference) - if you check, there may be a reduction only at the radiator nipple/valve... I have few of those at work.

Then, the rad may be somehow venting quicker upstairs. Dial it down and open the 1st floor up. There is no logical explanation other than venting in terms of how soon rads get hot. Other thing may be that something changed downstairs and now steam is not getting there as easily as last year. Thus, broken vent, valve stem... got to check it out.

I really think/hope with increased venting, at least to the end of mains where they are capped, things will improve. Also, you may do something like this at the downstairs radiators to help them vent:

https://goo.gl/photos/799jcdx7B42Py8Hf9 @ChrisJ has this on one of his posts - helps vent the longer runs... For this you have to be very careful. You could instead, add a tee and then get the vent between the riser and the radiator valve. I'm in the process of building one like that right now.

Good luck and stay warm!1 -

-

IF you really want to get into this deep, see what EDR/BTU rad output downstairs is against design temp. Is it enough to heat the space? Your grandpa might have liked it cool and just put-up with it being cooler. Old timers who lived through a war or two or grew up with parents who lived through the 1920-30s had thick skin.

After you balance everything out, you may end up having to shuffle some rads around, or get bigger ones for the downstairs. Piano movers might make a quick job of moving these around for you safely.0 -

Just a suggestion but if you are going to be using and working with this system buy the books "We Got Steam Heat" and "The Lost Art of Steam Heating" and read them. By doing so you will understand your system in detail much more than the oil people who are telling you to close down the radiator valves on the second floor. Radiator valves on a one pipe steam system are either fully open or fully shut, it doesn't work any other way. You control the heat by adjusting the vent rate on the radiator or replacing it with a thermostatic vent. By buying the books you will be doing yourself a huge favor.

0 -

-

Where is the nice fella that did the install? Won't he help you.....0

-

J a

The people that have been skimming the boiler are the ones who installed it. I have talked with the techs many times and they are the ones telling me to just turn down the vents on the rads on the second floor.

I asked them about putting vents on the mains and they said its unnecessary. I feel that adjusting the vents on the second floor is a final step after the system is balanced. but maybe im wrong.-1 -

Contact Velocity plumbing he's one of my old students and well versed in Steam..he is located in Quincy Mass...6179384471...not sure how far he will travel..call him Monday if you want....What part of Mass are u in.0

-

MilanD,

Thanks for the info, I have all the rads fully venting. I just purchased some more vent-rite #1 vents to install on the first floor just to make sure. All the rads in the house heat up so would that rule out a blockage? I did mention this to the service tech that came to clean the boiler and he said I was reaching way outside the box.

I also readjusted the Pressuretrol System Pressure is .5 PSI Cut-in and "1" Differential. the pig tail is clean and not clogged.

Im also going to install a new LUX touch screen thermostat after Christmas just to cover my bases.0 -

You must have main vents before you have any hopes of properly balancing the system. The company telling you, you don't need them is clueless.0

-

@BCEAGLES

You must vent mains, as others have mentioned too.

Then, balancing.

In the meantime you can attempt to push more steam downstairs by adjusting rad venting alone, greater venting to downstairs, slower upstairs. But, slow venting of mains will waste a lot of fuel while cycling on pressure and until all air is expelled from the system throug the rads alone. It can be done, but to what end when main vents will only need a few nipples and a reducer to mount on the existing caps, with a minimal cost and much greater comfort and savings in fuel.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements