Hydronics and Computers....

The design idea is pretty straight forward. You have a 'waterblock' that sits in close contact with the part needing cooling using thermal paste, water is pumped through the waterblock, to a radiator (essentially the same as any AC coil or car radiator you have seen, basic fin tube design) that exhausts air from the inside of the computer case over the radiator using a fan. Simple hydronic circuit. Most custom water cooling set ups have a fluid reservoir somewhere in the loop as well, and a pump obviously.

What struck me first was the fact that pretty much every single one of the guides I read stated that the best way to do this was to make a single loop. Reservoir to CPU waterblock, to GPU waterblock, to pump, to radiator, back to reservoir. Well first of all, for optimal performance, it struck me that it would be bad to do a series loop like this. Also, since the reservoir has an air space in it, it is acting as the expansion tank as well, and should be pumped away from, especially considering most of these are operating at or near 0 psi (static when cold) with pumps that can actually produce up to 15 or 16 feet of head with max flows (at 0 head I'm assuming) of 5 or 6 GPM! (no joke, these pumps are pretty amazing considering their size of about a 2" cube). The common consensus online seemed to be that a parallel loop sounds good on paper as you will deliver colder water to each component, but because you are splitting the flow it would not work very well and trying to balance flow between components becomes impossible. With series you will always get the full flow through each component.....

Another thing that came up was that it was supposedly very important to install the pump after the CPU/GPU in the loop to ensure that the pump did not add heat to the water before hitting the units to be cooled. Further reading found all the complaints about how their pumps are noisier than they like, and how they are so glad they installed them downstream of the CPU/GPU because it was getting so hot.

Here is where I started laughing....

So to sum up, we have high head, vastly oversized pumps, pumping against a series loop of high resistance components, using 1/4" ID tubing (did I mention that?) pumping towards the PONC, with virtually no NPSH, and its a mystery as to why some of these systems are not performing up to expectations, and pumps are noisy and hot.

I decided to apply my knowledge and build a system that actually works. Unfortunately some of the calculations are going to be educated guesses as the important things to know, such as the Cv of a particular component, or even a real pump curve are things that I cannot even get from the manufacturers of the components yet. Still trying. Most of the pump data I have found gives a maximum head and a flow rate (I assume it is the rate at 0 head, but I have no idea) nothing more. I am hopeful that I can get something more useful, we will see.

My idea is basically use the reservoir as a hydro sep, pump a parallel reverse return loop to the CPU/GPU using generously sized tubing and few fittings, then pump a separate loop on the other side of the reservoir to the radiator. Use the reservoir (water heater tank shaped, smaller obviously) to try and create some level of stratification and keep the coldest water low (radiator to reservoir, and supply to system) and the hottest water high (system return to reservoir, and reservoir to radiator). Should work to my advantage as long as the radiator flow is higher than the system flow. After much digging I found one reservoir that has all the tappings that I need and a short dip tube so that I can have an air gap in the reservoir, and still be able to pump out of the top of it. Thinking about adding a fitting into the system at the top of the reservoir so I can add at least a little bit of static pressure to the system, though I will have to be careful as most components are rated for no more than 14 or maybe 16 psi. Thinking of maybe 3-5 psi static cold, and aim for a top pressure with everything as hot as It can get of about 7-8 psi. Will generously over size the radiator, and leave it completely outside of the computer case using room air to cool instead of using already warmed air from the computer case. The oversized rad allows me to run the fans for it at a low speed even under high load, and thus this thing will be very quiet. Using this approach I can then use the on-board PWM fan/pump control built into the mother board to adjust the flow through the radiator and the flow through the system independently and thus achieve the maximum efficiency, and the best cooling.

Just thought I would share, never thought Hydronics would help me build computers!

I would love other ideas and thoughts too, if anyone cares to comment or has any experience with PC water cooling systems

Comments

-

FWIW- the CPU's have advanced so much over the past few years- top of the line core i7 CPU's (4 logical cores 8 threads) don't even require water cooling unless stressed to the max for hrs on end for hi-end gaming systems.

If you're building a gaming system- water cooling would be a plus. For desktop computing including CAD/graphics air cooling is perfectly fine.

I've put quite a few core i3 and i5 Intel Nuc's together for clients lately and they absolutely love them. SSD M.2 solid state drives means complete silence and no moving parts in a computer no bigger than two slices of wonder bread stacked on top of each other.0 -

I agree, that NUC6i5SYK with an NVMe SSD really rocks. I've got a couple of serious CAD drafters who just love them.

A fanless server could be fun. With the Xeon-D's miniscule power budget, the bulk of the effort would be spent on cooling the storage components.0 -

Water cooling was big years ago, but in my opinion has died off big time. Modern processors don't produce the heat older ones did. I'm running a 120W AMD at work from 2008. Around 2008-2009 AMD had a 140W version as well.

I'd say it peaked around 2006-2008?

Doesn't mean you can't still have fun with it. It certainly can keep dust out of the machine and water cooling still looks awesome.

Back in the mid 2000s, I wanted to build a refrigerated rig but never got around to it.

The last non-gaming rigs I built for friends were the quietest and smallest ones I've ever built and they were some of the fastest.

Modern processors are quite impressive when it comes to power consumption.

One thing I insist on now is a decent SSD for the OS and programs and then a large 2-4TB mechanical drive for photos and music.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@NY_Rob

This is going to be a gaming build, Planning on overclocking the i7 5820k to somewhere around 4.5 or 4.7Ghz or so if I can get away with it, that combined with a Nvidia GTX1080 water cooling is making sense. Building this with the possibility of VR and multiple SLI graphics cards in the future.

The last time I built a gaming rig, I was really excited to be putting in 256 MB of Ram, going with 32GB on this one. Crazy how stuff changes. I was just really surprised at how poorly designed most of the custom water cooling gaming setups seem to be. Unless I'm missing something, most people are more concerned with looks than anything else, and just assume that it will cool well because 'water cooling is better'.0 -

Yes.delta T said:@NY_Rob

This is going to be a gaming build, Planning on overclocking the i7 5820k to somewhere around 4.5 or 4.7Ghz or so if I can get away with it, that combined with a Nvidia GTX1080 water cooling is making sense. Building this with the possibility of VR and multiple SLI graphics cards in the future.

The last time I built a gaming rig, I was really excited to be putting in 256 MB of Ram, going with 32GB on this one. Crazy how stuff changes. I was just really surprised at how poorly designed most of the custom water cooling gaming setups seem to be. Unless I'm missing something, most people are more concerned with looks than anything else, and just assume that it will cool well because 'water cooling is better'.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I remember reading a cpu was clocked at 8 GHz using liquid helium cooling.

They only had to boot and report the clock speed. If you tried to use it it would probably explode.0 -

@ChrisJ

I've always thought about a refrigerated one, seems logical, as if there was ever a leak, it wouldn't ruin anything. Don't know if it would be power prohibitive, or maybe sound prohibitive? Seems like it could be done with the recent advances in variable speed compressors and the like.....1 -

@delta T

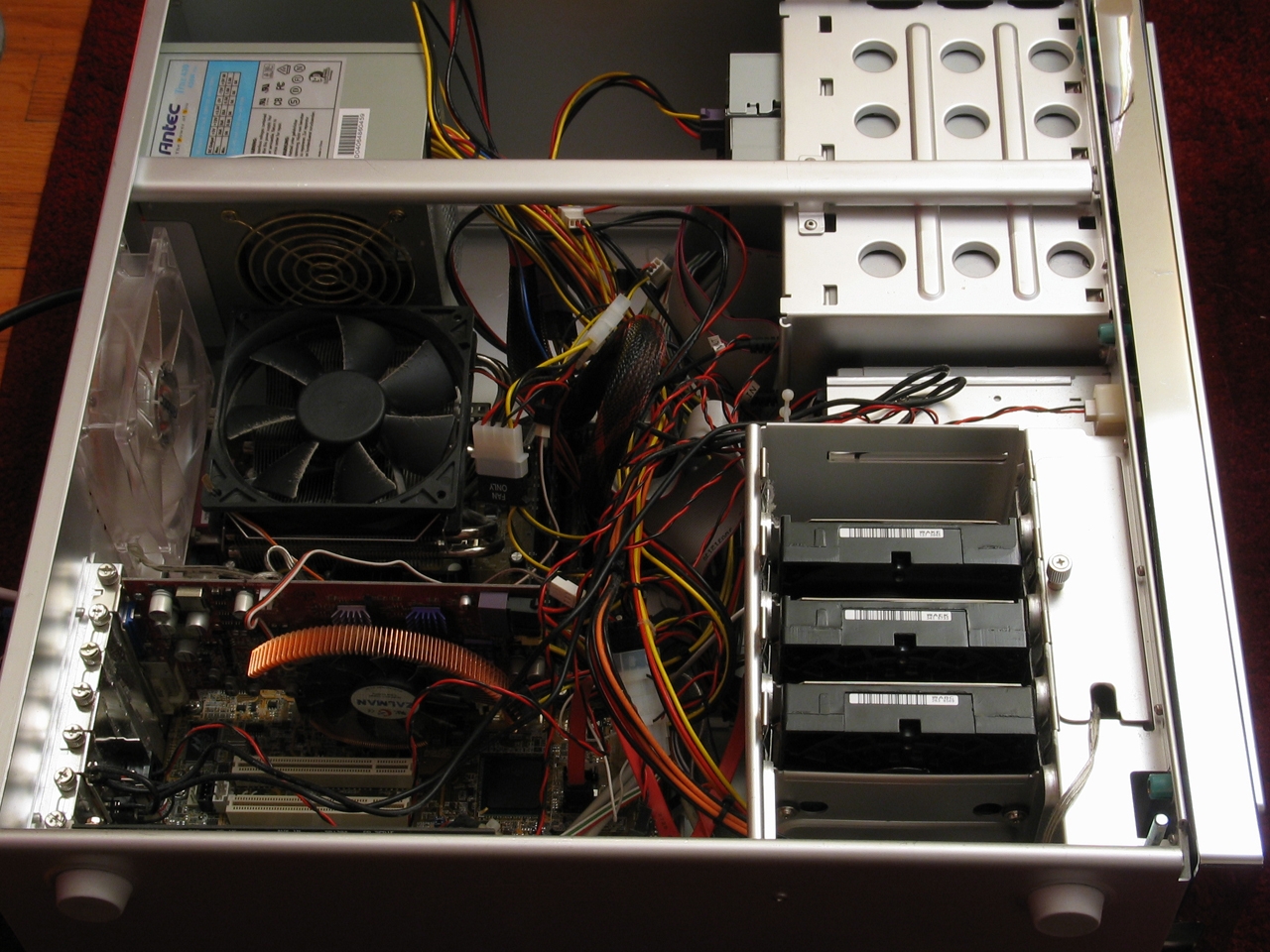

Here are my two "best" builds that were for gaming.

This was a 2004 Intel P4 3E that was overclocked big time. People complained it dissipated too much heat to overclock, but I pulled it off. I also had an X800XTPE which, at the time was selling for over $800 on Ebay as it was hard to find.

Here's my current machine, which is getting really dated. Built it back in 2009 and it's stock speeds are 2.66 x4 but I built it to run at 4.0 x 4.

It's been updated since 2009, it now has an SSD + large mechanical drive and I went up to 12 GB of ram at one point.

When it comes to fans I've been strictly a 120mm guy since 2003 or so. Smaller ones are just too loud.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I've heard of a couple liquid Nitrogen ones going to 6.5 or so reliably, 8 is crazy!0

-

I can remember buying a 486-33 computer with 16MB of ram for the company to run VersaCad. A cad file that took almost 5 minutes to open on a 386-20 opened up in 20 seconds flat on the new machine (Gateway). That machine cost $2,400 back in late 1990 and that did not include a monitor.

The machines we can buy now are lightyears ahead of that but realistically the software we run has not changed all that much and the speed is wasted on most apps. Lotus 123 and Wordperfect run faster on my old 486 with 4mb of ram than Microsoft office does on my i5 with 8gb of ram - not much progress considering the 16 years that have passed. Programs that used to fit on 2 or 3 1.44mb disks now take a couple of 680mb CD's, the coding is terribly inefficient. Hardware has gotten so cheap that nobody even tries to write tight code.

Gaming and video file trans-coding are two exceptions, you do need a lot of speed for them.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge2 -

It's an Intel I5 750. Was the first generation of it and I think it's an LGA-1156 socket that had huge failures early on. I got lucky and ended up with a non-Foxconn made connector. I think EVGA used a LOTES brand connector or something, but I'm trying to remember a long time ago.delta T said:@ChrisJ nice! good lifespan if its still chugging after almost 8 years!

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Interesting read here. For those who don't know, we spend a SIGNIFICANT amount of money, cooling server farms, only to waste the free heat to the ambient.

Imagine if you will, a server farm that transfers its heat directly to a radiantly heated building, thereby eliminating much of he current waste associated with cooling these processors. Last I'd read, they were using a refrigerant, which if it leaks will not destroy any of the PC boards or processors. I believe Google is heating their business campus from their wast heat from their server farm out in California if memory serves me correctly. Park a hot water intensive manufacturer next to a server farm and sell them the recovered heat at a discount over what they'd pay for it in the form of raw energy, and you have an enterprise.

Thi makes perfect sense with a ground source vertical bore hole system. Probably wouldn't even need any refrigerant compressors to run at all.

Hydronics rules!

ME3 -

Or maybe district snow melt systems......and then use it the summer for a thermally driven absorbtion chiller to cool the building. So many possibilities.....

Agreed, Hydoronics does rule!0 -

Just keep in mind, Steam is also part of hydronics.

So yeah, I'll concur.

Most of my computers have used multiple heatpipes which I also relate to steam in a sense. Sadly, we found a heat pipe on an Asus motherboard's chipset actually used water. Ran damn hot, but once you hit the boiling point it transferred heat fairly well. I think it was around 180-190F so I guess they had a slight vacuum in the pipe.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

@Mark Eatherton - I wish I had more room in my basement!

The end of this article references an April Fool's joke about requiring large-screen televisions to list their BTUH :-)

http://www.greenbuildingadvisor.com/blogs/dept/building-science/using-server-farms-heat-buildings

This Dutch start-up distributes their computing to people's homes (casting unneeded heat outside and running dummy computations when more heat is needed :-)

http://www.bbc.com/news/magazine-32816775

A lot more articles out there - fascinating idea.

m

Triangle Tube Prestige Solo 110 with Trimax Controls (3x oversized)

950 sqft of WarmBoard on 3 floors, 5 loops acting as one zone0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements