Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Condensation? Return water temperature vs Boiler temperature

Options

BBros

Member Posts: 41

Could someone explain the difference? I've read dozens of things and still don't understand.

Oil-fired low-mass cast iron boiler. What's the danger to allow 100-120dg mixed return water to flow into a boiler, while it's on standby and run the boiler temp down to 130ish. If the boiler is rated for cold-start and can maintain above 130 always, then what's the issue? Is the problem if the boiler can't maintain temp, and stays sub-130, that's when condensation happens? Because in my case, when it fires it will still be getting that low water temp for a short while, but it easily comes up to temp... in fact the cycle takes 2-3min right now. I'm looking at adding mass to the boiler loop.

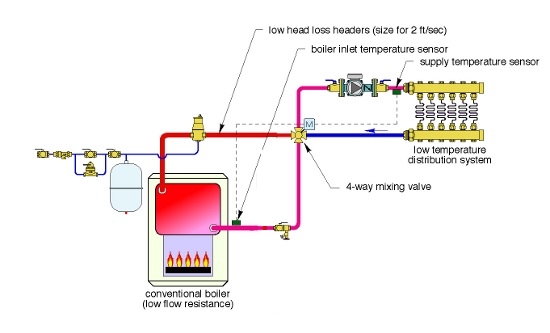

If I stop this action, by having the "smart" mixing valve shut down when return temps go below 135, then it's essentially always shut, and the low-temp system loop stalls out at too low of a temperature, and the boiler never cools down. The system fails essentially, yet it's designed exactly like figure 6-11 in idronics 7, like textbook style.

So which is really the important number? Return water or sustained boiler temp?

Oil-fired low-mass cast iron boiler. What's the danger to allow 100-120dg mixed return water to flow into a boiler, while it's on standby and run the boiler temp down to 130ish. If the boiler is rated for cold-start and can maintain above 130 always, then what's the issue? Is the problem if the boiler can't maintain temp, and stays sub-130, that's when condensation happens? Because in my case, when it fires it will still be getting that low water temp for a short while, but it easily comes up to temp... in fact the cycle takes 2-3min right now. I'm looking at adding mass to the boiler loop.

If I stop this action, by having the "smart" mixing valve shut down when return temps go below 135, then it's essentially always shut, and the low-temp system loop stalls out at too low of a temperature, and the boiler never cools down. The system fails essentially, yet it's designed exactly like figure 6-11 in idronics 7, like textbook style.

So which is really the important number? Return water or sustained boiler temp?

0

Comments

-

Cast iron boiler you should maintain a minimum of 140F return water temp.... always....ive seen CI boilers on low temp radiant systems fail in 2 years without boiler protection.... can you post the pic of the drawing in the idronics?..... what type of emitters you have? Radiators, baseboard, infloor?.....is the whole system low temp?ASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company0 -

A smart mixing valve for boiler protection simply mixes the hotter supply water with the return water to maintain 130 plus return water temp. It does not shut down the boiler if what I think you are assuming is correct.

The boiler if cold start will always go through a period of condensation until it gets above 130. The faster it gets above 130 the better, and staying above 130 at shut down until it cools off is fine.

Some photos of the boiler piping would help, and what kind of emitters are used.0 -

I didn't mean the boiler shut down when the valve rotates, rather the system loop gets isolated entirely, the boiler satisfies. In the end the system side barely gets water injection, thus it never heats up.

Whole system is low-temp, 6 loops, all to cast iron american radiator cortos, two-pipe w/trvs. This is what I've got, albeit in mirror-image form. I don't have any actual photos at this time, and I'm not on site to take them.

Taco vt2218 and i-series 4-way w/odr. Boiler is Trio 79k net (3.5gal capacity?) also with odr through a hydrostat 3250. It just seems to short-circuit it's self. At design (0F), I should be pushing 150F. Currently it's about 45F outside, and the i-series is set at 1.2 aiming for 110F or so. I'm witnessing about a delta 15 across the rads. Most TRVs are closing or throttling down for the bulk of the day, 2 remain basically open 24/7.

My next step is to add a circulator for the boiler loop. I think the momentum of system flow theory isn't working. Whether it's because the dT circ is running so low, or because the flow resistance of the boiler and/or piping is too much. Therefore the water isn't moving quickly enough to mix properly, hence tanking the return water temp.

So the answer is... return temperature is indeed the answer. Not just boiler temperature. Got it.

0 -

So to clarify for myself if I have had the correct understanding.

Condensation from low returning temps is only an issue if the boiler is firing, we are talking of the burner gases condensing onto the CI??

If pumps are running in standby/off cycle and boiler temp drops below 130, upon burner firing there may be condensation until temp rises, this is just a cold/warm start??0 -

Right, that's what I was asking essentially, seems the answer is return temps always need to be above condensing temp (130-140F).

I'm still a little fuzzy on why return temps matter if the boiler isn't firing.

I keep trying to picture pouring cold water onto a hot cast iron pan, and why that's an issue. Other than sudden thermal shock and cracking, but that would need to be extreme temp differences. I recognize condensation as being a cold mass in a hot room, the condensate would be on the cold mass. E.G. A cold beer out on the counter. But if the boiler is "hot room" and the water is the "cold mass" I don't understand where the actual condensation is occuring. There are no gases to condense if there is no fire.

On the other hand, I totally get where condensation would be if the return temp is keeping the actual cast iron of the boiler cool (read: 100F) while there is fire going. But if the boiler's contents and the actual cast iron itself, that is physically in the unit is staying above 135 while there is fire... then no dew point... no condensate.

For my constant circulation set up, and odr boiler controls, it's a narrow window where return temps stay above 130... when the boiler is only firing to 150F and the system loop is dumping 90F water! The boiler cycles for a couple minutes, then is on standby for 10 or so... return temps rise, valve opens, boiler cools... until it hits low limit... then runs to target again, and so on, with ultimately little transfer of energy from the boiler loop to the system loop.

I've played with running the boiler off a high limit of 180, thinking it would keep the return temp up, using the same mixed temp, and I experience the same issue. Return temps still crash and the valve shuts... isolating the heat from the system. Screwy. I'm pretty confident in my case I need higher flow rates through the boiler loop to encourage better ratios.0 -

Unless the return water temperature is dragging the boiler below 140 before it shuts down the only issue would be thermal shock. Thermal shock usually happens when a boiler is up to temp, and a high mass zone that's setback opens, and dumps 65 degree water in a 160 degree boiler. You are protected from that.

-1

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements