Daikin Skyair

Comments

-

Looks awesome I've have yet to see or play with these units. Are you able to run 2 air handlers off of 1 condenser?0

-

I've worked on Kirsten-Jet wave solder machines (Made in Switzerland). It came with a translated service manual that was pretty comprehensive but not the easiest thing to follow. At least it had good schematics.

these days after a manual goes through the translation department it then gets a going over by the legal department and that pretty much assures there will be zero useful information left.

The 1960's Tektronix and HP manuals were lucid and easy to follow - absolutely marvelous.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

This one only has one fan coil but I do believe you can run multiples off of it. Don't quote me on that because I'm not sure. It is from their commercial equipment line and uses the 2 wire communication system.

Here's one thing that has always slightly puzzled me. It's a three ton unit and uses a 5/8 suction line. The American unitary industry is normally 3/4" to 7/8" on a 3 ton. Think Daikin is running higher velocities as their standard? Or are they purposely taking an efficiency hit at full speed to remain trouble free and keep the velocities up when they modulate down?0 -

When I had my first training regarding 410 ( late 1990's ) , it was mentioned that we would see smaller pipe sizes and that oil return issues were to be no more. I think that it started that way but US pipe manufacturers nipped that as soon as they caught on , because it's back to the same sizes we ran with 22 ( speculation for the record ) . I installed a Carrier 410a 5 ton machine back in 1996 and recommended suction was 7/8 for my TEL in the IOM. Saw a similar machine recently , same SEER , checked the chart in the manual was 1 1/8 for the same conditions. I would say that maybe they figured 7/8 caused a problem but the VRF / VRV systems seem to have no problems with the smaller sizes.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

Sounds like it was selling 410A as a unrealistic miracle more than it is the pipe industry tricking us into buying more copper. For superior oil return you want smaller suction piping, not larger. Larger drops the velocity. A 5/8 line on a 3 ton will have better return than a 7/8. In theory.hvacfreak2 said:When I had my first training regarding 410 ( late 1990's ) , it was mentioned that we would see smaller pipe sizes and that oil return issues were to be no more. I think that it started that way but US pipe manufacturers nipped that as soon as they caught on , because it's back to the same sizes we ran with 22 ( speculation for the record ) . I installed a Carrier 410a 5 ton machine back in 1996 and recommended suction was 7/8 for my TEL in the IOM. Saw a similar machine recently , same SEER , checked the chart in the manual was 1 1/8 for the same conditions. I would say that maybe they figured 7/8 caused a problem but the VRF / VRV systems seem to have no problems with the smaller sizes.

As far as Daikin and 5/8, perhaps this is similar to manufacturers recommending under sized steam piping to undercut their competition?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I think that with the higher velocities and pressures that the original claims stated were correct , and in my mind the vrf and mini splits of today just confirm that. But now I'm seeing the same large suction piping , the same traps , pitch requirements and so on for US unitary equipment ( Aaon , Trane , Carrier for the most part ). All of the VRF sizing is similar throughout the brands I see ( Mitsu , Daikin , Samsung / Trane ) , example a 12 ton machine uses 1 1/8 suction.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

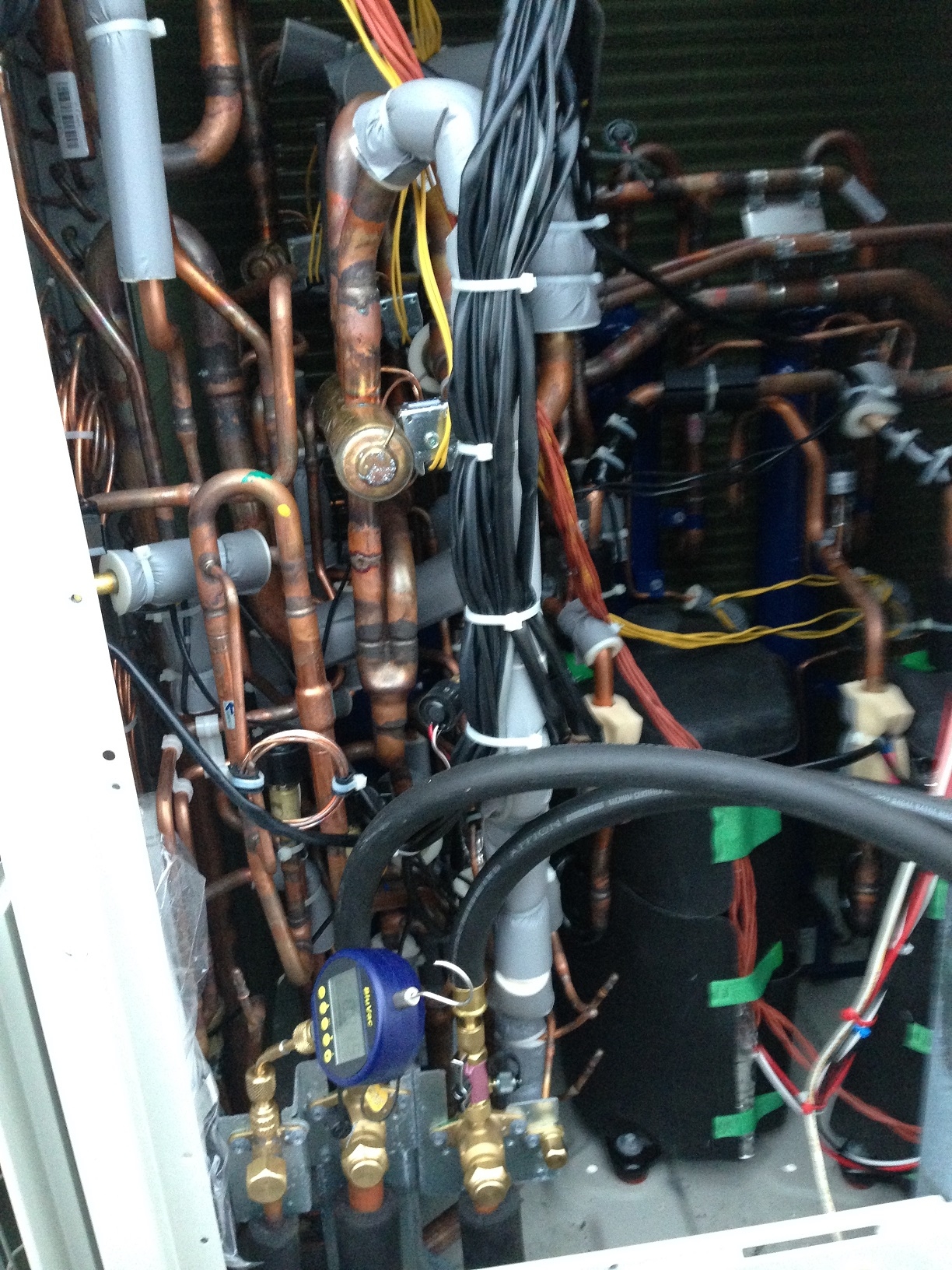

Daikin VRV IV REYQ144 from last week. It is a rather busy machine inside.

hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

3 -

I'm sure hoping their self diagnostics prove to be very good. We'll be fixing them sooner or later.0

-

I have done 1 inverter compressor on a VRV III 120 , determining between the inverter board and the compressor was difficult. Lesson learned on that one , just do both .hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

What procedures did you for diagnostics? Are you aware if they have any engineering bulletins on resistance readings and different voltages to the motors and compressors?0

-

For that I was going step by step in the detailed service manual , eventually leading to megging the compressor ( it checked good ). The service manuals are very specific ( Daikin ) , but the translation is sometimes not complete or correct. As far as I know they have not released a VRV IV service manual ( as of August when I was in class ).hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

The last vrv class I was at, we briefly touched on the vrv IV. They said it not only was vrv but also vrt (variable refrigerant temp). Which means they are changing the evaporator temperature when they can to increase the efficiency. I popped the question about humidity control and didn't get a straight answer. Mainly because the trainer didn't know. I'm sure they have it figured out.0

-

I didn't see anything regarding controlling humidity , but they do have a zoning kit where it may adjust the capacity based on leaving air temperature. There is now an adjustment to control how fast the system reacts to achieve setpoint ( efficiency is affected ). I believe that there will be many additions to the VRV IV line in the near future. The controls are still DIII Net , but there is a revised NAV controller BRC1E73 that now has a setback temperature feature.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

@Harvey Ramer humidity control is a big deal. I'm glad your brought that up.

What I've seen with the mini splits is they tend to be over sized for the spaces. Granted they do modulate, but they go straight up to 100% when first turned on then they will start to modulate back down. It seems they should also have a ramp delay or a longer one to help keep the unit running longer to pull the humidity out. I know Fujitsu does have a humidity control option and will drop space temp 2-3f below set point, but have yet to try it out. I'm not sure how these Daikins controls work/ programmed to control set points.

Also for your unit with Electric heat back up does it just stage on the electric heat package on or does it modulate the electric strip heaters?0 -

The unit stages on the backup if needed. There are like 8 different curves you can set regarding on and off time respective of indoor temp versus setpoint. The unit does not use the backup during defrost. It will turn the indoor blower off for that. It is setup to never blow cold air. It heats up the coil before turning the blower on.

Humidity is always a big deal in this area. In this particular unit, the blower operates on a continuous cfm unless the equipment commands it to do otherwise. Such as defrost cycle or humidifier operation both command a change in fan function. The user does have a fan button on the control which allows them to select from 3 different fan speeds. This is a nice feature to use in shoulder seasons to enhance dehumidification and create longer run times. It also has a dry mode similar to the Mitsubishi.

Sizing VRV to the heating load instead of cooling load is a mistake in my opinion, but many people are doing it.1 -

I think stopping the fan is a great way for defrost. No electric strip heaters to come on.0

-

For the evap coil?njtommy said:I think stopping the fan is a great way for defrost. No electric strip heaters to come on.

Could take quite a while, but it would keep humidity from being blown back into the conditioned space which is nice.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Here's a couple Daikin unit for you. This is at a school we do. They had the system done through a rebate program.0

-

Mucho dinero right there!!0

-

I don't know what that system cost, but it couldnt of been cheap. Although the piping was aluminum which I'm not sure how well that will work long term.

How's the sky air system running is it done?0 -

I thought aluminum piping was the new big thing?njtommy said:I don't know what that system cost, but it couldnt of been cheap. Although the piping was aluminum which I'm not sure how well that will work long term.

How's the sky air system running is it done?

Seems like everyone is worshiping all aluminum condensers and all aluminum evaporators.

Funny how the 1970s-80s General Electric Carry Cools (bottom of the line all plastic window unit) were all aluminum too, in fact, using spine-fin evaps and condensers. Now Trane sells it like it's some huge modern invention.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I'm Not a fan of Aluminum piping or condenser coils especially the mirco channel coils. Evaps are ok, but once they are attached to a heat pump the are subject to the same head pressures as the condensers.0

-

-

It's running like a charm. So far the homeowner has been monitoring his utility bill every day and cannot discern any difference in usage between now and when the old system was not running. It is shoulder season right now though so that doesn't say to much. He will be monitoring the usage monthly and comparing it to the previous year's usage, also accounting for average temps. I am excited to watch the performance moving forward.njtommy said:I don't know what that system cost, but it couldnt of been cheap. Although the piping was aluminum which I'm not sure how well that will work long term.

How's the sky air system running is it done?

There is really no comparison in the quality of this system and an American Unitary system. The sheet metal and frame work is much stronger. Service access is much better. System logic is better. The air handler has like a rubber neoprene insulation adhered to the inside walls; unlike the foil covered fiberglass that we are used to seeing. "The fiberglass always wants to rip loose when you pull the coil." The drain pan around the coil has a very good slope, the whole way around, towards the drain exit. This will prevent any standing condensate, rusting out the bottom of the coil supports.

I have long been impressed with Daikin's attention to detail. This system was no disappointment.1 -

That's awesome I will keep an eye for these in the future. Really the best part about these and the ductless units they are very quite and can almost go any where. Especially the condensers.

I have an older rheem heat pump out side my bedroom that drives me crazy listening to it run. Lol0 -

The prototype Monitor top in the mid 1920s used spine-fin tube for condenser and evaporator. It was ugly, and fragile. Point being, GE had that stuff for a very, very long time.bob said:Trane bought GE's air conditioning business a long time ago that's how Trane got the Christmas tree garland condensing coils. IMO they suck ever since they were invented. Hard to clean, and let me know how you like repairing aluminum.

I don't like it because of how fragile it is and always seems impossible to clean.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements