What is a good basic controller to replace an old triple aquastat?

http://www.supplyhouse.com/Honeywell-L6006C1018-High-or-Low-Limit-Circulator-Strap-On-Aquastat-65-200F-range-5-30F-Adj-Differential-1738000-p

would do the switching, but it needs an external transformer and doesn't include any ODR options. Be nice to have it all in one package w/some newer options.

A possible problem is that I have only one well available "in" the hx and, correct me here, but I think that s/b used for the over-temp manual-reset cut-off because direct immersion bulbs act faster than strap-ons. There _is_ another potential bulb location in the purger fitting but right now it has the bulb from the v5155A "modsnap" gas valve which is just before the burner. I have read that AOSmith put them on most of their Burkay boilers and I _think_ the most likely reason is to delay and control the first ignition. If that's true, it seems a good thing to leave in the system. The info I can find is not very specific about its operation. The concept is clear but the actual cause/affect behavior of the valve in various situations not so much. Maybe it's even possible that it still modulates to spec and could help lower costs.... Anyway. Leaving the V5155 bulb in place would mean using a strap-on for the main controller. I think that would work OK on one of the two supply risers off the purger.

Hopefully some folks can suggest make/models or post links to the "low-end" stuff from quality vendors that's appropriate for very simple systems. There's just so much out there and it's hard to figure out quickly from brochures what I'm looking at in each case.

Thanks for all thoughts.

Rufus

Comments

-

If you don't mind tinkering a bit, http://www.mydtcstore.com/ sells ΔT controllers that also have basic ODR capabilities.0

-

That's a great link! I used to groove on stuff like that.

Saved it for less busy days. I think I have enough assembly and fabrication getting the old boiler happy again.

Saved it for less busy days. I think I have enough assembly and fabrication getting the old boiler happy again.

Maybe I should be clear that I'm not looking for low cost especially. Just don't want bells, whistles, tinsel and the kitchen sink! Those things all tend to make life difficult to figure out. And come with deeper menus and/or (horrors) 3-finger control key combos. One of my especial peeves. (I designed user interfaces from '76 to '85.)

But that site looks like a good source for toys. Thanks.

Rufus

disclaimer - I'm a plumber, not a heating pro.0 -

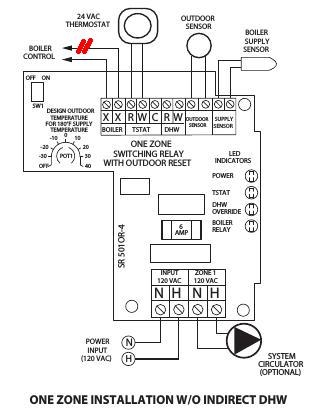

A Taco SR-501-OR-4 will provide basic (on/off) ODR control for less than $200.0

-

-

@SWEI -- I looked up the Taco and if I got the right one, it's a relay to build out zones, w/out the bits & pieces for a boiler control. My system just needs a boiler control for now.

@Robert O'Brien -- That 7600 looks like the cat's meow, just what I need. And they did a really good job with the documentation.

But there's one serious issue I didn't see spec'd: What size tapping does their well require? 1/2 or 3/4? I didn't see the diameter of the bulb spec'd either. Maybe I can call somebody tomorrow.

I also looked at the Tekmar 260 but it looks more than needed at the moment and after the Beckett docs, the Tekmar manual looked like Greek...

Thanks all. Narrowing the field so I only have to read through a few manuals instead of half dozen and more really helps.disclaimer - I'm a plumber, not a heating pro.0 -

-

No well change necessary, fits existing wellrlaggren said:@SWEI -- I looked up the Taco and if I got the right one, it's a relay to build out zones, w/out the bits & pieces for a boiler control. My system just needs a boiler control for now.

@Robert O'Brien -- That 7600 looks like the cat's meow, just what I need. And they did a really good job with the documentation.

But there's one serious issue I didn't see spec'd: What size tapping does their well require? 1/2 or 3/4? I didn't see the diameter of the bulb spec'd either. Maybe I can call somebody tomorrow.

I also looked at the Tekmar 260 but it looks more than needed at the moment and after the Beckett docs, the Tekmar manual looked like Greek...

Thanks all. Narrowing the field so I only have to read through a few manuals instead of half dozen and more really helps.0 -

@SWEI -- Yup, I had the wrong item. Reading up now. Thanks.

@Robert O'Brien -- So in your experience the bulb will fit a standard 1/2" well? My problem here is that I don't see any 3/4" tapping that puts the bulb close into the hx output stream. So I _have_ to get it into 1/2" threads.

Shouldn't be a problem except I don't see the specs in the AquaSmart docs. The existing seems to be a capillary compression fitting of some kind - it's out of the picture.

Strap-on is not an option. IIRC the instructions specifically say the control isn't tested for strap-on sensor placement.

Thanks

Rufusdisclaimer - I'm a plumber, not a heating pro.0 -

@SWEI -- Reading the Taco 501 docs, it looks nice bang/buck for ODR. The one thing missing appears to be a 24volt (nominal) supply and I think that installs into one of the "boiler control" lines (which in this case would mean the gas valve). The high limit manual lockout (separate additional control, not shown) would also break one of those "boiler control" lines. I marked up an image from the instructions showing where electrically the transformer would go (red slash marks). Look right?

Doubt I'd activate the ODR this season, though. Too many things to do before I leave town this fall. Also, want to see if the boiler actually wants to live before doing additional work. If I have to replace it, likely the contractor would do enhancements.

All said, the one piece AquaSmart that includes a LWCO circuit may be a better go. Not sure how reliable and long-lived that kind of resistance check for water level actually is, but it seems pretty valuable and worth a try.

Rufusdisclaimer - I'm a plumber, not a heating pro.0 -

The SR-501-OR-4 provides 24V for the thermostat and isolated relay contacts that go to the boiler's TT terminals. The boiler's safety string would typically remain intact (some are 24V, some are 120V.)

The AquaSmart is indeed a full-featured drop-in replacement. We typically see those on oil burners -- I forgot that they make a gas version.0 -

Thanks. I'd forgotten about the 24v supply for the t-stat. The existing 24v transformer is part of the aquastat with the bad sensor - so when the aquastat goes the 24v supply for the controls goes also. "Isolated contacts" means no power supplied and thus my concerns about the 24v transformer. Not a big deal but more pieces to assemble.

Rufusdisclaimer - I'm a plumber, not a heating pro.0 -

OK. To close on this topic and follow up after the help and comments here's a couple pics and brief summary of the work on this 1980 Burkay HW225p boiler. Gravity conversion w/CI radiators, 2-1/2" mains. Skip to the chase, it's back in service with new controls but not operating efficiently and I'll revisit it next spring to decide if I can make it a silk purse or not. The Beckett 7600B control is a very nice product with one exception: The 24volt source (unswitched) is kobbled onto one t-stat terminal and one boiler control terminal - and the t-stat terminals are smaller than the other connections and really hard to double up a connector onto. The 24v is needed for other powered controls. The control sensor is in the small supply manifold.

The long story:

I got into this because it had been 5 years since I cleaned the boiler. I had time this year so in addition to cleaning the outside of the hx and descaling: After checking the controls I decided to replace the aquastat and add a LWCO and and High Temp CO. Also moved the compression tank (Filtrol) to position before the pump and replaced the existing w/a new one. Added isolation ball valves on the system pipes because the dripping from the old gate valves got to me. Replaced the tridicator on the Purge fixture (AOSmith's word for a small manifold bolted on the outlet of the hx); added another tridicator just prior to the pump (which pumps combined system return into the boiler). Moved the PR safety valve to one of the supply pipes (2 zones) to make room for the additional sensor. Replaced missing insulation around the coil and hx. Added a bracket to hold the new control; redid various wiring and makeup supply plumbing. Rehung a some pipe (lot of hangers grew legs over the 60 years).

Learned about this installation.

Besides leaking at the capillary cap nut (direct immersion with packing sealing around the capillary tube), the bulb for the original aquastat had broken off; I fished it out of the manifold. Don't know exactly what was "controlling" the boiler because there were no other controls. Maybe the capillary was still sound and what broke off (appears to be a solid piece of copper) was designed to speed up heat transfer. Glad I got into that, anyway.

The modulating control just after the main gas/pilot control does not appear to be working. It's non-electrical and maybe the bulb is not installed far enough into the water manifold to react. The gas manifold pressure is at 2.75wc instead of 3.5wc as spec'd in the manual. I left it there as this boiler is too big and the pump may be a tad small. It clocks at 185k while spec'd at 225k. Been operating this way for at least 20 years at least so it gets to continue for another season even though it's cycling more than it should.

The temp rise from inlet to outlet is about 35F. According the the info from the manuals I've found that's w/in normal operating range (tables for the Burkays top out at 40F rise) and means there's about 9gpm through the hx. The 3/4" bypass (I put the original back on) doesn't do much for return temps. At 90F in and 125F out I saw only 2F (at best) rise in return temps when the bypass was open vs. when it was fully closed. I have read that these copper hx tolerate lower return temps (thank you) and have set the controller to maintain a minimum temp of 110F. The differential is set at 25 and it fires for about 5-6 minutes each 15-20 (approx) minutes. The pump runs constantly; I added a switch to select switched on constant run but constant seems to make more sense to me.

The top end hasn't been tested. Debating the value of roasting the tenants. I set the high temp at 190F (the manual reset cut-out is set at 205F). Once the system return temp reaches 165F it's going to start hitting the high temp limit "inside the boiler" when it fires (190F Hi-limit, 25F diff, 35F delta through boiler) and short cycling instead of continuing to heat the system water. The only solution to this I think of is a faster pump, but maybe there's enough radiation to keep things warm w/return temps lower than 165F. I'm not sure a "faster" pump would do good for the system as a whole because I think the radiators may be operating on gravity (or mostly) as opposed to being pumped. The "slow" pump moves the water through the mains gently allowing stratification. I'll start another thread on this question.

Here's a couple pix of the current state of the problem child. I can quite understand if there's a moment of "I DIDN'T need to see this!".

Thanks to all those that shared knowledge and opinion.

edited: fix numeric typo and explain clearlydisclaimer - I'm a plumber, not a heating pro.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements