Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Weird corrision leaks on a 2 year old system?

Options

samsimg

Member Posts: 4

I'm having some minor corrosion leaks on my 2 year old closed loop hydronic radiant system. Some of you may remember me from this thread:

http://forum.heatinghelp.com/discussion/150929/poor-radiant-floor-hydronic-installation

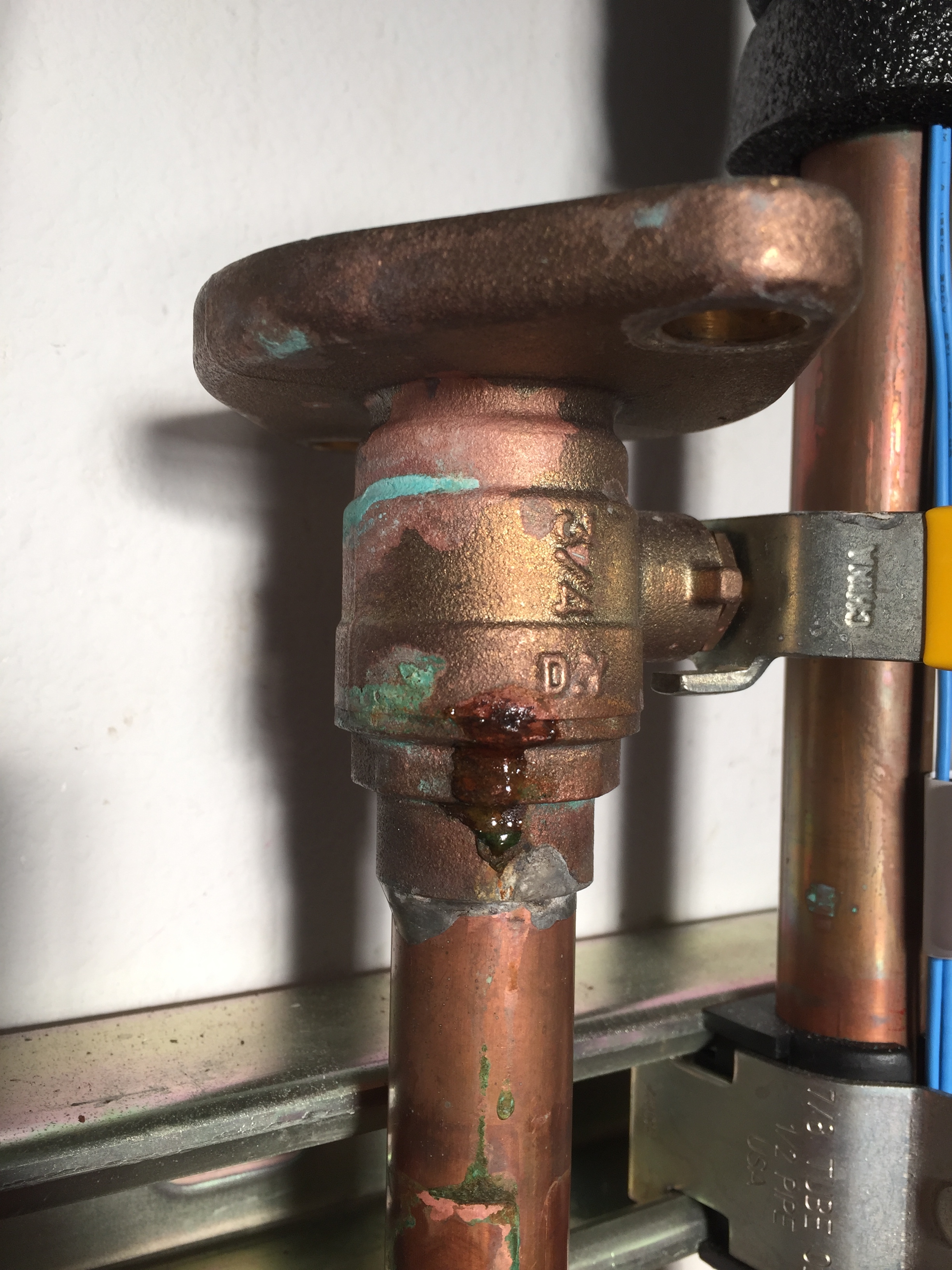

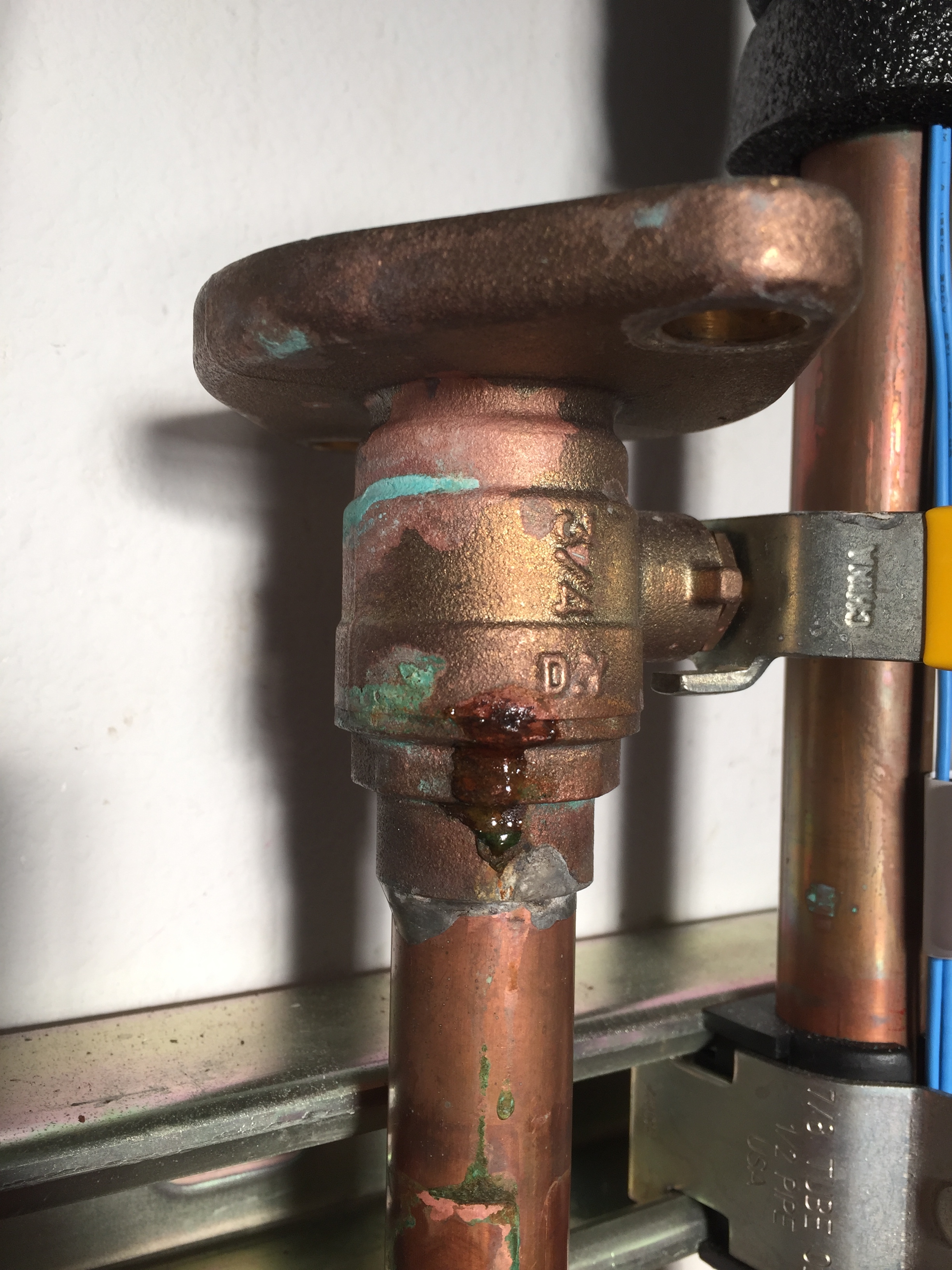

The good news is that the poor installation was fixed, but now I have some weird leaking brass valves, pump isolation flanges and dielectric unions (see pictures).

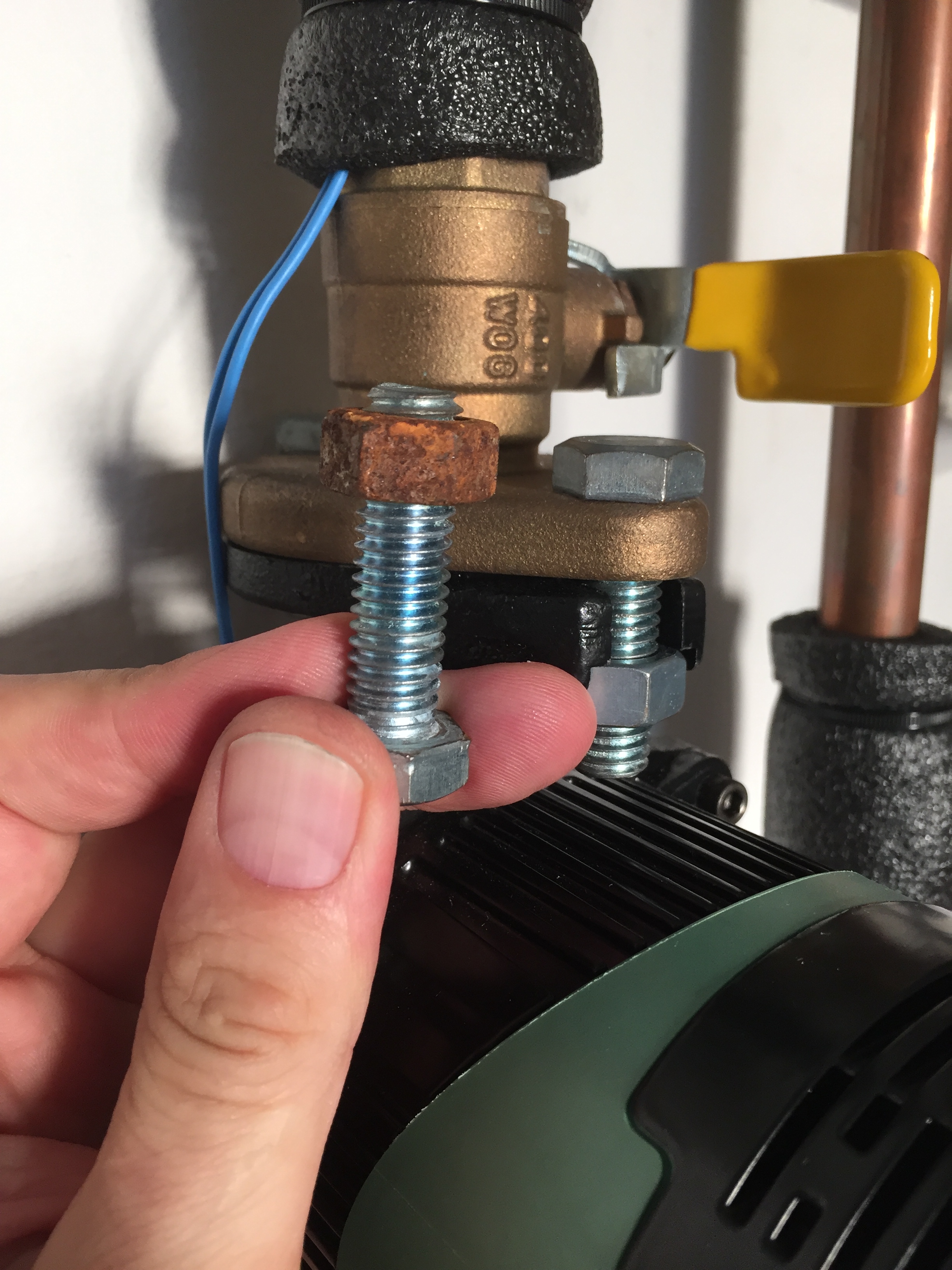

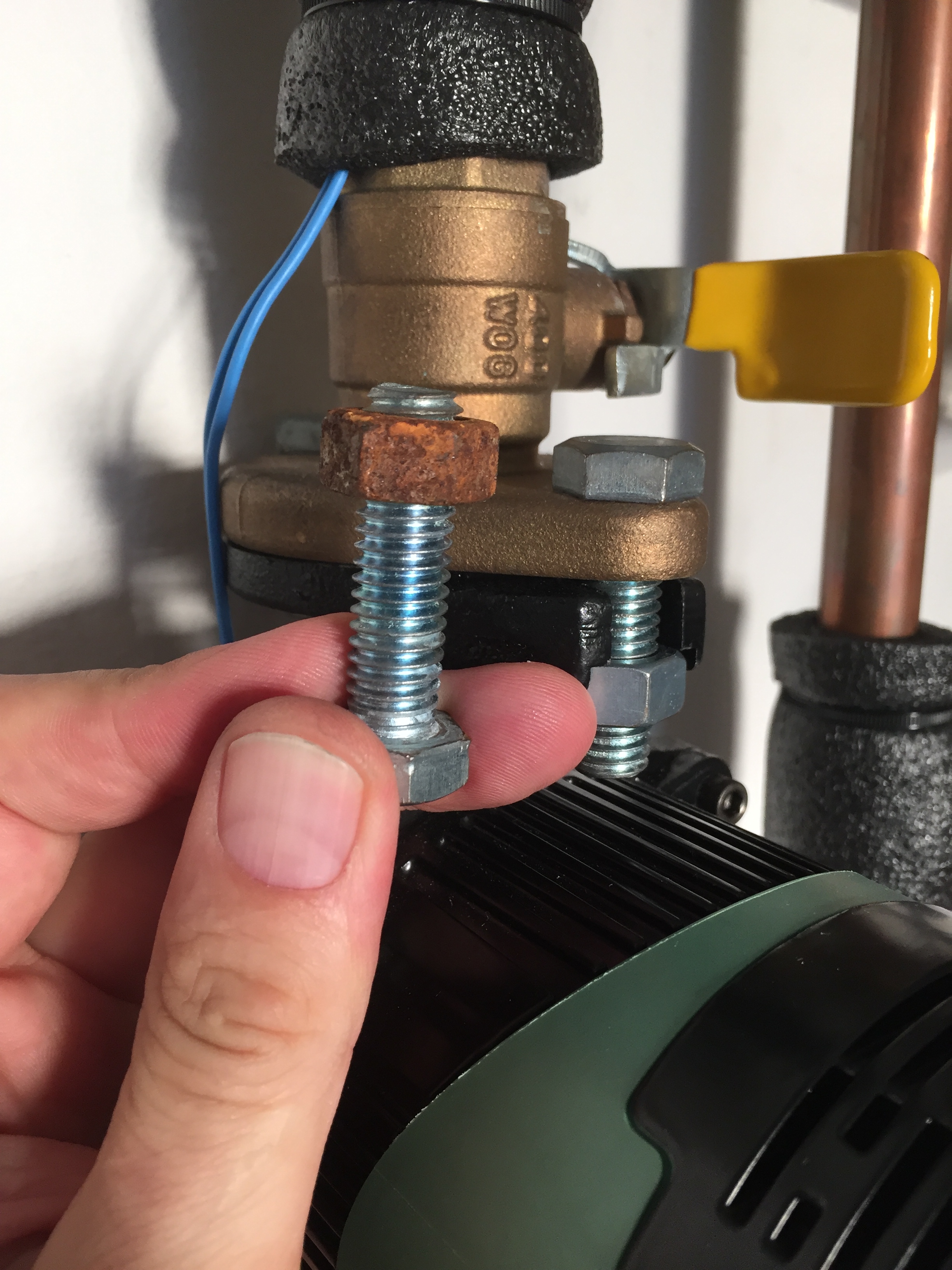

I' wondering if it's dielectric corrosion or something else, i.e. acidic water in the system. Checking the closed loop water showed concerning low pH Levels. I also found a corroded circulator bolt/nut (maybe a zinc nut!!) which is concerning.

After I removed the pump with the corroded bold the system suddenly stopped leaking. I'm completely puzzled.

Any tips or comments what could be going on?

Thanks,

Sam

http://forum.heatinghelp.com/discussion/150929/poor-radiant-floor-hydronic-installation

The good news is that the poor installation was fixed, but now I have some weird leaking brass valves, pump isolation flanges and dielectric unions (see pictures).

I' wondering if it's dielectric corrosion or something else, i.e. acidic water in the system. Checking the closed loop water showed concerning low pH Levels. I also found a corroded circulator bolt/nut (maybe a zinc nut!!) which is concerning.

After I removed the pump with the corroded bold the system suddenly stopped leaking. I'm completely puzzled.

Any tips or comments what could be going on?

Thanks,

Sam

0

Comments

-

Is there glycol in the system?0

-

No, just plain water. I rinsed the system after the contractor rebuilt it last year.0

-

The Dielectric union looks just like a simple leak. I like tape and dope on threads. That looks like blueblocker alone. I prefer a soft set dope.

The other drips are more mysterious. I would start w a water test. Is there any non barrier tubing in the system?0 -

-

I am going to sound like a broken record but... I would flush and clean the system w a good Fernox of Rhomar product then add a good inhibitor. Water quality is everything in these newer systems.0

-

I agree.kcopp said:The Dielectric union looks just like a simple leak. I like tape and dope on threads. That looks like blueblocker alone. I prefer a soft set dope.

The other drips are more mysterious. I would start w a water test. Is there any non barrier tubing in the system?

The leaks in the iso flange and the purge valve, I could almost guarantee are the result of overheating while soldering. Those valves are threaded together at the leak point. It is fine thread sealed with locktite. If you get it to hot you compromise the seal and it leaks. Only way to fix it is to disassemble it and reseal the threads.0 -

Thanks everyone for the replies. This is really helpful.

I ordered a Fernox express boiler commissioning kit with cleaner and inhibitor. I wanted to add corrosion inhibitor anyway...

With the kit I also got some pH test strips. My current water in the closed loop is acidic with a pH of 4. Any idea why this happened? 0

0 -

That is a very low ph number, was that a test strip check?

What is your tap water ph?

Sounds like an acid based cleaner may have been used and not flushed out completely.

A good cleaning then fill with water with low TDS, you may need to haul water or run yours through a DI unit.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 52 Job Opportunities

- 19 Recall Announcements