Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Adding a radiator

Options

tgbrew

Member Posts: 43

Hi All,

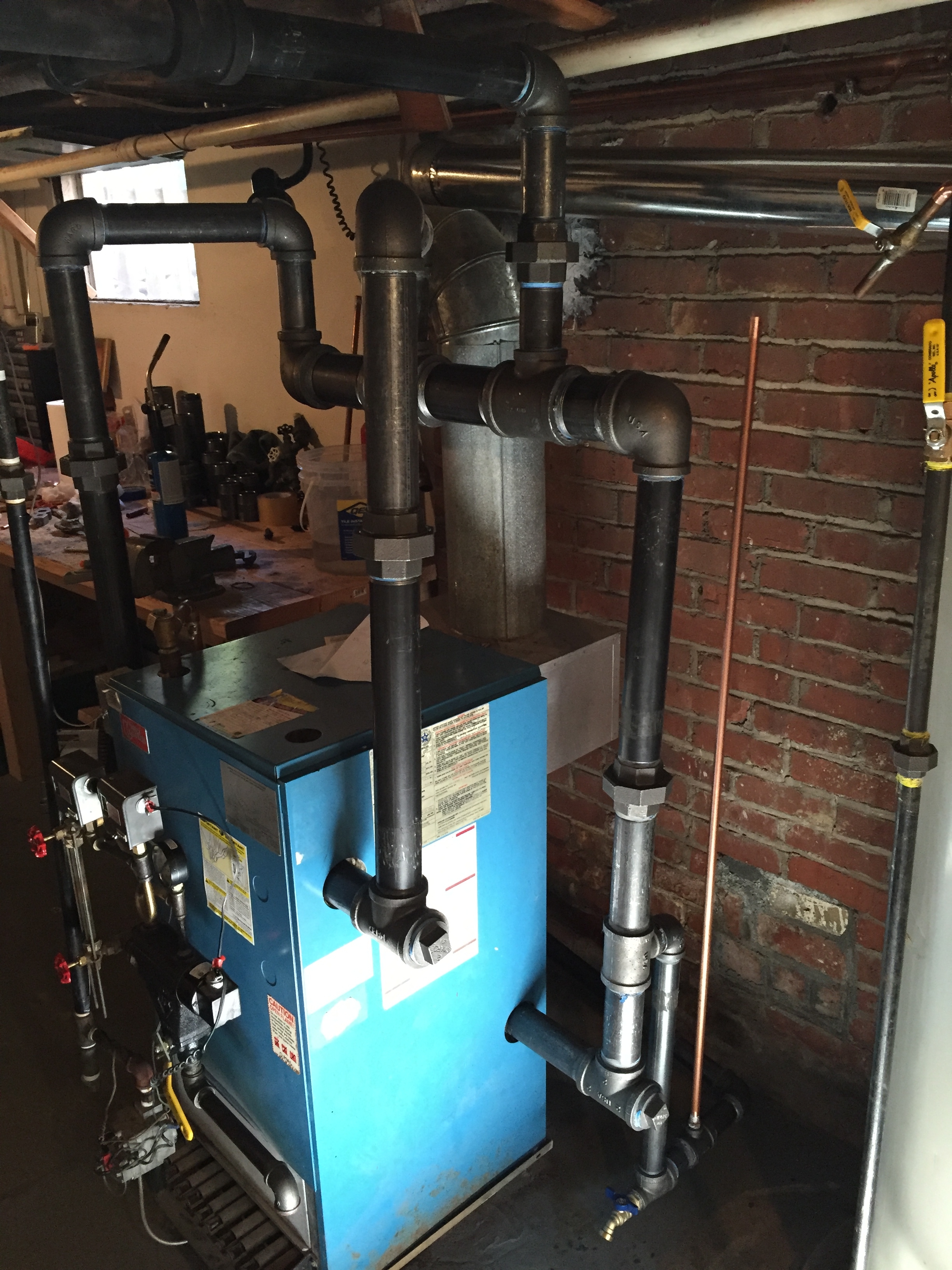

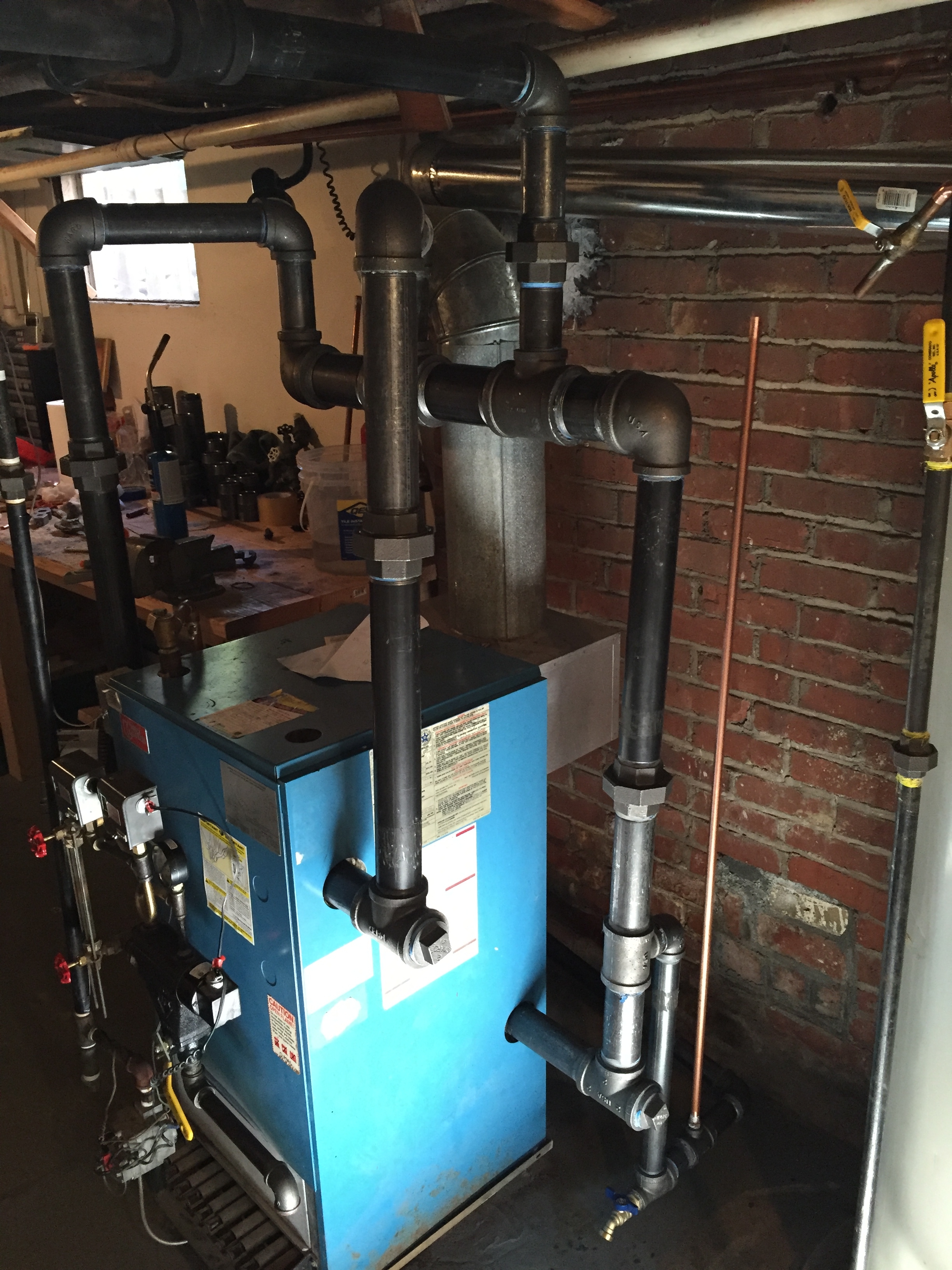

After successfully repiping our old boiler last year, I'm now looking to add another radiator, as well as one or two more to come later. One is for the first floor in a new bathroom and other one on the third floor (a riser to be capped for now). An additional radiator may go on the third floor but on the other side of the house. Boiler is very oversized so capacity isn't an issue.

I've come up with two scenarios. Putting another main off the header that will travel 12-15 feet to two new risers for radiators, and then drop into the existing wet return. The other option is to put a tee into the existing main that will do the same thing - drop to the wet return as a drip line. There are two radiators attached to the first main now that would be moved to this new main/arm because of where they are located.

I've attached drawings of existing setup and the two ideas. They simplified and not to scale. There are actually nine radiators on the current main. I would love to hear thoughts!

-Tom

After successfully repiping our old boiler last year, I'm now looking to add another radiator, as well as one or two more to come later. One is for the first floor in a new bathroom and other one on the third floor (a riser to be capped for now). An additional radiator may go on the third floor but on the other side of the house. Boiler is very oversized so capacity isn't an issue.

I've come up with two scenarios. Putting another main off the header that will travel 12-15 feet to two new risers for radiators, and then drop into the existing wet return. The other option is to put a tee into the existing main that will do the same thing - drop to the wet return as a drip line. There are two radiators attached to the first main now that would be moved to this new main/arm because of where they are located.

I've attached drawings of existing setup and the two ideas. They simplified and not to scale. There are actually nine radiators on the current main. I would love to hear thoughts!

-Tom

0

Comments

-

I like the new supply off the boiler header (scenario one). Then when you do the last radiator on the other side of the house, you can tee off the exiting main for that one (scenario two). Of course, you would want to do the math first to make sure the old main can handle it, and what size to make the new main, all of which can be found in TLAOS.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

What size is the current main and what load is on it?

It doesn't look like it will be easy to tie into your header due to lack of room.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

The current main is 2" with about 230 EDR in radiators on it. I figured the new arm/main would be 2" as well.

Indeed, the 3" header wouldn't have a ton of space between the input and the mains. I was concerned but understood that my oversized drop header would probably be OK?0 -

That 2-inch main can handle 386 square feet EDR, so if the total load doesn't exceed that figure, one might think the third diagram would work. But the pipe coming off the bull (side opening) of the tee won't get as much steam as the run (straight thru) since turning a corner involves more resistance.

But if there's not much room around the boiler, increasing the pipe size to 2-1/2" between the boiler and the tee will work fine, as long as the header is 2-1/2" or 3".All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Hi all - as always. Many thanks for the helpful advice and discussion. I really do love this forum.

So would the arm coming off the bull get helped if I angle it at 45 like a riser takeoff to encourage steam to head that way? Also it would, at most, have 115 of total square feet EDR on it. Does that make a difference? (It would also be replacing an existing tee that leads to two radiators). I wondering what sort of problem this causes.

I'm only avoiding the header because of the lack of space and the work involved of disassembled the whole thing. That being said, I don't want to avoid a problem I'll have to inevitably face.0 -

Ok - It sounds like people think it is better to add another main rather than risk less than perfect performance from an arm? Curious if others have thoughts on this. I'll probably start taking everything apart soon to get this done before the NJ weather takes a turn.0

-

Have you considered taking that main apart, at that first drop to the wet return, and carrying that single Main around, in a loop to where your new risers need to tie in, then dropping into the wet return? It sounds like that 2" main can handle the load and, if so, it looks like about the same amount of pipe, maybe a little more, but you could get rid of a lot of wet return piping and that will help a lot from a maintenance/flushing/rot perspective. It also keeps you from having to mess with the header.0

-

Wow - interesting idea. I didn't think of that at all. I have two issues with it - the first being that I don't think it would fit because of a staircase in the way. The second is that it would turn my ~22ft main into a 40+ ft run (the drawing is NOT to scale) and I worry that it would take forever for my third floor radiator to get any steam! Am I thinking of that wrong?0

-

If you can go along the side of the staircase, it should be fine. Also, If you put a good vent, like a Gorton #2 or even the Barnes and Jones Big Mouth at the end of that main, just before it drops down to the wet return, you will get steam to that riser in a minute or two. You can even put a vent, like a Gorton #1 at the top of that riser to evacuate the air from the riser too. A 40 ft. main is no problem at all. Steam will take the path of least resistance, so with good venting, it will fill the main, all the way around before flowing into the radiator run outs.The biggest advantage, aside from not having to tear into the header, is eliminating a lot of that wet return loop and not having to flush it out all the way around the basement.0

-

I like the thinking but - sadly - it won't fit. I would have to move the staircase because the pipe would go right across them and prevent their use! It seems a second main is inevitable. I'm wondering whether it makes sense to rearrange the header so the steam imputs are closer together have a little distances from the mains? Or just fit in the second main.0

-

Easiest method:

1. Undo the two unions pictured.

2. Replace the pictured 3" x 3" x 2" steam supply tee with a 3" tee.

3. Connect a 3" wye to the new tee.

4. Bush the wye outlets to 2"

5. The 45 off of the wye will be your new main.

6. Continue straight up from the wye to connect to the original main 90.

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

I would think the larger main with the most radiators and venting would rob all the steam, at least initially. No? Seems like it would be hard to balance the system with the wye?RI_SteamWorks said:Easiest method:

1. Undo the two unions pictured.

2. Replace the pictured 3" x 3" x 2" steam supply tee with a 3" tee.

3. Connect a 3" wye to the new tee.

4. Bush the wye outlets to 2"

5. The 45 off of the wye will be your new main.

6. Continue straight up from the wye to connect to the original main 90. 0

0 -

@tgbrew ,Can you draw your stairs in the picture? I see no reason why you couldn't turn your main with an elbow right at that first drop, carry it back and then elbow it again and carry it down to where you want your new radiator/riser, then drop down to the wet return. Seems like you have a lot of room to work with. Stairs can't eat all that space, can it?0

-

"I would think the larger main with the most radiators and venting would rob all the steam, at least initially. No? Seems like it would be hard to balance the system with the wye?" (Fred).

" High pressure goes to low pressure. Always". -Dan Holohan.

Just a matter of venting to equalize everything.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Fred - I can modify the drawing but can tell you that I spent a good amount of time looking at the setup downstairs to know it won't work. Part of it is the stairs, but the "double back" method won't fit either because of existing plumbing, wiring and house structure. Definitely a bummer.

Regarding the WYE - that is another interesting idea, but don't think I've heard of it. What is the advantage of it, since I'll be taking apart the header anyhow?

As always, thanks everyone for the lively discussion. It is so helpful.0 -

Oh well, I tried.

0

0 -

"Regarding the WYE - that is another interesting idea, but don't think I've heard of it. What is the advantage of it, since I'll be taking apart the header anyhow? "

The advantage would be how much of the header/equalizer you have to take apart (and replace). With a Wye the only thing you replace in the current header is a tee. You don't want to move the current supply tee because it's in perfect alignment with the supply main. So, if you can get a 2nd tee in ahead of the current tee with two close nipples, that would be fine as well. But a tee and two close nipples is going to be 4-1/16". If that is a 6" nipple after the riser tee and before the supply tee, -that will work, but it looks smaller. In which case your alignment will be off unless you've got some play in the main.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Thanks again for this. Indeed, the nipple is 7.5" so another tee would fit. I think I'll probably give that a try.0

-

Alas, the 3x3x2 tee is about 5" and the close nipple mean it won't fit. I can rejigger the steam inputs into the headers (maybe the best route) but I'm also rethinking the idea of a WYE tee from the main takeoff at the header to avoid a lot of work.

I can't seem to find the WYE tee anywhere? Does someone make one? As per above, I would be looking for a 3"0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements