Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Exploding Sight Glass leads to other issues

Options

JUGHNE

Member Posts: 11,513

Call from hospital boiler operator this AM, said sight glass blew apart, was spewing water like a fountain and the boiler had shut down.

Feed pump continued to operate to maintain level. This may have been leaking for maybe 2 hours before morning operator arrived. They switched over to alternate boiler. As they replaced the sight glass they noticed that the top glass valve had been off. 80 HP boiler runs 5 to 8 PSI. Any idea of what blew the glass in this scenario?

Operator said "flame failure" light was on as he shut off the leaking boiler.

Water got into the control box thru a top Flex KO fitting. By the time I got to the site the little water in the control box had dried up.....108 degrees in the boiler room dries everything pretty fast. The boiler fired off fine at that time.

I shut it down and pulled the HW RM7840 control module and found water spotting on the top and bottom of the device. I told operator we should replace the control even though it appeared to operate fine once it dried out.

Of course there is reluctance to do this on his part as this was just converted from the old R4140G 6 months ago.

I placed the module in his hands.

My logic is that it shut down on false flame failure (thankfully) because it got wet.....and it could perhaps not shut down on an actual flame failure in the future.

The parts supplier in Chicago says we could send it in as water damaged, they would check internally and possibly remove any residue, if so return it with a record of repair. Only maybe a 10% chance of success.

I know any controls that get submerged should be changed. This only got dripped on but enough to cause the flame failure. Any ideas or advice. Thanks

Feed pump continued to operate to maintain level. This may have been leaking for maybe 2 hours before morning operator arrived. They switched over to alternate boiler. As they replaced the sight glass they noticed that the top glass valve had been off. 80 HP boiler runs 5 to 8 PSI. Any idea of what blew the glass in this scenario?

Operator said "flame failure" light was on as he shut off the leaking boiler.

Water got into the control box thru a top Flex KO fitting. By the time I got to the site the little water in the control box had dried up.....108 degrees in the boiler room dries everything pretty fast. The boiler fired off fine at that time.

I shut it down and pulled the HW RM7840 control module and found water spotting on the top and bottom of the device. I told operator we should replace the control even though it appeared to operate fine once it dried out.

Of course there is reluctance to do this on his part as this was just converted from the old R4140G 6 months ago.

I placed the module in his hands.

My logic is that it shut down on false flame failure (thankfully) because it got wet.....and it could perhaps not shut down on an actual flame failure in the future.

The parts supplier in Chicago says we could send it in as water damaged, they would check internally and possibly remove any residue, if so return it with a record of repair. Only maybe a 10% chance of success.

I know any controls that get submerged should be changed. This only got dripped on but enough to cause the flame failure. Any ideas or advice. Thanks

0

Comments

-

You were right to pull it. If the control got wet, replace it! If it is damaged, it might not show up for awhile, and you would be liable.

And I will bet you are right about the flame issue being the wet control.

Rick0 -

Thanks, still wondering why the glass popped apart?

The board (owners) have accepted my proposal to replace the indirect DHW steam coil/tank with 2 condensing Phoenix commercial water heaters. Best guess for ROI is 4-5 years.

I love steam and its advantages but to keep 80 HP at pressure all summer long to maintain 115 degree water seems unreasonable for this facility. DHW usage is a fraction of previous years. Plus today the room was 108 mainly from boiler firing to furnish water that is only 115.0 -

What pressure are they running and were they using high pressure glass?

http://www.us.schott.com/tubing/english/download/schott-gageglassbro-web.pdf0 -

5-8 PSI. Glass had red line, that is at least a step up from original resi boilers. Several pre cut glass lengths were left by boiler repair service....I would guess that are rated for the application.

As mentioned the upper isolation valve was accidently left off with the lower valve open when this happened.

Could have been one of those things that happen.

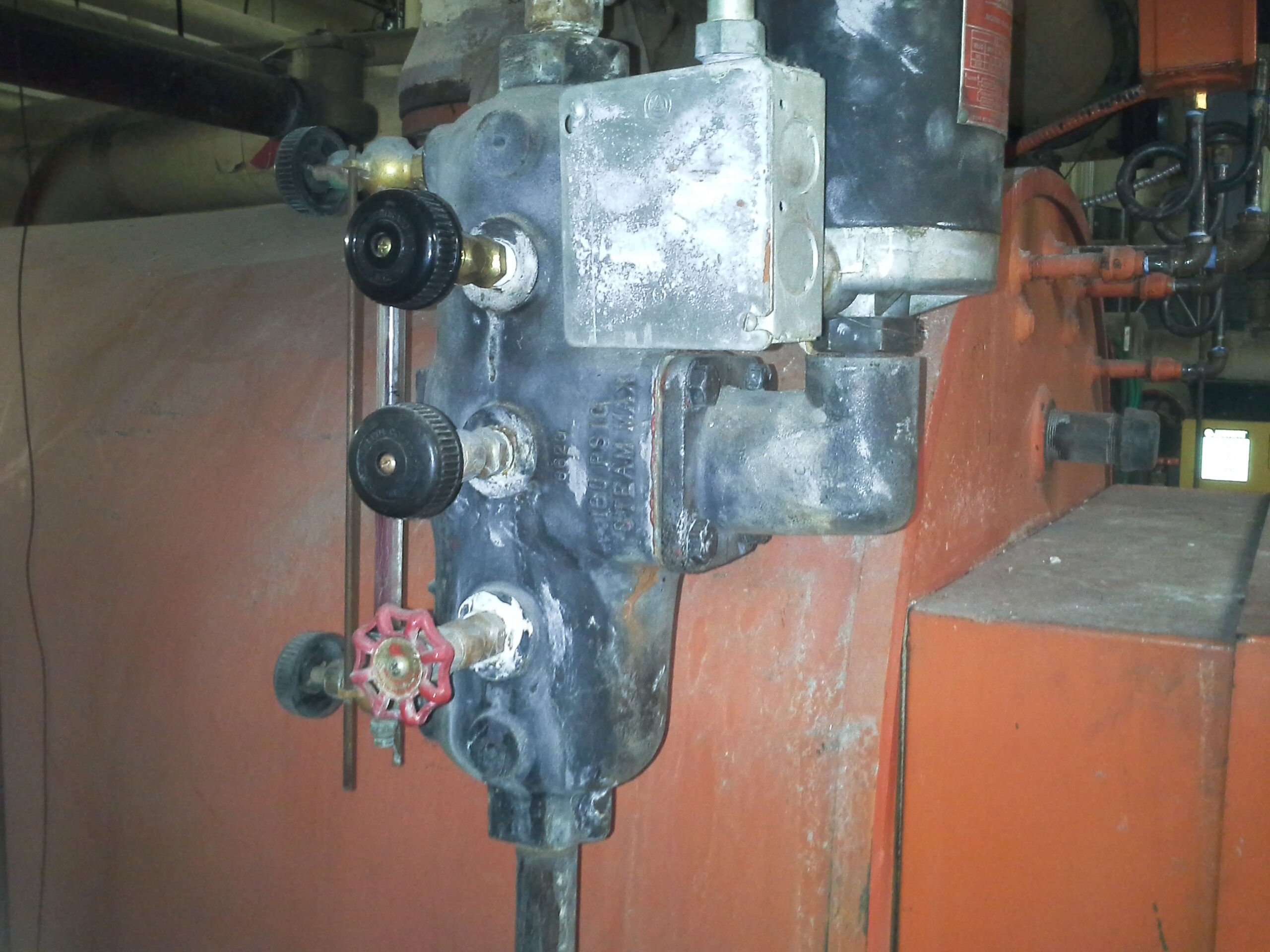

You can see the probably original 1975 LWCO/feed pump controller. The other boiler has the newer MM 150 HD.

It was replaced several years ago as owners were told parts were not available for this old girl.0 -

LWCO's should be replaced at 10 years.

Probably the valve and Murphy.0 -

Yes, so I have read. Each boiler also has a second LWCO connected to cold water supply also. Both are tested daily.

I am sure Murphy was around, (actually he works there).0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 167 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements