Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Whistling at the manifold.

Options

RonV_2

Member Posts: 32

In my new house's radiant system, we have used Watts Radiant stainless steel manifolds. But we have a problem. There is a fairly loud high pitched whistling coming from some of the manifolds when there is flow through one or a few loops in that manifold. It is loud enough to be irritating to the occupants. The whistling appears to come from the balancing valves on the upper part of the manifold assembly (the return section). What causes whistling in these units? Is it the result of too much pressure from the circulator, which in turn requires that the balancing valve for a low flow loop be nearly closed?

here is an example of this model of manifold:

http://media.wattswater.com/StainlessManifoldFlier.pdf

Ron

here is an example of this model of manifold:

http://media.wattswater.com/StainlessManifoldFlier.pdf

Ron

0

Comments

-

Is this system zoned? If so is there a DBV, or delta p pump installed? Sounds like velocity noise.0

-

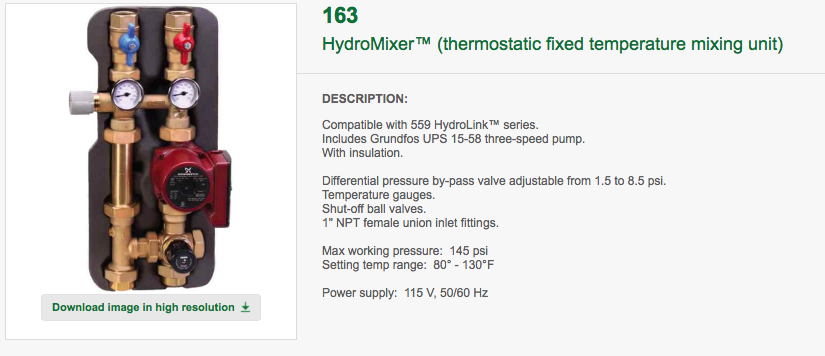

Yes, the system is zoned. The pump currently in place is a simple constant speed pump with three manually selectable speeds (Grundfos UPS25-58U 180). I do not see a DBV but that may be due to my inexperience.

0 -

Nice work at the manifold.

What speed is the pump currently set to? If not at the lowest speed setting, I would turn it down to that setting and see if the sound goes away.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Hi Alan

Good idea, but I already tried that. Switching from Hi to Low definitely helped, but did not eliminate the problem.

Credit for the tidy install goes to my plumber, not me.

It is ironic that this looks like an ideal application for an Alpha or similar programmable pump. The irony is that I requested that an Alpha be installed but, many months later, what the plumber put in was the prefab pump setup shown in the photo, and no Alpha. So now, it is hard to upgrade because the Alpha (and I think the Wilo Eco too) uses flanges while this setup is threaded, not flanged, for the pump connections. Can adapters be used to fit an Alpha into this?0 -

are you sure that it doesn't have a bypass valve in that crossover piece?

We offer both 3 speed and ∆P circulators in the Caleffi stations. The single speed assemblies do have a bypass valve.

We do sell the ∆P circ only, with union ends, it's a 25-55U (union)

It is very close to the 15-58 spec, pump wise.

Caleffi Part # NA16002Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

See if you can identify which loop or loops the sound is coming from. The first thing I would do is remove the actuator and operate the valve manually to see if you can reproduce the sound. If so, isolate the manifold and replace the valve.

If everything seems fine on the return side, you will have to inspect the flow meter on the supply side.

Or just call the plumber back and ask him to figure it out. Are you still in the warranty period?8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Bob, thanks for that question about the DPV. I had a closer look and yes indeed it does have one. I haven't figured out what model it is yet, but since the entire station package has a WATTS brand on the front, I'm assuming its a watts part. The DPV appears to be set for 0.37bar or 12 ft of head. I'm now studying what this should be.0

-

Bob, do you have the performance curve for the UPS 25-58U pump? I'm having trouble finding it.0

-

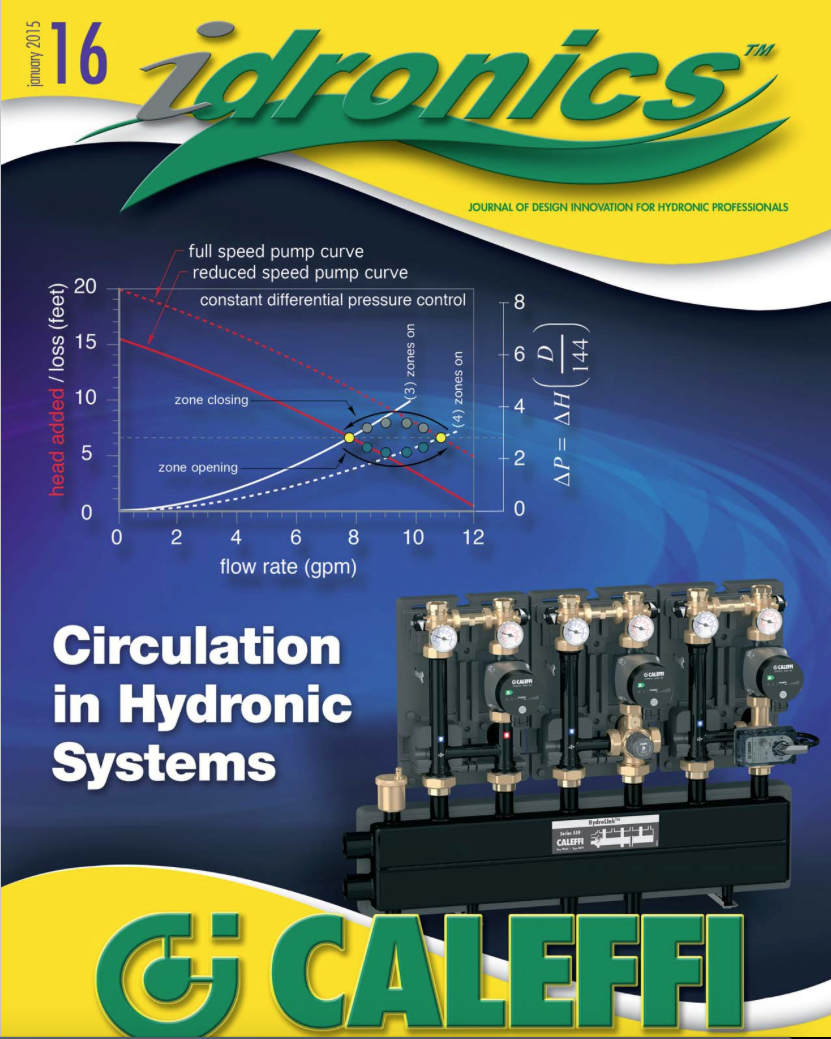

Let me check, I think the 25-55 Alpha has been replaced with the 25-60, the Alpha 2. Both are Euro versions.

Here is what the 25-60 looks like connected to our mix valve assembly, in metric units.

On speed 3 should be around 9 gpm, 17 feet.

Also a sheet that shows what all the Grundfos letters and numbers mean on the label.

http://www.pumpsalesdirect.co.uk/media/wysiwyg/datasheets/grundfos-light-commercial-circulators-data-sheet.pdf

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks Bob. Its the old pump curve that I can't find, the UPS 25-58U, although I have one for UPS 25-58F which is probably good enough. I've been looking around, and while the Alpha2 looks good, the Wilo Stratos-Pico 25/1-6 looks better. Its the 50Hz thing. The Grundfos data sheets are a bit coy but seem to be saying 50Hz only, whereas the Wilo product is clearly 50 or 60Hz. You guys are using Alpha2L...was there any issues running it at 60Hz?0

-

Probably not much performance difference, the U pump is union, the F pump is flanged body.

This number for example 15-88

the 15 is mm of the suction port, the 58 is max head in metric units,

m3/hr "cubic meters per hour". So the difference between the 55 and 58 should not matter much, since you don't have the pump spec the system was designed for anyways.

The only Wilo Picos I have seen are 230V. Are 120V available now?

They will work on a 240V, 60 Hz circuit, I have tried them. Running on 240V may not be doable for you?

Be careful, those Euro pumps are sold in 3 different union sized bodies. Is yours a 30mm?

I doubt there is much difference between the 15-58, 25-58, and the 25-55 and 25-60. Are you short on performance when all zones call? It sounded like you are over pumping if you have noise.

Ideally a radiant design would spell out the exact pump performance you need. Without that, you may need to guess and measure flow rates on the manifold flowmeters, or temperature drop in the loops.

The noise could be actuators that are not opening 100%, make sure they are screwed down tightly on the manifold.

Sometimes manufacturers switch actuator brands or styles and the travel length varies. This could cause partial opening, or failure to close completely. That is not the actuator that originally sold with those manifolds, maybe just a more updated style?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I have most of the details of the radiant design, including loop physical layout, dimensions, heating loads, flows and head losses for all the circuits in the system, so I'm in pretty good shape. The design does not identify a specific circulator and while the UPS 15-58 appears to be a good choice to suit the design point, it has a fairly steep slope to the curve shooting well above 14 ft of head at lower flows (like when one of my whistling zones is ON). The DPV should be limiting things to about 12 ft, according to its setting, but even that is much higher than it needs to be and I'm guessing the flow control valve is very nearly closed as a consequence. So, your suggestion of velocity noise is a good one. It is interesting that you are suspicious of the actuator installation, I will check that out.

I'm going to try an experiment, wherein I set the pump to low speed, then tune the DPV way down to about 5 feet of head while the whistling zone is ON, to see if the whistling changes. I may even re-adjust the flow in that zone back to its designed value. If this works, it is a good indication that I want to use a deltaP-V pump.

As for the Pico, I have no problem running it at 230V. I have used a Stratos in a previous project and it needed no controls run to it as it is happy to run at idle with all zone valves closed. I hope the Pico has the same capability, in which case I would just wire it to a 230V breaker and leave it on.

My application is a 180mm long body with 25mm unions. I presume the threading for US unions is the so-called G type mentioned in the Euro data sheets.

I would be very interested to know if the Alpha2 offered in your model 166 product is a stock Alpha2, which would tell me that it is fine running at 60Hz. I expect it would be. Is it?0 -

If you have all the design info, and the loops were installed per design, you can develop a head loss curve. Plot the head loss curve over the pump curve and you will see where the two intersect. That becomes the OP operating point of the circulator.

It sounds like the bypass could be stuck, have crud in it or throttled down too much. i would guess the valve was speced to handle the pump that is packaged with the assembly?

Here is a good journal if you want to do some number crunching to help solve the mystery, start on page 20 to develop a head loss curve. Plenty of generic pump info in this issue.

Regardless, a delta P circ would probably better match a multi-zoned installation like that.

As for the Alphas, I believe the 25-60 Alpha 2's are replacing the 25-55 on our assemblies as the inventory rotates.

http://www.caleffi.com/sites/default/files/coll_attach_file/idronics_16_na_0.pdf

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Are you positive the water is flowing in the right direction?

ME0 -

I was just going to ask that? Also looks like the flow meters are almost at 0 meaning very little flow...LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

-

Wanted to update that the water is indeed flowing in the right direction, thanks Mark.

Rod, thanks for the journal. I went through it fairly quickly. My reference book for hydronic theory is Modern Hydronic Heating by John Siegenthaler and your journal reference covered much of the same territory.

I'm seriously considering putting in a Wilo pump, but I'm stuck on what kind of thread the unions have in what I have. I don't have a data sheet for the UPS 25-58U 180 pump that is installed now, and I don't know if the union threads on the Wilo line (which are Rp) will match. Why is it so hard to find a data sheet for this UPS 25-58U pump?0 -

It is probably an OEM pump built for Watts. I'd bet that it is a 1-1/2 G thread. The 180 is the length from union to union face in mm

I think we hav the Wilo replacement in that union thread, Wilo Star 16 or the Alpha 25-60 I union. They are 115 VBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I'm not a radiant pro, so I am getting bogged down overthinking this thread issue, but my gut says that my Grundfos UPS 25-58U likely has a G type thread (British Standard BSPP, parallel, same as ISO 228). But if I'm wrong, what else would it be? Unified (SAE)? NPSC or NPSM? I have seen this same pump supplied with other packaged pump stations, mainly for solar application.

I notice that the Caleffi 166 is specified with ISO 228-1 connections for both boiler and system sides, and that the pump connections are also ISO 228-1. When a pro is hooking this unit up, does he just use standard brass fittings from his supplier, or does he order special ones? What is the standard parallel taper in common brass fittings in North America, and likely on the valves in my Watts setup?

The Wilos that I've got my eye on are the Yonos-PICO 25/1-6, or Stratos PICO 25/1-6 (both with Rp 1 thread, same as G, 180mm body). I wonder if these will fit in place of my 180mm long UPS 25-58U?0 -

" What is the standard parallel taper in common brass fittings in North America, "

Oops, I didn't mean to say parallel taper, just parallel thread.

0 -

There is no standard union thread in the US. I'd guess that 95% of the EU pumps have BSPP threads (sometimes called a G union.)0

-

What you will find is the threads per inch match up between BSP and NPT. Since the diameter of NPT varies from start to finish, that is where you run into problems combining BSP and NPT..RonV said:" What is the standard parallel taper in common brass fittings in North America, "

Oops, I didn't mean to say parallel taper, just parallel thread.

As ar as the large diameter of say a 1/2" black union, I don't believe there is a standard? I know different brands of unions don't always go together. I don't think that i a G thread.

BSP connections usually require a gasket, or in the case of a BSP pipe to fitting, either hemp, Loctite "string" or an aerobic glue like a Loctite thread locker.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 52 Job Opportunities

- 19 Recall Announcements