Will adding a mixing valve increase the available hot water?

Comments

-

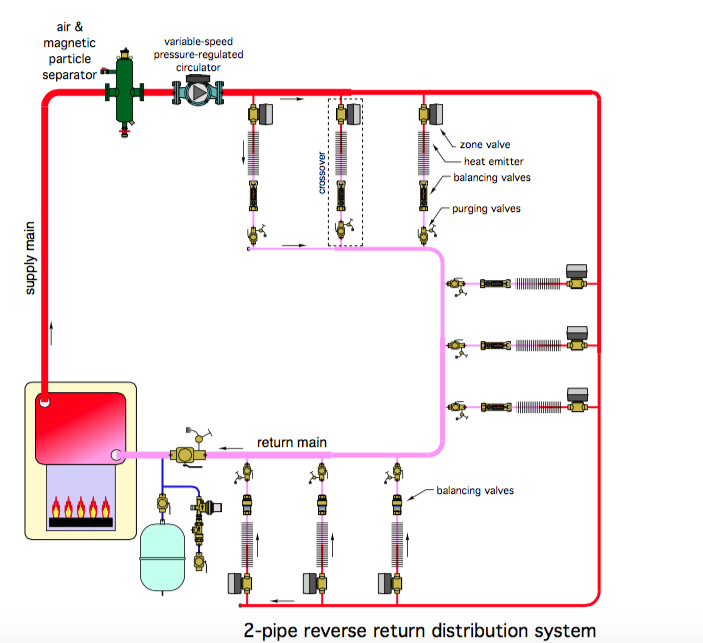

The next Idronics issue, #19 deals with common piping errors. Here are a couple graphics that help visualize the differences between various RR piping methods.Mark Eatherton said:Jonny, here is a simple parallel piping arrangement. The reverse return doesn't really show, but it is a reverse return piping configuration, minus the reverse return. I have drawings on an older PC showing all of the differences I will try and dig up.

An easy way to look at this is that if the in and the out flow in the same direction, it is reverse return. If they flow in opposing directions, it is direct return, which will require balancing on flow.

HTH. Share it with your other plumbing friends. I never intentionally try and offend my plumbing bretheren (or sisterens), but there are always better ways of doing pretty much anything. We just get too used to doing it a certain way that we are comfortable with, and don't bother to look around at other methods.

If you count the number of soldered joints (potential leaks) there are less on this config than there would be on a pyramydic parallel piping, which equates to a worthwhile savings of materials, labor and risk exposure.

ME

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

So looking at ME's RR with 2 tanks and adding a TMV, the hot connection to the fixtures seems obvious..... where would you pick up the cold for the TMV? Tee into CW before it gets to the first WH?0

-

In that example it would be good to place the supply before the T and XP tank feeding both tanks. I would add a check to prevent the hot water recirc from damming the T.LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

Adding a TMV with a recirc loop gets a bit more involved. I don't know why you would recirc thru both tanks?

The goal with a recirc loop is to circulate just enough flow to overcome the temperature drop of the loop. Treat it as an injection mixing loop. Balance just enough to then loop, the rest to the tank.

Insulating the entire DWH piping loop makes a big difference in the gpm required to keep the loop warm, and the amount of run time on the DHW tank to "heat" that loop.

With commercial tanks you often have a port mid tank to recirc just the top portion of the tank and maximize stratification. Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Sure gravity can be a powerful way to move energy. Entire buildings are heated with gravity power. Engineers worked the numbers to show what was possible. I include this slide in my boiler piping trainings, to demonstrate how simply you can move heat energy.Gordy said:Heck I recirc by gravity works beautiful.

Does your recirc have a mixing valve though? I think the pressure drop my be too much for gravity to overcome.

It would be interesting to see a gravity recirc designed with a TMV.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Referring back to the ME 2 tank drawing; with no recir...no check valves....no Xtank; would you center the TMV between the tanks with equal piping lengths from the hot from the left tank and the cold Teed in before the right tank? Am I correct to assume that the need for balanced flow to the TMV thru tanks should be maintained? Though there would be more pressure from the cold line available.

Just trying to KISS for a project like this. (No back flow device in water service.....hot water could expand back into main as most situations.0 -

You can install the TMV after the 2 hots go back to 1 or 2 TMV's 1 at each water heater. Bradford White offers a kit that is made by Honeywell. It comes with stainless steel pre determined flex able lines if you use 2.LANGAN'S PLUMBING & HEATING LLC

Considerate People, Considerate Service, Consider It Done!

732-751-1560

email: langansph@yahoo.com

www.langansplumbing.com0 -

Gordy said:

Heck I recirc by gravity works beautiful.

No I do not have a TMV. Yes that would be interesting to try gravity recirc with TMV.

As you know from gravity HW heating what makes gravity work really well is large deltas.

With the TMV your limiting that delta spread capped to 120 or what ever desired mix temp is on the top end out in the supply piping.

By gravity 120 works with no TMV, but throw a TMV then as you say the PD may be to much to over come.

I gravity recirc with 3/8" copper line from farthest fixture. I live in a ranch so elevation is not a freind. Plus my branch piping to fixtures is relatively short. 15' max. Mostly 6' or less.0 -

Success!

Thank you for recommending I install a second identical WH.

Thank you for recommending they be piped in parallel.

Thank you for recommending Reverse Return piping be used. (Plumber said he had recently done reverse return on 3 tanks in a hotel but he also had a copy of the PVI diagram you posted and I had sent to the owner of the plumbing company.)

The two do start up at about the same time. I haven't noticed yet how close together they stop.

.2 -

Yes, we are both happy. smile:

The t-stat doesn't show degrees. It has "HOT" and then four higher settings -

"A"

"B"

"C"

"Very Hot".

I now have it set at "B". I have not measured the temp yet but can say that I put the shower single handle at about the same place I put it with the old Bock and the Bock was set at 120F0 -

More education for me.

Why is keeping water at 120F potentially dangerous?

Thanks0 -

-

OK thanks!!0

-

There was a remark that here in New Jersey, a TMV is required on hot water heaters, that the aquastat in a water cannot be the sole temperature regulating device. I do not know the code (I am not a heating professional), but I wanted to run my (indirect fired) water heater at 140F, not to extend the hot water, but to keep it hot enough to kill most bacteria. I installed a thermometer in the supply and the output. (No point having one in the cold.) I am glad I did.

One thing I noticed is the large hysteresis in the aquastat on the indirect. I set the knob on the indirect so that the supply to the TMV never went below 140F and set the TMV so the mixed water out was a little over 120F; Actually so that it was 120F at the nearest hot water tap.

I then took a very accurate mercury thermometer in s beaker and ran the hot water as fast as it would go. Around a gallon a minute. The supply to the mixer valve went between 140F and 160F, which is pretty far. I guess if I set it to 120F, it would run up to 140F. So it goes all the way from Safe to Sorry. So I would install such a valve even if the code did not require it.

A little while after I installed that valve and thermometers, the aquastat in the indirect quit (demanding heat all the time), and I had a new one installed. It worked the same way. This is a Weil-McLain (Triangle Tube) indirect tank.0 -

Try the Ranco ETC-141000 control for the tt tanks. They have a remote sensor that I believe will fit the well, and an adjustable differential of 1 to 30 degrees. The drawback is you have to feed it 120 volts. But a nice control.

Rick0 -

To hatters and 4john

In regards .."With a TMV, the HW temp at the TMV is 140. The user wants 115. The split is .68/.32. The mixing valve delivers a steady 115 to the shower valve at a rate of 2.5 GPM. 1.7 GPM hot and .8 GPM cold. The tank is filling with 1.7 GPM. The shower valve is set to 100/0 and there is NO mixing happening at the shower valve."

- firstly I would love to thank both of you for a spirited and interesting debate and you both remained 'sufficiently' respectful while presenting your points. But to hatters I wish to point out something that you are not seeing in 4johns argument and also the fact that the argument itself while is laid out with to good guys coming from a wealth of experience I'm sure and I'm still pretty sure that hatters suggestion was best solution for the question at hand, my thought is this...

I referenced the above quote for this is where I think there is where hatter is missing johns point...hatters you point out that the combined fixed outlet rate with Tmv is 2.5 at shower head ... and that rate is split roughly 60/40 hot cold, at the shower with 100/0 shower handle operation.

Well when you calculated.. you should have said

It is 60/40 mix/cold and you calculated your hot twice for flow leaving mixing valve because the shower valve is receiving mix/cold not hot/cold and there is the less hot leaving leaving mixing thus the tank that 4john is referring to and it would be nice to see you credit him for this given that he was merely trying to point out the inherent merits of the mixing valve however less significant in the overall solution to the question at hand. But don't get me wrong I think we all benefited from the exchange but I hope that you might see what I think you may have missed.. You came up with 86 at the head using that method you used which was good for demonstrating your point but based on some creative math.0 -

If OP is still around, really long showers at high temp is perfect situation for a power-pipe or other drain water heat recovery devices.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements