0 - 2" Magnehelic without pigtail, with and without snubber

This is the difference a snubber can make. In this specific case, a 0.015" snubber from McMaster Carr.

Here's the Magnehelic without a pigtail and without a snubber. This is with extremely clean and relativity calm boiler water.

https://youtu.be/Sndnc4ZFFVs

https://youtu.be/Sndnc4ZFFVsHere's how it behaves without a pigtail but with the 0.015" snubber. There are two other differences in these videos though. The without a snubber video was done with the EG-45 boiler, so average pressure was around 1". The snubber video, is done with an EG-40 where average pressure is around 0.5". The system was just warming up when I filmed this.

https://youtu.be/SRomfHLiDr8

https://youtu.be/SRomfHLiDr8That said, the behavior of the gauge is accurate. Without a snubber or pigtail it's completely useless and likely bad for the instrument. With a 0.050" snubber it becomes a very nicely behaved gauge and yet doesn't suffer from issues pigtails cause.

A large air gap is still necessary to protect the gauge from steam, in my case an 18" length of 1/2" pipe mounted vertically.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

Comments

-

This older video, was done with the EG-40 but I was using a 1/4" ball valve to throttle the gauge instead of a snubber.

This was as calm as I could get it, anytime I tried to close the valve more it would end up stopping all movement. The snubber works far nicer.

The pressure is averaging 0.75 in this video because my manifold pressure was set slightly too high on the new gas valve from the factory. https://youtu.be/hH36luC9GKU

https://youtu.be/hH36luC9GKU Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

The pressure in which dry return, the long or short?

Long main is 29', short is like 11' or does it not matter?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

What would I use to measure it?Hatterasguy said:I would think the pressure drop in the long main would be greater............so that would be the interest.

If I've got .25 - .50" WC at the boiler outlet I'd have a whole lot less at the end of a 29' + 15-20' of dry return.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I highly doubt it would show much.

I'd need to find one of these to do anything useful. Model 2000-00

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Not at this time.

But maybe down the road.

Besides, maybe afterwards I can talk the wife into letting me install it in the bathroom to show the fartfan's performance.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Keep an eye on eBay. Search terms with email, you'll probably find one.0

-

eBay will email you when a search hits. Probably no need, given how many are up there now.0

-

Ah

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

For a one time measurement why not make an inclined manometer with some clear plastic tubing and a ruler.

There was an error rendering this rich post.

0 -

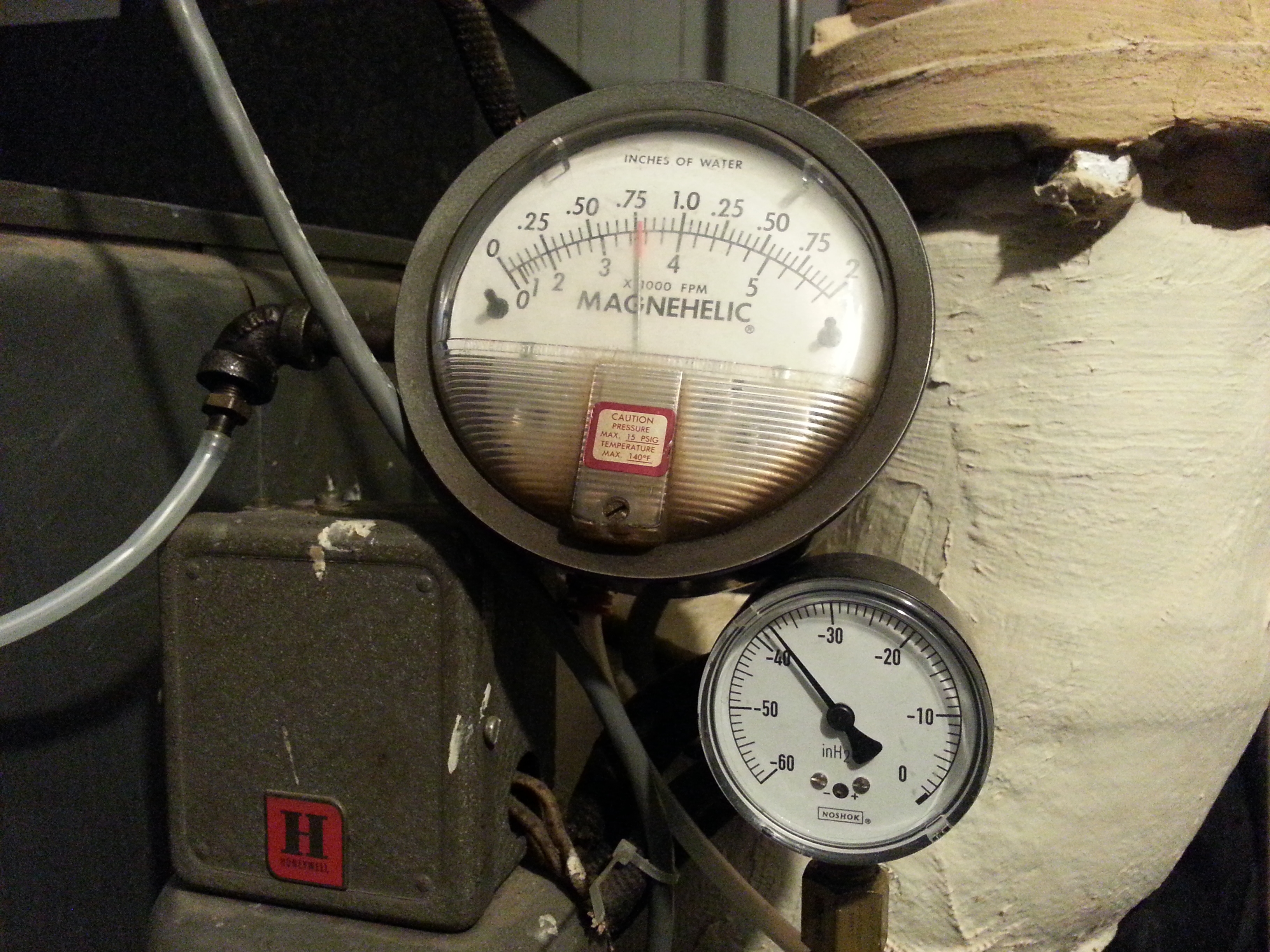

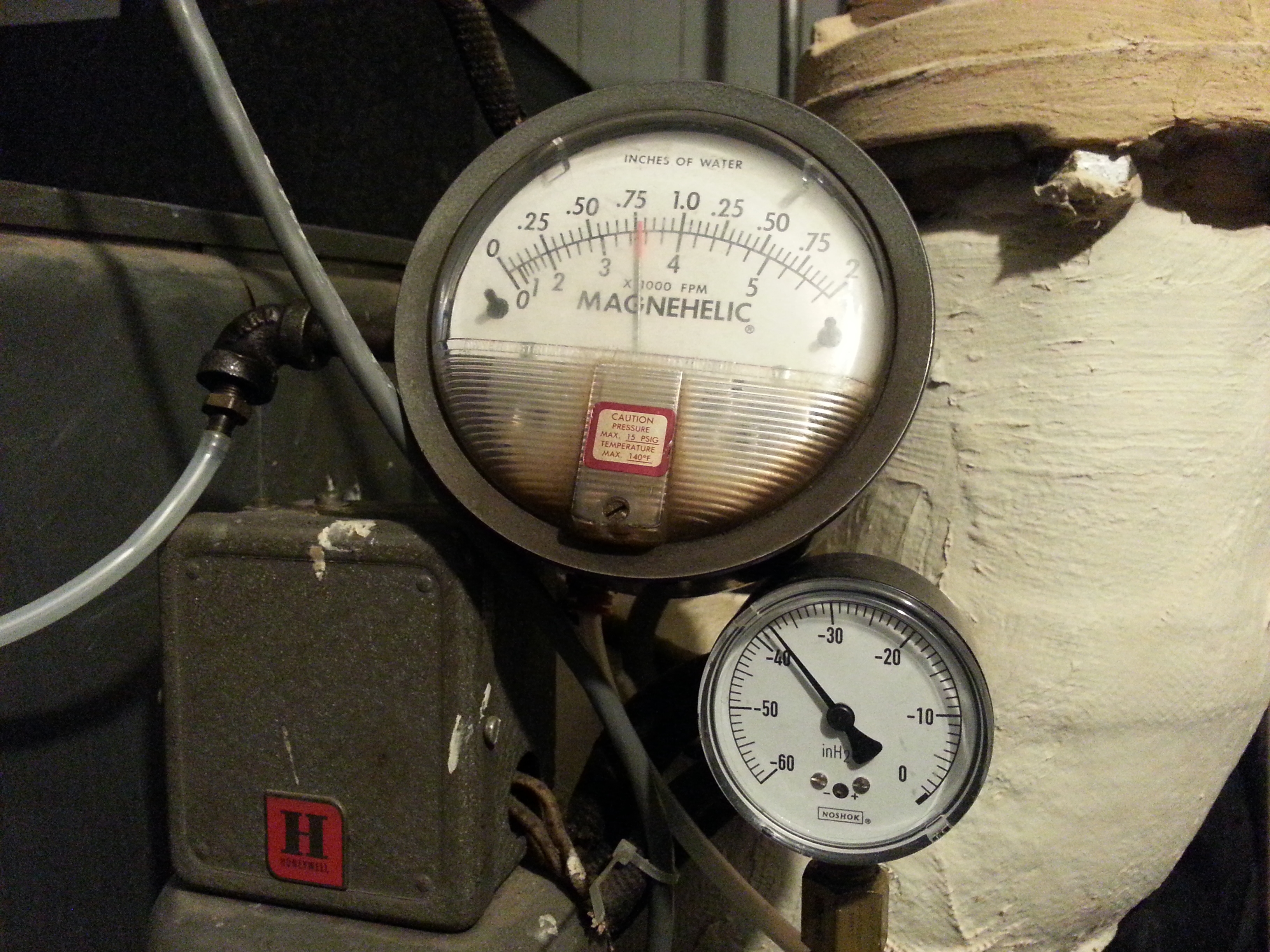

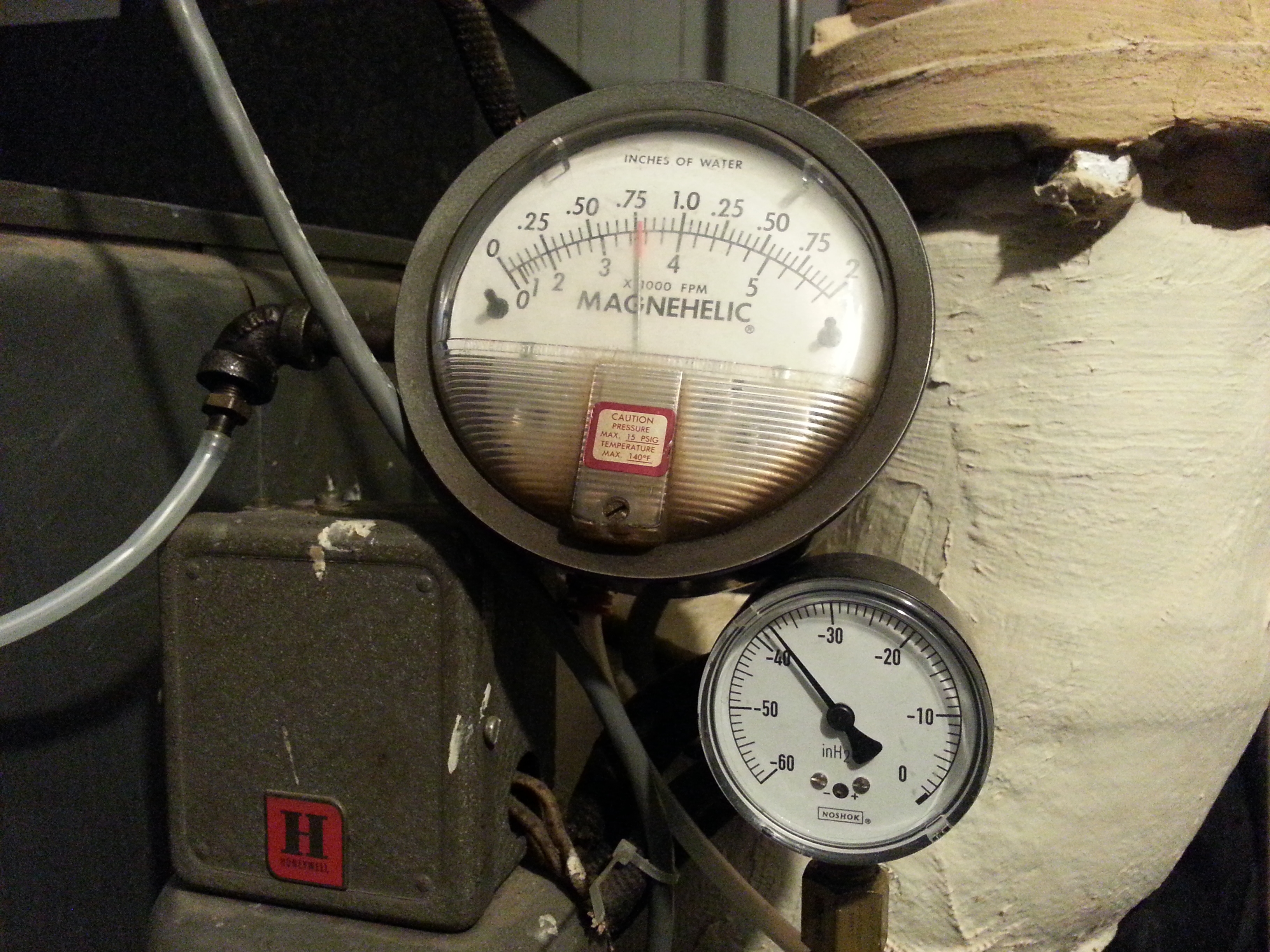

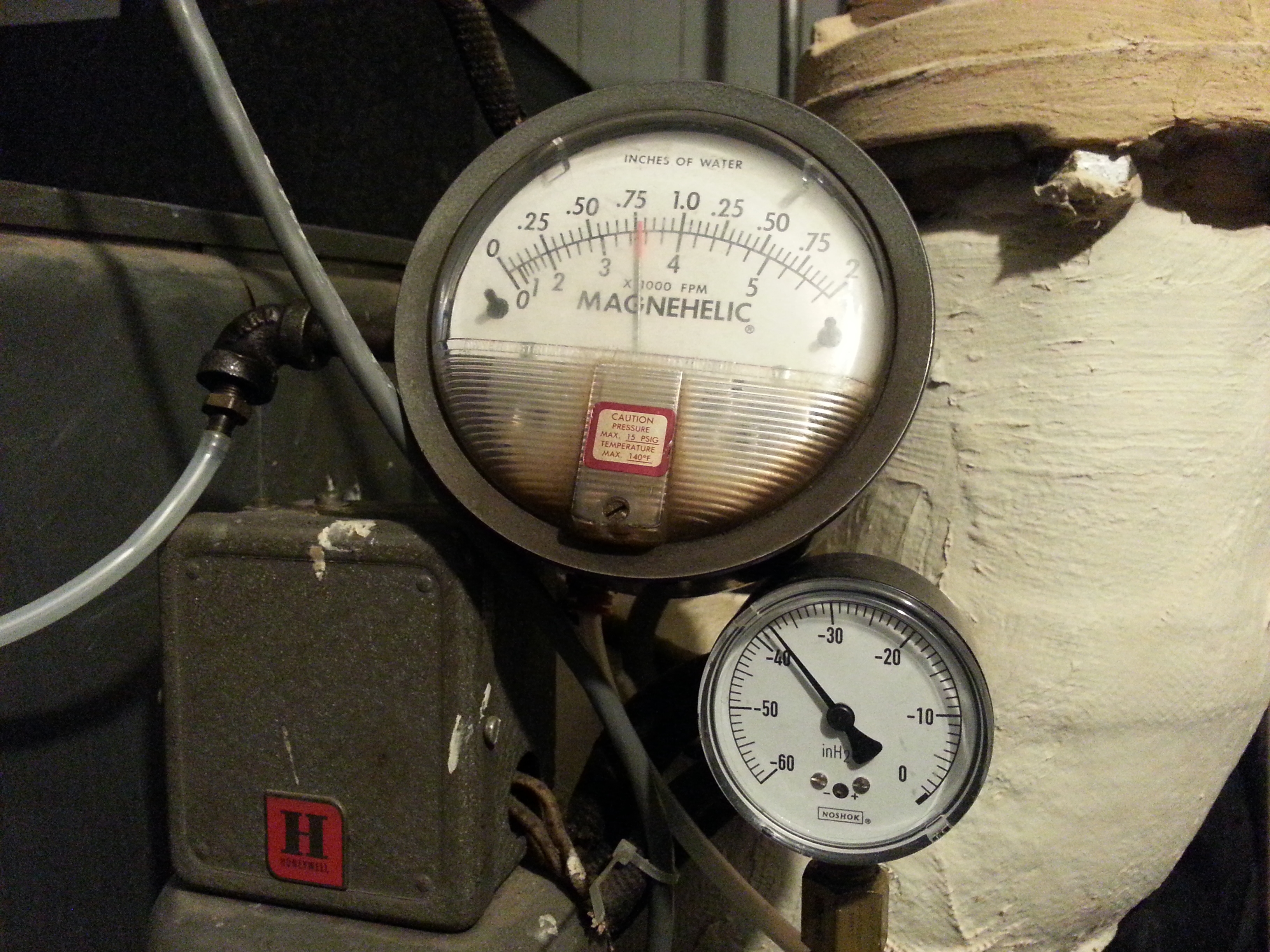

Hopefully attached are two photos - one showing conditions in my system with burner on and the other burner off in vacuum. The Magnehelic is showing the pressure difference between the header and the dry return. When the burner is running the dry return is open to the atmosphere. Burner off the entire system is closed off (less leaks). The dry return is at slightly lower pressure compared to the header in the vacuum condition. There appears to be no pressure drop to speak of in my system either.

The .5 inches differential while running is also only on a cold system warming up in the first few cycles. After everything is hot the running differential drops down to near zero - I have even seen negative. Still trying to explain that. All these devices are on the pigtail and after a snubber.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control1 -

Are there any pigtails in this or is this direct coupled?PMJ said:Hopefully attached are two photos - one showing conditions in my system with burner on and the other burner off in vacuum. The Magnehelic is showing the pressure difference between the header and the dry return. When the burner is running the dry return is open to the atmosphere. Burner off the entire system is closed off (less leaks). The dry return is at slightly lower pressure compared to the header in the vacuum condition. There appears to be no pressure drop to speak of in my system either.

The .5 inches differential while running is also only on a cold system warming up in the first few cycles. After everything is hot the running differential drops down to near zero - I have even seen negative. Still trying to explain that. All these devices are on the pigtail and after a snubber.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Yes, they are on the pigtail.PMJ said:Hopefully attached are two photos - one showing conditions in my system with burner on and the other burner off in vacuum. The Magnehelic is showing the pressure difference between the header and the dry return. When the burner is running the dry return is open to the atmosphere. Burner off the entire system is closed off (less leaks). The dry return is at slightly lower pressure compared to the header in the vacuum condition. There appears to be no pressure drop to speak of in my system either.

The .5 inches differential while running is also only on a cold system warming up in the first few cycles. After everything is hot the running differential drops down to near zero - I have even seen negative. Still trying to explain that. All these devices are on the pigtail and after a snubber.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0 -

That's your problem them.PMJ said:

Yes, they are on the pigtail.PMJ said:Hopefully attached are two photos - one showing conditions in my system with burner on and the other burner off in vacuum. The Magnehelic is showing the pressure difference between the header and the dry return. When the burner is running the dry return is open to the atmosphere. Burner off the entire system is closed off (less leaks). The dry return is at slightly lower pressure compared to the header in the vacuum condition. There appears to be no pressure drop to speak of in my system either.

The .5 inches differential while running is also only on a cold system warming up in the first few cycles. After everything is hot the running differential drops down to near zero - I have even seen negative. Still trying to explain that. All these devices are on the pigtail and after a snubber.

Ditch the pigtails and use a length of straight tubing mounted so it can drain.

Pigtails cause problems, trust me. Problems like exactly what you're seeing.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

The vacuum is accurate. Same as in a remote part of system away from the pigtail so I think the data is good in the off condition anyway. Remember, I am comparing the pressure there to the dry return in a remote part of the system connected with a long tube - not to atmospheric as you are.1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements