Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Boiler will not handle more than 3 loops

Options

Long0

Member Posts: 14

Good afternoon,

2 summers ago I built a 48x44 garage to replace the old garage I had that collapsed the previous February. With the advice of numerous plumber friends from jobsites (I’m an electrician) I installed 1/2 pex on 12" centers throughout the slab and 6" centers within 6' of door openings with 2" blue board below. I have 2 manifolds with 4 loops on each manifold and 1" pex connecting the 2 manifolds. Additionally, I have another 1" loop that is for a future exterior apron. The apron loop is currently not connected to the system.

This fall I had a plumber buddy come up and install my boiler. It's a WM GV6 that I purchased from another contractor that removed it from a high end residence near Aspen. He sold it to the customer new and serviced the unit for the 5 or so years it was in service. All was well when removed.

The boiler fires fine and comes up to temperature without issue. The problem arises when I add more than 1 loops to the system. I should mention since this is an open shop, I kept it simple with only 1 zone controlled via 1 t-stat. I have a Taco multi speed circ pump on the supply side prior to going to the manifold. When adding more than 1 loop, boiler temp drops and my return goes cold. I thought it might be an issue of cold glycl/water so I let it run for 60 hrs with 4 loops with no change. This told us we have an issue with the boiler. Purchased a new controller, primary circ pump and a sensor (maybe return temp??) with no change. High temp cutoff is running about 200.

This was all around November or so. I was slammed during December with work so no troubleshooting happened again until a week or so ago. I dove back into this thing and came up with the following:

- When I add more than 1 loop, the primary pump on the boiler drops out. I know this as I put an amp probe on the pump. With all loops off, pump pulls 7.8amp (rated at 8amps). With more than 1, it drops to less than 1/2amp. Secondary pump does the exact opposite. Less than 1/2amp with no loops on the system, then just over 7.5amps with more than 1 on.

- When I connect 120v directly to the primary pump (bypass the controller), I can run 3 loops without the return turning cold. I have been running it this way for a couple weeks just to keep the shop at a decent temp inside.

Any in-site you could provide me would be greatly appreciated. I have attached a few pictures for reference.

Thank you - Andy

2 summers ago I built a 48x44 garage to replace the old garage I had that collapsed the previous February. With the advice of numerous plumber friends from jobsites (I’m an electrician) I installed 1/2 pex on 12" centers throughout the slab and 6" centers within 6' of door openings with 2" blue board below. I have 2 manifolds with 4 loops on each manifold and 1" pex connecting the 2 manifolds. Additionally, I have another 1" loop that is for a future exterior apron. The apron loop is currently not connected to the system.

This fall I had a plumber buddy come up and install my boiler. It's a WM GV6 that I purchased from another contractor that removed it from a high end residence near Aspen. He sold it to the customer new and serviced the unit for the 5 or so years it was in service. All was well when removed.

The boiler fires fine and comes up to temperature without issue. The problem arises when I add more than 1 loops to the system. I should mention since this is an open shop, I kept it simple with only 1 zone controlled via 1 t-stat. I have a Taco multi speed circ pump on the supply side prior to going to the manifold. When adding more than 1 loop, boiler temp drops and my return goes cold. I thought it might be an issue of cold glycl/water so I let it run for 60 hrs with 4 loops with no change. This told us we have an issue with the boiler. Purchased a new controller, primary circ pump and a sensor (maybe return temp??) with no change. High temp cutoff is running about 200.

This was all around November or so. I was slammed during December with work so no troubleshooting happened again until a week or so ago. I dove back into this thing and came up with the following:

- When I add more than 1 loop, the primary pump on the boiler drops out. I know this as I put an amp probe on the pump. With all loops off, pump pulls 7.8amp (rated at 8amps). With more than 1, it drops to less than 1/2amp. Secondary pump does the exact opposite. Less than 1/2amp with no loops on the system, then just over 7.5amps with more than 1 on.

- When I connect 120v directly to the primary pump (bypass the controller), I can run 3 loops without the return turning cold. I have been running it this way for a couple weeks just to keep the shop at a decent temp inside.

Any in-site you could provide me would be greatly appreciated. I have attached a few pictures for reference.

Thank you - Andy

0

Comments

-

Need a system schematic to see exactly what is going on. Too many pipes and no depth perception to see if it is piped correctly.

I can tell you this much about the Gold boiler. It has an internal bi-metal thermostat on the return that doesn't allow the boiler to push any heat out to the zones as long as the internal boiler temperature is below the thermostat (automobile type) setting.

When starting this system cold, you will probably play hell getting it caught up to the point where it will allow heat from the thermostat into the building. You may need to "jump start" the building by placing large LP heaters to get things up and running, and keep it there once its up. If you shut if OFF, and let it go idle, you might have to go through the jump starting process again. High mass radiant is not conducive to deep set back and recovery unless connected to a fully condensing boiler.

The function of this internal bimetal thermostat is to keep the boiler from condensing, and it sounds like it is working exactly as designed. I presume from your statement that this boiler is in Colorado, and we have been well below normal temperatures for along time ow, so not only are you starting out cold, but are also playing a game of catchup. I have a home near Dillon, and it is -12F up there right now, and was even colder last night due to night sky r-radiational cooling.

Generate a simple schematic if you will and get back to us, but it sounds as though its working "normal"...

ME0 -

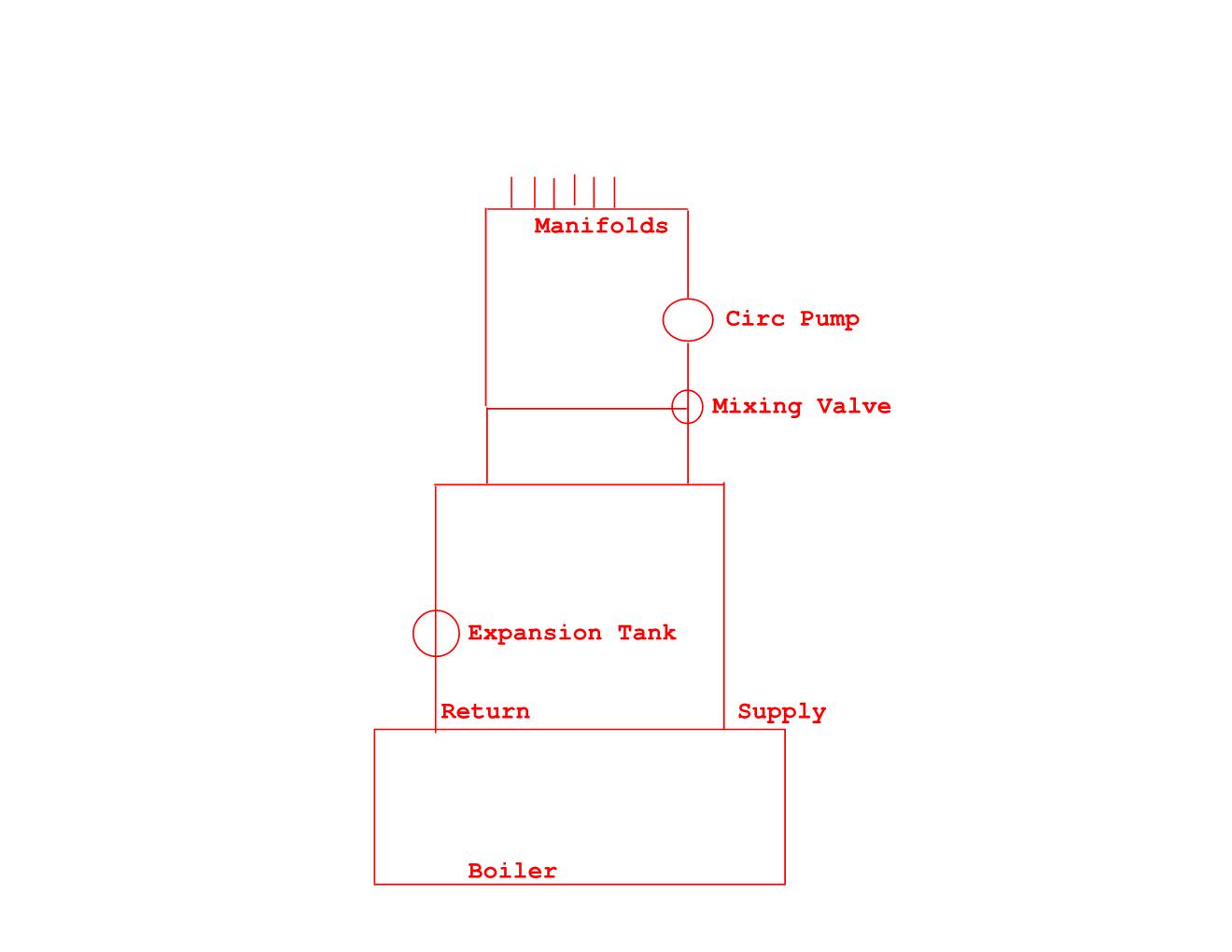

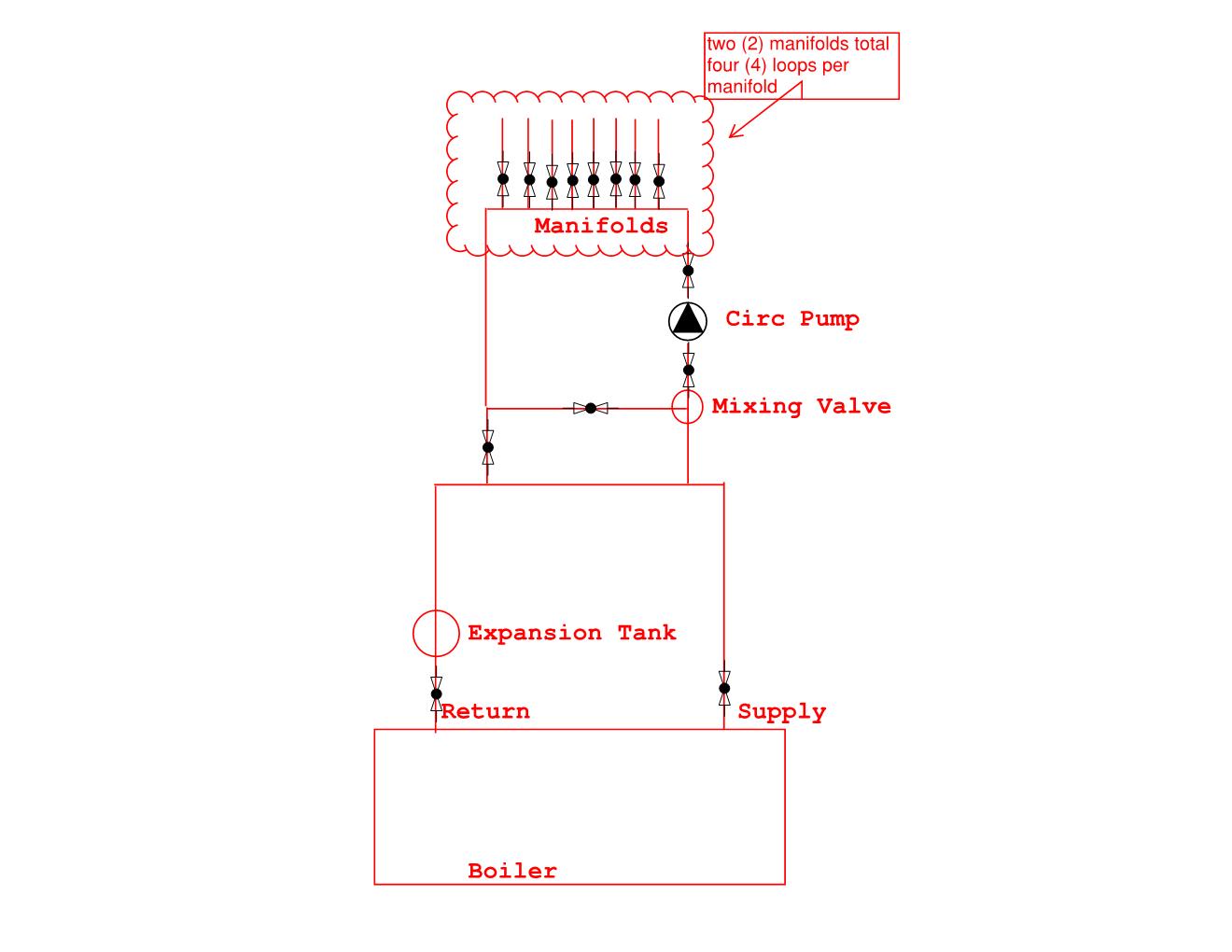

Attached is what I can come up with a schematic. Remember i'm an electrician not a plumber so please excuse the crudity. I did not include any valves.

Regarding your comments regarding jump starting the system - I have a 160K BTU diesel heater I have been using to keep the shop warm while boiler is out of commission. I'm well insulated, so the temp has not been below about 50 since we first started tackling this project. What I have been doing is disconnecting power to the circ pump and closing the valve on the supply side of the pump until the boiler gets to temp, then opening the valve and applying power from it's controller.

Thanks Again! 0

0 -

Please verify that there is a functioning Taco 007 inside the boiler that provides the boiler with its circulation. Can't use your amprobe on it because it draws the same amperage when its working as it does when its locked rotor. If you want to test it cold, turn system on and call for heat, but turn gas valve off so boiler can't fire, and then use a flame torch, hold on one spot of the internal boiler piping for 10 seconds, then wait 10 seconds and touch the spot (carefully) and see if its hot. if it is, pump is dead. If its not, pump is working.

Also, the pump on the upper right of the drawing, is it pump up, or down? Us hydronics peeps usually put a triangle on the pump to show direction of flow, which can be critical at times.

ME1 -

Thanks for the input Mark

I have verified the internal pumps are operating, both primary & secondary.

I have updated the schematic showing the pump - I'm assuming I put the arrow in the correct direction - the pump pulls from the mixing valve and pushes towards the manifold. I realized my electrical software also has some plumbing symbols so I also updated where shut-off valves are located (although I don't believe this helps much).

Thanks again for any information you can provide

Andy 0

0 -

Well, it looks like its plumbed correctly. I looked at the O&M manual for your boiler, and although they show the body of the anti-condensing thermostat, they don't show a replacement for it. It is exactly like an automobile thermostat, and I suspect that it has failed in the closed position. It has a 1/8" hole in it to allow some bypass, and I suspect that is why you are seeing some flow. It's a bear cat to remove, (probably need a basin wrench and that monster pipe wrench showing in one of the pictures) but you can pull it out TEMPORARILY, to see if you get heat.

You can then place the thermostat in a pan of boiling water and see if it actuates. If it does, then we will have to look elsewhere for resolution. If it doesn't open, take it to the local auto parts store and find a replacement. I didn't even see a part number or identification for that component, and unless something has drastically changed, that could be your problem.

I am assuming (also based on the fact that I saw a healthy looking charge pump) that all of your zones are correctly filled and purged, and that you have a decent (30 to35%) percentage of glycol and aren;t trying to push maple syrup consistency fluid through your system, and that the boilers circ pump is in fact moving water (flame test).

Another quick test you can do is to temporarily dead head the radiant distribution pump and allow only the primary (boiler) pump move water around the circuit,and see how fast and how hot the primary loop gets. If it takes f o r e v e r, then either the boiler pump or thermostat is bad.

I am also presuming that the appliance has been checked for proper input and output. I also assume that any fuel conversions have been properly performed. If it came out of an LP job and was placed on a NG job, and no orifi were changed, it could be significantly under fired.

Also, in your photos I noticed that none of the drains (combustion chamber and vent) are directed to a floor drain. This could be problematic with the wooden base your boiler is sitting on. The condensate is acidic, and will corrode any metal it comes into contact with, and it WILL condense, in the vent if not in the boiler.

You will also want to make sure that this boiler has received its factory upgrade on the condensate trap drain assembly. There was a recall years back.

A fire marshall in Aspen was the one that determined that the trap seal would evaporate, and allow the appliance to dump products of combustion directly into the mechanical room (carbon monoxide)... They kept getting calls out for CO alarms, and he realized the only thing they had in common was the Weil McLain GV boilers.

Pull the thermostat and check it and go from there.

ME0 -

Could you tell us what make model that mixing valve is .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

I have reviewed my O&M manual thoroughly and I am unable to find the t-stat or t-stat housing you are referring to. Maybe you can point me in that direction. I understand the workings behind an auto type t-stat quite well and that really makes sense based on the issue I am having.

The system comes up to temp fine and then reaches hi-temp and the flame shuts down. As mentioned before, I have accomplished this by removing power from the external circ pump and closing the valve ahead of it.

All loops have been purged multiple times as my plumber and I both suspected air. We are both 100% certain there is no air in the loops. I have run each loop one at a time for 2+ hours and they heat fine. Glycol / water is a tad under 30% so everything should flow fine. Both the circ pump and primary pump in the boiler are new, both power and flow have been confirmed.

Regarding fuel, it was originally set up for NG. We replaced the existing white/silver NG plate with a red LP plate prior to firing for the first time.

Drains have been taken care of since the pictures were taken. Combustion drain is piped thru the wood base to floor level. I did not want to pipe this directly to the floor drain as there might be a chance I would not notice fluid if it was piped directly to the drain. This is my personal preference that some may not agree with. I apologize in advance should you not agree with me!! Condensate is fully piped in the pictures, it just hard to make out. In one picture you can see a roughly 18" piece of maybe 2-1/2" pre-fab'd PVC mounted to the underside of the wood base. The condensate is tied into this and then piped to the floor drain.

I have a call into the contractor I purchased the boiler from regarding the condensate drain assembly.

Mixing valve is a Caleffi 521 that was purchased new from a local supply house.0 -

http://www.weil-mclain.com/en/multimedia-library/pdf/weil-mclain-pdf/products/discontinued/discontinued-boilers/gv-boiler/gv2manual.pdf

Page 26, item 1. Listed as "mixing valve". The top screws off for thermostat access.

ME0 -

Thanks Mark but that is not the boiler I have. I don't have an internal mixing valve. I'm setup with a primary and secondary pumps internal to the boiler to basically do the same function as the mixing valve you listed. Here is a link to my unit - see description on page 2 items 6 & 7

http://www.weil-mclain.com/en/multimedia-library/pdf/weil-mclain-pdf/products/boilers/gas-boilers/gv/550141856_0703.pdf0 -

Recall notice. http://www.weil-mclain.com/en/multimedia-library/pdf/weil-mclain-pdf/cpsc_weil_mclain_announces_recall_to_repair_gas_boilers.pdf

Your boiler may be too young, but better safe then dead...

Google GV6 recalls and see what pops up. Numerous recalls for numerous reasons. And this shouldn't reflect upon W-Mc, because I don't know of a company that HASN'T had their products recalled at some point...

It's not a question of IF, but more a matter of WHEN, and then it comes down to the companies response.

ME0 -

Recalls are something I'm familiar with and I agree that they should not reflect on the manufacture. I have printed out the two (2) that I could find and will check this afternoon. Nothing in either recall popped out at me that would cause the issue I'm having.0

-

May we inquire ?

1. Would the presumption that those 2 - 1" pex lines go to a remote manifold ?

2. Is some of the floor heating ? Possibly the parts that have the loops from the visible manifolds ?

3. What is the head loss of each of the manifolds ? The remote manifold is obviously higher than the one that can be viewed .

4. What GPM does the system require ?

5. What Taco 3 speed circ do you have and does it have an IFC installed ? I only see a Grundfos .

6. This boiler requires a bypass loop to protect against low RWTs . Your system piping return is before the the system supply on the boiler loop and there is no bypass or so it would seem , maybe it's my old eyes . May we look at the illustrations on pages 33 -34 to get to the bottom of the issue ? As Mark stated , it does lack clarity in the photo .

You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

I will answer the best I can but some of your terminology I don't understand

1. That is correct – the 2 on the right go to the 2nd manifold

2. Right now I have my 3 longest loop valves turned on. I get heat in the floor for those loops. Once I turn on any additional loops, return side goes cold and I don’t get heat past my mixing valve.

3. Again I’m an electrician so head loss means nothing to me. I can see if any of my plumbing buddy’s would know but they were not around when I installed the PEX

4. See response to question 3

5. Sorry, my mistake – I should have stated Grundfos and not Taco. I will have to get a number off it tonight

6. I’ll post the schematic again in case it is no longer working

Sorry for my ignorance regarding this, I’m just trying to get to the bottom of this thing before anybody convinces me to throw more parts at it.

Andy 0

0 -

Andy, what altitude are you opearting this at. My quick check on math said you should be OK boiler sizing wise, but I didn't account for altltudinal deration. We have to knock 4% per 100 feet above sealevel off the rating tag, so 8,000' would mean 32% less output.

Depending upon the size of your future snowmelt, you MAY have to prioritize all space heating calls over the snowmelt, but its still better than grabbing a snow shovel.

Rich, that boiler has its own internal bypass (thermostat) which I think may have failed or may be stuck, or it could be operating exactly as it is supposed to.

I was eventually going to head down the road you are taking him on, but thought we'd kick the tires and make sure nothings flat before we try moving forward

He's a sparky and I didn't want to completely overwhelm him from the get go. I envy sparkies, because they have an inherent better understanding of hydronics than most hydronics people do due to their exposure to the Ohms law, our equvilant to the UHF.

Thanks for chiming in as always.

Andy, if your plumb crazy friend don't have the hydraulic figures, give us a detailed (linear foot, this size pipe) schematic of the distribution system and we can perform our own hdyraulic (head loss) analysis. We have software... As noted, will also need the Grundfos specfications, but am guessing its a series UP1542 or UP1558.

Also, didn't mean to infer that the recalls were related to your issues. They aren't, but you need to be aware of them just the same.

ME0 -

Can you tell us how long each loop is in Total length and which manifolds they are on ( visible - not visible ) ?

How much insulation is below the floor and is it below the ENTIRE slab ?

How many windows are on each wall ? Include lineal footage of wall and height , window type and garage door type .

Are the walls insulated , if so please give R Value ?

Need the model number off of that circ . What type glycol did you introduce , ethylene glycol , propylene glycol ?You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

-

Morning Guys

Here is what I came up with in regards to your questions

- Attached is the layout of the garage – I included wall lengths and heights, door dimensions, concrete information, manifold locations with loop lengths.

- Walls and ceiling are fully insulated – R38 on the ceiling – R19 for the walls

- 2” Blue-board below the entire slab

- Pex manufactured by Uponor

- Circulation pump is a Grundfos No. UPS26-99FC

- Propylene Gycol – My notes indicate 30% solution

- Elevation is right @ 8,000’

I looked all over the boiler last night and I’m not seeing the thermostat you are referring to Mark. Attached is the parts list that is indicated in my manual

0

0 -

Well powder my butt and call me a biscuit... That is a new one on me.

Give us the model number and serial number and I will contact a friend of mine who is a rep and see what's going on. With no bimetal thermostat, the only option of control is to vary pump speeds to control condensing. I need to do more research.

Also, just a quick note. We typically recommend not varying tube lengths by plus or minus 10%. If the 150' circuit is on its own control, it will be OK, but if grouped with all the other tube circuits on that manifold, you will need to choke flow to even out the spread and flow. Using delta T (temperature) works best in that situation.

I've got some homework to do...

ME0 -

Good news is that this can be made to work . bad news is , it's gonna take some money and labor .

Circ cannot and never will do what it was intended for .

Based on a 3* odt from Denver ASHRAE data I ran some numbers based on information provided by you . The reports are attached .

This is probably a best / worst case , meaning your design conditions could vary to the lower outdoor temp side and you may want a higher setpoint inside . This would make the numbers worse as we would interpret them .

Maybe others will jump in and give their opinions . This is what happens when you ask for help .

Caleffi mixing valve has Cv of 3 . Manifold flows are listed at design . That additional head must be added to the manifold report numbers .

Both manifold heads should be increased since both will be running simultaneously our additional head becomes 6.93' for both manifolds since all the fluid runs through the same device if we attempt to keep this as a single circ system . We'll need to use the highest head manifold and the sum of the flows .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Thanks again guys,

Mark,

Model is a GV-6 Series No. 3

I did not have any luck finding a serial number, just the series #.

A direct quote from the manual regarding condensing.

"The GCM operates the bypass circulator to mix hot water from the boiler outlet with colder return

water from the system as needed to prevent condensation of flue gases in the boiler"

If I understand your comments on tubing length, I need to reduce the flow into the shorter length runs to make up for the longer runs? The more I think about it, it makes total sense.

Labor I can handle, money may put this project off for a while. I only understand about 25% of your reports. What are you thinking would need to be changed?Rich said:Good news is that this can be made to work . bad news is , it's gonna take some money and labor .

Andy

1 -

You may want to separate the manifolds , this way you only need one larger circ and one normal circ as opposed to the mining pump that will be required in this present configuration .

You could also entertain the thought of removing the glycol from the equation and tightening up the system side settings and outdoor reset to employ constant circulation . If there is ever a catastrophic event you could add Glycol then to avoid further disaster and remove when catastrophe is over . An outdoor reset mixing valve with a higher Cv would be very good also .

You must be aware of ones true qualifications when you ask for assistance with something . While head and flow mean nothing to you I ask this , How would you recommend I use 100' of 18/3 wire to deliver 240v ? Unfortunately the advice you received was bad or you did not quite understand . It happens , now let's fix it .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Thanks Rich,

I'm perfectly fine with making it right as it appears I did receive poor advice during the building process.

Separating the manifolds would actually be failry straight forward. From your statement regarding this above, I might be able to get away with the existing pump I have now for M1, and add a larger pump for M2?0 -

Possibly . What about losing the Glycol ?You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Loosing the Glycol scares me due to my location. It is not uncommon to see negative temperatures for multiple weeks. I'm out of town a good deal of time in the winter for work and I don't think it will go over well with my wife if I tell her she has to check the boiler in the garage every day while I'm not around. Plus if something did happen to the boiler in the winter, I'm not convinced a heater plus a wood burner would warm the slab enough to keep it from slushing.

What are your thoughts on dropping the glycol down to maybe 15%? I would be much more comfortable going that route.0 -

Well, upon further review...

Andy, please verify that there are two Taco pumps under the cover of the boiler. If there are, one of them is the boiler protection pump, and it should run constantly at full speed.

According to the I&M manual, there is supposed to be an additional bypass cut into the S&R piping BEFORE the secondary take off.

From the manual,

Temperature mixing system

1. Carefully check the temperature of the system return piping as it passes through the boiler jacket and on the return pipe inside the boiler jacket just before it enters the boiler sections. You may do this with a surface pyrometer or by lightly touching the piping with your fingers.

To avoid potential of severe burn — Do not rest hands on or grasp pipes. Use a light touch only. Return piping may heat up quickly.

2. The temperature of the water entering the boiler sections should quickly heat up to about 130 °F, being considerably hotter than the return water from the system.

3. This is accomplished with the two internal boiler circulators. The Bypass circulator (page 2, item 7) takes hot water from the boiler supply outlet and blends it with return water. The System circulator (page 2, item 6) slows down to aid in raising the return temperature entering the sections.

4. If the temperature mixing system does not work correctly, check the two circulators to be sure they are flowing water. If the circulators are operating normally but the temperature mixing system does not maintain water at the enterance to the boiler sections at 130 °F, you may need to replace the boiler control module or water temperature sensor (page 2, item 8).

In your case, when you open the additional floor circuits, and the GCM senses this flood of cold water coming in to the boiler, it slows down the secondary distribution pump (I assume you just used the GCM's control wiring, moved the main distribution output to the Grundfos, and eliminated the other onboard Taco pump). If in fact this is the case, it is going to take some time to get the system up to temperature,because its basically on a roller coaster ride, hitting the throttle while pressing on the brakes. If the other Taco is still on board and wired, you need to modify your piping per the I&O manual per the drawing on page 33 =(adding valves 15 and 16, adding crossover between S&R.).

You may then have to set a separate control relay to power the main (Grundfos) distribution pump(s) on line, and send a signal to the GCM calling for heat and its internal circulators.

As for the glycol, industry standard says that you should use a glycol mix of not less than 30% to 35% in order to maintain proper corrosion inhibitor levels to protect the cast iron and other ferrous components in the system. In fact, fluid maintenance is going to have to become an annual thing.

Please verify the presence or not, of the 2nd Taco circulator under the cover of the boiler jacket. This will give us a better idea of what needs to be done hydraulically.

This new piping methodology has done away with the bimetal thermostat mentioned in previous threads.

ME

0 -

Mark – I have verified two (2) pumps under the hood, the system circ is new and bypass circ is the original that came with the unit. Both are operational via the control module in the unit.

The Grundfos is connected to my Taco SR502 controller. T-stat controls the relay in the controller, thus energizing the Grundfos only when heat is called.

It appears to me that I already have valve 15 & 16 in my current piping (see attached). The only real deviation I see is I have a mixing valve installed where WM does not show one. 0

0 -

Alrighty then, other than the undersized pump issue that Rich pointed out, and the possible need for a separate/additional pump, you should be good to go. Turn on all the loops and let it rip. It could take 24 to 48 hours, but it should eventually top off. If not, then there may be some other issues up or down stream to be resolved, but it should get warm on its own. This is a high mass system, and they are not fast in responding,

Turn it on and let er rip. You will notice on their drawing that they have those two valves partially closed. Personally, with it piped and pumped as it is, it shouldn't make a difference, but you could try tweaking the boiler side to slow the flow and increase the differential temperature on that loop.

Let it runs and see what haps and if it still doesn't come up, you may need have a qualified technician look at the fire side of the equation.

Sorry it has taken so long to get to this point... But gotta make sure the tranny's good before we engage the clutch.

Do you know anyone with a good combustion analyzer that could check its health? They'd need a manometer that reads in hundreds of an inch water column too.

ME0 -

Thanks again for your help guys

I let the system run all weekend (16th & 17th) and the boiler ran the full 48hrs without sending enough heat thru the system to keep the garage at 40. I suspected the mixing valve as I was not getting much heat past that point. I removed the valve and hard piped at that location and we are running great. No issues since the 19th. Garage is sitting at 60 and the boiler only runs for about an hour every 18hrs.

Really appreciate all your help

Andy1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements