What happened?

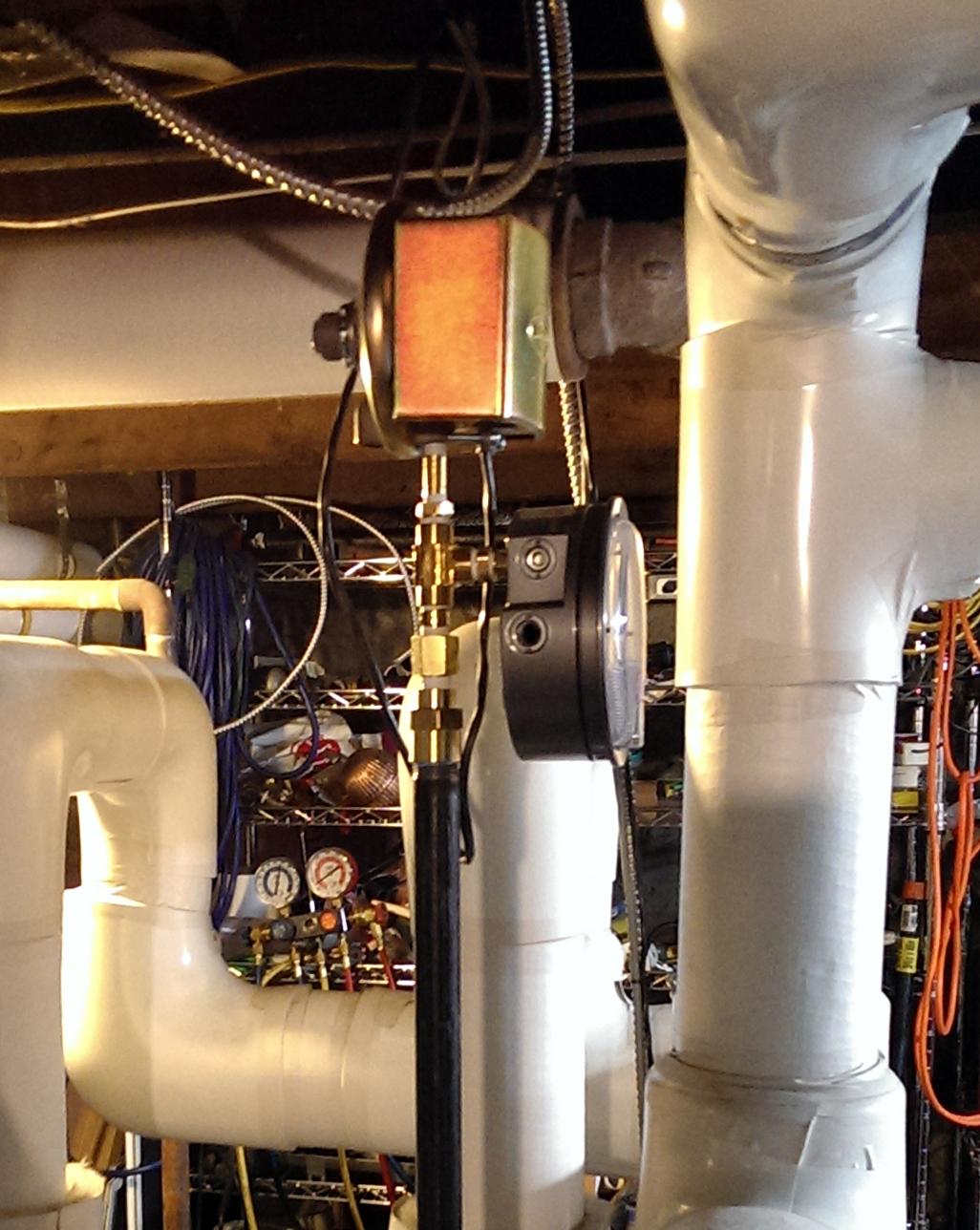

I believe, this is a red brass nipple and when I tried to remove it, it tore the threads out of the connection on the switch. The switch housing and threads appear to be aluminum and are an 1/8" NPT connection.

What gives!?

It seemed almost impossible to remove the nipple and the mini-pipe wrench I have really tore it up to get it moving so it's like the aluminum bonded to the brass.

I saw absolutely no signs of liquid being in any of the connections or corrosion of any kind which was surprising. Anytime I removed gauges from the siphon I always saw nasty stuff from the moisture being trapped so "going commando" really kept things clean as well.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

Comments

-

Brass and aluminum don't play well together.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I was kind of thinking that is what had happened.Steamhead said:Brass and aluminum don't play well together.

What does Dwyer expect you to connect these switches and gauges with if not brass?

The Magnehelic housing is aluminum as wellSingle pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Some sort of isolation union or coupling would be my guess.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Good luck finding anything like that in 1/8".

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Would stainless steel be ok?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Of all the gall ! Both stainless steel and aluminum are sticky metals, they gall easily . One wrap of teflon and some never sneeze is what we use on industrial instrument.piping. Silver Goop from Swagelock is the best but $$. Any anti-seize with nickel should work fine. Any 1/8" pipe fitting you can think of is available in most common metals

There was an error rendering this rich post.

3 -

What would you use if you were me?bob said:Of all the gall ! Both stainless steel and aluminum are sticky metals, they gall easily . One wrap of teflon and some never sneeze is what we use on industrial instrument.piping. Silver Goop from Swagelock is the best but $$. Any anti-seize with nickel should work fine. Any 1/8" pipe fitting you can think of is available in most common metals

I need to go from 1/8" brass female to 1/8" aluminum female.

And I guess, there's some moisture present from time to time.

McMaster has many options for 1/8" NPT.

I just took the switch and gauge off and luckily the brass nipple came out of the gauge no problem. I was concerned as it had been in there just as long as the other had been in the switch.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Understood, but I had things tight for two reasons.

1: I didn't want anything moving if bumped.

2: If any of this leaks it means guaranteed death to the stuff attached.

Can I use Megaloc dope instead of anti-seize and just go easy on the torque?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Because this is a siphon-less connection to a steam boiler. The only thing stopping steam from getting to the devices is the air trapped in the 18" long nipple. As long as it's air tight, it's safe for the stuff attached.Hatterasguy said:The fitting doesn't care why you overtightened it.

Why would a leak create "guaranteed death"? The pressure would fall to the device...............

You can use anything you want if you don't overtighen it.

I recently installed some 3/4" stainless fittings for DHW. I absolutely know I am f'ed if I ever have to remove them. I can feel the threads permanently lockup. Whether I could have gone one less turn...............unknown.

Aluminum is similar. Use the minimum amount of torque necessary to seal (fully realizing that that value is uncertain at the time of the install).

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Brass & Aluminum = galvanic corrosion.

You can use galvanized or black pipe on aluminum0 -

-

CGV?RobG said:Think about a gas valve. What's it made of and what screws into it?

Aluminum body.

Typically black iron pipe screws into it, but the plugs are steel and the pilot tube has a brass ferrule and connector.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

-

Yep........It only takes one time, to make you realize you shouldn't do it that way.0

-

I've always read that you must allow an aluminum head to cool to prevent galling, but never heard of using a lubricant.Paul48 said:Yep........It only takes one time, to make you realize you shouldn't do it that way.

I also use a torque wrench when doing plugs on aluminum heads. The plugs my two car engines use call for 16 ft/lb. I've done them a few times now.

Now, the oil drain plugs on the other hand............. that I've had serious problems with and am now going to be using a torque wrench on those as well because apparently my gorilla hands just can't get it right.

They used a 10mm head on a 14"mm aluminum plug that has a huge shoulder built into it going into an aluminum pan. It calls for 14nm of torque. I had to remove the last plug using a pipe wrench so from now on, torque wrench when installing. I never realized how little 14nm is, which is approx 10ftlb.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

In my case, I was putting the first set of plugs in after the manufacturer. The car had been sitting over night. Three plugs came out "funny"(felt odd). The fourth one turned about a quarter turn and locked solid. For years, I had laughed at other guys, that snapped plugs off. I've been working on cars for about 40 years. I pulled the head, and took it to the machine shop the next day. I've been putting a speck of nev-r-sieze on them ever since. It's cheap insurance.1

-

Have you tried testing for air leaks with bubble solution? You could run the pressure up to your high cutoff of 4.6 oz. NG leaks show up well at 4 oz.

Then there is always the "feel" test during operation. With the traditional pigtail one can always tell where and if the water seal is.0 -

I wonder if GCV would be a special aluminum alloy. Old standing pilot valves have up to 3 brass fittings installed maybe 2 black iron pipes. Usually even after 30 plus years they have always come out, as long as the flats were not messed up with the farmer CeeTee pliers.0

-

Paul48 said:

In my case, I was putting the first set of plugs in after the manufacturer. The car had been sitting over night. Three plugs came out "funny"(felt odd). The fourth one turned about a quarter turn and locked solid. For years, I had laughed at other guys, that snapped plugs off. I've been working on cars for about 40 years. I pulled the head, and took it to the machine shop the next day. I've been putting a speck of nev-r-sieze on them ever since. It's cheap insurance.

I've heard if you feel binding like that on a spark plug you should loosen them all slightly and then start the car. This will blow any carbon that is in the threads out. Never had to do it my self, but that's what I've heard.

my 1930's refrigerators have aluminum bolts holding a stainless steel evaporator to a steel plate using steel washers and nuts. They also condensate often. The amount of corrosion was scary around the nuts, picture a nasty corroded battery terminal on a car battery.

After 80 years the aluminum bolts just snapped off and I replaced all of it with 316 stainless. Either way, aluminum, stainless and steel together lasted 80 years until someone wanted to remove it.

I'd love to know why they chose aluminum bolts to mix with stainless steel and steel. There had to be a reason.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

That's a strange one...........I wonder if it was for vibration? The aluminum would be so soft, they wouldn't have issues. Just a thought.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements