Gasification Boiler pump to storage system design question

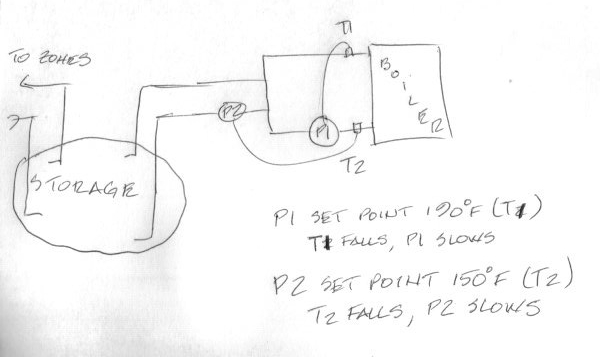

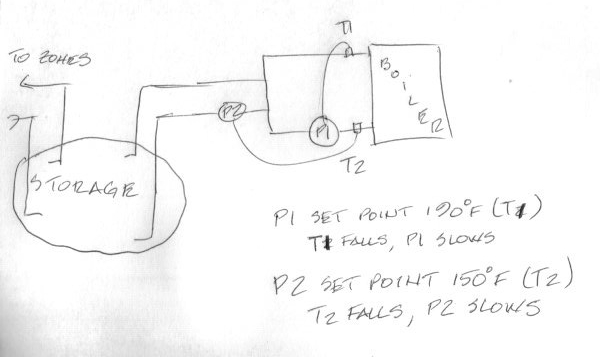

I am planning to install a 60kW wood gasification boiler in an outbuilding and piping the supply and return underground to 1000 gallons of pressurized storage in my basement. The storage will feed 4 zones of infloor radiant heat. I would like to set up the pumps to circulate water from storage through the boiler as shown in the diagram. I would like to use the temperature set point function of the new Taco Viridian pumps to do the following:

P1 would turn on when the boiler water reaches 140-150F and be set to control the output of the boiler at a T1 180F setpoint. P1 would speed up to lower T1, slow down to increase T1. Flow through the boiler at max output would be about 16-18gpm. P2 would start when T1 reaches 180F and control to T2 150F set point for boiler protection. If T2 falls, P2 slows, etc. Flow through P2 to storage would vary but at max boiler output would be about 5-6 gpm. Water to storage would be at 180F, water returned from storage would be a constant (in theory) 100F.

Should I be concerned with interaction between these pumps making the system unstable? Any comments appreciated.

Comments

-

There are a few way that can be done. A delta t circ

, if it has a wide enough temperature range, or a couple tekmar controls.

some good piping and wiring schematics here

http://www.nyserda.ny.gov/-/media/Files/EERP/Renewables/Biomass/biomass-hydronics-training.pdf

Credit: John Siegenthaler, NYSERDA Biomass TrainingBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks but I don't think any of these give a set boiler output temp which is the major goal of my system. The other being boiler protection.0

-

Have you seen the Laddomat or the Caleffi equivalent? while that function is built into the devise it is a little difficult for me to determine if it can send it a quarter mile away or whatever..little more detail might help out. is it aquatherm or the type of pipe to and from the building? is there a way to load the slab/s in a type of overide to help with a longer term burn ?

i think if you look up idronics 15 and 16 in 16 they have one of these laddomats made by caleffi. Maybe Hot Rods still here and will know what i am babbling about.

found the link . hope this helps you .

http://www.caleffi.com/usa/en-us/catalogue/thermobloctm-recirculation-and-distribution-unit-npt-281165a

The Laddomat 21 looks like the esbe ltc141

http://www.centrometal.hr/3-putni-termostatski-ventil-grupe-esbe-ltc-141-171-laddomat21/

i read something about wireless thermostatic control then i read ,

MANAGEMENT BY PHONE OR MOBILE PHONE Voice communication in the Croatian language. ok well that option might not be real great for me ...:)

I looked into the circulator made by grundfoss that drives this a year or two back , when a guy named Jeff had some minor technicality with an air bubble lock in a zone off an experimetal beta testing type lash up. i think it was a 15-55 U-130 NOT AN EASY FIND IN MY BOOKS ok not even in the book. so it took a while to find what it meant in grundfossese. While some circ have long life spans into 3 or 4 decades , i was and am still curious if there is a replacement cartridge type thing or replacement motor. 0

so it took a while to find what it meant in grundfossese. While some circ have long life spans into 3 or 4 decades , i was and am still curious if there is a replacement cartridge type thing or replacement motor. 0 -

often times you can just change the motor with another. The 15-55 is an Alpha. The 15-55 U-130 is probably a union body with a 130 MM dimension. The Alpha 15-55 should be an easy find, Ive seen them on the shelves in Anchorage and Fairbanks.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don't see how the two circulator controls would fight each other, but I do see the potential for P1 to fight with the boiler. What benefit do you anticipate from running P1 off of setpoint control? Or, more to the point: what benefit do you anticipate from throttling down flow through the boiler, given that these are ideally run in batch burn mode and shouldn't see part load situations?

Weezbo, if you need someone to whisper sweet nothings to your gear in Croatian, I can help. :-)0 -

Not sure how controlling the boiler output to say 190F will result in throttling of the boiler as that is a normal boiler output temp. I want a stable output temp from the boiler to charge storage in a one and done manner. The storage pump will only pump enough to remove whatever heat output the boiler is producing at any moment. Flow through the boiler is simply varied to keep a steady output temp.0

-

It's "normal" because the boiler aquastat is there to keep it from steaming. Solid fuel boilers are tricky to control -- even the best gasifiers can only do so much.chrisbowen said:Not sure how controlling the boiler output to say 190F will result in throttling of the boiler as that is a normal boiler output temp.

0 -

Well that is what I meant- boilers are normally controlled so that they don't overheat. As long as the same amount of heat is pulled from the boiler loop as the boiler is outputting, I don't see the issue....0

-

the boiler manufacturer will usually have a minimum flow rate that they allow. Most solid fuel, steel boilers can run down to a 30° ∆T.

So what ever flow rate that equates to based on the boiler output.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

=====================================================chrisbowen said:Hello-

I am planning to install a 60kW wood gasification boiler in an outbuilding and piping the supply and return underground to 1000 gallons of pressurized storage in my basement. The storage will feed 4 zones of infloor radiant heat. I would like to set up the pumps to circulate water from storage through the boiler as shown in the diagram. I would like to use the temperature set point function of the new Taco Viridian pumps to do the following:

P1 would turn on when the boiler water reaches 140-150F and be set to control the output of the boiler at a T1 180F setpoint. P1 would speed up to lower T1, slow down to increase T1. Flow through the boiler at max output would be about 16-18gpm. P2 would start when T1 reaches 180F and control to T2 150F set point for boiler protection. If T2 falls, P2 slows, etc. Flow through P2 to storage would vary but at max boiler output would be about 5-6 gpm. Water to storage would be at 180F, water returned from storage would be a constant (in theory) 100F.

Should I be concerned with interaction between these pumps making the system unstable? Any comments appreciated.

First things first,

Solid fuel boilers do overheat and I can tell you that from 33 years of experience.

A coal stoker boiler will provide you with plenty of hot water and eliminate the need for hot water storage completely.

You can have plenty of hot water in your forest eater using 140 low 160 high OR 150 low 170 high.

I use one circulator and have been for 42 years in my baseboard heating loop(WHICH I HATE). as I wish I had cast iron radiators instead.

You can heat everything very well with one simple 3 speed circulator like I do and simplify your heating system with a forest eater but a coal stoker boiler like the Axeman Anderson130S or 260S or the EFM DF520 will work much more effectively for your heating needs.

I have used these temperatures for years in my hand fed wood and coal boiler and 150-170 now in my coal stoker boiler.

You do not need those high temperatures simply because the recovery will be faster at the lower temperatures.

The other thing is firewood has to be split to its thinnest wedge to enable it to burn well and cleanly and to suck all the usable BTU out of it.

If you have not done this already have you considered using a copper coil or copper coils in simple open storage tanks that act as thermal mass for your heating load?

Rather than having a pressurized vessel in the basement like refurbished propane tanks you can use rectangular storage tanks from New Horizons or their open storage tanks with lids with large diameter copper coils in them that have huge amount of thermal mass.

0 -

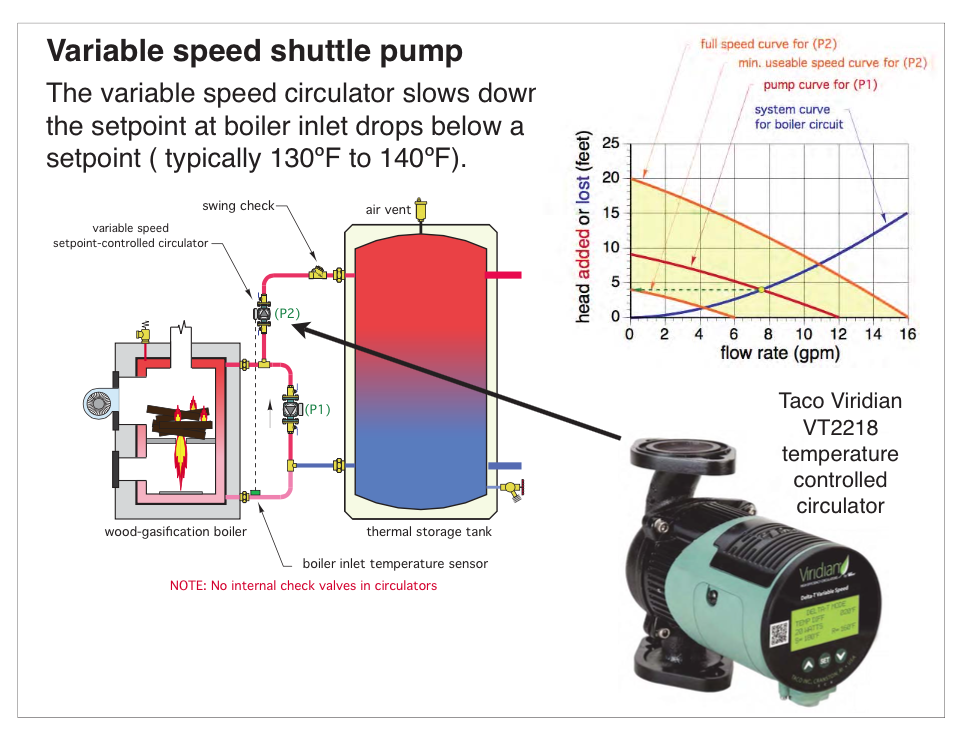

Here is a simple and appropriate boiler protection with off the shelf components. A Taco Delta T circ would have all the control logic built in.

Your variable speed circ needs to be the tank one, not the boiler.

You have plenty of storage to prevent over-heatingBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements