Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

New shorter furnace and what to do with the extra space...

Options

furnaceNewby

Member Posts: 38

in Gas Heating

New furnaces I am looking at are 12 inches shorter than my existing furnace. I have the option to raise the new furnace on a box (plenum?), or insert a piece of duct-work (plenum?) between the new furnace and the A/C unit that sat on top of the existing furnace.

Does one have benefits over the other?

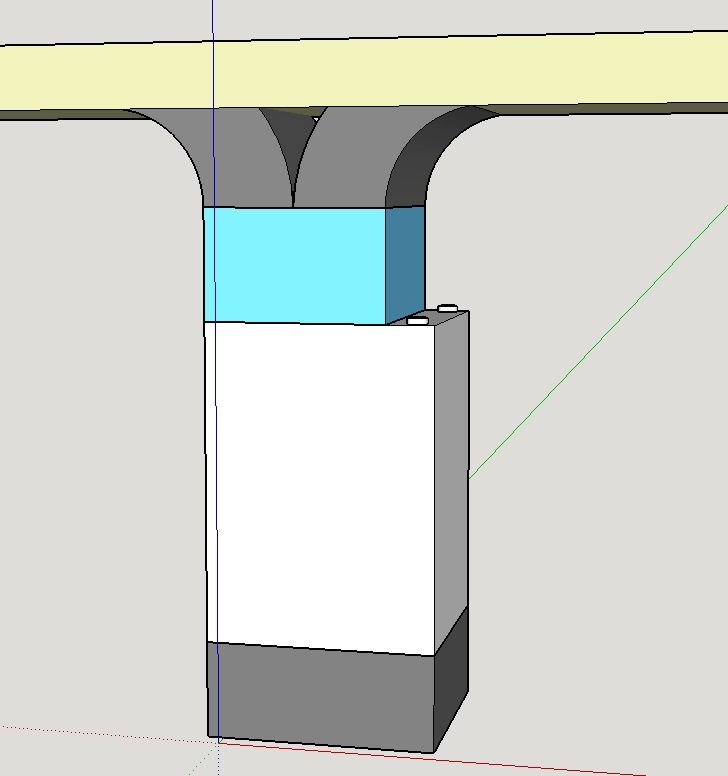

Here are some drawings that may help explain. White is the new furnace, blue is the A/C unit, dark grey represents a new part of ducting, yellow/beige are the existing duct-work. Thanks for any replies.

Does one have benefits over the other?

Here are some drawings that may help explain. White is the new furnace, blue is the A/C unit, dark grey represents a new part of ducting, yellow/beige are the existing duct-work. Thanks for any replies.

0

Comments

-

I like getting the furnace off the floor and then you can do a side- bottom return that will improve air flow.0

-

Thanks. Is there a term that I can use to refer to the box that the furnace would rest upon to get it off the floor?0

-

Conversely, I prefer to have more distance between the furnace and coil. It allows for better airflow and provides a good location for static testing and HX inspection.0

-

I am not trying to scare anyone. Only trying to learn.

JStar, this is one thing I was wondering. Whether adding volume between the heat exchanger(s) and the cooling coil (evaporator?) helps or hinders the airflow of the system.

It sounds to me that adding volume in one of these two ways will improve the system.

Would the modification below be an improvement as well?

0 -

What model furnace? What size suplply and return duct? How many CFM does the house require?

You can also add a wrap-around return that pulls air from both sides of the furnace.0 -

You don't want to do it as your last picture suggests. Or any of them for that matter.

What I do is fabricate a new plenum to fit the new furnace and then install offset trunkline starters to pick up the rectangular trunkline. Typically, you don't need a bottom return or return on both sides unless the furnace is near 2000 CFM.

Having a space between the top of the furnace and coil is nice as Joe suggestsSteve Minnich0 -

This will give you a better visual. The top of the plenum should stop short of the bottom of the ceiling joists to allow for drywall or something else your local code may require for fire code.

You can see what I mean by the offset starter on the one side of the plenum. The side of the starter that connects to the plenum is usually something like 10 x 12 that will offset/transition to an 8 x 12 rectangular duct (trunkline). I just chose that size randomly to give an example.Steve Minnich0 -

Are you the poster from the Denver area?

Are you going to keep your existing AC system?

Snowmelt, that is an exciting picture. That has been on here before,

did that really happen somewhere? 0

0 -

Hi found it on hvac- talk hall of shame. I don't know if it really happened but I'm going to assume it did.0

-

I understand why you included it here. This op has a previous posting concerning his furnace.... I thought he had a contractor on board for change out.....I just wanted to tell OP that the main reason for furnaces being shorter is to get the much taller 410A coil box to fit in most basements. So if keeping the old coil box to keep the furnace close to the floor and maintain the extra space above for future AC change out. However everything I install in a basement gets set on 4" solid blocks if at all possible. Just a little insurance on water damage and a little elevation for servicing help for tired knees etc.0

-

First things first: the newer furnaces are now 33" tall. To accomplish this, they had to shorten the blower compartment as-well-as the heat exchanger. The shortened blower compartment has created a problem that never existed before. The opposite side of the blower - from the return drop - is choked down from how much air it can draw, putting undue stress on the blower motor. By putting the furnace on a return air base (no less than 5" tall) and tapping the return air boot into both the base and furnace; both sides of the blower can now pull air without struggling for it. Also important: the blower can only push the amount of air that is equal to what it can pull. Increase what it can pull, and you increase what it can push. A 3" space, or greater, between the furnace and cooling coil is a large plus. If the existing supply plenum is larger than the opening on top of the furnace; then yes, replace the whole plenum with a new plenum to keep it the same size as the top of the new furnace. When replacing a furnace, one must consider that the near furnace ducts have total control of how much air travels through the furnace - period! The near furnace ducts (S/A plenum & R/A drop) should not cause any resistance on the blower. The resistance, that is necessary in a forced air duct system, should begin in the Trunk Lines - ONLY!!!0

-

Thanks for all the great information!

I am working with the hand I've been dealt.

I do plan to keep my existing A/C, I'll be sure to leave enough space for a taller A/C unit. I have 84" of vertical space between the concrete floor and the bottom of the supply plenum.

My existing furnace is 46" tall, so it seems I could add a 6" space between the furnace and my existing A/C, as well as a put a 34" tall furnace on a 6" return air base. This would put the top of a new assy at the same height as the existing furnace (i.e. at the bottom of the existing A/C). The existing supply plenum is not larger than the opening on top of the existing furnace (see pictures at top of post).

According to the specs I can find on my existing furnace, it appears to be a 1600 cfm MAX blower, with taps for lower speeds. When I run the blower at the MAX setting, the air moving in and out of the supply and returns is quite loud. Even the low setting is loud in my opinion!

The supply duct runs horizontal with the furnace rising to meet it in the middle. The system looks like a "T" with the furnace being the leg and the supply plenum(s) being the crossbar of the "T". The supply plenums are each 17"x8". The vertical part of the supply starts out as 20.5"x20.5" on top of the A/C, and necks down to 17"x20.5" to meet the horizontal supply plenum. The vertical part of the return "T" is 14"x20.5".

Thanks again for all the wonderful help!0 -

Put a hot water coil in to heat with hot water from solar, wood, geo, nuclear, etcBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

As a rule of thumb i always use a pre made on any thing over 3 tons ,espically since now most furnaces are either a 3 or 5 ton drive unless you have a very small furncae like 40 mbtu which may have a small blower but i doubt it ,there usually about 10 inch high amd fairly cheap in the scope of things I personal have never used a base less then 9 inches high .The pre made bases let you use central duct to return instead of cutting out both sides and you can flip it of either left or right return drop ,If you don t use a base i would suggest at the least to raise the furncae off the floor i believe most hvac supply house carry plastic blocks that raise the unit a few inch off the foor.If you look through the i and o manual they will give you clear specs on the return duct .Undersized retrns can leave to over heating heat exchanger and short cycling of the gas side durning operation .peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

Heating supply houses near me carry return air bases that are 18" tall. What do guys do if they only need 12" of height? Are the pre-made bases meant to be cut to fit?0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements