Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Steam piping advice for Brewery

Options

OrmondBrewing

Member Posts: 4

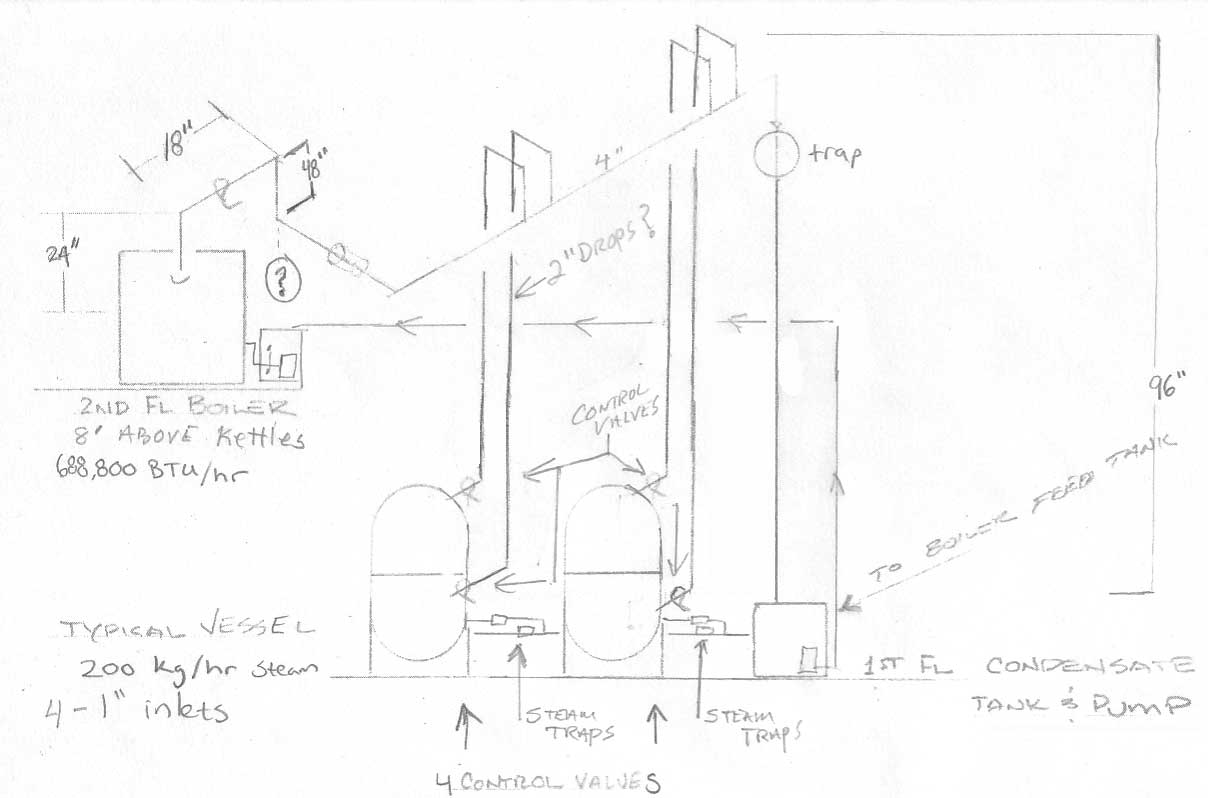

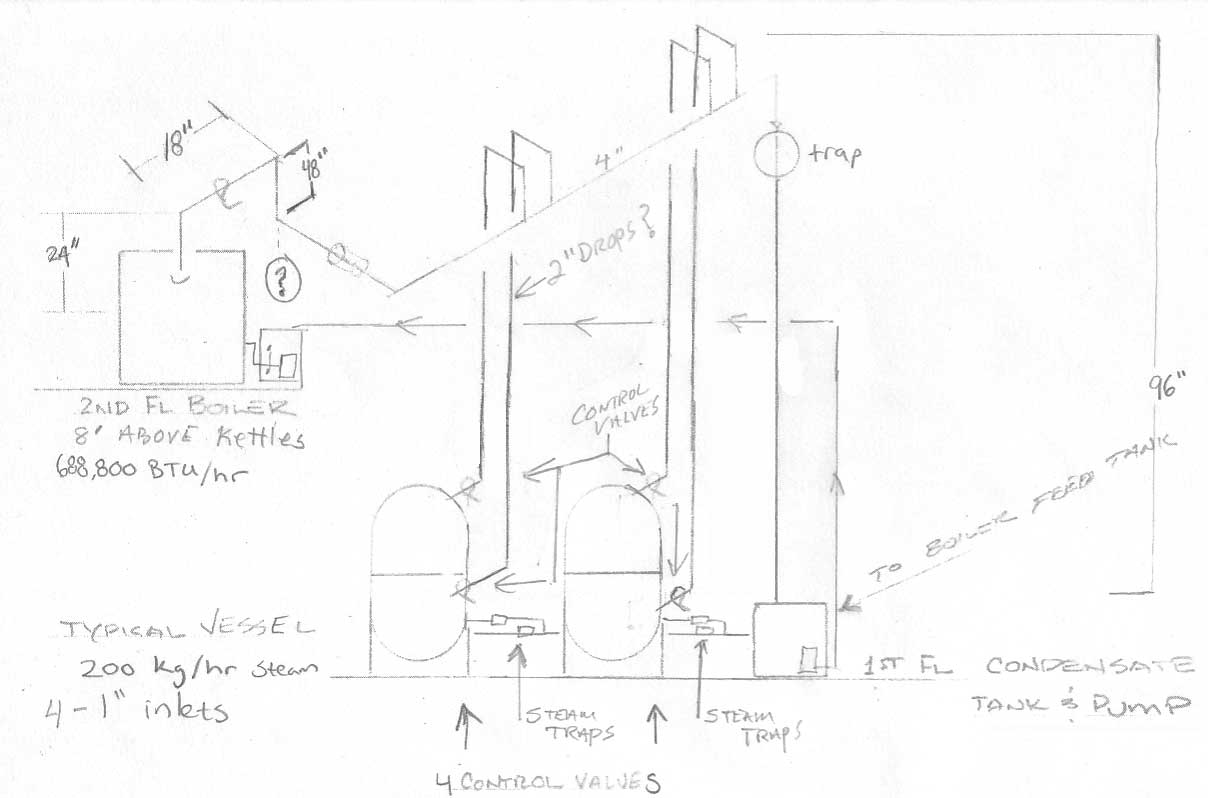

We are installing a boiler on a roof above our process equipment. I would like some comments on my design, and have a few questions.

Our boiler is a Columbia MPH-20 rated at 688,800 BTU/hr. We have 2 vessels that require 200 kg/hr of steam each. The header pipe is going to be 4". The vessels each have 2 inlets, and 2 outlets that are 1". We also have 1" control valves.

1) The piping from the boiler header to the distribution header is going to be 4" black iron. On the initial drop, does it require a steam trap (indicated with a ? on the diagram).

2) Would 1" pipe be sufficient for (4) 8' drops to the vessels? (each vessel has 2 inlets with 200kg / hr). If not, what size?

Thank you for any comments.

Our boiler is a Columbia MPH-20 rated at 688,800 BTU/hr. We have 2 vessels that require 200 kg/hr of steam each. The header pipe is going to be 4". The vessels each have 2 inlets, and 2 outlets that are 1". We also have 1" control valves.

1) The piping from the boiler header to the distribution header is going to be 4" black iron. On the initial drop, does it require a steam trap (indicated with a ? on the diagram).

2) Would 1" pipe be sufficient for (4) 8' drops to the vessels? (each vessel has 2 inlets with 200kg / hr). If not, what size?

Thank you for any comments.

0

Comments

-

What kind of steam pressure are you going to run in the boiler?0

-

15psi max steam pressure0

-

Why are you putting it on the roof? Besides the much greater heat loss in the winter, can the roof support the load?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

"" 15psi max steam pressure ""

15# steam pressure is tough to maintain when making beer. In fact, the brewery I had experience with didn't run their steam boiler that high and they made fine beer.

They also had a distillery. They tried running 15# steam. It was a disaster. We found a digital adjustable controller that maintained it within 1/4#.

Listen to what Steamhead says. For he knows of what he is speaking about.

IME, it isn't how much steam you can generate to make the beer, it is how much potable hot water you need to generate. When you think you have enough, you'll need more.0 -

The roof has been engineered to support the boiler (and a chiller) which are currently sitting in place. The boiler on the roof will have a building built around it. Our building does not have a mechanical area besides the roof, it is our only option. As for heat loss, it is in Florida - today the low was 70 degrees F. All pipes will be insulated as well.

When I mentioned 15# max, I was referring to the fact that it is a low pressure boiler. Can you tell me the name of the digital controller that modulated the boiler to maintain the 1/4# of steam? That sounds exactly like what I need.

The only other questions I have are on my piping sizes (off of my 4" main going down to my 1" steam inlets on the equipment). Do I need to maintain a larger pipe size up to the 1" reduction or should 1" be fine from the header? The length of run from the header is approximately 8 feet.

Also, on the first drop do I need a steam trap on my 4" main (where the ? mark is on the diagram).0 -

make sure the building around the boiler can accommodate any future boiler addition/replacement down the road. Are you sure you have no ground level space? The boiler needs frequent watching, and maintenance. On the roof sounds like out of sight, out of mind to me.--NBC0

-

I can't tell you where to put all your steam traps etc. or how to pipe it.

I sent a message to someone about the controller, It just controls the settings very accurately. There is a sensor that goes on the "Antler". Its just another control There is a box that mounts on an electrical box and all the settings are done on a LED board.

How big is this steam boiler going to be? What is the fuel?

Where's your brewery going to be?

They need more craft beer in Florida restaurants. Bud Light on tap? I'll be heading for the head.0 -

In regards to the operating pressure of the boiler, I don't think you will need a control that is incredibly accurate and keeps your boiler operating at 14.5 psig. You could run boiler at 12-13 PSI. The difference in heat between 13 PSI and 15 PSI is 4 degrees F. I have worked with a lot of breweries who are using low pressure steam systems and they all start out with needing 15 PSI because the equipment states that it uses 15 PSI. After I tell them the same thing I just told you, they operate between 12-13 and have no problems. Just a heads up. Cheers.0

-

@Wolfie2132:

The control I'm talking about I didn't buy. I only piped the probes. The owner had a large Peerless steam boiler that was in a distillery. The normal operation was that it did a lot of thermal lead/lag because of the settings. The new control was extremely accurate in operation over the standard analog controls, and was extremely easy to adjust.

The boiler they had in the brewery ran at 6# or 8# I don't remember. In the distillery, they had planned on having 3 stills. The price of copper went way up so they only bought one still. So, the boiler is sort of way oversize. They run all their beer and wine waste through the still to extract every bit of sugar and alcohol. And anything they can grow to flavor it.0 -

Some sort of steam preheating circuit in the condensate tank might be able to remove some of the oxygen in the makeup feed water, before it rots out the boiler.

How did you arrive at that boiler size? I'm not sure that two one inch supplies will use all of your BTU's. If you are allowing for future expansion, then maybe having two smaller boilers would be better.

What is the capacity of your heating vessels, in gallons?

What is your location in case we want to try the product?--NBC0 -

You need steam traps on each drop to the vessels upstream of the control valves otherwise when the control valves close or modulate the drop will fill with water and hammer on start up.

You can avoid the traps by putting the control valves at the top horizontal pipe coming out of your steam header. They will work fine there but I am sure someone here will probably have an issue with it. You do not need a trap at your ? mark as long as all the steam piping is pitched away from the boiler and the condensate can drain to your end of main trap.0 -

Hello,

Thank you for all of the comments. The boiler room will be able to accommodate upgrades down the road without a problem. It is easily accessible so we will be up there almost daily to blow it down.

Is this controller similar to the one you mentioned Ice?

http://cdn.heat-timer.com/wp-content/uploads/2013/01/SPC-Elite-Lit-056050C-Color.pdf

The boiler is a Columbia MPH-20 which is rated at 688,800 BTU/hr. It will be run on LP gas. We were recommended this boiler and that size based upon advice from a boiler company who had sold these to many other breweries that were the same size as ours. Our brewery is close to Daytona Beach, FL.

I'm sure I'll find running it at 12PSI or even 8PSI will be adequate for my process. Thanks for the heads up.

I am still working out the water pre-treatment side of things, but was planning on pre-heating to remove oxygen as one of the steps. One thing I don't understand is why it calls for a pH of 10-11 - that seems really high.

Our vessels are approximately 500 gallons for the boil kettle (which needs to boil), and the other one is 500 gallons on the top and 500 gallons on the bottom but will be maintained at approximately 160 F.

All of my piping is going to be pitched downward The reason for the initial 48" drop is to make it low enough inside the building to where we can have the 4' header suspended from a steel beam. Thank you for confirming that I do not need a drop there.

The question I'm still trying to figure out is if 1" pipe from the header is adequate, or if I should use larger pipe and reduce it to 1" at the vessels? As I mentioned it is approximately 8' long from the header. I could alternatively weld a larger supply threadolet to the tank if necessary...

If any of you want to PM me your address, and what "style" of brew they like I'll get you some samples. Thank you for all of the help.0 -

Perhaps one of the wet heads here can tell us how many BTU can be delivered through two one inch pipes, and that information, coupled with the desired boil time, would determine the size of the boiler, as 688 KBTU seems oversized. Oversized boilers will short-cycle themselves to earlier problems, especially when only one kettle is being heated.

Some sort of staged firing, such as the "mod-u-pack", which is an add on for Peerless boilers. Alternatively, two smaller boilers could be used, with the lead boiler always on, and the lag boiler, turned off and on as pressure rises and falls. These could be piped into a common header., with good swing joints on the risers of the boiler(s).

I'm sure you will need a larger supply pipe than one inch to supply both kettles. Down the road, if you have a boiler replacement, you can still keep going at slower speed on the one good boiler. The aim should be with the piping to get the air out quickly, when the system is fired up, and deliver a constant supply of dry steam to the kettles.

Make sure the combustion air does not get too much salt spray from the sea, as this can lead to early failure of the cast iron sections (see "galvanic corrosion").

The Heatimer control is mainly for space heating control of large buildings, and not for process control.

Good luck--NBC

0 -

@OrmondBrewing:

That Heat Timer control looks like the same or newer model. It used the 0-30# pressure sensor.

I didn't do this install and I'm not any form of a Steamhead. Because the installers were not really Steamers, there were mistakes.

The brew kettles had two jackets and two steam traps each (as I remember) because one was not placed properly, One for the bottom and one for the sides. Once I flipped the traps, they worked fine.

The distillery is probably of more interest to you because although the boiler and still were on the same floor, they had to run way overhead to get from the boiler to the still. Is 4" supply going to be big enough for future expansion? On the Still, the drop pipe off the overhead main might have been 2" or 1 1/2, but it reduced to 1" to a steam trap which drained into a condensate pump just above the steam entrance to the still. With the brewery, all kettles had their own traps draining in to one condensate pump/tank.

Like I said before, I'm not a steamer. Others here are the ones. I just fixed a Peerless 18 section LE/LGE. Anything correct about it was by accident. And after careful observation, they lucked out. You have a lot of upsy's and downsy's around the boiler. Whatever boiler you get, be sure that the near boiler piping is correct as far as the manufacturers instructions go. Just because some company claims to be "experts" in steam installations, does't mean they are. You must have some concerns about something as far as steam. You came to the right place.

Hot Water: If you think you have enough, you'll need more.

0 -

If this is a closed system, you should be using very little make-up water. Unless your tap water is really, really awful you should be fine, perhaps just something to bring up the pH a bit. 10-11 is too caustic for some components.OrmondBrewing said:I am still working out the water pre-treatment side of things, but was planning on pre-heating to remove oxygen as one of the steps. One thing I don't understand is why it calls for a pH of 10-11 - that seems really high.

0 -

IMO. it better be a closed system. If you are using municipal water and it is anything like WPB where I live (Royal Palm Beach/Wellington) the excessive chlorination they do to kill all the bacteria in the water will rot that boiler out in no time. Even so, I might consider a large carbon filter on the feed/make up water.

Just boiling water and eggs to make egg salad stinks up my kitchen and I use filtered water for my black coffee. Otherwise, it was undrinkable. Can you drill down and get decent water up where you are?

The place I helped out had really good well water. The municipality health department found a way to prohibit their use of their wells and made them connect to municipal water. With floating queebs in the water and didn't make the same quality beer.0 -

Obviously you need to know your water chemistry and take appropriate measures if needed. My point was really that you should not be using all that much makeup water if the system is running properly. Buy an auto-feeder with a meter on it and make sure somebody logs those readings as part of your normal operational process.

Activated carbon converts chlorine to chloride. The ions (while far less active) remain in the water.0 -

Well, whatever. It shouldn't be an open system, and if his water smells anything like mine does when I'm in the shower or boiling water, it doesn't seem like the best fluid for any system.

That's all I was saying.

And it makes for crappy beer.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements