Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Kelmac Retarder Traps revisited

Options

JUGHNE

Member Posts: 11,508

This is a follow up to the March 4, 2014 posting by homeowner in Nebraska. The system has had orifices added to most CI rad valves. System has vaporstat and 0-32 oz gauge installed, A total of 6 #2 Gortons were installed, 2 on each steam main and 2 on the dry return. System was started with vaporstar set to cutout at 12 oz and is heating but boiler needs cleaning as there is surging, foaming and priming in sight glass contributing to short cycling.

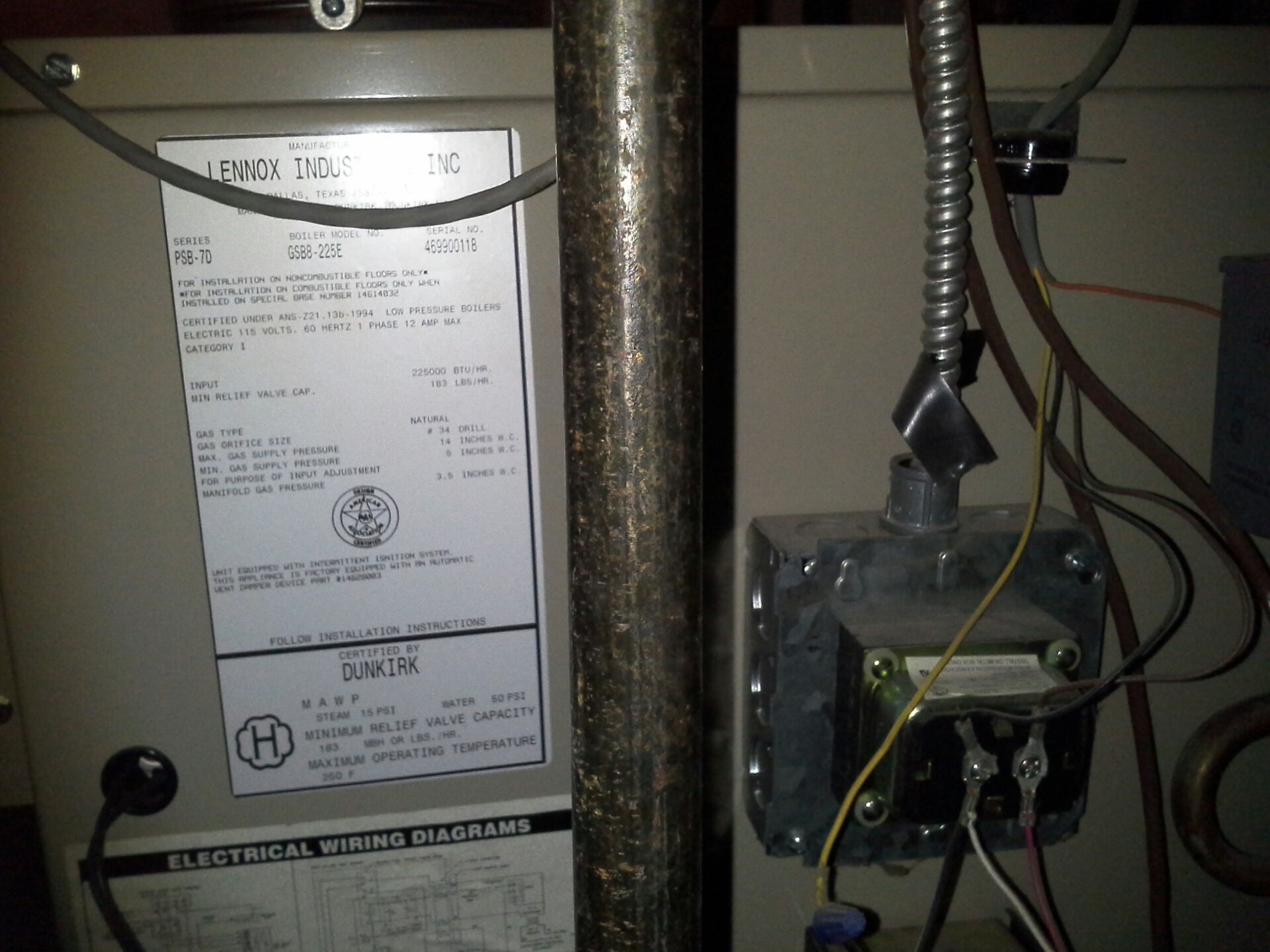

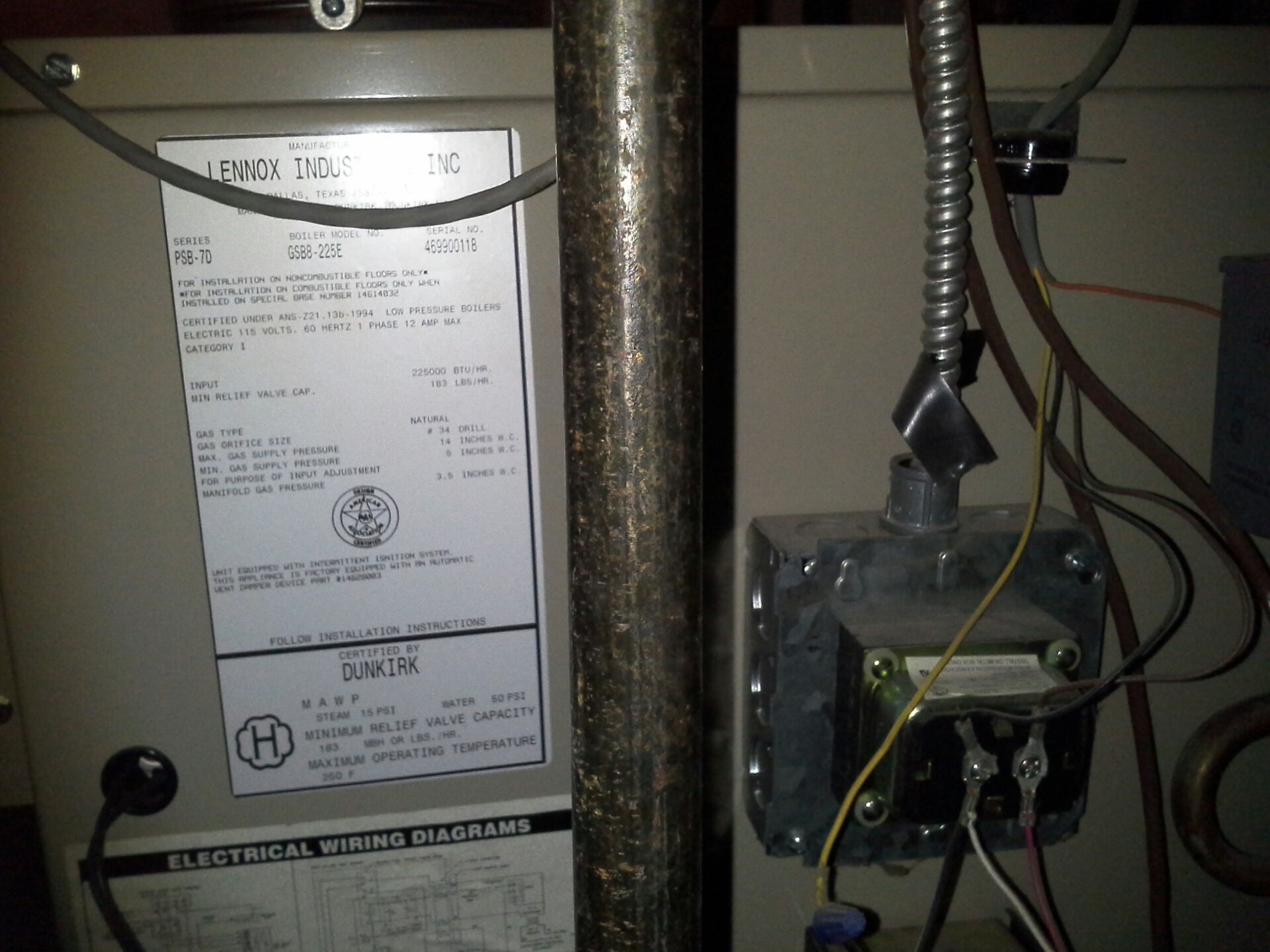

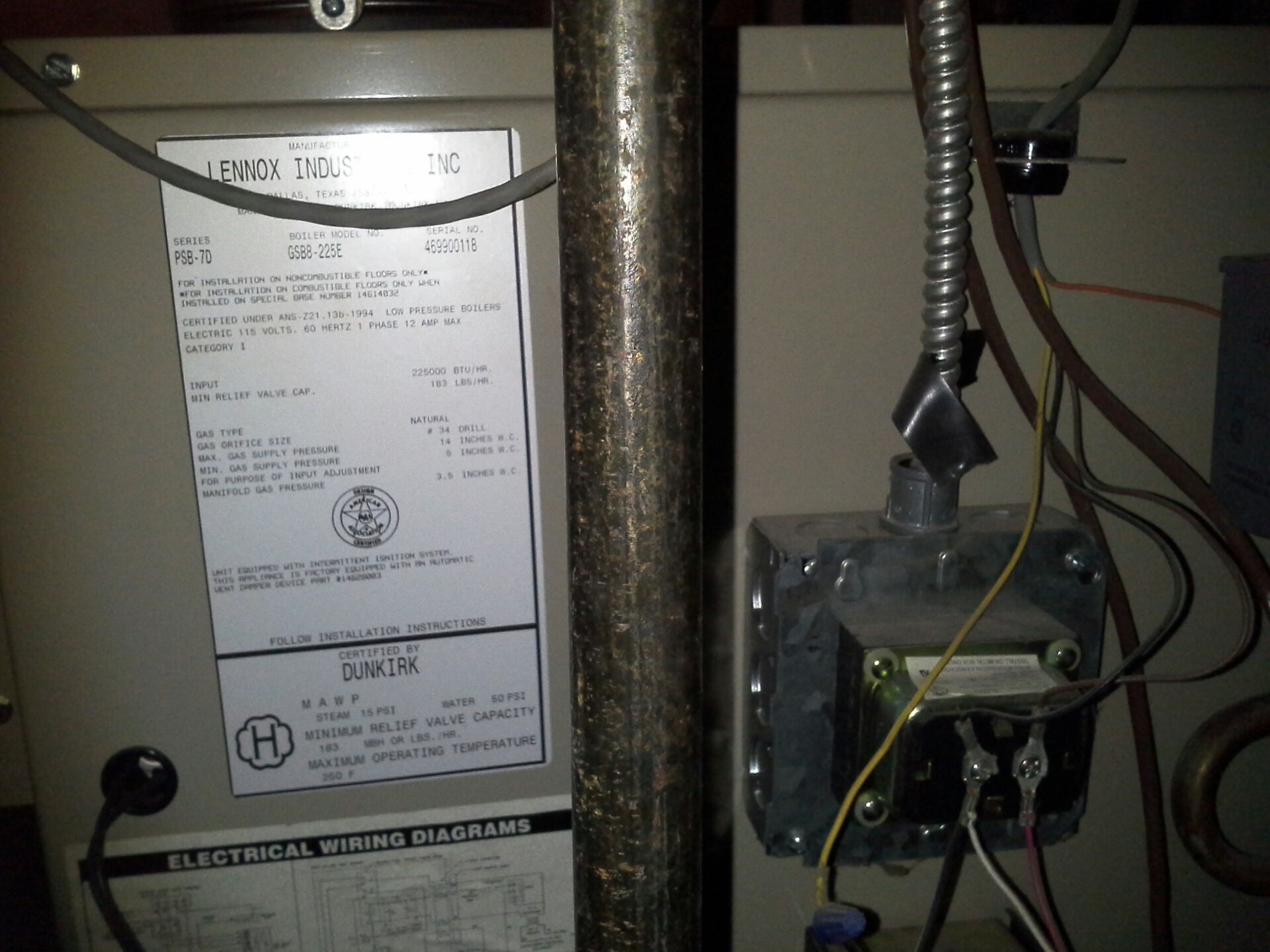

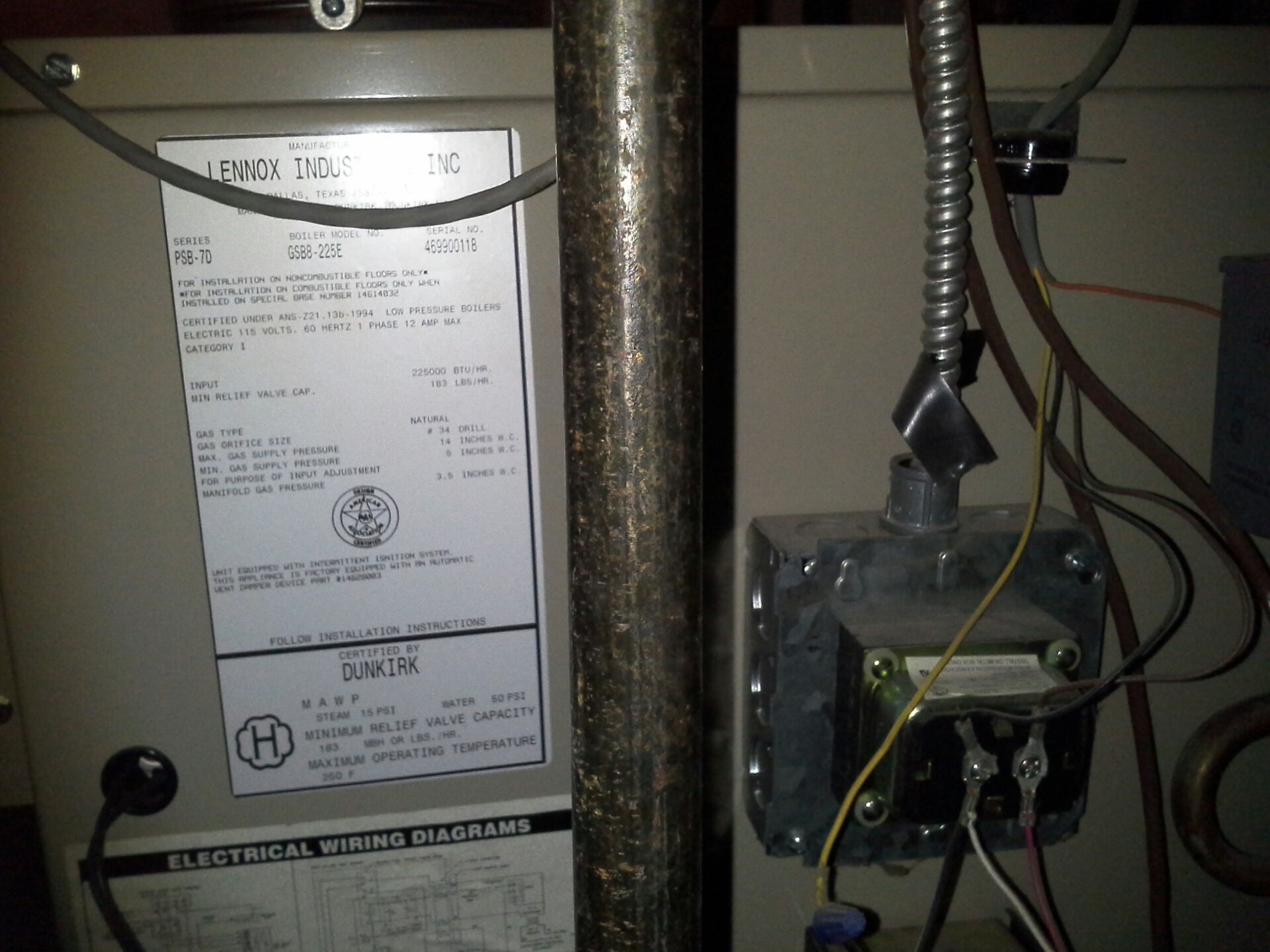

Question #1: Nameplate indicates PSB-7D (Dunkirk/Lennox) GSB8-225E; with input of 225,000 input. gas orifice size of #34 drill."For purpose of input adjustment 3.5" WC". However there are 7 sections with 6 burners with orifices measured with a #34 drill size; several charts indicate that #34 @ 3.5" WC = 31,283 BTUH; which X 6 burners = 187,698 BTUH. This is the input of a PSB-6D (according to the downloaded I&O manual). So which boiler do we have? I have not clocked the meter nor check manifold pressure and it was the end of several long days. This is 140 miles away.

Question #2: With rad valve inlet orifices is the actual connected EDR based on the size on each orifice at the max pressure applied? For starters I have sized the orifice @ 18oz pressure for 80% of CI EDR. (The plan is to go for the 12 oz sizing--easier to drill larger than reduce if needed). For example 56 EDR CI rad X 80% = 45 EDR and at 18 oz the charts call for a 1/4" orifice to deliver 45 EDR; at 12oz I would increase this to a 5/16" orifice. There are no traps on any CI rads. The system did heat and most condensate lines were barely warm. Total EDR connected via orifices @ 18oz = 382 EDR,

Boiler nameplate & I&O net rating is 571 EDR. There are 2 more unmeasured baseboard/cabinet rad connected that have traps and receive steam and are heating.

Although we could only run for 3 hours the system is quiet running and shows promise of good operation. (It was a warm day). HO has back up heat pump/electric heat so there is no urgency to have full steam heat available.

Question #3: Is cold skimming effective? The installers of this did actually read the part about a skimming tee off the steam main tapping, (and buried a 2 1/2" plug to the hilt with no threads showing---torch time). The homeowner has wand washed the boiler 3 times from top and bottom before start up to get the water clear. On start up water got black pretty quick and HO will wash again as needed. I suggested he could cold skim as I believe I read an article from Dan that cold skimming is quite effective and this would be a simpler way for HO to clean the boiler??

Thanks to everyone for input, advice and suggestions.

Question #1: Nameplate indicates PSB-7D (Dunkirk/Lennox) GSB8-225E; with input of 225,000 input. gas orifice size of #34 drill."For purpose of input adjustment 3.5" WC". However there are 7 sections with 6 burners with orifices measured with a #34 drill size; several charts indicate that #34 @ 3.5" WC = 31,283 BTUH; which X 6 burners = 187,698 BTUH. This is the input of a PSB-6D (according to the downloaded I&O manual). So which boiler do we have? I have not clocked the meter nor check manifold pressure and it was the end of several long days. This is 140 miles away.

Question #2: With rad valve inlet orifices is the actual connected EDR based on the size on each orifice at the max pressure applied? For starters I have sized the orifice @ 18oz pressure for 80% of CI EDR. (The plan is to go for the 12 oz sizing--easier to drill larger than reduce if needed). For example 56 EDR CI rad X 80% = 45 EDR and at 18 oz the charts call for a 1/4" orifice to deliver 45 EDR; at 12oz I would increase this to a 5/16" orifice. There are no traps on any CI rads. The system did heat and most condensate lines were barely warm. Total EDR connected via orifices @ 18oz = 382 EDR,

Boiler nameplate & I&O net rating is 571 EDR. There are 2 more unmeasured baseboard/cabinet rad connected that have traps and receive steam and are heating.

Although we could only run for 3 hours the system is quiet running and shows promise of good operation. (It was a warm day). HO has back up heat pump/electric heat so there is no urgency to have full steam heat available.

Question #3: Is cold skimming effective? The installers of this did actually read the part about a skimming tee off the steam main tapping, (and buried a 2 1/2" plug to the hilt with no threads showing---torch time). The homeowner has wand washed the boiler 3 times from top and bottom before start up to get the water clear. On start up water got black pretty quick and HO will wash again as needed. I suggested he could cold skim as I believe I read an article from Dan that cold skimming is quite effective and this would be a simpler way for HO to clean the boiler??

Thanks to everyone for input, advice and suggestions.

0

Comments

-

Well it did attach, didn't mean to do it twice though.0

-

With the great distances you travel to service your clients, it reminds me of an old television serial- man from Blackhawk-maybe?

it would be so much easier to have the sort of inlet valve which could be adjusted to let in the required steam, and then locked down (a Mepco valve?) The homeowner could do the fine tuning himself.

We really need to develop a piping method where the oil will be segregated from the rest of the boiler, and can be periodically drained off. The drop header probably collects most of the oil in the equalizer, which could have a small drain valve, at about waterline height minus two inches. Opening this would remove all the oil. Even if not drained, it would be in an area which would not affect the boiling.--NBC

0 -

Enjoyable Work

Thanks Nicholas for responding, I had a good time doing this job. (We have to travel 100 miles to a Walmart or Menards or a parking meter also it is 30 miles to a traffic light) This is the smallest steam boiler I've got to work on and the challenge to make it work without traps makes a real treat. Eventually I'll get a picture of the near boiler piping on line. One can then see that it will be amazing that it works very well at all. The HO wants to learn about the steam system he has and will learn a lot hopefully about skimming etc. I just threw something on the wall about your Iowa hydrants. And also saw the enlarged view of your new profile.....just so you know I have slide rules (both linear and round) in my desk drawer! Also after digging around there is also a pocket protector!

How is the Chapel progressing? It is a very impressive building.

I would like to have had more time there but we interrupted by of all things--a funeral. From the few pictures I took I can see the boiler piping was quite wrong. Did the sections crack because of the lack of swing joints on the header?

Thanks, Jugne0 -

It certainly was piped wrong, by today's standards, in 1966.

My local boiler man says that the instructions which came with boilers years ago were not as exacting in layout, as they are now, and left the piping design up to the installer.

Probably, the pressure went out of control, and caused a fluctuating waterline which caused constant thermal shock.

I'm just waiting for some fundraising to occur so we can restore the Dunham system to its former glory, with a new boiler or two (staged).--NBC0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements