Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Manufacture recommended piping - one riser or two.

Options

ProblemSolver

Member Posts: 190

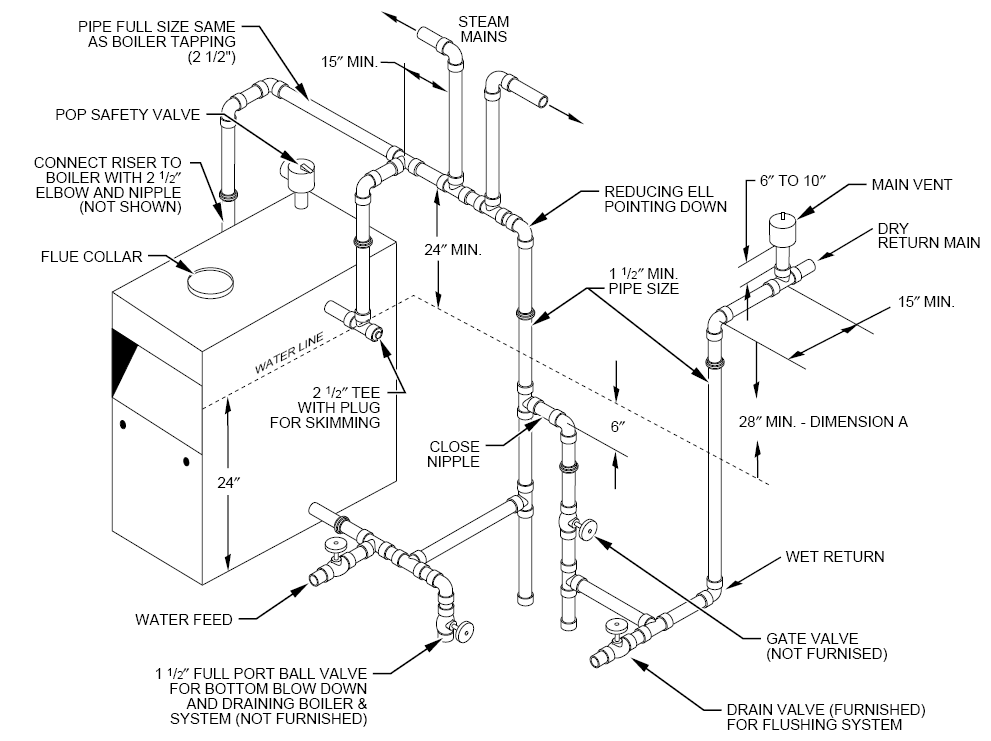

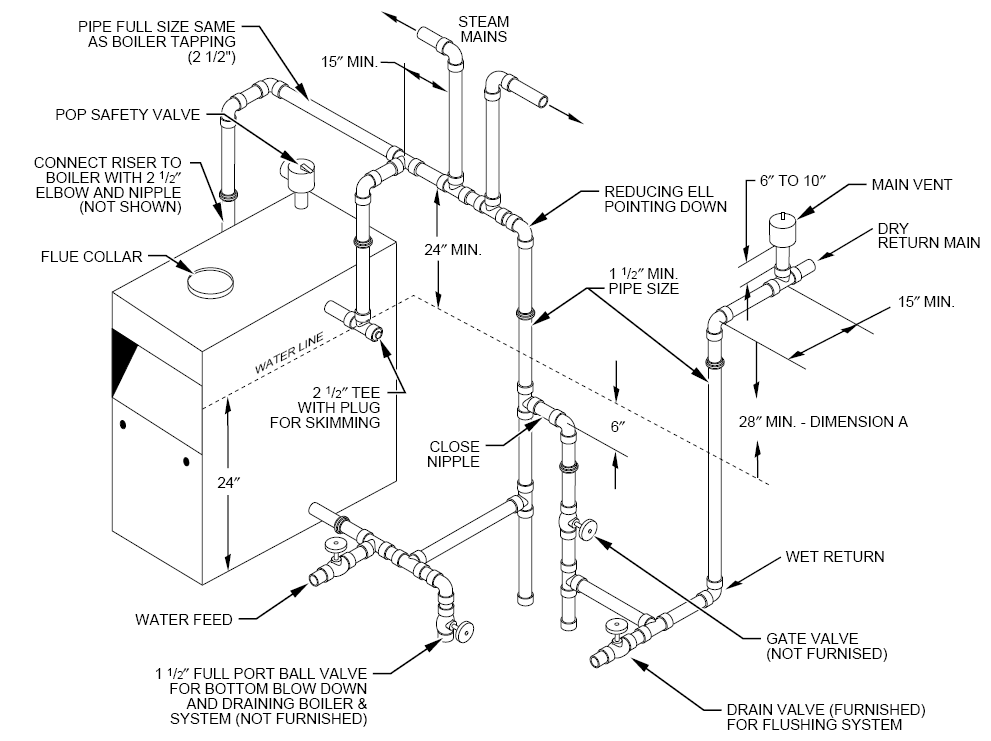

The recommended piping on a CAC-BDP BS2A boiler, shows using 1 riser or 2 risers, but does not explain what should govern the choice of either one. The 2 riser example shows 2 1/2" riser and 2 1/2" horizontal. Where does the wet and dry steam separate? I am considering making the horizontal a 3" with a 3" rise to the main with a reducing ell to the main steam line (one pipe, parallel flow) 2 1/2". It should also be noted the 2 1/2" main runs about 6 feet, then splits off to 2 mains, one remains 2 1/2" and the other is 2". Both returns are 2" drops at the boiler. This boilers existing piping arrangement is fu-bared, and I am going to re-pipe it. Should I brake away from the recommended piping, or follow it? Also, what in the world determines 1 riser or 2 risers, when the manufacture leaves that choice to the installer? with no numbers to help the installer make a choice. The other thing I found strange, the Hartford loop into the equalizer is shown to tie-in 6" below the water line, not 2". What-up with that? This is a 187500 BTU residential boiler. The attachment is the 2 riser drawing.

0

Comments

-

2 risers is better than 1. Slower exit velocity of the steam out of boiler makes for dryer steam. If manufacturer reccommends 1 or 2 being acceptable, to me it means 1 will just barely work, but 2 will work much better. If the manufacturer states to set the loop at 6" below water level, I'm guessing they feel that there's a sufficient amount of water left in the boiler at 6" below waterline for safety.5

-

Two risers is better than one -- especially for those side exit designs. Lower velocity = drier steam.

Is the boiler output 150,000 BTU/hr? According to @JStar's chart, a 3" header is good for about 142k -- I'll bet he would use a 4" header there. Can you bring the 2" and 2-1/2" mains both back to the header?5 -

SWEI: 150,000 BTU out is about right; and NO, I am not changing the main steam line layout, I am only interested in the near boiler piping to get 100% dry steam out to the steam mains.

Abracadabra: the 6" would lead me to believe they think the water level jumps aggressively in their boiler, no other reason for such a distance. That's my take anyways - anyone with more ideas.0 -

The most important thing here is my wanting to increase the horizontal pipe (off the risers) to 3" and then rise to the 2 1/2" main steam line with 3" and connecting with a 3 x 2 1/2" reducing ell. The change to 3" should give me what is needed to keep wet steam out of the mains. Or is the manufacturers suggestion adequate?

Thank you for your response guys.0 -

http://www.tlv.com/global/TI/calculator/steam-pipe-sizing-by-velocity.html

150,000 BTU/hr is roughly 155 lbs per hour-1 -

SWEI: holly smokes, that link is a whole new can of worms for me. I'll have to look at it later, but I am not trying to re-design the whole system, just the near boiler piping. This is the re-pipe I am dealing with.0

-

This is high season for the heating business, so the real steam pros are probably out in the field.

http://www.tlv.com/global/TI/calculator/steam-velocity-through-piping.html tells me that at 1 PSI, the steam in your 2-1/2" main will be moving at nearly 33 feet per second. I would seriously consider bringing both of those mains back to the header if at all possible.0 -

I would absolutely use two 2-1/2" boiler risers into a 3" (borderline minimum) header. A 4" header would be better, but might not be necessary. All of my charts are based on 1psi of pressure. If you are running on a Vaporstat, the 3" header will be okay.

As for the main...if it's 2-1/2", then it won't do any good to feed it with a 3" take-off. You could install a 10" x 2-1/2" reducer and still have no benefit. The main size is all that matters. And it needs to be 2-1/2" all the way back to the header.

Is this also a counterflow main with a drip return?0 -

As SWEI also noted, it would be best to separate the mains and have them come off the header individually. What is the total connected EDR?5

-

A steam system is a...system. You cannot replace a boiler without thinking about the entire system.ProblemSolver said:SWEI: holly smokes, that link is a whole new can of worms for me. I'll have to look at it later, but I am not trying to re-design the whole system, just the near boiler piping. This is the re-pipe I am dealing with.

1 -

Jstar: It is a parallel flow with drip returns.

I am re-piping the boiler because the mrs. wants an auto feeder and the water inside the boiler jumps so radically I refused to install it. I am the second tech telling her the piping, as-is, is trouble.

I lost my total EDR sheet, but the boiler is large enough to effectively handle a cold start up, and slightly over sized for the middle of winter.

I hear what your saying! I do look at the entire system for important points, but I do not re-engineer it then compare that to what is actually there. I do that kind of thing with force air, but I have never engineered an entire steam system (header, risers, vents, etc.) to double check the original engineer's design. Here in the northern suburbs of Detroit, we see 3 or 4 steam boilers a year, and replace one, on average, every 3 years; mostly because of dry firing. Not a whole lot of opportunity to maintain knowledge, so I do a lot of reading this time of year.

I 100% agree with you, both steam mains need to come back to the header - thanks for that!

My concern about the 3" header had nothing to do with the amount of steam being delivered; it was all about giving the wet steam a place to drop out before entering the 2-1/2" main.0 -

Whichever name is on it, that boiler was made by Dunkirk. This boiler model series is not at all forgiving of bad piping- IMHO a 3-inch header should be mandatory on but the smallest of these units.

Two 2-1/2" risers to a 3" header, and an individual takeoff for each steam main, is the way to go on this job.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting5 -

Proper near-boiler piping will prevent the production of wet steam. Save your time and money on the riser. Although, threading and installing 2-1/2" pipe is about the same effort as 3".0

-

Thanks fellas, I am all set. Thanks for your time!0

-

Perhaps you could do a drop header while you're at it to ensure even drier steam. JAHO here, but that seems to be the preferred way.Two-pipe Trane vaporvacuum system; 1466 edr

Twinned, staged Slantfin TR50s piped into 4" header with Riello G400 burners; 240K lead, 200K lag Btus. Controlled by Taco Relay and Honeywell RTH6580WF0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements