Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Oil to gas

Options

bio_guy

Member Posts: 93

I really do not know that much about modern boilers for hydronic heat having lived more in forced air/cooling environments for the last 3 decades. I grew up with them. I do pay attention to detail, however, and I think that can understand how more modern systems work. Dad is elderly and still living in the house I grew up in. It is a 1959 ranch in central New York with its subzero temps in the dead of winter. That is lots of flue gas, from oil sacrifices, up the chimney.

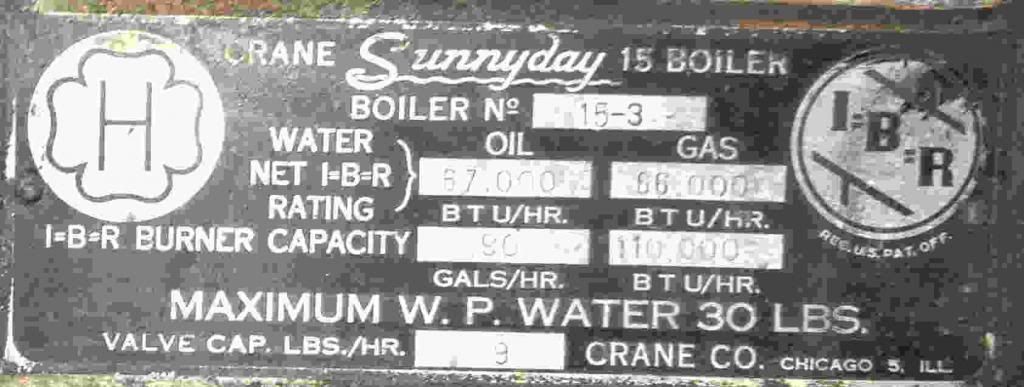

Dad still has the original Crane Sunnyday 15 (Gas rating 66K/110K) boiler in the basement with its later Beckett oil burner. I used to avidly watch the service man with his Fyrite and brushes when he came every summer to worship it in the cool of the basement. I thought of myself as an acolyte of sorts. Eventually, I made offerings of my own of too much oil in the B&G circulator with dad’s oil can. The house has many improvements, insulation, windows and three zones in place of one. One zone is the main floor. Another is the basement that had about 2/3 its space finished, and a third heats a small added sun room that does not get much use when very cold, but it is weather-tight. It is nearly all finned baseboard except for a little heat of some sort under some subfloor to alleviate some condensation in an entry hall/closet, and a toe kick, now broken, installed in a kitchen reno.

Dad has gas in the house, running only the dryer, for decades. The main line runs right past the boiler on the way to the dryer and there is a stub ready to connect. I’ve been nudging him for years toward one of two alternatives, replacing the oil burner with a gas burner, or installing a higher efficiency boiler. Yesterday he surprised me and scared me at the same time. He told me, from a thousand miles away, that he called his oil supplier/service co of 50+ years and asked them to price him a replacement gas boiler and include cutting up the ole 275-gallon tank and hauling it out. Dad says that he stopped buying green bananas a long time ago so I was speechless. He seems to have been thinking about how much he can cut his heating costs this winter. I asked him about the new gas gun option, but he appears to be worried about the longevity of the boiler. Dad, however, needs more and more help with these kind of decisions as time goes on. His mind does not work as fast as it used to and he forgets a lot.

OK, now I am scrambling to keep up. Is a modulating/condensing boiler a good fit for this situation to selectively, and set-back, run three radiator loops and make DHW? If condensing will not work well, will any efficiency gain with a new boiler be eaten up by the replacement cost when compared to just putting a new gas burner in the iconic Sunnyday.

PS. I have my own Fyrites now at work, but I use them for incubators.

Dad still has the original Crane Sunnyday 15 (Gas rating 66K/110K) boiler in the basement with its later Beckett oil burner. I used to avidly watch the service man with his Fyrite and brushes when he came every summer to worship it in the cool of the basement. I thought of myself as an acolyte of sorts. Eventually, I made offerings of my own of too much oil in the B&G circulator with dad’s oil can. The house has many improvements, insulation, windows and three zones in place of one. One zone is the main floor. Another is the basement that had about 2/3 its space finished, and a third heats a small added sun room that does not get much use when very cold, but it is weather-tight. It is nearly all finned baseboard except for a little heat of some sort under some subfloor to alleviate some condensation in an entry hall/closet, and a toe kick, now broken, installed in a kitchen reno.

Dad has gas in the house, running only the dryer, for decades. The main line runs right past the boiler on the way to the dryer and there is a stub ready to connect. I’ve been nudging him for years toward one of two alternatives, replacing the oil burner with a gas burner, or installing a higher efficiency boiler. Yesterday he surprised me and scared me at the same time. He told me, from a thousand miles away, that he called his oil supplier/service co of 50+ years and asked them to price him a replacement gas boiler and include cutting up the ole 275-gallon tank and hauling it out. Dad says that he stopped buying green bananas a long time ago so I was speechless. He seems to have been thinking about how much he can cut his heating costs this winter. I asked him about the new gas gun option, but he appears to be worried about the longevity of the boiler. Dad, however, needs more and more help with these kind of decisions as time goes on. His mind does not work as fast as it used to and he forgets a lot.

OK, now I am scrambling to keep up. Is a modulating/condensing boiler a good fit for this situation to selectively, and set-back, run three radiator loops and make DHW? If condensing will not work well, will any efficiency gain with a new boiler be eaten up by the replacement cost when compared to just putting a new gas burner in the iconic Sunnyday.

PS. I have my own Fyrites now at work, but I use them for incubators.

0

Comments

-

That boiler is as old as I am

and is probably in better shape :-O

I don't have the info handy but I believe those Sunnyday boilers were three-pass units, which were surprisingly efficient if properly installed, tuned and maintained. Three-pass means the combustion products travel the length of the boiler three times, which is key to their efficiency. Some Crane 3-pass boilers, however, had extra-large final passes which didn't extract much heat unless they were baffled well. Baffles also work well in the other passes of these boilers.

With that said, however, a newer boiler will be more efficient, even if it's a cast-iron one.

The issues with condensing boilers are 1- that they cannot exhaust through a standard chimney, and 2- some of them have had rather short life spans.

The exhaust situation means you either exhaust them through the sidewall, or drop suitable piping through the existing chimney (assuming this is even possible) which also means you can't connect anything else, such as a water heater, to that chimney. If you come out the side of the house, you have to come out at certain distances from windows, doors and other wall penetrations, and at least a foot above the highest snow accumulation in the area. That last point doesn't appear in all manufacturers' instructions, but if the unit gets a noseful of snow and shuts down or runs poorly, no one is going to be able to come and fix it until the roads are cleared.

Some condensing boilers, particularly those using heat exchangers made by Gianonni, have started leaking after 5-10 years of use. Since these are typically more expensive to buy and install, and require more maintenance than the typical gas boiler, that represents a rather poor value.

Fortunately, non-condensing boilers are getting more efficient. We've been using the Burnham ES2 (85% AFUE) and 3 series (84%) atmospheric units, with good results. A modern 3-pass boiler with a power burner like the Carlin EZ-Gas will also give as good or maybe slightly better efficiency. This is quite a jump from the 80% gas boilers offered as recently as a couple years ago.

Whichever way you go, add an outdoor-reset control which adjusts the water temperature based on the outdoor temperature. This will give you a saving of at least 10% of your fuel.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

To add....

Just to add to what Steamhead said, that 10% saving he mentions is just for the outdoor air reset, then there is the additional savings for using the natural gas.

In my opinion, if your dad is getting up there in years he probably will never realize the savings from a mod-con in his lifetime. He will probably be more comfortable with a cast iron boilers technology as well.

JMHO,

Rob0 -

more questions

Thanks, very much, Steamhead and RobG. Yesterday I did some reading here on Mod/Con boilers. It seems like it might be tricky to operate them grafted into an old system and get the best efficiency out of them. I'd like to get all my ducks in a row in case the discussion comes up with the bidders and we consider going that way. I am seeing that the return water needs to be reasonably cool to get condensation of the flue gas. If that is true, how can I be sure that happens in an mature house that was not designed for it? If it matters, each zone is a linear loop with no branches.

Outdoor reset just means that the system monitors outdoor temperature and adjusts accordingly? I remember when my uncle, who was in the business, installed one of those in his house when they were a new thing. I suppose that the minimum temp would probably have to be set to supply DHW at an adequate temperature?

Last time I checked, fueling the same boiler with gas would save about half over oil. Am I correct that the current set-up is about 61% efficient. (The input/output numbers for gas on the boiler plate are 110K and 66K, respectively.) If I have this right, a mod/con boiler will get us up in the 90s and a modern, non condensing will get us somewhere between 80 and 86%. Is that correct?

I am sure that I will have more questions, but here is something that I thought of right away. If a tank is installed for hot water, it seems to me that it would make sense in dad's house to put it some distance from the boiler near the use points. If the tank is moved across the basement in the short dimension, It will be a lot closer to both baths, right under the kitchen and next to the washer. The DHW copper all branches from a point right there. That would mean installing a well-insulated loop from the boiler, I suppose.

I can post links to pics of ole Sunnyday if anyone would like to look!

Thanks, again.0 -

Please

Please feel free to post pics, no one here gets tired of seeing boilers. As to your questions: There is no problem integrating a mod-con into an older system. Most houses are over radiated, meaning you can run the water at lower temps and provide the same comfort (which saves money). With a cast iron boiler you have to watch that the return water does not drop below 130-140 degrees. The first thing that needs to be done in this endeavor is a heat loss for the home. If windows, insulation, additions, etc... have been done, the heat load has changed (and that's assuming that the original heat-loss was correct). Go to the Slant-Fin website and download their App. If you have any questions just ask. You will probably save about 40% on fuel switching from oil to gas. The better the design of the system the more the savings. You can locate an indirect tank anywhere nearby in the type of home you describe, just insulate the lines. I, personally would rather relocate a tank than do a recirculation system.

Any other questions feel free to ask

Rob0 -

Honestly

If I were in your shoes, I wouldn't install a mod/con in my folks house. There are issues with a lot of folks getting use to the type of heat a mod/con produces. When properly set up, they heat the house perfectly, but older folks are use to cranking the heat to chase away a chill. The homeowner should be a little tech savvy, as they need to be involved dialing in the process of a mod/con. It all boils down to your father.0 -

Cranking it up

Any boiler with outdoor reset could be slow to respond to the cranking it up manoevre, due to the lower water temp in mild weather. Outdoor reset is definitely better "set, and forget,", rather than using any sort of setbacks.--NBC0 -

So much

So much of the decision of what is the best boiler for the application,depends on a few basic considerations…..I totally agree with Paul, stick with cast iron and no reset,,,let them feel the heat they have been used to….0 -

Be ready

Go with the product of the month from utica with a indirect or install a navian which is advertised on her0 -

questions

Thanks everyone. I have two lines of questions.

First, about the current boiler. Is it about 60% efficient?

Second, with an outdoor reset. there is no override when a large differential in indoor temp has to be made up?

I would think that the outdoor reset would not make as much difference as one might think in making up a set back. With a constant boiler temp, recovery is much slower with colder outdoor temps than with higher indoor temps. When outdoor temp is lower and the modulating boiler is running hotter, recovery might be expected to be similar to a standard boiler. With outdoor temp relatively high, the boiler will be lower and recovery will also be slower than with a standard boiler. Does that make sense?

Thanks for reading!

Here is a link to a pic of the current, Sunnyday, boiler plate: 0

0 -

Boiler

Looks like that boiler is about 74% efficient.

I am a firm believer in mod/con technology for all systems. You should never use a setback with ODR. The reset curve will be the brains of the operation, and the thermostat should only act as a high-limit safety. Plus, boilers are most efficient in a steady-state of operation. Set it for one temperature and forget about it.

Right now, the cost of a mod/con is incredibly close to the cost of a cast iron boiler after buying and installing a thermal bypass and ODR control.0 -

the chimney

Liner that will be needed with replacing that relic closes the gap in cost between stone age boiler and mod con. Advise the mod con all the way.0 -

time

To put the Sunnyday out to pasture, hang a mod con on the wall, use it's ODR feature and use an indirect water heater for DHW.0 -

Not as bad as 74%

We're missing the "Gross Output" figure (now called "DOE Heating Capacity"). The rating plate only shows the burner capacity (a.k.a. Input) and the Net rating, which inserts a pickup factor. This doesn't help us when determining a boiler's thermal efficiency.

I'd post an example, but I'm out of town and the calculator that comes with Windows doesn't have the right % function to do it.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Thanks to The Lovely Naoko

I got the calculations done. Thank God I married a teacher...........

As an example we'll look at the Solaia SL-4100, whose capacity is just a bit larger than the Sunnyday in question. It has a burner capacity of 1 GPH (140,000 BTU per hour), a DOE rating of 122,000 BTUH and a Net rating of 106,000 on oil. Its AFUE rating is 86.1%.

122,000 is 87.1% of 140. So this boiler's thermal efficiency is 87.1%.

But- 106,000 is only 75.7% of 140,000. That pickup factor really changes things.

I would not expect the Sunnyday in question to do as well as the Solaia or some other current 3-pass boiler, but it's certainly not as bad as 74%. Also, they may have been using a higher pickup factor when this boiler was made. Without knowing the Gross Output, we can't tell for sure.

I'm sure some of you will want to run the numbers yourself. If you don't have a hardware-based calculator with the right % functionality available, here is an online one you can use. It even shows you the formulas:

http://www.calculatorsoup.com/calculators/math/percentage.php

Try this on some of your favorite boilers. The results might interest you.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

struggling

I am struggling to understand this with little boiler knowledge. It is interesting. The output rating of the Sunnyday has a built-in fudge factor of 1.33 that downgrades it actual output? In order to get the "real" output, I need to multiply the 66 kBTU by 1.33? That would yield 88 kBTU. That divided by 110 kBTU is 80%. Is that equivalent to a "modern" AFUE rating?

If that is the case, there would be little efficiency gained in moving to a low-cost gas boiler as a replacement. Those units are going to be what, 83 or 84%? Are these units using indoor air for combustion or are they sealed? I suppose there will be a gain getting rid of the power vent drawing all the outside air into the house if they are sealed. Even with that, it seems like it would take way too long to get back the investment. It might be more comfortable indoors since not so much outside air is not being drawn in for combustion.

Are there sealed boilers that are not condensing? How do I evaluate the cost savings of going to a sealed boiler from one using indoor air for combustion?

Going to a condensing system from a basic gas boiler, gets me to 95%. That would save $225 annually in gas cost if I am doing my arithmetic correctly. That does not seem like much, but I don't yet know the increased cost of equipment or relining the chimney.

I am seeing some information that is leading me to the idea that the boilers are sized to the radiators attached, not the heat loss of the home. That troubled me at first, but sense, as long as the radiators are matched to the rooms in question. Since the house has been modified to reduce heat loss, we should pluck fins off of most of the radiators to get a match to the heat demand. Presumably, that could all be overcome with a modulating boiler as would the problem of the sporadic demand of a DHW system.

Is my thinking going in the right directions, is my reasoning FUBAR, or something in between?0 -

Even a cast-iron gas boiler

would lower your operating costs.

1- natural gas is much cheaper per BTU than oil

2- you'd size the new boiler from a heat-loss calculation, not the amount of radiation you have. Only steam boilers are sized to the radiation.

And you wouldn't have to worry about where to safely exhaust a mod-con.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Change for sure

"1- natural gas is much cheaper per BTU than oil"

That we get for sure. Change will happen. It is only a question of to what kind of nat gas burner/boiler. The fuel change is what made dad sit up with a start and call for an estimate a week ago. I've given him the numbers a two or three times in mid summer over the last two or three years. Halfway through the heating season last year he sent me an article that he noticed that confirmed my calculations. Last week, he saw his estimate for the coming season and that lit a fire in his boiler. Now he is ready to make a change. I think that he had a hard time being interested for a couple of years because life without mom was a hard adjustment after she died after a tough struggle after being married 50+ years.

"2- you'd size the new boiler from a heat-loss calculation, not the amount of radiation you have. Only steam boilers are sized to the radiation."

Thanks for that correction.

"And you wouldn't have to worry about where to safely exhaust a mod-con."

To confirm, windows and snow cover are not a big deal? I am not so worried the latter as the roof overhang and heat loss does a good job of keeping the sides of the house clear. What is the typical pipe length limit for a condensing boiler if there is such a thing as typical? If there is no typical, can someone give me a SOTP range between manufacturers?0 -

triangle tube

Solo 110 Prestige allows 45' vent as an example. That is a rock solid boiler I have been installing for years with 0 issues. I have yet to find a residential job in SW CT I could not vent these. The combustion air inlet doesn't need to be near the exhaust for more flexibility. Could always chase up the old flue with poly flex for exhaust if need be.

You are looking at thousands on average to line a typical 20-25' clay chimney. Just makes more sense to step into 2015 with a mod con and an indirect hot water storage tank.

As an aside, my condolences re your Mom. We went through the same scenario and boiler change too in 2008. Oil prices were beginining to chafe and today I would have converted him to Lp at least.0 -

Windows and snow cover

ARE a big deal. Dealing with the exhaust from ANY boiler has to be done just right. This can be a matter of life and death.

In the old days, pretty much every boiler manufacturer published detailed information regarding chimney specifications for their boilers (and furnasties too). These units were all coal-fired, and the chimney had the job of pulling air through the bed of coal in the firebox as well as getting rid of the combustion products. If the chimney did not perform properly, you might get combustion fumes in the basement. Fortunately, you could smell these fumes, and houses were nowhere near as tight as they are now, so plenty of air leaked into the house to dilute them.

But chimneys cost money, which led builders to try to direct-vent heating units out the side wall of the house. Doing this with oil has often resulted in stained siding, because the burners and boilers were improperly serviced. This is one of many reasons oil heat is declining.

Now we have gas units using sidewall exhaust. If something goes wrong with one of these, you may or may not smell it. That's why we have to maintain clearances from windows, so if the unit is making CO it will be diluted before it can get inside the house. And we have to be above the snow line, so the snow won't block the intake and exhaust pipes which can also cause the release of combustion products inside the house.

I see a lot of sidewall vent pipes exiting buildings a foot above grade. In Baltimore, we have gotten up to three feet of snow. You can't fix stupid.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Bob

I think they only pay thousands in Fairfield County, and maybe Beverly Hills.0 -

you can

Think what you want, Paul. I know what a stainless liner roll costs, and I know what the job entails. I've done them, and I've subcontracted them out as well. Easily in the 4 digit range. And that doesn't address combustion air.

This is a critical step and expense to consider.0 -

Considerations

There are many considerations. First and foremost , should be the end user. It's a multi zone, fin-tube system with at least 2 different curves. Then there is the issue of not setting back at night. What are his expectations? There's no sense in beating a square peg into a round hole.0 -

Hi, I am back. We are much delayed because the boiler project was thrust upon me after I started managing another home improvement project at dad's house. I've been learning a few things since then and thanks for getting me started.

I still don't really know how much time the system will be operating in a more efficient mode, because I don't know what temp the radiators will need to be in. I suppose that could be deduced from a heat-loss calculation and a radiator measurement and associated calculation. The house has been significantly improved with insulation and windows since it was built in 1959 and the heat has been divided up into zones from the single loop that was originally installed. Since the envelop is much upgraded, one would think that the radiators can be much cooler.

I have quotes for a Baxi DuoTec and a Weill-McClain GV90+ from one contractor (with Branford-White tank). He said that dad will not get his investment back on an outdoor reset for either. He will pay for the residual oil.

I have quotes for Triangle tube and Navien, with separate DHW heater) but the guy is too far away to consider. (He came in as an energy evaluator associated with a state energy efficiency program.

I have a second quote (lowest) for Weill-McClain GV90+ (with a PurPro tank). He said that He said that dad will not get his investment back on an outdoor reset. Neither did he recommend a modulating boiler. He installs them but thinks that in this application, the cast-iron/stainless combo along with other features offers a more robust solution. They will pay for the residual oil.

I have another quote for a Rinnai RINE110CN. This is enough higher than the Baxi and Weill-McClain proposals to make dad eliminate it. This outfit said that they will pump the residual oil out, but they say since they can not sell it, they won't compensate him for it.

What I still don't have a clear understanding of is whether any of these boilers will be operating in condensing mode very much of the time and if there is any real advantage to a modulating boiler in this application. I don't understand how modulation is done without an outdoor reset since the boiler processor won't have an input to tell it what the demand might be. (It seems to me that the control designers should be making smarter thermostats so the boilers can both adapt to set-back recovery in an efficient mode and react to larger temperature differentials to increase the water temperature. At this point, they are operating similar to a dumb thermostat in the early heat pump days forcing the system to hit the resistance heat inappropriately.)

Another issue is that I think that much of the difference between the two quotes for the Weill-McClain is due to one contractor running the vent up the existing chimney by pulling in a new plastic pipe, whereas the other is planning on going out the side of the house. The latter is not that simple, I think, but probably less costly. There are lots of barriers outside (porch, sidewalk, deck,...) near the current boiler location. In the areas without these barriers, there is a bay window and shrubbery. I am not certain about how much vapor will have to be tolerated and how much of that might freeze on the plants.

At this point, dear old dad may just pick the guy that can do it the soonest after we get the exhaust figured out.

I'd love some comments and I will try to provide any other information that you might find useful to advise me.

0 -

P.S. The only place that I can see that a vent can go out the side of the house is in front, near the living room window. That is the most conspicuous place we might find. Then there is the snow so it should be high enough.0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 167 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements