Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Another Water Hammer Question

Options

Sil

Member Posts: 71

At the beginning of the heating season I posted some issues I was having with my system and most everything works now - except I have a water hammer issue (and I had it all winter)... but at least I had some pretty even heat, which seemed pretty good to me considering how things looked this past fall...

Background

I lived in this house for 15 years. Has single pipe oil fired steam. When I bought the house, I immediately changed the asbestos boiler to a Dunkirk boiler with Beckett burner... and its worked fairly well since. I was the guy with the reverse Hartford Loop.. but its been that way for all 15 years.

This past summer I had all my radiators removed to be sandblasted and painted. And then the troubles began.

I had severe surging issues, spitting rads, no heat in the furthest rads, and the paint smell... awful.

At the end of the day, I replaced my whole return line, replaced the coil gasket, skimmed and skimmed, pitched the rads, messed around with my rad air valves, finally found my under sized main vent (I replaced it, but its still and under sized vent).

At the end of the day, surging stopped and all the rads got heat in a reasonable amount of time... so I left well enough alone... even though I had a fair amount of water hammering.

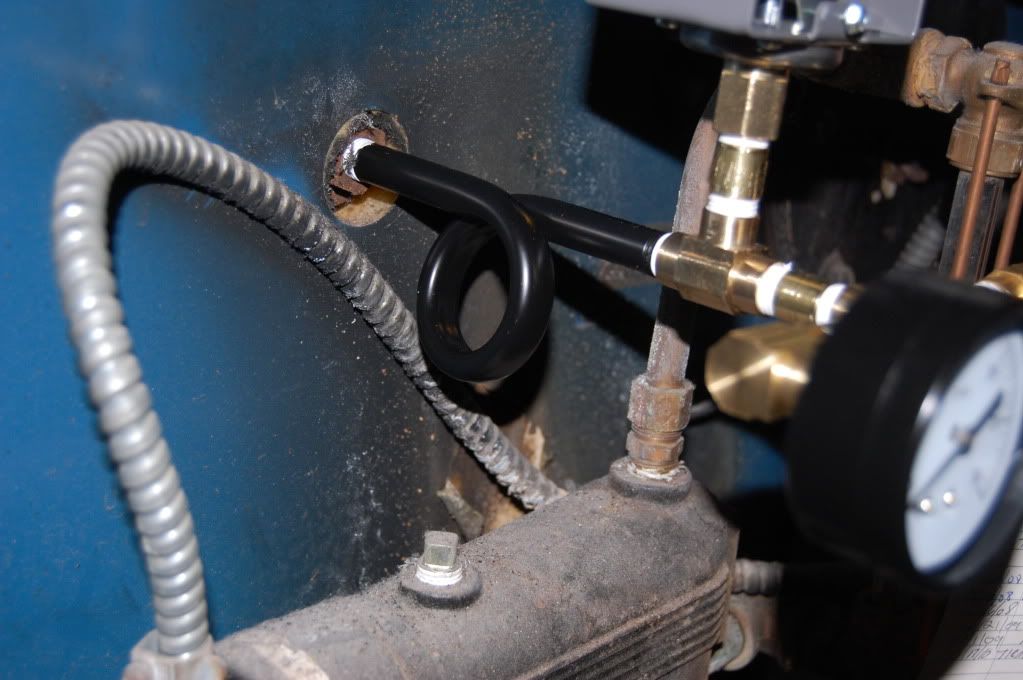

Now that we are near the tail end of heating season I'd like to address when the experts here think might cure the hammer. The hammer seems to mostly be around the end of the header - where in meets the equalizer Seems to happen well into a fire or after the fire goes off.

I will post some of my near pipe pics (these are before I did any work.. but she looks the same now)...

<img src="http://i203.photobucket.com/albums/aa262/silmarg/DSC_0111.jpg" alt="" />

<img src="http://i203.photobucket.com/albums/aa262/silmarg/DSC_0110.jpg" alt="" />

Background

I lived in this house for 15 years. Has single pipe oil fired steam. When I bought the house, I immediately changed the asbestos boiler to a Dunkirk boiler with Beckett burner... and its worked fairly well since. I was the guy with the reverse Hartford Loop.. but its been that way for all 15 years.

This past summer I had all my radiators removed to be sandblasted and painted. And then the troubles began.

I had severe surging issues, spitting rads, no heat in the furthest rads, and the paint smell... awful.

At the end of the day, I replaced my whole return line, replaced the coil gasket, skimmed and skimmed, pitched the rads, messed around with my rad air valves, finally found my under sized main vent (I replaced it, but its still and under sized vent).

At the end of the day, surging stopped and all the rads got heat in a reasonable amount of time... so I left well enough alone... even though I had a fair amount of water hammering.

Now that we are near the tail end of heating season I'd like to address when the experts here think might cure the hammer. The hammer seems to mostly be around the end of the header - where in meets the equalizer Seems to happen well into a fire or after the fire goes off.

I will post some of my near pipe pics (these are before I did any work.. but she looks the same now)...

<img src="http://i203.photobucket.com/albums/aa262/silmarg/DSC_0111.jpg" alt="" />

<img src="http://i203.photobucket.com/albums/aa262/silmarg/DSC_0110.jpg" alt="" />

0

Comments

-

Water Hammer

Hi- If you haven't corrected the "reverse Hartford Loop" I would suspect

that this is what is causing the water hammer. With the reverse setup

you are getting a greater percentage of cooler water in the equalizer. When this cooler water comes in contact with the steam in the upper equalizer pipe, the steam collapses resulting in water hammer". (see attached diagram) Below is a link to a really good video which shows visually (with sound) this happening.

- Rod

http://www.kirsner.org/pages/WaterCannonVideo.html0 -

Even After 15 Years?

I agree with your theory, and will probably rectify this issue once it gets warm, but I have had this reverse loop for 15 years, and am only getting the water hammer now.0 -

another possibility for hammer

your pressuretrol may have become dysfunctional, allowing the pressure to rise above the normal [2 psi for basic function, or 12 ounces for efficiency and comfort].

only a good low-pressure gauge [0-3 psi gaugestore.com] will show you what your true pressure is, as the supplied pressuretrol/30 psi gauge is just to inaccurate.--nbc0 -

Water Hammer after 15 years.

Hi Sil- There are only a couple of things that will cause water hammer in a properly sized equalizer. One is reducing the piping on the horizontal coming out of the header which causes a pool of water to form and the other is the wet return connection to the equalizer.

As I remember you replaced a slow wet return which would mean that now the cooler condensate returns faster to the loop connection. As the flow was slower before, this may have given the water that was located at the connection more time to be absorb heat from the piping/water connected to the boiler and warm up. Now with the increased efficiency of the wet return this warming doesn't have time to happen and the cooler water causes the steam to collapse.

Inefficacy of one part of the system quite often masks a problem in another part of the system so that when you fix the first one, another one is dumped in your lap. When I first fixed my barely functioning system all sorts of other problems cropped up.

- Rod0 -

Why I think it is now an issue

The return is now nice and new. It is allowing the condensate to flow back like it should. This is making the cool water like Rod diagrammed.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating0 -

next steps

I guess I will buy the gauge now.. as thats a simple install...

But I better bite the bullet and plan to replace the loop. I am debating whether I have the gumption to do it myself... gonna have to do some soul searching... then again, I have all spring and summer to figure it out (as I have a gas fired tankess hot water heater for the non heating season).

looking at gaugestore web site, am I buying WIKA model 33041? That one is good upto 140 degrees. Wont that eventually fail?0 -

wika gauge

don't worry about the temperature of the boiler water affecting the gauge, as the pigtail will keep a cushion of air between the gauge and the steam. don't forget that the useless 0-30 psi gauge must remain somewhere on the boiler.

i think you will gain great satisfaction from doing the hartford loop repipe yourself, and you do have all summer to get it done.--nbc0 -

Step 1...

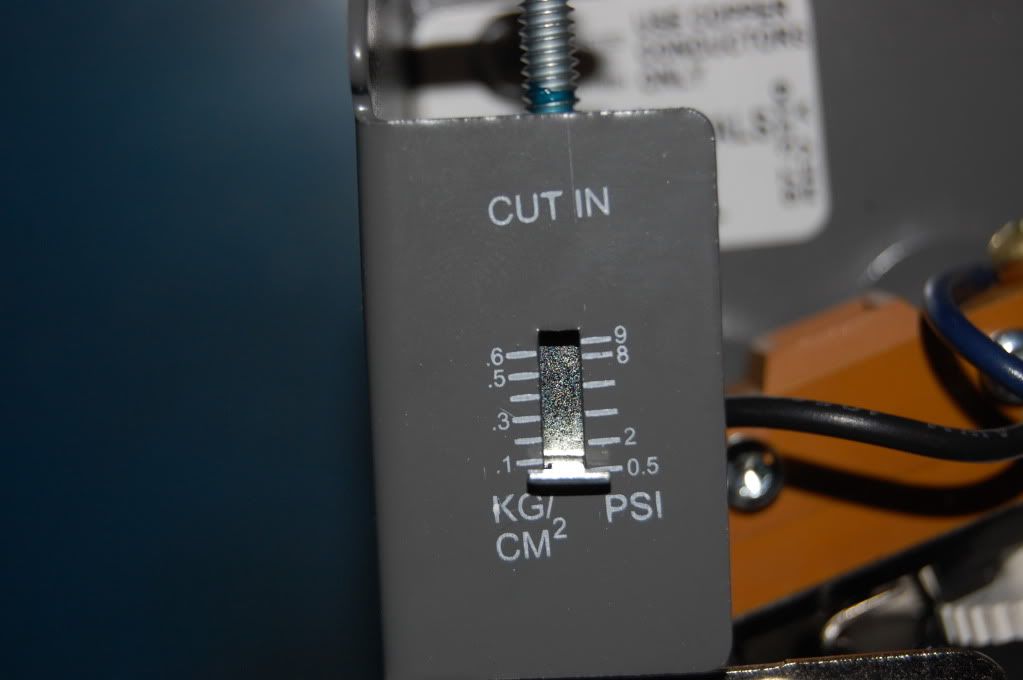

Considering that the pressuretrol, pigtail and 0-30 gauge is 13 years old, I decided to replace all these items and add in the 0-3 gauge for starters. Heck, if the were to cure the hammer... it would sure be much easier than replacing the hartford loop. In any event considering the age of these components and the fact that I never did any maintenance... replacing makes sense in my opinion anyway.

Everything came off and went back in fairly easily.

So I decided to test drive these components by cranking up the t-stat up nice and high. For most of the time the boiler ran under 1 pound. After about 30 mins all the rads were hot end to end and all the vents were closed. The 0-3 began to steadily rise in pressure - but the pressurtol never turned the boiler off! I manually turned the boiler off as the gauge neared 3 pounds. Am I doing something wrong? Here are some pics:

0

0 -

looks right to me

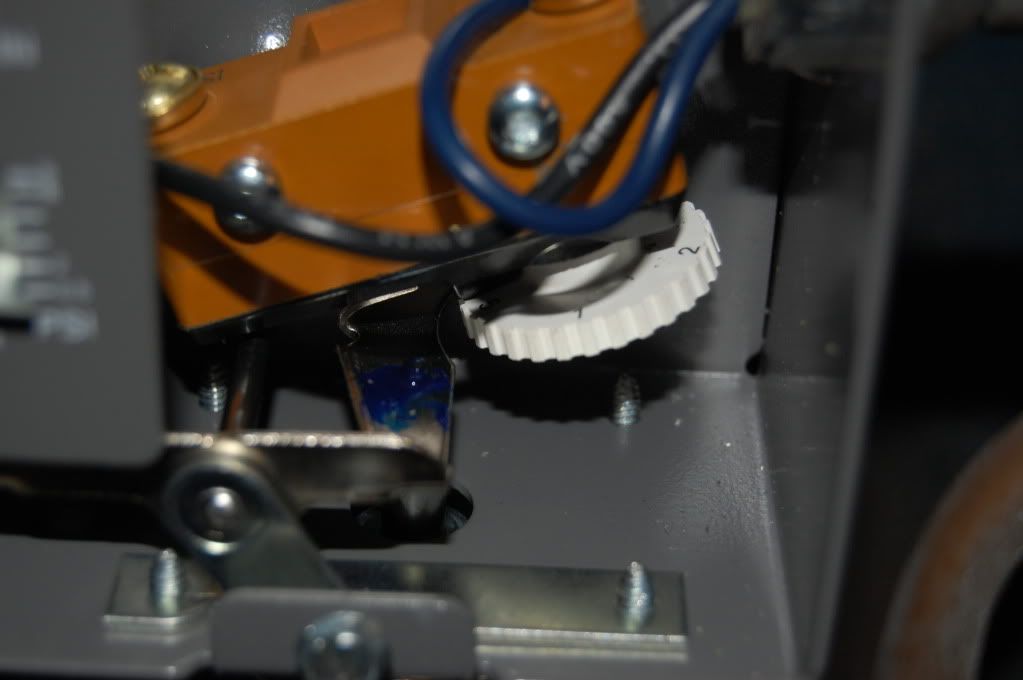

It looks like your old 30 psi gauge is reading correctly, does it read zero when there is no pressure and did it read the same before everything was swapped? Also be sure your pigtail is oriented correctly so you have a water trap to isolate all the controls from steam.

If you use a small screwdriver you should be able to actuate the lever (to the left of that white thumb wheel) that actuates the micro-switch. When you actuate that micro-switch you should hear a click, if the boiler was running it would turn it off.

If moving that lever does not turn the boiler off, the new pressuretrol might be bad, try putting the old one back on and see how it works. If moving the lever did shut things down it's possible the port into the boiler is gummed up. take everything apart and use something to clean that port out with and check the base of the new pressuretrol to be sure nothing is blocking that little (0.05"?) hole at the base of the brass coupling. And if that does not pan out try the old control.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

"new" pressuretrol malfunction

this is exactly what happened with our new [55- radiator] boiler installation: an uncontrollable rise in pressure using the brand "new" supplied pressuretrol.

next step was the installation of a vaporstat, and that got the pressure cut-off down to 12 ounces, although with quite a bit of short-cycling [due to inadequate main venting].

next step: 6 new hoffman 75's, and although now better, still not enough, as the back-pressure was still too high at 16 ounces. finally installed 18 gorton #2's, and voilla, pressure nirvana at 1-2 ounces!

did your work have any effect on the hammering?--nbc0 -

Take 2

To be clear both gauges, the p-trol, pigtail and piping are all new. Both gauges needle sit at zero when at rest. I never tested the old p-trol and never witness the old gauge read anything other than zero.

I am running a test as we speak (still will all the new components). The p-troll does shut off then toggling the micro switch. Lets see if my messing with it maybe "un gummed" the rocker.

The p-trol seems awfully rudimentary/ mechanical (for a component that costs over $100).. How accurate is the cut off psi?

I will attach a pic of the pigtail. I think is fairly close to vertical.. It may be off 5 -10 degrees. I did use a straw to put water in the trap.

For sure my main vent is too small... so I will have the same issues as u NBC... that is one of my items "to do" in this off season.

As for the water hammer.. I still get one early in the cycle with these new components... clearly the new steam in the equalizer hitting the cold water in the backwards loop. Once warm, there is no banging. So pressure is seemingly not the cause of the water hammer. So the loop seems to still be in the cards this off season. 0

0 -

Take 2.5

The new p-trol never triggered - even as we were approaching 3psi.

With the boiler still hot I swapped out the old p-trol (which took a few extra mins as the new p-trol had screws for the electrical connectors, but the old one had these slip on connectors - which I clipped off when installing the new p-trol).

I fired her back up... and the old p-trol tripped at exactly 2psi and cut back in at 1psi.

So the new PSI must not be as well calibrated as old (both are made in Mexico).

So I guess I need to return the new one... and then build up the gumption for the hartford loop replacement.0 -

bad Ptrol

Well you have confirmed your new pressuretrol is not working at low pressure, that is all to common. Someone mentioned a while back that it seems like they check these things out at 15PSI and correct operation at low pressure is just a matter of luck. Honeywell obviously just doesn't care about proper operation at low pressure, thus forcing people to pay twice the price for a vaporstat.

I agree that these are pretty poorly made and tend to not be very accurate. I replaced mine about 7-8 years ago and when that one started to get strange I bit the bullet and bought a vaporstat a couple of years back.Your setup looks fine mechanically, I would not worry about the pigtail not being at exactly 90 degrees.

BTW I don't think the newest version of the pressuretrol works below 2 PSI so you might just as well stick with the old one you have and see if you can get your money back for the one that won't work correctly.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

pressuretrols "poorly made"?

i advise everyone who has had problems with these poorly-made and over-priced devices to change to a vaporstat. even though the vaporstat is made by the same company as the worthless pressuretrol, it is our only choice. having a good low-pressure gauge will enable the "keeping honest" of these [to our steam systems] important devices.

remember that if the honeywell quality sinks even further, there is always the siemens rwf-40 controller [only needing a bit of addaption to our steam needs].--nbc0 -

Interesting controller but not cheap

This looks like a very capable controller but I would never trust it as the only pressure control device, it's just too complex. having worked with all sorts of electronic safety systems i can say they are just not as reliable as a simple mechanical safety.

Aside from the cost I'll take my mercury Vaporstat for it's simplicity, sadly they are no longer available but when m boiler dies I will remove it and install it on whatever boiler I decide to install. I'll then use the supplied pressuretrol as a backup safety.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0

This discussion has been closed.

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements