Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Heating Main Loops -- No \"Ends\"

Options

Anthony Menafro

Member Posts: 200

DO NOT tie the both of those drips together before dropping them below the boiler's water level. You will make other problems for yourself that you don't need.

Anthony

Anthony

0

Comments

-

I'm a homeowner trying to solve a problem with severe water hammer in a two-pipe system. I suspect the system is also short-cycling, but I don't know enough yet to say.

I've got The Lost Art of Steam Heating and today got my copy of We've Got Steam. From the study I've done so far, it's clear we've got several problems -- pressure set too high, no insulation on heating main, air vent installed on at least one radiator.

But before I can really begin to fix the problem, I'm baffled by the basic layout in the basement. My heating main doesn't have an "end." I read that I should look there for the main vent(s).

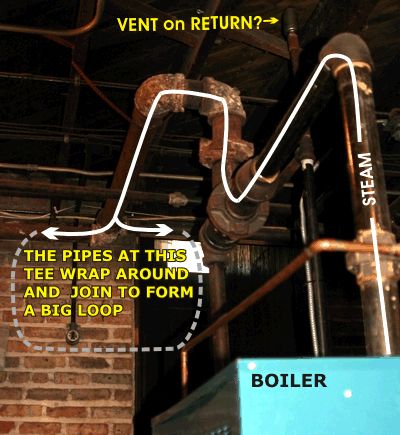

A large pipe emerges from the boiler, rises up and turns, then attaches to a big huge loop that goes around the whole basement. Out from this loop come many smaller pipes going out to the various radiators. Nowhere on the main to I see any kind of vent.

What's more, it looks to me like this big loops is actually pitched such that the middle of the loop is the lowest point -- rather than where it connects to the big pipe from the boiler. Haven't checked with a level, but that's how it looks.

There are two vent-looking things atop two return pipes. Is that where they should be in a two-pipe system, or are there supposed to be additional vents on the returns?

I really need to figure out this vent business before doing anything else. Perhaps the pressure is too high because there's not vent. I don't even want to bother insulating until I know where I'm going to have to install a vent, if there's one missing.

Any insight on this whole loop business and where a vent ought to go would be hugely appreciated.0 -

Eric

Can you take some more pics of the system piping ? Like where the vents are on the returns and some more pics from different angles of the boiler and piping ? Do the return pipes drop down to floor level and go back to the boiler , or do they run back high ?

You definitely want a slight pitch downward to the returns with the main pipe . Get a small level and support the piping where it sags .0 -

Well, let's turn the lights up a tad bit

and look again.

That vent on the "dry return" looks like a Dole vacuum vent, which is a rather slow vent if it's anything like the ones I've seen. Depending on the size of the system you should probably have at least a Gorton #1 there and maybe a #2.

The steam mains loop around the basement to this "low point"- is there a drip line there to take condensate back to the boiler? If so, that's where the ends of the mains are- take a pic here please. They really should be vented at this point, and each half should have its own drip going below the water line.

Have you found any manufacturer's info on any of the system's hardware that would help us identify it? Take pics of some radiators and any hardware in the piping around the boiler, if any. We love this old stuff!

0 -

More Pix

Thanks for the speedy reply. Here are a couple more pix --

All of the radiator returns go to one of those two return pipes, and both of them, as you can see, go down to floor level before returning to the boiler.

At the top of each of those pipes is what I take to be a vent. I don't know if they're working.

After taking this picture, I cleaned out the water level glass, which was completely jammed with silt. I discovered that the water level was too high (about 3/4 up the glass instead of 1/2). I lowered the level.

Here's another angle:

Also: After further inspection, I'm convinced the pipes are sagging in the middle of the "main loop." But how much can I shore them up without having to re-pipe anything? I assume there's only so much "give" in there.0 -

The steam mains loop around the basement to this "low point"- is there a drip line there to take condensate back to the boiler?

No, there are no drip lines there. It's just one big loop that seems to reach a low point opposite the boiler. Hard to get a picture of the whole thing, but here's a rough drawing:

I've left off the equalizer and Hartford loop for simplicity (you can see them in the second set of pictures I sent). But I've included where the take-offs to the various radiators are, roughly.

Is this unusual -- to have a big loop like that, rather than a main with a beginning (at the boiler) and an dead-end somewhere?

Have you found any manufacturer's info on any of the system's hardware that would help us identify it?

The only hardware I've ID-ed so far is the boiler, a Burnham Independence, model #IN8N. It was apparently installed in 1998.

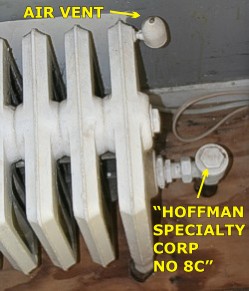

The radiators are a mix of tall 3-column and short, long 5-pipe, but are too painted up to read the manufacturer labels on a quick inspection. The radiator here in my home office has "American Radiator Co." stamped on the side. The valve knob says, "Hoffman Specialty Co. Indianapolis, Ind."

Take pics of some radiators and any hardware in the piping around the boiler, if any.

There really isn't any hardward in the piping around the boiler, other than those two vents, and the water feeder and low water sensor on the side of the boiler (see second set of pictures), above.0 -

The returns with vents on them

handle the air and condensate from the radiators. The air is vented, and the condensate goes down the "drip" and returns to the boiler. This is probably a Vapor system, designed to run at a few ounces.

Since both sides of the steam main pitch down from the boiler, there has to be a drip (vertical pipe dropping below waterline) coming out of them someplace to keep any condensate from building up. I'll bet this drip is near the sag that you mention. How about a pic of that location?

0 -

That's screwy

there has to be a way of draining that main, we just haven't located it yet.

Are there traps on the radiator outlets?

Is that Hoffman valve original to the system? I bet it's not, the dry return vent configuration sounds like a Richardson, O-E or later model Trane system.

Where is this system located?0 -

Just an observation about the IN8 - it appears that they didn't rebuild the header when they installed the new boiler and therefore didn't use the 2nd tapping. I believe that the IN8 has two. (This probably has nothing to do with his problem but doesn't help the system either.)0 -

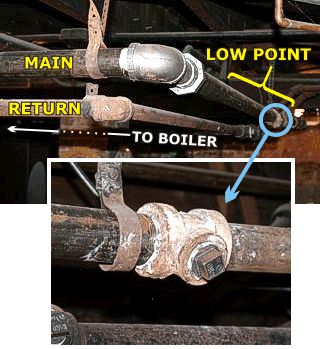

Since both sides of the steam main pitch down from the boiler, there has to be a drip (vertical pipe dropping below waterline) coming out of them someplace to keep any condensate from building up. I'll bet this drip is near the sag that you mention. How about a pic of that location?

There's no drip there, believe it or not. There is, however, a plug. Observe:

At just about the low point, you see this plug, right on a corroded coupling. If this is our missing drip, it seems strange to me it would be on this side of the pipe, on the outer edge of the loop, pointing essentially away from the boiler, rather than on the inner edge.

Can some knucklehead have removed a drip from this spot at some point? If so, how exactly would it have routed back to the boiler? Would seem mighty inconvenient to me, routing through the middle of the basement.

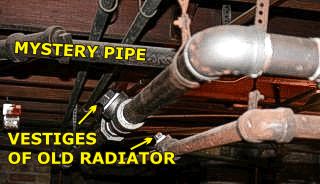

Just for fun, here's another pic, looking to the left of the above. You can see where they removed a radiator at some point (there's holes in the floor of the family room).

And you can see the "mystery pipe" that is cut off at both ends, and which I'm pretty sure was for the central vac this place had when it was built in 1917. 0

0 -

Just an observation about the IN8 - it appears that they didn't rebuild the header when they installed the new boiler and therefore didn't use the 2nd tapping. I believe that the IN8 has two.

Is the tapping the thick pipe coming up out of the boiler? If so, yes, I noticed that there's one that goes up to the header, and one that's capped.

Should I have the header rebuilt? Looks to me like the guys who installed it made some mistakes. So I'd rather find someone else to do the job -- but I don't see a listed contractor anywhere near Aurora, IL, where I live.0 -

Eric, I'm just a 'HO but we are replacing our boiler with an IN8 shortly and I am pretty sure it has two steam tappings. My contractor is aware of that and tells me they will pipe the thing correctly. For the correct answer, ask Steamhead about the near boiler piping. It may or may not affect your system.

Doesn't Glenn Harrison work out of the Chicago metro? Maybe I'm confused about that. Also, Dave "Boilerpro" Bunnell is just west of the I-88/I-39 junction. I have a brother in Naperville but he is a scientist at BP/Amoco and can hardly run a screwdriver:)0 -

Are there traps on the radiator outlets?

I must confess that I'm not sure, but perhaps this picture will answer the question:

This is the radiator in my office, the one with the Hoffman valve. Another radiator, a 5-pipe type, has a one-pipe system style air vent on it, for some reason.

Is that Hoffman valve original to the system? I bet it's not, the dry return vent configuration sounds like a Richardson, O-E or later model Trane system.

I can't be sure. I've only lived in this house since late April of this year. The former owner let the whole place go to pot. The quanries I'm facing with the heating system are echoed in plumbing, wiring, windows, everything.

Where is this system located?

The boiler is just about in the center of the basement, with that big main looping all around the basement. The two main return pipes also loop around the basement, most of the time parallel to the main.0 -

This is probably a Vapor system, designed to run at a few ounces.

Okay, between the books, all these awesome responses, and the close observation I'm making taking all these pictures, I'm starting to get my head around this whole thing a little bit.

Page 48 of We Got Steam Heat says a vapor system is meant to run on no more than 8 ounces of pressure. My pressuretrol was set to cut in at 2psi, and the diff inside was set at 2.5.

Early today I had already lowered it to 0.5 (the lowest setting marked on there), and set the diff, more or less arbitrarily, at 1.5 or so. What ought it to be, if this is indeed a vapor system?

And why do you suppose it was set so high? An ignorant contractor? A problem they were trying to "fix" with extra pressure?0 -

I still hope that Steamhead will see your pictures of the missing drip at the low point of your main and analyze the problem.

In the meantime, I found Glenn Harrison's new employer. Is this close to Aurora?

"Glenn Harrison, now of Jett's Heating and Air. McHenry, Illinois."

Edit: I just looked up McHenry on Mapquest. Looks to be well north of I-90. Maybe you could call him anyway and get a recommedation if out of their service area.0 -

The mystery pipe looks like a sanitary drain.0 -

Bob is right

The IN-8 is required to have both 2 inch boiler risers connected into a 3 inch boiler supply main . I would make repiping the boiler high on my priority list to get this system purrin' .0 -

That's not a trap- it looks like a plain return elbow

but it could have a little check valve inside, as on the Kriebel system. Or it could be an early "orifice" system, where steam is kept out of the dry return by installing properly-sized orifices on the inlet valves, or using valves with orificing capability. As long as the pressure is kept low, the steam won't enter the dry return.0 -

That's where the drip was

Why they put the tee at an angle like that is beyond me. The pipe dope on the joints there looks fairly new. That elbow and union look rather new also.

What I'd do is break the union, and put a main vent and a drip there. Then I'd drip the existing plugged tee and put a main vent right before it. To size the main vents, measure the length of each main from the boiler to where it will drip, and the diameter of each main also. We can tell you what vents you will need.

This will involve some cutting and threading of pipe, which a pro should handle.0 -

Turn the diff all the way down to 1 pound

you don't need any more than that. And yes, that pressuretrol was visited by a Knucklehead.

As long as steam doesn't get into the dry return, you should be OK. If it does, install a Vaporstat where the Pressuretrol is now.0 -

A Few Questions for Steamhead

Steamhead -- Thanks for all the advice and answers. I hope you don't mind if I ask a few more. I'm getting into this whole steam thing, all the more since my grandfather studied steam engineering and used to work on the boilers in his plants.

First, what do you think about Ron Jr.'s suggestion that I have the head rebuilt so that we're using both tappings out of the IN8 boiler?

What I'd do is break the union, and put a main vent and a drip there. Then I'd drip the existing plugged tee and put a main vent right before it.

So we're talking about two drips here. Do these need to go straight down below water level right under the main, or can I have them routed overhead to near the boiler, then dropped down below the water level. This would avoid having pipes running along the floor.

And how about doing just one drip, since everything is pitched down to that spot already? Do you reckon there were once two drips and somebody joined everything up, or what? Have you ever seen a main that loops into itself like that?

That's not a trap.... As long as the pressure is kept low, the steam won't enter the dry return.

Would it be best to go ahead and install traps or find out what's in there and clean them if necessary? BTW, some of the radiators appear to have traps (the 5-tube ones) -- I'd upload a picture, but my PC is giving me trouble today.

Thanks again for all your help.0 -

Here ya go

I haven't looked at the IN8 piping diagram, but if Ron says it needs two risers to the header, it's obvious he has so I don't need to check it. The diagram should be in the instructions and will tell you what sizes and heights the various pipes should be.

If you can drip those mains individually, straight down to floor level and run the wet return around the perimeter of the basement, that would be best. Failing that, you would run two overhead returns to a point where you could drip them individually to the wet return. You don't want to connect the two pipes above the waterline, this can cause distribution and venting problems. This is pretty labor-intensive, so you'd do best to have a pro handle it.

If you take the rad return ells apart, be very careful. I'll wait to see pics of the 5-tube rads, post when you can.0 -

header re pipe

When you repipe that near boiler piping get rid of that bull head tee on the system and run 2 supplies off of your new header also how about a hartford loop on that return .I would also get rid of the tye together at the low point of the supply main and drop them into a wet retrn and run back to the boiler before doing so install a air vent in each supply main before dropping that way you'll vent your main quicker .Have who ever is doing the work check and re pitch all the pipes if need be .I would also check those ells on the return side of the rads to see what type of trap it is .Is this system using a pressurtrol or a vapor stat and how old is your home and how about insulating your supply mains saves alot of engerny .You may be able to install air vents at the end of your dry returns before they drop into a wet .PS are the inlet valves graduated and connected to the top of the rad peace andd good luck clammyR.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

Is this system using a pressurtrol or a vapor stat and how old is your home.

It's a pressuretrol. The home was built in 1917.

0 -

If you can drip those mains individually, straight down to floor level. . . . This is pretty labor-intensive, so you'd do best to have a pro handle it.

I was going to have the local contractors who installed the boiler and maintained it the past several years look at it, but they had to cancel the appointment. I don't think I'll reschedule -- main with no drips (or vents), vent on one radiator (see below), no Hartford loop, etc.

That means I need a local pro I can count on. I'll post a separate thread about that, but if you know somebody in or near Aurora, IL, please let me know.

If you take the rad return ells apart, be very careful. I'll wait to see pics of the 5-tube rads, post when you can.

Here's the radiator in our bedroom. As you can see, there's an air vent on it. It hisses like a mother. I've pointed it downward (it turns easily), which seems to close it pretty well. Radiator still heats with it that way.

BTW, the return from this radiator is not really that warm, down in the basement. Is that normal? I would expect it to be at least warm, if hot condensate is running down it.

Also, when the boiler is running, the main loop is not getting all that hot all the way around. About halfway around each direction is so hot you daren't touch it, but past the low point it's hot to cool, depending on how much the boiler's been running.

It's clear to me now that I have to drip that spot, but I'm curious about what's going on in there right now—NONE of the radiators fed off the cooler section of the main ever get the slightest bit warm.

Man—like everything else in this old house, this job is shaping up to be several orders harder than I guessed.0 -

Quick answer

Eric,

just jumping in with a quick answer until the pros get you more. For the steam to make it all the way around the mains, everything else has to move out of the way. When the steamer fires, there's air int he mains as well as the condensate in your low spot. Since neither of these can get out of the way, there is no way for the steam to get to that part of the main.

You have one of those completely clear cases that fixing your piping will make a much happier system.

jerry

0 -

Okay, Get This . . .

The thought of all that water backed up at the low point of my main loop was just getting to me, so I decided to go ahead and wrench off this plug, where the drip out to be:

I got more than five gallons of water out of there.

Then I plugged it back up and cranked up the thermostat to see what would happen. No water hammer.

I also noticed that, once the system was going, the boiler was only burning for 3-4 minutes before shutting off. The pressure guage, at one point, read 4psi, even though I've got the cut-out set at 1.5psi.

Ever radiator in the house but one got at least warm during the hour or so that I was monitoring things (four of which had been consistently stone cold). Not sure what the story is with that one.

I also checked the vents up high in the rafters at the ends of the two return lines. One of them was hissing a bit at one point. The other was silent.

Only near the end of the hour did water hammer begin again, and right where you'd expect it—at the low point where that plug is. Also, the automatic water feeder came on at one point. Clearly the pipe is filling back up with water quickly.

Can it be that this steam main was so full of water that it was basically dripping back by way of the header? I can't think of what would keep it from filling all the way up.

Now, to the point: I'm considering adding a drip at this low point myself. I'm not prepared to split the loop and add two drips, vents, etc. But I think I could handle putting in one drip pipe and a vent and sending it back along the floor to the boiler.

If this isn't an insane thing for a homeowner who's very handy, not afraid of major projects and always willing to buy the right tools for the job, then I'll post again later with some specific questions about how to proceed.

I also want to replace the return vents. Steamhead mentioned that with info on how long the returns are, he could say what type of vents to use. But exactly what am I measuring—the total length of pipe coming from each radiator, plus the returns in the basement; or just the returns in the basement?

What a rush to get the system to run nearly an hour withour hammering! There's light at the end of the tunnel. The long, long, long tunnel . . .0 -

DO NOT tie the both of those drips together before dropping them below the boiler's water level. You will make other problems for yourself that you don't need.

Thanks for the input. I wasn't planning to tie drips together like that, but I've got a question about that below. First, let me clarify that right now, I've got one big loop for a main, rather than two branches. Eventually I want to break the loop into two mains, each with it's own vent and drip.

But right now, there's no drip at all on the main, nor any vent. What I want to do is install a single drip at the spot pictured above (as well as a vent, either there or in another nearby spot where there's already a tee).

Then later I can split the main there, and install another drip and vent on the. I plan to take each below the water line before linking them.

So here's the question: is it okay to join the drips whereever convenient, once they're below the water line? If so, I might even go ahead and do both at once.

Another question: how far does the vent need to be from the elbow or tee where the drip is located? -- I mean horizontally. I have probably 18" of vertical space to work with too.

Thanks.0 -

Vents

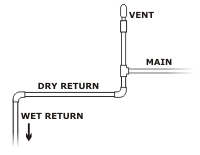

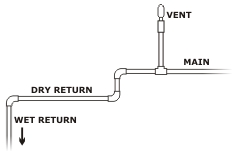

You have to keep the vents at least 10 inches back from where the mains end and 90 down to avoid shocking or slamming them with live steam therefore rendering them useless.

Anthony0 -

Problem is, my main doesn't have any ends. It's a big loop around the basement -- apparently a thow-back to the days of coal. Eventually it will be split, making two branches; I'll bear the 10" in mind while setting up the drip on the loop.

Also, what do you mean by "90 down"? --Eric0 -

90 down

At the end where you'll separate the main and make it two, you'll have to 90 them either down to the floor and return back to the boiler or double 90 them back to the boiler as a dry return and then drop them down into your return piping. I would place the air vents in the boiler room prior to dropping the mains into the return piping with the dry return arrangement. I would place the air vents at the ends of the mains prior to dropping them if you drop them in their existing location.

Anthony0 -

90 down

At the end where you'll separate the main and make it two, you'll have to 90 them either down to the floor and return back to the boiler or double 90 them back to the boiler as a dry return and then drop them down into your return piping. I would place the air vents in the boiler room prior to dropping the mains into the return piping with the dry return arrangement. I would place the air vents at the ends of the mains prior to dropping them if you drop them in their existing location.

Anthony0 -

0 -

0 -

Vent Placement

Even if you're running dry returns it's still best to put the vents on the mains before they connect to the dry returns. If you put them in the boiler room, you'll be filling the dry returns with steam unnecessarily, and if your boiler room gets too warm it can close some vents prematurely.0 -

A couple more questions (probably not the last):- If I place the vent high enough above the main, can I place it directly above where I drop down for the wet return—a tee with the vent above and the drip below?

- What type of vent(s) should I use?

- One run is 19'—16' of 2" pipe, then 3' of 1.5"pipe.

- The other run is 30'&mdash:9' of 2.5" pipe, then 3' of 2" pipe, then 18' of 1.5" pipe.

- What size pipe should I use for the returns?

- The first one (on the shorter main) will run about 6' down to the floor, then 12' back to the boiler.

- The second one will run 6' overhead, then 6' down to join the other return below the waterline.

0 -

A couple more questions (probably not the last):- Will the following configuration work?

Or does it have to be like this:

(Note: The pipe marked Dry Return will be about 2' in the first return, and about 6' in the second, to reach a wall; I have to 90 down and over to get past the returns from the rads.) - What type of vent(s) should I use?

- One run is 19'—16' of 2" pipe + 3' of 1.5"pipe.

- The other run is 30'—9' of 2.5" pipe + 3' of 2" pipe + 18' of 1.5" pipe.

- What size pipe should I use for the returns?

- The first one (on the shorter main) will run about 6' down to the floor, then 12' back to the boiler.

- The second one will run 6' overhead, then 6' down to join the other return below the waterline.

0 - Will the following configuration work?

-

Here's a close up of those vents on the dry returns:

The small print on the Dole No. 5 reads, "Quick vent float air valve," followed by the patent numbers and "Dole Valve Co., Morton Grove, Ill, USA."

The small pring o the Dole No. 6B reads, "Vacuum valve," followed by the parent numbers and "Dole Valve Co., Chicago, Ill, USA."

The 6B looks a little rustier than the other, but the could possibly be the same age.

Please advise which vents I should replace these with.

Also: does this printing on the 6B mean that I've got myself a vacuum system? If so, what does that mean vis-a-vis adding drips, main vents, rad traps, pressuretrol vs. vaporstat, etc.?0 -

Change them!

How much radiation does your system have? This will give us an idea of how much air is coming into those vents.....0 -

See this post for a detailed description of the radiators on my system, as well as pictures of radiator valve handles.0

This discussion has been closed.

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements