Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

First Post: Help getting started on DIY maintenance, frequent low-water cutoff on Burnham Boiler

sparkleworker

Member Posts: 7

Hi!

I'm new to this forum, and hoping to get some help with maintaining my residential steam heat system. I'm a novice at home repair, but I'm good at math and handy with tools, and enthusiastic about learning to care for the system myself. I'm also concerned there might be a serious problem that needs professional help.

I live in a 1920s duplex in the Boston area. It's a one-pipe steam system with a gas-fired Burnham boiler, which I had installed in 2009. It's been serviced about once a year by a general HVAC company. The pipes/radiators have had no maintenance in at least the past two decades. The radiators seem to be mostly the original ones except one small one in the third floor bathroom that looks newer. The house has hard water.

I'm recently divorced, and as I've taken over maintaining the house, I've discovered a serious problem with the heating system: the low-water cutoff on the boiler shuts down the heat every ten hours or so. I go down to the basement and refill the sight glass to about an inch from the top every morning, and it's shut off again by the time I get home in the evening. If I refill it then, it will be out again before morning. There's a sticker on the boiler that says it shouldn't need to be filled more than once a month. I believe that until 2015 it never needed to be done more than once or twice a year.

The glass is pretty full of rust and sediment, and there's a bucket below it that's always full of rusty water. I've observed steam rushing out of the openings around the sight glass, and drops of water leaking down the sides, but I'm not sure how it leaks enough to keep that bucket full.

Once I started paying attention, I became aware of some other issues. The third floor bedroom radiators all hiss and spray small amounts of steam, and overheat the rooms they're in. The second floor living areas are comfortable and quiet.

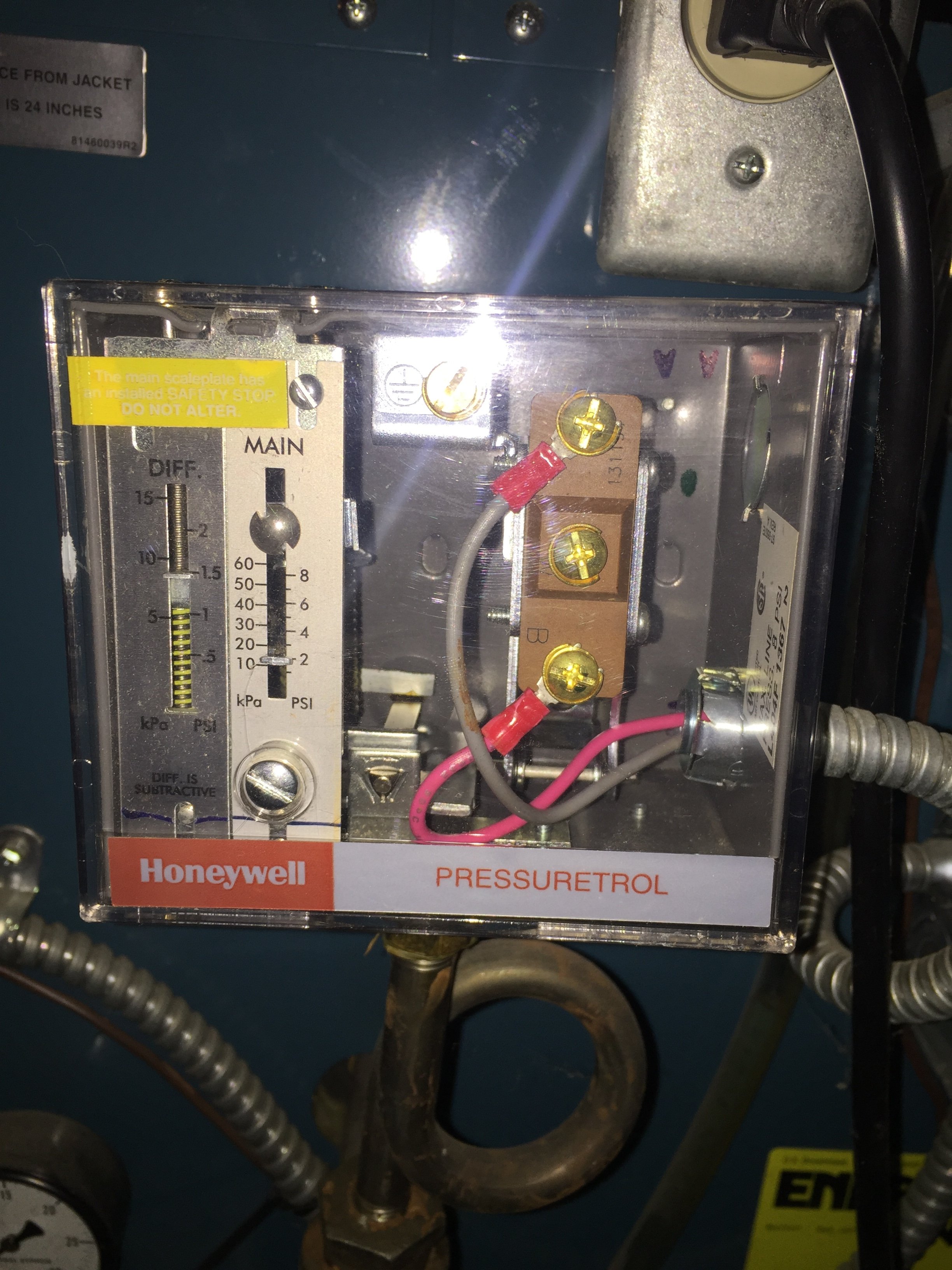

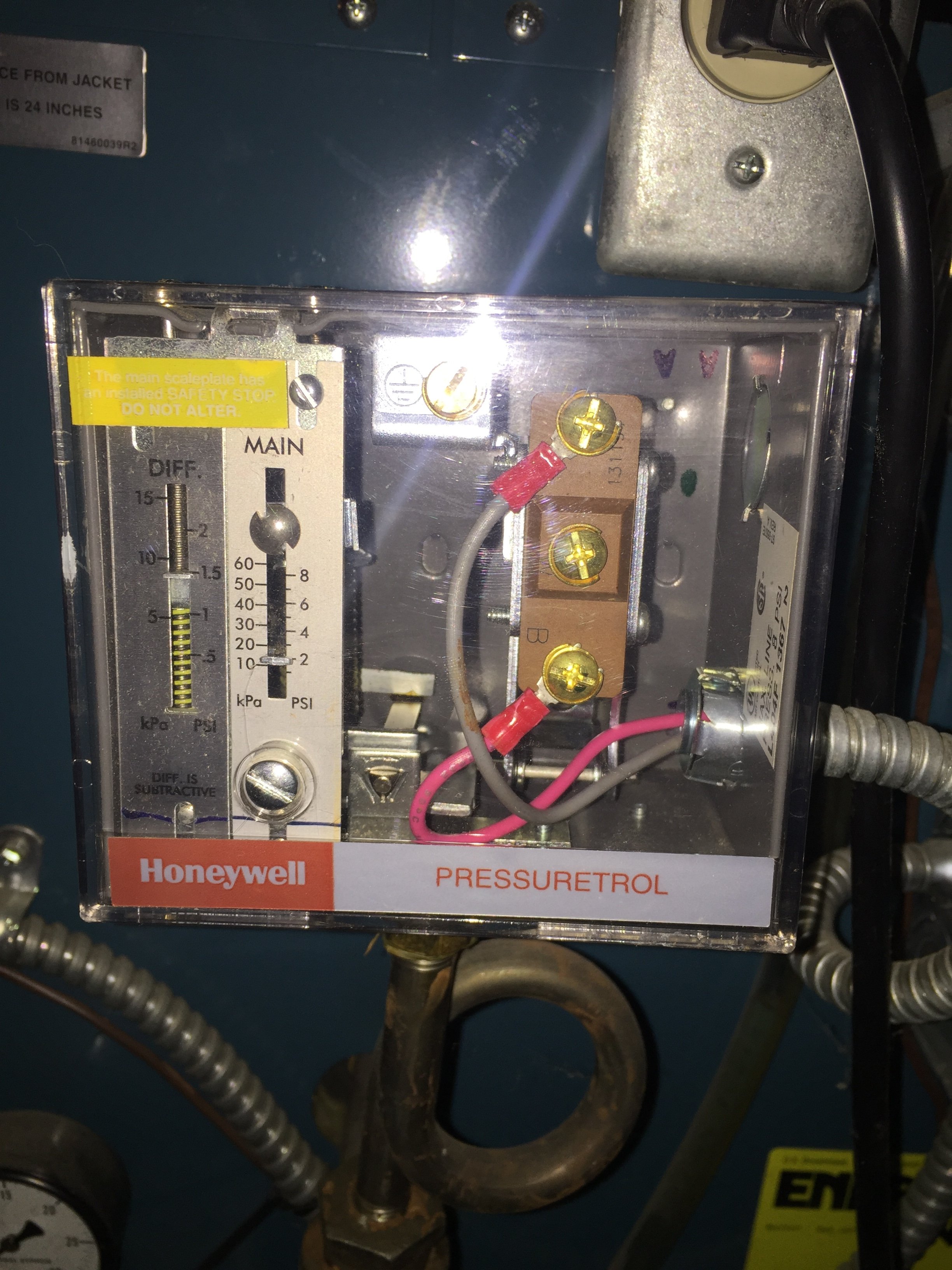

I talked to a local plumber who encouraged me to try replacing/repairing the valves on the radiators. I then read through The Lost Art of Steam Heat and We Got Steam Heat, and a number of threads in this forum. I felt confident enough to lower the Pressurtrol on the boiler from 5 to 2, and I boiled the radiator valves in vinegar, which did pull a lot of scale and dirt off, but doesn't seem to have helped with either the hissing/overheating or the low-water issue. I have some ideas about what to do next, but also some questions.

My best guesses about things I could reasonably do are:

- flush/clean the boiler by opening the lowest faucet on it when it is cool, letting all the water run out, refilling it, and repeating this until the water coming out runs clear.

- put some kind of descaling agent (citric acid? a commercial boiler cleaner? nothing?) in the boiler to clean out sediment and rust in the boiler and the pipes/radiators. Continue the flushing/cleaning process as above.

- replace the sight glass.

- replace the radiator valves. most of the valves are roundish and say 'Dole' on the bottom with some numbers (maybe a dial?), and have a 1/4" threaded opening. Two are newer, lighter metal, and have a made in Taiwan stamp on the bottom (those might be 1/8"?).

- Check and possibly replace the vents on the horizontal and vertical mains

My questions are:

-- First and foremost, is what's happening still in the realm of DIY maintenance, or do I need professional repair work?

If I can proceed on my own, I have these detailed questions:

- - Which tap is the lowest? There seem to be two that are parallel on opposite sides of the boiler.

- - How often should I be changing out the water on the boiler? I've seen advice from weekly to never.

- - how do I open the boiler itself to add a cleaning agent? should I do this at all - opinions on these forums seem mixed? How often should I empty and refill the boiler once I start this process?

- - what valves should I put on the radiators? Can I put a thermostatic radiator valve in the kids' bedrooms to allow them to adjust their own room temp? If so, which one?

- - I read that sometimes the mains in systems like this have capped and need to be vented, but I can't figure out which of the maze of pipes in the basement is the "main". It makes sense in the charts at the back of the book, but all the pipes downstairs are wrapped in silver insulation and the first floor has been converted to forced hot air, so it's visually very confusing to someone who doesn't know what she's looking for.

Here are some photos of the boiler, the pipes, and the valves:

Thanks so much! I've been really enjoying reading this site and getting to know the steam system inside my house.

Sierra

I'm new to this forum, and hoping to get some help with maintaining my residential steam heat system. I'm a novice at home repair, but I'm good at math and handy with tools, and enthusiastic about learning to care for the system myself. I'm also concerned there might be a serious problem that needs professional help.

I live in a 1920s duplex in the Boston area. It's a one-pipe steam system with a gas-fired Burnham boiler, which I had installed in 2009. It's been serviced about once a year by a general HVAC company. The pipes/radiators have had no maintenance in at least the past two decades. The radiators seem to be mostly the original ones except one small one in the third floor bathroom that looks newer. The house has hard water.

I'm recently divorced, and as I've taken over maintaining the house, I've discovered a serious problem with the heating system: the low-water cutoff on the boiler shuts down the heat every ten hours or so. I go down to the basement and refill the sight glass to about an inch from the top every morning, and it's shut off again by the time I get home in the evening. If I refill it then, it will be out again before morning. There's a sticker on the boiler that says it shouldn't need to be filled more than once a month. I believe that until 2015 it never needed to be done more than once or twice a year.

The glass is pretty full of rust and sediment, and there's a bucket below it that's always full of rusty water. I've observed steam rushing out of the openings around the sight glass, and drops of water leaking down the sides, but I'm not sure how it leaks enough to keep that bucket full.

Once I started paying attention, I became aware of some other issues. The third floor bedroom radiators all hiss and spray small amounts of steam, and overheat the rooms they're in. The second floor living areas are comfortable and quiet.

I talked to a local plumber who encouraged me to try replacing/repairing the valves on the radiators. I then read through The Lost Art of Steam Heat and We Got Steam Heat, and a number of threads in this forum. I felt confident enough to lower the Pressurtrol on the boiler from 5 to 2, and I boiled the radiator valves in vinegar, which did pull a lot of scale and dirt off, but doesn't seem to have helped with either the hissing/overheating or the low-water issue. I have some ideas about what to do next, but also some questions.

My best guesses about things I could reasonably do are:

- flush/clean the boiler by opening the lowest faucet on it when it is cool, letting all the water run out, refilling it, and repeating this until the water coming out runs clear.

- put some kind of descaling agent (citric acid? a commercial boiler cleaner? nothing?) in the boiler to clean out sediment and rust in the boiler and the pipes/radiators. Continue the flushing/cleaning process as above.

- replace the sight glass.

- replace the radiator valves. most of the valves are roundish and say 'Dole' on the bottom with some numbers (maybe a dial?), and have a 1/4" threaded opening. Two are newer, lighter metal, and have a made in Taiwan stamp on the bottom (those might be 1/8"?).

- Check and possibly replace the vents on the horizontal and vertical mains

My questions are:

-- First and foremost, is what's happening still in the realm of DIY maintenance, or do I need professional repair work?

If I can proceed on my own, I have these detailed questions:

- - Which tap is the lowest? There seem to be two that are parallel on opposite sides of the boiler.

- - How often should I be changing out the water on the boiler? I've seen advice from weekly to never.

- - how do I open the boiler itself to add a cleaning agent? should I do this at all - opinions on these forums seem mixed? How often should I empty and refill the boiler once I start this process?

- - what valves should I put on the radiators? Can I put a thermostatic radiator valve in the kids' bedrooms to allow them to adjust their own room temp? If so, which one?

- - I read that sometimes the mains in systems like this have capped and need to be vented, but I can't figure out which of the maze of pipes in the basement is the "main". It makes sense in the charts at the back of the book, but all the pipes downstairs are wrapped in silver insulation and the first floor has been converted to forced hot air, so it's visually very confusing to someone who doesn't know what she's looking for.

Here are some photos of the boiler, the pipes, and the valves:

Thanks so much! I've been really enjoying reading this site and getting to know the steam system inside my house.

Sierra

2

Comments

-

Doesn't the blood rush to your head being upside down in your Avatar?

Here are the things which need to be checked/cleaned. The numbers indicate the order of operation.

1.When cooled off, over fill the boiler, until you can feel cold in the pipes on top of the boiler, and look for any signs of moisture underneath the boiler in the firebox, or on the return pipes behind, over a period of an hour or so, while the other items are taken care of. There are two valves which will need to be drained until the water runs clear. The boiler drain, low on the boiler itself, and the wet return piping drain, on the pipe coming back to the boiler, (think I saw one in the pictures). The elevated waterline will give a bit more pressure to push out any debris from both the valves. Restore the water level to the sight glass halfway point before firing it again.

2.the pigtail under the pressuretrol should be removed and cleaned thoroughly, so the pressuretrol can "feel" the pressure. This will involve turning the boiler switch off, and unwiring the two wires connected to it, making a diagram of which terminals are used. Next the pressuretrol can be unscrewed first and the the pigtail. You should be able to blow through the pigtail after running water through it. Reassemble and turn the boiler back on.

3.The sight glass should not leak, and with the valves closed, and rods pulled up and away, the nuts at top and bottom can be unscrewed from the threads, and finally the glass tube manipulated out for cleaning. A small bottle brush will help with this, but a small rag could be rolled up, and shoved inside. While the glass is out, make a tracing of its length and diameter on a piece of paper, so a replacement can be obtained, along with new washers for later use. As they say, "Installation is the reverse of removal". During reassembly, the nuts should be snug enough to prevent leaking. A good hardware store should be able to provide these parts. Finally open the sight glass valves back up.

4.take out the burner tubes, and brush them off, inspecting them for any signs of water leakage. I don't suppose that either of your service possibilities have a combustion tester to check the burn, so they will just have to be put back in carefully

5. I don't have much faith in the "made in Taiwan" radiator vent, (not valves), so it would be best to get a Hoffman 1a, or Gorton radiator vent. You will also need a big main vent for each pipe coming back high to the boiler, before it drops back to the floor.

6. These do the heavy lifting of air removal, and shorten the burn times, and fuel consumption.

I commend you for wishing to be able to do this yourself. Even if you later farm the work out you will have more confidence in describing the scope of the work to the tech doing the dirty part.

Tools needed, medium adjustable pliers, such as "Channelock", safety glasses, and teflon tape for any threaded joints. Maybe your plumber friend will be a help in this.

If you have the bad luck to discover a leak in the boiler, then consult us first here, as the sizing of a replacement boiler follows a set routine, and not merely reading the rating plate on the old boiler. Good luck,--NBC3 -

I'll second @nicholas bonham-carter 's comments, with only one additional: all of the things he said to try are things which a DIY person can do, and do safely. Give it a shot!

And I have a couple of other comments. When you take the sight glass out, a)be careful. The darn things are fragile. b)there should be rubber "o" rings to seal it when the nuts are tightened back up. If these o rings are missing or have gotten hard, you will have to replace them. They are not hard to get -- even Home Depot has them. So if you find that they are hard -- or missing! -- measure the o rings carefully (or the outside diameter of the glass if they are missing) and go out and get some and try again. Second, I'm not a fan of putting chemicals in a boiler, although there are a few -- a very few -- which can make things better. Most make things worse, particularly cleaners. Come spring, though, when you don't need the system, there would be no harm and probably a good deal of benefit to draining and refilling the boiler a couple of times to flush out some of the loose crud.

If, in the meantime, you follow NBC's suggestion to overfill and look for wet spots, and you find any... you probably have gotten out of DIY territory. As he said, consult us first, please -- we can help a lot, and we know good people who can help you in person who cover your area.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Thank you so much! This is exactly the kind of detailed response I was hoping for. This community is such a gem. I'll do the steps NBC recommended and report back.

I talked to my former spouse, who supervised the boiler maintenance and did the occasional upkeep until this winter, and he confirmed that in past years it never needed to be filled more than twice a month.0 -

update, mostly good news:

I followed the instructions above. The boiler does not leak! Hurray! The only place water escapes from it is a slow leak around the sight glass.

I wasn't able to detach the pigtail; I think I'm just not strong enough to loosen the bolt. I soaked it in WD40 and plan to try again, but in the meantime I used a flute cleaner to clean out at least the top of it.

I was able to disassemble and clean the sight glass. The little rubber rings inside were hardened, and one was cracked in half. I bought replacements at the local hardware store, but they aren't quite the same - they have a little gusset in the sides whereas the original ones were solid.

I overfilled and drained it twice, and tons of rust and gunk came out. It never got to the point of running clear, so I'll keep doing that periodically on warm days when I can have the heat off for awhile.

Only downside:

I cracked a small chunk off the bottom of the glass putting it back together. The leak is a little worse now, so I think I should replace the glass and maybe the rubber rings with the correct type? Where should I go to get those things? Home Depot did not have them, nor did the local hardware store.

0 -

Bravo!!

Can you replace the tube upside down, so the imperfect end is on the top, just for the moment? If the washers fit around the tube and inside the nut, then they are probably going to do the job. Make sure the tube extends into the gauge cock body at the top and bottom. This fiddly business will become second nature, as you remove and clean the glass tube at least once during the winter, or as needed. If that does not work, keep the valves, (gauge-cocks) closed, during the leaking, but open them to check the level frequently, and test the LWCO while you run with closed gauge-cocks.

Were you able to trace the length and diameter on a piece of paper? A more old fashioned hardware store may have the tubes, and would be able to cut them to the traced length. Let your fingers do the walking, and telephone several stores to see if they have what you need. A spare tube and washers should be always be available.--NBC0 -

Thank you! I'll go flip it over now.

The other place steam seems to be escaping is from the upstairs radiator vents. The vents in one bedroom and the bathroom have some visible steam and hissing.

In another bedroom, there's a thingy on the side of the radiator opposite the vent that is actually spraying hot water. The fire alarm has been randomly going off in this bedroom recently, I suspect because it gets very humid in there.

Here's a photo of the thingy. It's the little gray round bit near the floor that is leaking:

0 -

Do you have two pipes going into and coming out of the radiator?

Were you able to clean the pigtail under the pressuretrol?

I suspect the pressure has gone up too high. Those systems will work best on just a couple of ounces of pressure, hence the need for a low pressure gauge, reading ounces of pressure-less than would be required to blow up a balloon!--NBC0 -

That looks like a valve with the knob missing. That enclosure should lift off exposing the whole radiator? With that cover off you will get a clear working area. You should be able to tighten the nut that the valve stem passes through. Be gentle and only tighten until the steam stops coming out. The large nut between the valve and the radiator could possibly need a snug as well. You'll need a pipe wrench (18" or so) for that. It's pretty surprising how much water in the form of steam you can loose through fittings like that. Check all of them and give all of them a snug.

The pressure trol has a nut on the bottom that threads onto the pig tail. after disconnecting the wiring put a wrench on that nut and a large screw driver through the pig tail as a backing point that should get the pressure trol off of the pigtail. That screw driver should then be able to turn the pigtail off of the LWCO. Good luckMiss Hall's School service mechanic, greenhouse manager,teacher and dog walker0 -

-

Do you want a job?

You've got more tech savvy and common sense than a lot of 1-5 yr. Techs.

Even at 2 psi, the cut in is too high. Lower it, by turning the screw on top to just above the psi mark, which should be approx. .5 psi. Adjust the differential to 1.

Has your low water problem been solved? If not, some pics of the piping between the boiler and water heater, low and high, and where the piping leading away from the boiler goes. Rise up, along the floor, down into the concrete slab floor?

Note: the Empire State Building runs on 3 psi.0

Categories

- All Categories

- 86.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 52 Biomass

- 422 Carbon Monoxide Awareness

- 88 Chimneys & Flues

- 2K Domestic Hot Water

- 5.3K Gas Heating

- 99 Geothermal

- 156 Indoor-Air Quality

- 3.4K Oil Heating

- 63 Pipe Deterioration

- 910 Plumbing

- 6K Radiant Heating

- 380 Solar

- 14.8K Strictly Steam

- 3.3K Thermostats and Controls

- 53 Water Quality

- 41 Industry Classes

- 47 Job Opportunities

- 17 Recall Announcements