Tips for 1920s American Radiator steam boiler?

It's not working at 100%. One radiator gets very hot, some don't work at all, and the rest put out decent heat.

I replaced a few air vents on some and that seemed to help one of them. I think the entire system needs a cleaning; I don't think the previous owners ever cleaned it, just skimmed it once in a while.

Any tips for getting those cold radiators to work once I've replaced the vents?

Any tips for cleaning out a boiler this old?

Should I wait until the summer to clean it out? I heard conflicting ideas about if it's okay to empty the boiler or not.

It's converted to gas, I'm guessing from coal.

Thanks in advance!

Comments

-

Honestly, you should start considering a boiler replacement (though you must save that awesome pressuretrol). I would start researching contractors and come up with a plan. In my professional opinion, a boiler of that age, likely converted from coal to oil to gas, isn't worth any investment.0

-

However,Danny Scully said:Honestly, you should start considering a boiler replacement (though you must save that awesome pressuretrol). I would start researching contractors and come up with a plan. In my professional opinion, a boiler of that age, likely converted from coal to oil to gas, isn't worth any investment.

It is a 3 pass design and if set up properly can perform ok.

That, and the fact it'll likely outlast a modern boiler 10 times would make me hesitate replacing it if I already had it.

It's the same style as what my friend had but his ran on oil. You need baffles in the passages and I would make sure there's a new and working 15 PSIG pressure relief on it.

Dump the LWCO and make sure it shuts the burner off as well.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

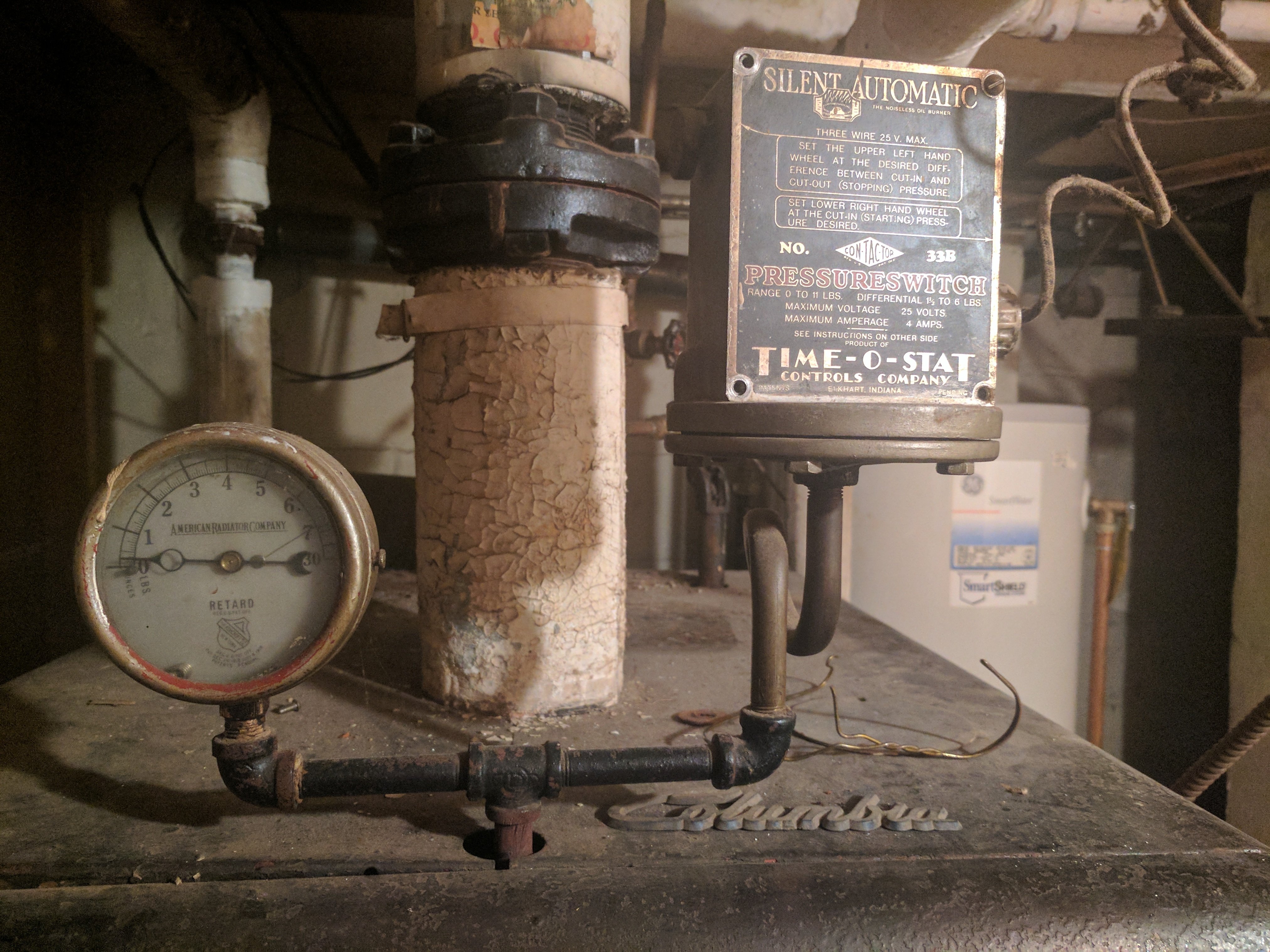

Oy. Well, that's a nice antique -- antique controls and all. Before I go there...

First question: other than having rather uneven heat, does it work with little or no water hammer? If so, we're a little ahead of the game.

Now. There is a water level control -- the sort of triangular rusty thing in the first picture. It is essential for your safety that that is working. Fortunately, it is properly installed, so it's easy enough to check. The valve with the yellow handle beneath it is the drain. That should be (should have been!) flushed once a week to once a month. If you open it with the boiler running, the burner should shut off when the water in the gauge glass next to it drops near the bottom. If it does all is well (the water will be pretty grungy -- use a bucket). If it does not, turn off the boiler, let it cool, and fill it back to half way up the gauge glass and do it again (and probably again... and again...) until the water is at least vaguely clear; weak tea, perhaps. Then try the will it shut off bit again.

If it still doesn't shut off the boiler, it will need to be taken apart and cleaned, and probably some parts replaced. It's not a big deal and, oddly, parts are still available for it. But, as I say, it is a safety device.

There is no need to drain and refill the boiler.

Other than that there isn't much else on the system that needs cleaning. Can the boiler be cleaned? Yes it can, and it should be if you plan to keep using it, but that's really not a DIY job, and it only needs to be done once a year. At which point the burner also needs to be cleaned and adjusted -- which takes a good technician with instruments who knows how to use them.

However... a boiler that old isn't terribly efficient (it will be using about twice as much oil as a modern boiler doing the same job), so you might want to think about having it replaced this summer.

To return to the even heat. The chances are excellent, given that boiler, that there are no main vents on the steam pipes in the basement. There should be, and they will help even out the heat.

You should also check and make sure that all the radiator valves (not the vents, the valves) are fully open (left, counterclockwise, to open). If there are radiators which still don't work at all, check that the pipes going to them don't have any big dips or sags and that they can drain. If that's OK, try larger steam vents on them.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@ChrisJ, if you operated a plumbing/heating company, you might think differently

All jokes aside @erickehoe, ultimately, it's a gamble, and it's your gamble to make. I would consider replacement. It doesn't have to be tomorrow, but you should definitely start planning (interview contractors, research boiler manufacturers, measure your connected radiation, notate any system deficiencies, etc). 2

All jokes aside @erickehoe, ultimately, it's a gamble, and it's your gamble to make. I would consider replacement. It doesn't have to be tomorrow, but you should definitely start planning (interview contractors, research boiler manufacturers, measure your connected radiation, notate any system deficiencies, etc). 2 -

Also make sure the pigtails (looped pipe(s) and any pipe attached to it, under the Pressuretrol are taken off and cleaned. They will clog and those don't look like they have been off in years. That McDonnell Miller #67 Low water Cut-off really should be replaced. At a minimum it should be taken apart and scraped out. You can order new gaskets/parts for it but McDonnell Miller recommends replacement every 10 years. I doubt if that one will actually shut the burners down if the water get too low. They build up crud on the floor and side walls of the float chamber and prevent the float from working.0

-

The low water cut off does work properly for now, which is good. But I'll look into replacing it ASAP.

I think we'll probably have to nurse it along for one more winter after this one before we can replace the whole system!

@Jamie Hall All of the valves are fully open but a couple of them seem broken... like if you keep twisting the cap will come off and I am able to see inside of the pipe! I'm guessing this is bad. Also... there isn't really any water hammer.0 -

I'm not as much of a fanatic about replacing the McDonell Millers as some. If it shuts off the boiler, it's working. However, at your convenience taking it apart and cleaning it is not a bad idea -- as @Fred says, replacement gaskets and parts are available. His suggestion about checking the pigtails is a good one, but again there is a check: if you really crank up the thermostat and let the boiler run, does it shut off for a while (and turn back on) before the thermostat is satisfied? If so, that antique pressure control is working -- and the pipe leading to it is open. The way that is installed is much less subject to clogging than some of the more modern installations. I'd be a wee bit cautious about taking that old piping apart...erickehoe said:The low water cut off does work properly for now, which is good. But I'll look into replacing it ASAP.

I think we'll probably have to nurse it along for one more winter after this one before we can replace the whole system!

@Jamie Hall All of the valves are fully open but a couple of them seem broken... like if you keep twisting the cap will come off and I am able to see inside of the pipe! I'm guessing this is bad. Also... there isn't really any water hammer.

And no, one really shouldn't be able to take the valve all the way apart by keeping turning the handle! They may not, however, be actually broken. They are very like an old faucet: there is a piece -- the bonnet -- which screws onto the valve body, and the shaft should turn within that bonnet and move the valve seat in an out (or open and down or whatever). While you have the valve apart (!) check the seat -- again, like an old faucet, it is a washer and it is not unheard of for them to come off or be worn out. Then see if you can get the bonnet to turn on the shaft. This may take some doing. It may also make the valve leak, as the bonnet is sealed to the shaft by packing, which is probably shot. Fortunately repacking them is pretty simple. If you are into DIY, this is something you can do, or learn to do, pretty easily -- but don't do it when you may want the boiler to run, in case something wrong and you can't get the valve back together! Also, so long as the valve is or can be made to be fully open, you don't need to worry about them. They should never be closed anyway -- and radiator valves is not for the faint of heart, since they are individually matched to the pipe coming out of the radiator, and replacing the whole assembly is somewhere between difficult and darn near impossible.

I do agree with @Danny Scully , though. That poor old thing is doing you no favours in terms of fuel use, even if it is working, and you should begin planning on how to replace it. Do plan to keep the steam heat -- you can't beat it, and the alternatives are all more expensive -- but finding a good contractor for steam can be a real problem, so it's worth starting to look.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

erickehoe said:

The low water cut off does work properly for now, which is good. But I'll look into replacing it ASAP.

I think we'll probably have to nurse it along for one more winter after this one before we can replace the whole system!

@Jamie Hall All of the valves are fully open but a couple of them seem broken... like if you keep twisting the cap will come off and I am able to see inside of the pipe! I'm guessing this is bad. Also... there isn't really any water hammer.

I understand Danny,Danny Scully said:@ChrisJ, if you operated a plumbing/heating company, you might think differently

All jokes aside @erickehoe, ultimately, it's a gamble, and it's your gamble to make. I would consider replacement. It doesn't have to be tomorrow, but you should definitely start planning (interview contractors, research boiler manufacturers, measure your connected radiation, notate any system deficiencies, etc).

All jokes aside @erickehoe, ultimately, it's a gamble, and it's your gamble to make. I would consider replacement. It doesn't have to be tomorrow, but you should definitely start planning (interview contractors, research boiler manufacturers, measure your connected radiation, notate any system deficiencies, etc).

It has it's downfalls, it holds something like 40 gallons and takes FOREVER to get hot enough to steam on mild days. On very cold days it runs decently because it stays hot between cycles.

My point was it's not a snowman so it's not a horrible boiler is all. My friend's is still going, he passed away in the summer and the house went into foreclosure so I'm sure the boiler's days are limited.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Start by going over the system, measure the steam mains and look for main air vents. Make a simple diagram that shows the mains and the radiator pipes that feed all the radiators. Make sure all the radiator piping slops back towards the boiler so water can find it's way back, be on the lookout for any dips in the piping that might let water pool in the pipe.

If you replace radiator vents don't buy the home depot brand, they suck. Get a good adjustable vent like the ventrite #1 (http://www.hvacrsupplynow.com/VENT-RITE-1-STEAM-AIR-VALVES-ADJUSTABLE_p_1787.html) , maid o mist 5L (comes with 5 different orifices and can be bought from amazon), or the Hoffman 1A (good but tricky to adjust). before trying to fiddle with radiator vents you have to get working main air vents on the system.

The very first thing you should buy is "The Lost Art of Steam Heat" which can be bought from this site or amazon. That book will give you the understanding to ask the right questions AND to recognize if someone s feeding you a line of bull.

http://astore.amazon.com/heatinghelp-20/detail/0996477241/163-8073773-6769532

That $40 will save you thousands of dollars. IF you can find the right man that old boiler can be fixed up but only one in 500 techs will know what to do to get it working right; where do you live, maybe one of the techs that contribute here are close by. You could dump a lot of money into it and end up with bupkis so be careful. Iwould concentrate on the piping and the radiators for now but you should have someone go through the boiler now if your not going to replace it this year.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Would this be a main vent? I see two of them on two separate pipes. Any idea where to find replacements?

0 -

Eeek. I think that that may have been a main vent... once upon a time...

It's in a decent sort of place for one, but you don't want a direct replacement -- a nice BigMouth from Barnes & Jones ( @Sailah ) would do nicely, or a Gorton #2.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

That's a Dole #4. Kind of useless. Replace it.0

-

I would check the size of the boiler against the connected load. If it is oversized then plan for a replacement as it won't be efficient and the standby loss and warm up time is a killer.

If it close to being the correct size and you get someone that knows what he's doing you can probably down fire it and baffle it (as @ChrisJ said) and get close to 80% combustion efficiency.

0 -

What a cute little main vent................... looks like it's just decoration, doesn't do much.

How long are your steam mains, and what pipe size?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0

Categories

- All Categories

- 86.9K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 110 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 105 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 981 Plumbing

- 6.3K Radiant Heating

- 387 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 47 Job Opportunities

- 18 Recall Announcements