Monoflow/Reverse Return Piping Question

Hello Everybody,

I am installing three hydronic Modine Heaters in an auditorium and it's main entrance. The auditorium is approximately 200k BTU with the entrance way being about 25k.

Per my supply house's heat loss and design I have 2) 100k Modine convector floor units for the auditorium with an additional 20k unit for the entrance way.

I planned on running each unit in reverse return with monoflow tees on the main 1-1/2" Loop and I was pretty confident in this plan. The problem I am encountering is I cannot find any 1-1/2" monoflow tees. This is making me second guess my choice for monoflow tees in the first place.

Any advice would be appreciated.

Thanks.

Comments

-

Got a sketch of what you are thinking, monoflos are not so common anymore, hard to purge, often the emitters are in series so the SWT drops from one to the next.

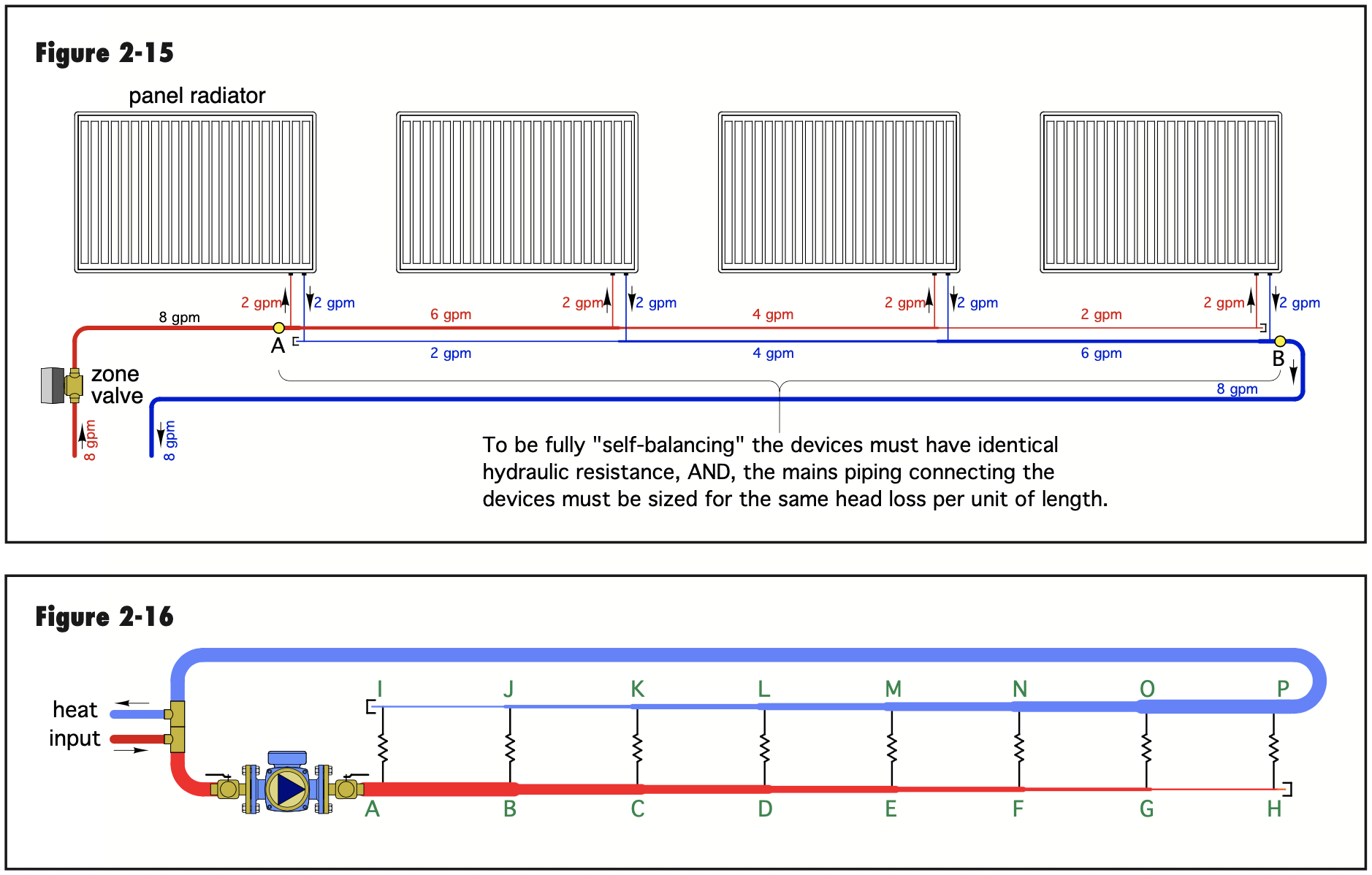

Seems like a basic reverse return simplifies the project without needing monoflo tees?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

This is great thank you!

My original plan was almost exactly what the second image is except with monoflow tees. I suppose I am over thinking it.

I will double check my measurements and flow rates, but I think my original design will be fine without the tees!

Thank you very much!

0 -

Monoflo tees are for…monoflo, where there is a single main that circulates from and back to the boiler, not with separate supply and return mains. The monoflo tee divides the flow in the single main between the main and the emitter. When you have separate supply and return mains the water has no place to go but through the emitter so ordinary tees are used. Put some balancing valves on the emitters if you aren't controlling each individually with separate thermostats(which is a whole different discussion we can delve in to if you need to understand that). I would not do monoflo in a new system with 3 emitters, I would do separate supply and return mains.

0 -

the selling feature if monoflo was a sinhle pipe loop around the structure. It took some calculations to get the sizing correct

Im not sure that single pipe benefit offsets the other issues

As you can see this RR example takes more pipe/ insulation

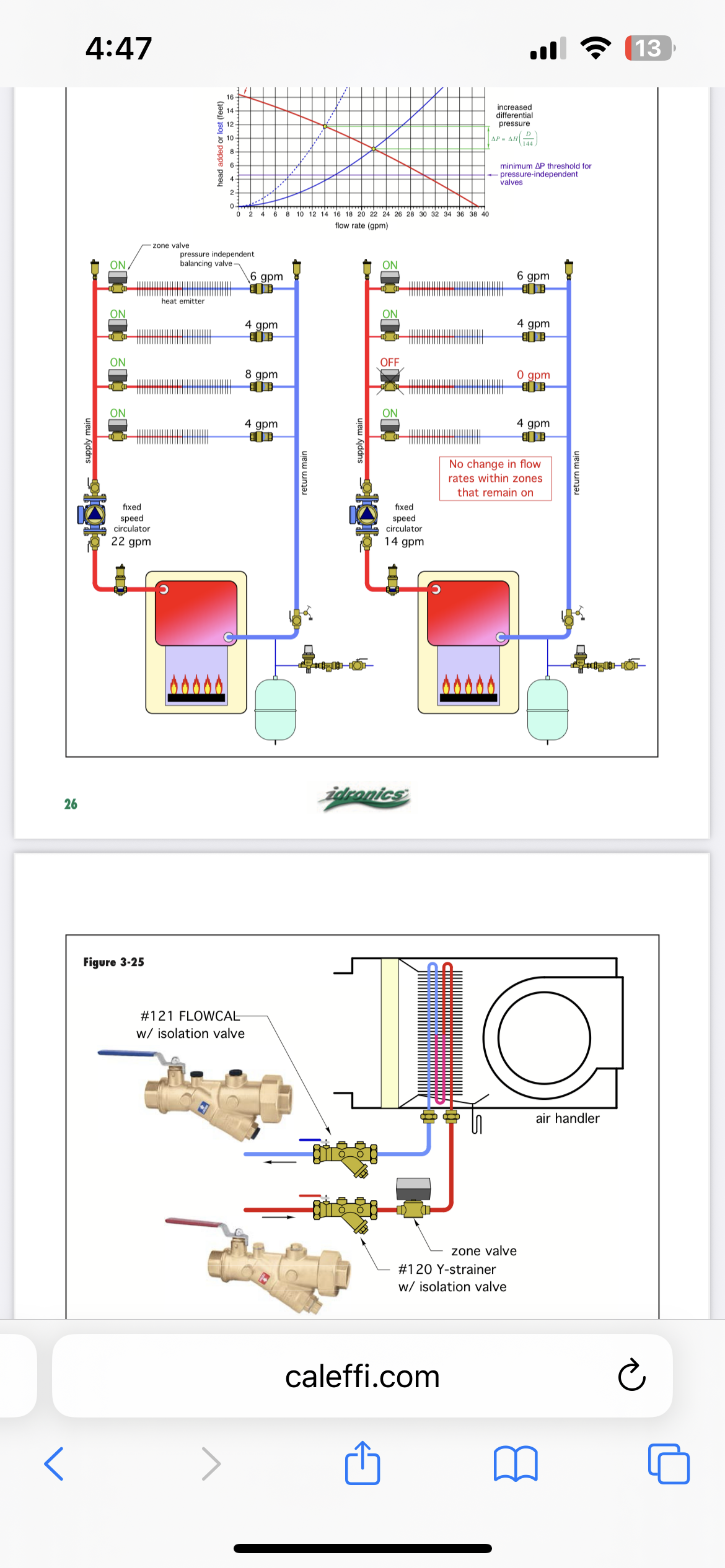

PIC balance valves are another option for flow balancing, commonly used with air handlers and zone valvesHome-run is yet another option

More info herehttps://www.caleffi.com/sites/default/files/media/external-file/Idronics_8_NA_Hydronic%20balancing.pdf

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Does the sizing of the entryway account for groups of people entering and leaving en mass at the beginning and end of a show?

0 -

If you can't find Monoflow you could use regular tees with a valve between the tees but why bother?

Reverse return is better and is self-balancing to some extent.

Dont forget with reverse return you can decrease the pipe size of the supply pipe as you take load off and the same with the return the pipe increases as you add load.

Monoflow you have to run the same size all the way around full size. Reverse return has more pipe but the cost is offset somewhat with smaller pipe.

1 -

Viega does make a venturi fitting made to be installed between 2-1 1/2" tees

I've never seen them in use ,but, they should work. The charts are there with all the information for a 1/2 inch brach line, The manufacturer may have more information for a larger branch.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements